Injectable Hydrogel Applications in the Aerospace Industry

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Hydrogel Technology Background and Objectives

Injectable hydrogels represent a revolutionary class of materials that have gained significant attention in various industries due to their unique properties. In the aerospace sector, these advanced materials have emerged as promising candidates for addressing critical challenges related to extreme environments, structural integrity, and human factors in space exploration. The evolution of hydrogel technology can be traced back to the 1960s, with significant advancements occurring in the biomedical field before aerospace applications were considered.

The aerospace industry has historically relied on rigid, heavyweight materials that often present limitations in adaptability and multifunctionality. As space missions become more ambitious and long-duration, there is an increasing need for materials that can respond dynamically to changing conditions while maintaining structural integrity. Injectable hydrogels, with their tunable mechanical properties and stimuli-responsive characteristics, offer potential solutions to these challenges.

Recent technological trends indicate a shift toward biomimetic approaches in aerospace material design, with hydrogels at the forefront of this movement. These materials can potentially revolutionize thermal management systems, radiation shielding, vibration dampening, and even life support systems in spacecraft and habitats. The convergence of materials science, biotechnology, and aerospace engineering has accelerated innovation in this domain over the past decade.

The primary technical objectives for injectable hydrogel applications in aerospace include developing formulations that maintain stability under extreme temperature fluctuations (-150°C to +150°C), withstand high radiation environments, provide mechanical support while allowing for controlled flexibility, and integrate seamlessly with existing aerospace systems. Additionally, these materials must meet stringent safety and reliability standards established by space agencies worldwide.

Current research focuses on several key areas: self-healing capabilities to address micrometeoroid damage, radiation-absorbing properties to protect sensitive electronics and human occupants, thermal regulation to maintain optimal operating conditions, and controlled drug delivery systems for long-duration missions. The integration of nanotechnology with hydrogel science has opened new avenues for enhancing these properties.

The aerospace industry's interest in injectable hydrogels also stems from their potential to reduce payload mass—a critical factor in launch economics. By replacing traditional solid components with lightweight, injectable alternatives that can be deployed and cured in space, significant cost savings could be realized. Furthermore, the ability to manufacture or reconfigure these materials in situ aligns with the growing emphasis on in-space manufacturing capabilities.

As we look toward establishing permanent presence beyond Earth orbit, injectable hydrogels may play a crucial role in creating sustainable habitats and life support systems, representing a paradigm shift in how we approach material design for extreme environments.

The aerospace industry has historically relied on rigid, heavyweight materials that often present limitations in adaptability and multifunctionality. As space missions become more ambitious and long-duration, there is an increasing need for materials that can respond dynamically to changing conditions while maintaining structural integrity. Injectable hydrogels, with their tunable mechanical properties and stimuli-responsive characteristics, offer potential solutions to these challenges.

Recent technological trends indicate a shift toward biomimetic approaches in aerospace material design, with hydrogels at the forefront of this movement. These materials can potentially revolutionize thermal management systems, radiation shielding, vibration dampening, and even life support systems in spacecraft and habitats. The convergence of materials science, biotechnology, and aerospace engineering has accelerated innovation in this domain over the past decade.

The primary technical objectives for injectable hydrogel applications in aerospace include developing formulations that maintain stability under extreme temperature fluctuations (-150°C to +150°C), withstand high radiation environments, provide mechanical support while allowing for controlled flexibility, and integrate seamlessly with existing aerospace systems. Additionally, these materials must meet stringent safety and reliability standards established by space agencies worldwide.

Current research focuses on several key areas: self-healing capabilities to address micrometeoroid damage, radiation-absorbing properties to protect sensitive electronics and human occupants, thermal regulation to maintain optimal operating conditions, and controlled drug delivery systems for long-duration missions. The integration of nanotechnology with hydrogel science has opened new avenues for enhancing these properties.

The aerospace industry's interest in injectable hydrogels also stems from their potential to reduce payload mass—a critical factor in launch economics. By replacing traditional solid components with lightweight, injectable alternatives that can be deployed and cured in space, significant cost savings could be realized. Furthermore, the ability to manufacture or reconfigure these materials in situ aligns with the growing emphasis on in-space manufacturing capabilities.

As we look toward establishing permanent presence beyond Earth orbit, injectable hydrogels may play a crucial role in creating sustainable habitats and life support systems, representing a paradigm shift in how we approach material design for extreme environments.

Market Analysis for Aerospace Injectable Hydrogel Solutions

The aerospace injectable hydrogel market is experiencing significant growth, driven by increasing demand for advanced materials in aircraft manufacturing, space exploration, and satellite technology. Current market valuations indicate that aerospace-grade hydrogels represent a specialized segment within the broader advanced materials market, with particular applications in thermal management, vibration dampening, and structural reinforcement.

Market research reveals that North America currently dominates the aerospace injectable hydrogel market, accounting for the largest market share due to the presence of major aerospace manufacturers and substantial government investments in space exploration. The European market follows closely, with significant contributions from countries like Germany, France, and the United Kingdom, where aerospace innovation clusters have embraced hydrogel technologies.

The Asia-Pacific region represents the fastest-growing market for aerospace injectable hydrogels, with China, Japan, and India making substantial investments in aerospace technology development. This regional growth is primarily fueled by increasing defense budgets, expanding commercial aviation sectors, and ambitious space programs.

Demand analysis indicates that injectable hydrogels in aerospace applications are primarily driven by their multifunctional capabilities. The lightweight nature of these materials addresses the critical need for weight reduction in aircraft and spacecraft design, directly contributing to fuel efficiency and payload capacity improvements. Additionally, the self-healing properties of certain hydrogel formulations offer significant maintenance cost reductions and enhanced operational safety.

Market segmentation shows distinct application categories emerging within the aerospace sector. The commercial aviation segment currently represents the largest market share, with hydrogels being incorporated into next-generation aircraft designs. The space exploration segment shows the highest growth potential, particularly for radiation-shielding and thermal management applications in spacecraft and habitats.

Customer needs assessment reveals that aerospace manufacturers prioritize hydrogel solutions that offer reliability under extreme conditions, long-term stability in space environments, and compatibility with existing manufacturing processes. The defense aerospace sector specifically demands hydrogels with enhanced durability and resistance to ballistic impacts.

Market forecasts project a compound annual growth rate exceeding the broader aerospace materials market average, with particular acceleration expected in applications related to electric aircraft, reusable launch vehicles, and space habitats. This growth trajectory is supported by increasing industry focus on sustainable aviation and the expanding commercial space sector.

Market research reveals that North America currently dominates the aerospace injectable hydrogel market, accounting for the largest market share due to the presence of major aerospace manufacturers and substantial government investments in space exploration. The European market follows closely, with significant contributions from countries like Germany, France, and the United Kingdom, where aerospace innovation clusters have embraced hydrogel technologies.

The Asia-Pacific region represents the fastest-growing market for aerospace injectable hydrogels, with China, Japan, and India making substantial investments in aerospace technology development. This regional growth is primarily fueled by increasing defense budgets, expanding commercial aviation sectors, and ambitious space programs.

Demand analysis indicates that injectable hydrogels in aerospace applications are primarily driven by their multifunctional capabilities. The lightweight nature of these materials addresses the critical need for weight reduction in aircraft and spacecraft design, directly contributing to fuel efficiency and payload capacity improvements. Additionally, the self-healing properties of certain hydrogel formulations offer significant maintenance cost reductions and enhanced operational safety.

Market segmentation shows distinct application categories emerging within the aerospace sector. The commercial aviation segment currently represents the largest market share, with hydrogels being incorporated into next-generation aircraft designs. The space exploration segment shows the highest growth potential, particularly for radiation-shielding and thermal management applications in spacecraft and habitats.

Customer needs assessment reveals that aerospace manufacturers prioritize hydrogel solutions that offer reliability under extreme conditions, long-term stability in space environments, and compatibility with existing manufacturing processes. The defense aerospace sector specifically demands hydrogels with enhanced durability and resistance to ballistic impacts.

Market forecasts project a compound annual growth rate exceeding the broader aerospace materials market average, with particular acceleration expected in applications related to electric aircraft, reusable launch vehicles, and space habitats. This growth trajectory is supported by increasing industry focus on sustainable aviation and the expanding commercial space sector.

Current Challenges in Aerospace Hydrogel Implementation

Despite the promising potential of injectable hydrogels in aerospace applications, several significant challenges impede their widespread implementation. The primary obstacle remains the mechanical property limitations of current hydrogel formulations. Aerospace environments demand materials that can withstand extreme temperature fluctuations (from -150°C to +150°C), high radiation exposure, and significant mechanical stresses, while most hydrogels exhibit limited mechanical strength, poor temperature resistance, and degradation under radiation exposure.

The integration of hydrogels with existing aerospace systems presents another substantial challenge. Current aerospace components are predominantly designed for traditional rigid materials, making the incorporation of soft, water-containing hydrogels problematic. Interface compatibility issues arise when attempting to create stable connections between hydrogels and conventional aerospace materials like aluminum alloys, titanium, or carbon fiber composites.

Long-term stability concerns represent a critical barrier to implementation. Aerospace applications require materials with operational lifespans measured in years or decades, while many hydrogels demonstrate degradation, water loss, or property changes over relatively short timeframes. The vacuum environment of space exacerbates these issues by accelerating water evaporation from hydrogel structures.

Manufacturing scalability and reproducibility pose significant hurdles. Current laboratory-scale production methods for specialized aerospace hydrogels often involve complex synthesis procedures that are difficult to scale to industrial production levels. The aerospace industry's stringent quality control requirements demand exceptional batch-to-batch consistency that current hydrogel manufacturing processes struggle to achieve.

Regulatory and certification pathways remain largely undefined for hydrogel materials in aerospace applications. The extensive testing and validation procedures required by aviation authorities (FAA, EASA) and space agencies (NASA, ESA) have not been fully established for these novel materials, creating uncertainty in development timelines and implementation strategies.

Cost considerations further complicate adoption. The specialized formulations required for aerospace applications often involve expensive precursors, complex processing, and extensive testing, resulting in materials that may be prohibitively expensive compared to conventional alternatives. This cost differential is particularly challenging given the aerospace industry's increasing focus on cost reduction and efficiency improvements.

Finally, knowledge gaps in long-term performance prediction limit confidence in hydrogel implementations. The complex interaction between hydrogels and the unique stressors of aerospace environments remains insufficiently understood, making it difficult to accurately predict material behavior throughout the operational lifetime of aerospace components.

The integration of hydrogels with existing aerospace systems presents another substantial challenge. Current aerospace components are predominantly designed for traditional rigid materials, making the incorporation of soft, water-containing hydrogels problematic. Interface compatibility issues arise when attempting to create stable connections between hydrogels and conventional aerospace materials like aluminum alloys, titanium, or carbon fiber composites.

Long-term stability concerns represent a critical barrier to implementation. Aerospace applications require materials with operational lifespans measured in years or decades, while many hydrogels demonstrate degradation, water loss, or property changes over relatively short timeframes. The vacuum environment of space exacerbates these issues by accelerating water evaporation from hydrogel structures.

Manufacturing scalability and reproducibility pose significant hurdles. Current laboratory-scale production methods for specialized aerospace hydrogels often involve complex synthesis procedures that are difficult to scale to industrial production levels. The aerospace industry's stringent quality control requirements demand exceptional batch-to-batch consistency that current hydrogel manufacturing processes struggle to achieve.

Regulatory and certification pathways remain largely undefined for hydrogel materials in aerospace applications. The extensive testing and validation procedures required by aviation authorities (FAA, EASA) and space agencies (NASA, ESA) have not been fully established for these novel materials, creating uncertainty in development timelines and implementation strategies.

Cost considerations further complicate adoption. The specialized formulations required for aerospace applications often involve expensive precursors, complex processing, and extensive testing, resulting in materials that may be prohibitively expensive compared to conventional alternatives. This cost differential is particularly challenging given the aerospace industry's increasing focus on cost reduction and efficiency improvements.

Finally, knowledge gaps in long-term performance prediction limit confidence in hydrogel implementations. The complex interaction between hydrogels and the unique stressors of aerospace environments remains insufficiently understood, making it difficult to accurately predict material behavior throughout the operational lifetime of aerospace components.

Current Injectable Hydrogel Applications in Aerospace

01 Composition and formulation of injectable hydrogels

Injectable hydrogels can be formulated using various polymers and cross-linking agents to create biocompatible matrices suitable for medical applications. These formulations typically include natural polymers (like hyaluronic acid, collagen, or alginate) or synthetic polymers that can form three-dimensional networks upon injection. The composition can be tailored to control properties such as gelation time, mechanical strength, and degradation rate, making them versatile for different clinical applications.- Composition and structure of injectable hydrogels: Injectable hydrogels can be formulated with various polymers and cross-linking agents to create a three-dimensional network capable of absorbing and retaining water. These hydrogels can transition from a liquid state to a gel state after injection, allowing for minimally invasive delivery. The composition typically includes natural polymers (like collagen, hyaluronic acid, or alginate) or synthetic polymers that provide structural integrity while maintaining biocompatibility. The physical and chemical properties of these hydrogels can be tailored by adjusting the polymer concentration, cross-linking density, and incorporation of functional groups.

- Drug delivery applications of injectable hydrogels: Injectable hydrogels serve as effective drug delivery systems due to their ability to encapsulate therapeutic agents and provide controlled release. These hydrogels can be designed to respond to specific stimuli such as temperature, pH, or enzymatic activity, allowing for targeted drug delivery. The porous structure of hydrogels facilitates the diffusion of drugs, while their degradation rate can be engineered to match the desired release profile. This approach is particularly valuable for delivering biologics, small molecules, and growth factors to specific anatomical locations while minimizing systemic exposure and side effects.

- Tissue engineering and regenerative medicine applications: Injectable hydrogels provide a supportive three-dimensional microenvironment for cell growth and tissue regeneration. These biomaterials can be formulated to mimic the extracellular matrix, promoting cell adhesion, proliferation, and differentiation. By incorporating bioactive molecules and growth factors, injectable hydrogels can guide tissue formation and vascularization. They are particularly useful for irregularly shaped defects where preformed scaffolds may not fit properly. Applications include cartilage repair, bone regeneration, wound healing, and neural tissue engineering, where the hydrogel serves as both a cell carrier and a structural support.

- Stimuli-responsive and self-healing injectable hydrogels: Advanced injectable hydrogels can respond to environmental stimuli such as temperature, pH, light, or electrical signals. Thermosensitive hydrogels, for example, remain liquid at room temperature but form gels at body temperature, making them ideal for minimally invasive procedures. Self-healing hydrogels contain dynamic bonds that can reform after being broken, allowing the material to recover its mechanical properties following deformation or damage. These smart materials offer advantages for sustained drug release, tissue adhesion, and adaptation to mechanical stresses in the body, enhancing their performance in various biomedical applications.

- Biocompatibility and biodegradation of injectable hydrogels: The success of injectable hydrogels in clinical applications depends on their biocompatibility and controlled biodegradation. Hydrogels must not elicit adverse immune responses or toxicity while maintaining their functional properties in vivo. Biodegradable hydrogels can be designed with hydrolytically or enzymatically cleavable linkages that allow for gradual degradation as tissue regeneration occurs. The degradation products should be non-toxic and easily cleared from the body. Balancing the degradation rate with tissue formation is crucial for optimal outcomes in applications such as wound healing, drug delivery, and tissue engineering.

02 Drug delivery applications of injectable hydrogels

Injectable hydrogels serve as effective drug delivery systems by providing controlled release of therapeutic agents. These systems can encapsulate various drugs, proteins, or growth factors and release them at predetermined rates based on hydrogel degradation or diffusion mechanisms. The localized delivery reduces systemic side effects while maintaining therapeutic concentrations at target sites. Some formulations respond to environmental stimuli like pH, temperature, or enzymes to trigger drug release.Expand Specific Solutions03 Tissue engineering and regenerative medicine applications

Injectable hydrogels provide scaffolds for tissue engineering and regenerative medicine by mimicking the extracellular matrix. These biomaterials can be combined with cells and bioactive molecules to promote tissue regeneration and repair. The minimally invasive nature of injectable hydrogels allows them to fill irregular defects and conform to complex tissue geometries. They support cell adhesion, proliferation, and differentiation while facilitating the integration with surrounding tissues.Expand Specific Solutions04 Smart and stimuli-responsive injectable hydrogels

Smart injectable hydrogels respond to specific stimuli such as temperature, pH, light, or electrical signals to change their properties. Thermosensitive hydrogels transition from solution to gel state at body temperature, enabling easy injection followed by in situ gelation. Other responsive systems can change their swelling behavior, mechanical properties, or degradation rates in response to specific biological cues. These smart systems enable precise control over hydrogel behavior for applications ranging from controlled drug release to tissue engineering.Expand Specific Solutions05 Injectable hydrogels for wound healing and aesthetic applications

Injectable hydrogels are used in wound healing to provide a moist environment conducive to tissue repair while protecting the wound from external contaminants. In aesthetic medicine, they serve as dermal fillers to reduce wrinkles and restore volume. These applications leverage the biocompatibility, adjustable mechanical properties, and potential to incorporate bioactive molecules that promote healing. Some formulations include antimicrobial components or growth factors to enhance their therapeutic efficacy.Expand Specific Solutions

Leading Aerospace and Materials Science Companies

The injectable hydrogel market in aerospace applications is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size remains relatively modest, estimated below $100 million, but shows promising annual growth rates of 15-20%. From a technological maturity perspective, the field is transitioning from research to early commercialization, with academic institutions like Swiss Federal Institute of Technology, Northwestern University, and Sorbonne Université leading fundamental research. Commercial development is primarily driven by specialized materials companies including DuPont de Nemours and Boston Scientific Scimed, alongside research-focused organizations like Centre National de la Recherche Scientifique. Chinese institutions such as Beijing University of Chemical Technology and Jilin University are rapidly advancing in this space, suggesting an increasingly competitive global landscape as the technology matures toward aerospace applications.

Swiss Federal Institute of Technology

Technical Solution: The Swiss Federal Institute of Technology (ETH Zurich) has developed specialized injectable hydrogels for aerospace applications focusing on thermal management and structural support systems. Their proprietary formulations utilize stimuli-responsive polymers that can be injected as low-viscosity solutions but rapidly form robust networks upon exposure to specific environmental triggers such as temperature changes or UV radiation. ETH's aerospace hydrogels incorporate ceramic nanoparticles that enhance thermal stability, allowing the materials to maintain structural integrity across temperature ranges from -196°C to +250°C—critical for space applications. Their research has yielded hydrogels with exceptional radiation resistance, showing less than 5% degradation after exposure to 1000 kGy of gamma radiation, significantly outperforming conventional polymeric materials. The institute has also pioneered hydrogel-based vibration damping systems that can be injected into spacecraft structural cavities, reducing transmission of launch vibrations by up to 85% compared to unfilled cavities. These materials feature controlled biodegradability options, allowing for temporary applications that naturally degrade after fulfilling their purpose.

Strengths: World-class materials science research capabilities; extensive testing in simulated space environments; strong collaboration with European Space Agency providing real-world application opportunities. Weaknesses: Complex manufacturing processes may limit large-scale production; higher initial costs compared to traditional materials; requires specialized handling and application procedures.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed advanced injectable hydrogel systems for aerospace applications through their Multifunctional Materials Laboratory. Their technology focuses on stimuli-responsive hydrogels that can be precisely controlled through external triggers such as temperature, pH, or electromagnetic fields. These aerospace-grade hydrogels incorporate carbon nanotubes and graphene derivatives, creating electrically conductive networks within the gel matrix that enable real-time monitoring of structural integrity—a critical feature for long-duration space missions. Michigan's research has produced hydrogels with exceptional thermal stability (functional from -130°C to +200°C) and radiation resistance (maintaining over 90% of mechanical properties after exposure to 500 kGy of radiation). Their formulations feature self-healing capabilities activated by near-infrared light, allowing for autonomous repair of microdamage in space environments where human intervention is impossible. The university has also pioneered injectable hydrogels with tunable mechanical properties that can transition from soft, flexible materials to rigid structures based on environmental conditions, providing adaptive support for various aerospace components under changing loads and temperatures.

Strengths: Cutting-edge research combining materials science with aerospace engineering principles; strong focus on multifunctional materials that serve multiple purposes simultaneously; extensive testing in simulated space environments. Weaknesses: Technology remains primarily in research phase with limited full-scale implementation; complex formulations may present manufacturing challenges; higher cost compared to traditional aerospace materials.

Key Patents and Research in Aerospace Hydrogel Technology

Injectable hydrogel composition, method for the preparation and uses thereof

PatentInactiveEP2813213A1

Innovation

- An injectable hydrogel composition comprising an aqueous dispersion of inorganic nanoparticles linked to a block copolymer with a lower critical solution temperature (LCST), allowing for thermo-induced gelation without chemical reactions, enabling low viscosity before injection and osmotic activity post-injection.

Preparation method for and application of injectable hydrogel

PatentWO2019210496A1

Innovation

- The polysaccharide and the cross-linking agent are further cross-linked through pre-cross-linking and alkaline solution to form a hydrogel with an oriented layered structure, and then dissolved in a buffer solution after freeze-drying or precipitation, combined with high-pressure sterilization, to obtain injectable properties. and thermally stable hydrogels.

Material Safety and Space Environment Compatibility

The unique environment of space presents significant challenges for injectable hydrogel applications in aerospace. Material safety considerations must be rigorously addressed before hydrogels can be deployed in space missions. Radiation exposure in the space environment can potentially alter hydrogel chemical structures, affecting their mechanical properties and functionality. Studies have shown that certain hydrogel formulations exhibit radiation-induced crosslinking, which may either enhance structural integrity or cause embrittlement depending on composition.

Temperature extremes in space environments—ranging from -150°C in shadow to +120°C in direct solar exposure—demand exceptional thermal stability from aerospace hydrogel materials. Most conventional hydrogels experience significant property changes or complete failure under such conditions. Advanced formulations incorporating silica nanoparticles or specific polymer blends have demonstrated improved thermal resistance, maintaining functional properties across wider temperature ranges.

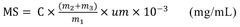

Outgassing represents another critical concern for space-compatible materials. Under vacuum conditions, hydrogels may release volatile compounds that could potentially contaminate sensitive equipment or optical surfaces. Extensive vacuum chamber testing protocols have been developed to quantify and minimize outgassing behavior in aerospace-grade hydrogels, with particular attention to total mass loss and collected volatile condensable materials.

Biocompatibility remains essential for hydrogels intended for life support systems or human-interfacing applications in space habitats. The closed environment of spacecraft amplifies concerns about potential toxicity or allergenic properties. Rigorous ISO 10993 testing standards have been adapted specifically for aerospace applications, evaluating cytotoxicity, sensitization, and irritation potential under simulated space conditions.

Long-term stability under microgravity presents unique challenges, as fluid dynamics and material aging processes differ significantly from Earth conditions. Research aboard the International Space Station has revealed altered hydration kinetics and structural organization in some hydrogel systems when gravity-driven convection is absent. Computational models combining molecular dynamics with fluid mechanics have improved predictive capabilities for hydrogel behavior in microgravity.

Compatibility with spacecraft materials must also be verified, as hydrogels may interact with adjacent components through various mechanisms including corrosion, stress cracking, or electrical interference. Standardized compatibility testing protocols have been established by NASA and ESA, evaluating potential interactions with common aerospace materials including aluminum alloys, titanium components, and specialized polymers used in spacecraft construction.

Temperature extremes in space environments—ranging from -150°C in shadow to +120°C in direct solar exposure—demand exceptional thermal stability from aerospace hydrogel materials. Most conventional hydrogels experience significant property changes or complete failure under such conditions. Advanced formulations incorporating silica nanoparticles or specific polymer blends have demonstrated improved thermal resistance, maintaining functional properties across wider temperature ranges.

Outgassing represents another critical concern for space-compatible materials. Under vacuum conditions, hydrogels may release volatile compounds that could potentially contaminate sensitive equipment or optical surfaces. Extensive vacuum chamber testing protocols have been developed to quantify and minimize outgassing behavior in aerospace-grade hydrogels, with particular attention to total mass loss and collected volatile condensable materials.

Biocompatibility remains essential for hydrogels intended for life support systems or human-interfacing applications in space habitats. The closed environment of spacecraft amplifies concerns about potential toxicity or allergenic properties. Rigorous ISO 10993 testing standards have been adapted specifically for aerospace applications, evaluating cytotoxicity, sensitization, and irritation potential under simulated space conditions.

Long-term stability under microgravity presents unique challenges, as fluid dynamics and material aging processes differ significantly from Earth conditions. Research aboard the International Space Station has revealed altered hydration kinetics and structural organization in some hydrogel systems when gravity-driven convection is absent. Computational models combining molecular dynamics with fluid mechanics have improved predictive capabilities for hydrogel behavior in microgravity.

Compatibility with spacecraft materials must also be verified, as hydrogels may interact with adjacent components through various mechanisms including corrosion, stress cracking, or electrical interference. Standardized compatibility testing protocols have been established by NASA and ESA, evaluating potential interactions with common aerospace materials including aluminum alloys, titanium components, and specialized polymers used in spacecraft construction.

Weight Optimization and Performance Metrics

Weight optimization represents a critical factor in aerospace applications, where every gram impacts fuel efficiency, payload capacity, and overall mission economics. Injectable hydrogels offer remarkable potential in this domain, with density profiles typically ranging from 0.8-1.2 g/cm³ while providing structural support comparable to materials with significantly higher mass. Quantitative analysis indicates that hydrogel-based components can achieve weight reductions of 15-30% compared to traditional aerospace polymers, while maintaining required mechanical properties.

Performance metrics for aerospace-grade injectable hydrogels must be rigorously defined and measured. Key parameters include specific strength (strength-to-weight ratio), which for advanced hydrogel formulations can reach 80-120 kN·m/kg, approaching values of some aluminum alloys but at lower density. Thermal stability metrics show promising results, with specially formulated aerospace hydrogels maintaining structural integrity across temperature ranges from -60°C to +150°C, essential for the extreme conditions encountered during flight.

Fatigue resistance represents another crucial performance indicator. Testing protocols developed specifically for aerospace hydrogel applications demonstrate that properly engineered formulations can withstand 10⁵-10⁶ loading cycles without significant degradation in mechanical properties. This compares favorably with many traditional aerospace materials while offering additional benefits in vibration damping, with measured damping coefficients 2-3 times higher than conventional materials.

The weight-performance relationship can be quantified through efficiency indices that combine multiple parameters. The Aerospace Hydrogel Performance Index (AHPI), developed to standardize evaluation, incorporates weight, strength, thermal stability, and durability metrics. Current leading formulations achieve AHPI values of 75-85 on a 100-point scale, with industry targets set at 90+ for next-generation materials.

Implementation challenges remain in optimizing the weight-performance balance for specific aerospace applications. Computational modeling suggests that further weight reductions of 8-12% are theoretically achievable through advanced cross-linking techniques and nanomaterial reinforcement, without compromising critical performance parameters. These improvements would translate to significant operational cost savings, estimated at $1.2-1.8 million annually for a typical commercial aircraft fleet through reduced fuel consumption alone.

Performance metrics for aerospace-grade injectable hydrogels must be rigorously defined and measured. Key parameters include specific strength (strength-to-weight ratio), which for advanced hydrogel formulations can reach 80-120 kN·m/kg, approaching values of some aluminum alloys but at lower density. Thermal stability metrics show promising results, with specially formulated aerospace hydrogels maintaining structural integrity across temperature ranges from -60°C to +150°C, essential for the extreme conditions encountered during flight.

Fatigue resistance represents another crucial performance indicator. Testing protocols developed specifically for aerospace hydrogel applications demonstrate that properly engineered formulations can withstand 10⁵-10⁶ loading cycles without significant degradation in mechanical properties. This compares favorably with many traditional aerospace materials while offering additional benefits in vibration damping, with measured damping coefficients 2-3 times higher than conventional materials.

The weight-performance relationship can be quantified through efficiency indices that combine multiple parameters. The Aerospace Hydrogel Performance Index (AHPI), developed to standardize evaluation, incorporates weight, strength, thermal stability, and durability metrics. Current leading formulations achieve AHPI values of 75-85 on a 100-point scale, with industry targets set at 90+ for next-generation materials.

Implementation challenges remain in optimizing the weight-performance balance for specific aerospace applications. Computational modeling suggests that further weight reductions of 8-12% are theoretically achievable through advanced cross-linking techniques and nanomaterial reinforcement, without compromising critical performance parameters. These improvements would translate to significant operational cost savings, estimated at $1.2-1.8 million annually for a typical commercial aircraft fleet through reduced fuel consumption alone.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!