Understanding Injectable Hydrogel's Role in Crop Protection Formulations

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Injectable Hydrogel Technology Background and Objectives

Injectable hydrogels represent a significant advancement in agricultural technology, evolving from their initial applications in biomedical fields to becoming increasingly relevant in crop protection systems. These versatile materials consist of three-dimensional networks of hydrophilic polymers capable of absorbing substantial amounts of water while maintaining their structure. The evolution of hydrogel technology in agriculture began in the late 1980s with simple water retention applications, progressing through several generations of increasingly sophisticated formulations designed specifically for controlled release of agrochemicals.

The technological trajectory of injectable hydrogels has been characterized by continuous improvements in biocompatibility, biodegradability, and stimuli-responsiveness. Early generations focused primarily on water retention properties, while contemporary formulations incorporate advanced features such as targeted delivery mechanisms, environmentally-responsive release triggers, and enhanced stability profiles. Recent innovations have introduced smart hydrogels capable of responding to environmental cues such as temperature, pH, and enzymatic activity, enabling precise control over the release of active ingredients.

The primary objective of injectable hydrogel technology in crop protection formulations is to address several persistent challenges in conventional agrochemical delivery systems. These include reducing environmental leaching, minimizing off-target effects, extending protection periods, and decreasing the frequency of applications. By encapsulating active ingredients within their matrix, hydrogels can provide controlled release profiles that maintain effective concentrations of crop protection agents over extended periods while reducing overall chemical usage.

Additionally, injectable hydrogels aim to enhance the efficacy of biological control agents by providing protective microenvironments that shield beneficial organisms from harsh field conditions. This capability represents a significant advancement toward more sustainable agricultural practices by facilitating the integration of biological and chemical control strategies.

The development of injectable hydrogels for crop protection also seeks to address the growing regulatory pressure to reduce environmental impacts of agricultural chemicals. By enabling precise placement and controlled release of active ingredients, these systems can significantly reduce the environmental footprint of crop protection practices while maintaining or improving efficacy against target pests and pathogens.

Future technological objectives include developing fully biodegradable formulations with predictable degradation profiles, creating multi-functional systems capable of simultaneously delivering multiple active ingredients with different release kinetics, and designing hydrogels that can adapt their release characteristics in response to pest pressure or environmental conditions. These advancements would represent significant steps toward more sustainable and efficient crop protection strategies.

The technological trajectory of injectable hydrogels has been characterized by continuous improvements in biocompatibility, biodegradability, and stimuli-responsiveness. Early generations focused primarily on water retention properties, while contemporary formulations incorporate advanced features such as targeted delivery mechanisms, environmentally-responsive release triggers, and enhanced stability profiles. Recent innovations have introduced smart hydrogels capable of responding to environmental cues such as temperature, pH, and enzymatic activity, enabling precise control over the release of active ingredients.

The primary objective of injectable hydrogel technology in crop protection formulations is to address several persistent challenges in conventional agrochemical delivery systems. These include reducing environmental leaching, minimizing off-target effects, extending protection periods, and decreasing the frequency of applications. By encapsulating active ingredients within their matrix, hydrogels can provide controlled release profiles that maintain effective concentrations of crop protection agents over extended periods while reducing overall chemical usage.

Additionally, injectable hydrogels aim to enhance the efficacy of biological control agents by providing protective microenvironments that shield beneficial organisms from harsh field conditions. This capability represents a significant advancement toward more sustainable agricultural practices by facilitating the integration of biological and chemical control strategies.

The development of injectable hydrogels for crop protection also seeks to address the growing regulatory pressure to reduce environmental impacts of agricultural chemicals. By enabling precise placement and controlled release of active ingredients, these systems can significantly reduce the environmental footprint of crop protection practices while maintaining or improving efficacy against target pests and pathogens.

Future technological objectives include developing fully biodegradable formulations with predictable degradation profiles, creating multi-functional systems capable of simultaneously delivering multiple active ingredients with different release kinetics, and designing hydrogels that can adapt their release characteristics in response to pest pressure or environmental conditions. These advancements would represent significant steps toward more sustainable and efficient crop protection strategies.

Market Analysis for Hydrogel-Based Crop Protection Products

The global market for hydrogel-based crop protection products is experiencing significant growth, driven by increasing agricultural challenges and the need for sustainable farming solutions. Current market valuations indicate that the agricultural hydrogel sector reached approximately 3.1 billion USD in 2022, with projections suggesting a compound annual growth rate of 7.2% through 2030. This growth trajectory is particularly pronounced in regions facing water scarcity and soil degradation issues.

Consumer demand patterns reveal a strong shift toward environmentally friendly agricultural inputs, with hydrogel-based formulations gaining traction due to their biodegradability and reduced environmental footprint compared to conventional agrochemicals. Market research indicates that farmers are increasingly willing to pay premium prices for products that offer multiple benefits, such as water conservation alongside pest management.

Regional market analysis shows varying adoption rates, with North America and Europe leading in terms of market value due to stricter environmental regulations and higher awareness of sustainable farming practices. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential, driven by large agricultural sectors and increasing government initiatives promoting water-efficient farming technologies.

Segmentation analysis reveals that hydrogels for controlled release of pesticides currently hold the largest market share at approximately 42%, followed by fertilizer delivery systems at 35%. The remaining market is divided among specialized applications such as soil conditioning and seed coating technologies. This distribution reflects the versatility of hydrogel technology in addressing multiple agricultural challenges simultaneously.

Competitive landscape assessment identifies several key players dominating the market, including established agrochemical companies that have expanded into hydrogel technologies and specialized startups focused exclusively on innovative hydrogel formulations. Market concentration remains moderate, with the top five companies controlling approximately 48% of the global market share.

Price sensitivity analysis indicates that while initial adoption barriers exist due to higher upfront costs compared to conventional products, the total cost of ownership calculations often favor hydrogel-based solutions when accounting for reduced application frequency and improved efficacy. This economic advantage becomes more pronounced in water-scarce regions where irrigation costs represent a significant portion of operational expenses.

Future market projections suggest that the integration of nanotechnology with hydrogel formulations will create new market segments, potentially expanding the overall market size by an additional 15-20% by 2028. Consumer education and demonstration of long-term economic benefits remain critical factors for accelerating market penetration, particularly in emerging agricultural economies.

Consumer demand patterns reveal a strong shift toward environmentally friendly agricultural inputs, with hydrogel-based formulations gaining traction due to their biodegradability and reduced environmental footprint compared to conventional agrochemicals. Market research indicates that farmers are increasingly willing to pay premium prices for products that offer multiple benefits, such as water conservation alongside pest management.

Regional market analysis shows varying adoption rates, with North America and Europe leading in terms of market value due to stricter environmental regulations and higher awareness of sustainable farming practices. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential, driven by large agricultural sectors and increasing government initiatives promoting water-efficient farming technologies.

Segmentation analysis reveals that hydrogels for controlled release of pesticides currently hold the largest market share at approximately 42%, followed by fertilizer delivery systems at 35%. The remaining market is divided among specialized applications such as soil conditioning and seed coating technologies. This distribution reflects the versatility of hydrogel technology in addressing multiple agricultural challenges simultaneously.

Competitive landscape assessment identifies several key players dominating the market, including established agrochemical companies that have expanded into hydrogel technologies and specialized startups focused exclusively on innovative hydrogel formulations. Market concentration remains moderate, with the top five companies controlling approximately 48% of the global market share.

Price sensitivity analysis indicates that while initial adoption barriers exist due to higher upfront costs compared to conventional products, the total cost of ownership calculations often favor hydrogel-based solutions when accounting for reduced application frequency and improved efficacy. This economic advantage becomes more pronounced in water-scarce regions where irrigation costs represent a significant portion of operational expenses.

Future market projections suggest that the integration of nanotechnology with hydrogel formulations will create new market segments, potentially expanding the overall market size by an additional 15-20% by 2028. Consumer education and demonstration of long-term economic benefits remain critical factors for accelerating market penetration, particularly in emerging agricultural economies.

Current Challenges in Hydrogel Formulation for Agriculture

Despite significant advancements in hydrogel technology for agricultural applications, several critical challenges persist in developing effective injectable hydrogel formulations for crop protection. The primary obstacle remains achieving optimal rheological properties that allow for easy injection while maintaining structural integrity post-application. Current formulations often struggle with the balance between flowability during application and stability once deployed in field conditions.

Material selection presents another significant challenge, as agricultural hydrogels must withstand harsh environmental conditions including UV radiation, temperature fluctuations, and microbial degradation. Many promising laboratory formulations fail when scaled to field applications due to premature degradation or structural collapse under real-world conditions.

Controlled release mechanisms represent a particularly complex hurdle. Developing hydrogels that can release active ingredients at precise rates in response to environmental triggers (such as soil moisture levels, pH changes, or temperature fluctuations) remains technically challenging. Current systems often exhibit "burst release" profiles, where a large percentage of the active ingredient is released shortly after application, followed by inadequate sustained release.

Compatibility issues between hydrogel matrices and diverse agrochemicals further complicate formulation efforts. Many active ingredients interact unfavorably with hydrogel components, leading to reduced efficacy, premature precipitation, or chemical degradation. This is especially problematic for formulations intended to carry multiple active ingredients simultaneously.

Manufacturing scalability represents a significant industrial challenge. Laboratory-scale production methods often fail to translate effectively to industrial-scale manufacturing, resulting in inconsistent product quality, increased production costs, and limited commercial viability. Current production methods frequently struggle with batch-to-batch consistency when scaled up.

Regulatory hurdles and safety concerns further constrain innovation in this space. Novel hydrogel components must undergo extensive testing to ensure they do not persist in soil or water systems, accumulate in crops, or disrupt beneficial soil microbiota. The lengthy approval process for new materials significantly extends development timelines and increases costs.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current injectable hydrogel formulations for agriculture are typically too expensive for broad-acre crop applications, limiting their use to high-value specialty crops. Developing formulations that deliver meaningful benefits at economically viable price points continues to challenge researchers and product developers in this field.

Material selection presents another significant challenge, as agricultural hydrogels must withstand harsh environmental conditions including UV radiation, temperature fluctuations, and microbial degradation. Many promising laboratory formulations fail when scaled to field applications due to premature degradation or structural collapse under real-world conditions.

Controlled release mechanisms represent a particularly complex hurdle. Developing hydrogels that can release active ingredients at precise rates in response to environmental triggers (such as soil moisture levels, pH changes, or temperature fluctuations) remains technically challenging. Current systems often exhibit "burst release" profiles, where a large percentage of the active ingredient is released shortly after application, followed by inadequate sustained release.

Compatibility issues between hydrogel matrices and diverse agrochemicals further complicate formulation efforts. Many active ingredients interact unfavorably with hydrogel components, leading to reduced efficacy, premature precipitation, or chemical degradation. This is especially problematic for formulations intended to carry multiple active ingredients simultaneously.

Manufacturing scalability represents a significant industrial challenge. Laboratory-scale production methods often fail to translate effectively to industrial-scale manufacturing, resulting in inconsistent product quality, increased production costs, and limited commercial viability. Current production methods frequently struggle with batch-to-batch consistency when scaled up.

Regulatory hurdles and safety concerns further constrain innovation in this space. Novel hydrogel components must undergo extensive testing to ensure they do not persist in soil or water systems, accumulate in crops, or disrupt beneficial soil microbiota. The lengthy approval process for new materials significantly extends development timelines and increases costs.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current injectable hydrogel formulations for agriculture are typically too expensive for broad-acre crop applications, limiting their use to high-value specialty crops. Developing formulations that deliver meaningful benefits at economically viable price points continues to challenge researchers and product developers in this field.

Current Hydrogel Formulation Approaches for Crop Protection

01 Composition of injectable hydrogels for drug delivery

Injectable hydrogels can be formulated with specific polymers and cross-linking agents to create effective drug delivery systems. These hydrogels can encapsulate various therapeutic agents and provide controlled release over time. The composition typically includes biocompatible polymers that undergo gelation in situ after injection, allowing for minimally invasive administration while maintaining structural integrity at the target site.- Composition and formulation of injectable hydrogels: Injectable hydrogels can be formulated using various polymers and cross-linking agents to create biocompatible matrices suitable for medical applications. These formulations typically include natural polymers (like hyaluronic acid, collagen, or alginate) or synthetic polymers that can undergo gelation in situ after injection. The composition can be tailored to control properties such as gelation time, mechanical strength, degradation rate, and biocompatibility, making them versatile for different medical applications.

- Drug delivery applications of injectable hydrogels: Injectable hydrogels serve as effective drug delivery systems that can provide controlled and sustained release of therapeutic agents. These systems can encapsulate various drugs, proteins, growth factors, or other bioactive molecules and release them at the target site over extended periods. The hydrogel matrix protects the encapsulated drugs from degradation while maintaining their bioactivity, and the release kinetics can be modulated by adjusting the hydrogel's physical and chemical properties.

- Tissue engineering and regenerative medicine applications: Injectable hydrogels provide three-dimensional scaffolds that support cell growth, proliferation, and differentiation for tissue engineering applications. These hydrogels can be designed to mimic the extracellular matrix of natural tissues, providing structural support and biochemical cues necessary for tissue regeneration. They are particularly valuable for minimally invasive delivery of cells and bioactive factors to injury sites, promoting tissue repair and regeneration in applications such as cartilage repair, bone regeneration, and wound healing.

- Stimuli-responsive and smart injectable hydrogels: Smart injectable hydrogels can respond to various stimuli such as temperature, pH, light, or specific biomolecules. These hydrogels undergo phase transitions or property changes in response to environmental triggers, enabling on-demand drug release, shape changes, or mechanical adaptations. Thermo-responsive hydrogels that solidify at body temperature are particularly valuable for clinical applications, as they can be injected as liquids and form solid gels in situ, providing precise spatial control for therapeutic delivery.

- Clinical applications and therapeutic uses: Injectable hydrogels have diverse clinical applications including dermal fillers for cosmetic procedures, viscosupplements for joint disorders, bulking agents for tissue augmentation, and platforms for cancer therapy. They can be used to deliver cells for cell therapy, create barriers to prevent surgical adhesions, or serve as hemostatic agents. The minimally invasive nature of injectable hydrogels makes them particularly valuable for treating conditions where traditional surgical approaches may be challenging or risky.

02 Injectable hydrogels for tissue engineering and regeneration

Hydrogels designed for tissue engineering applications can be injected directly into damaged tissues to promote regeneration. These formulations often contain bioactive components that stimulate cell growth, differentiation, and tissue formation. The hydrogels provide a three-dimensional scaffold that mimics the extracellular matrix, supporting cell attachment and proliferation while facilitating the integration with surrounding tissues.Expand Specific Solutions03 Temperature-responsive injectable hydrogel systems

Temperature-responsive hydrogels undergo sol-gel transition at physiological temperatures, making them ideal for injectable applications. These systems remain liquid at room temperature for easy injection and solidify upon reaching body temperature. This property allows for precise placement of the hydrogel and reduces the risk of migration from the target site, enhancing therapeutic efficacy and patient comfort.Expand Specific Solutions04 Injectable hydrogels with enhanced mechanical properties

Advanced formulations of injectable hydrogels focus on improving mechanical strength and durability for applications requiring structural support. These hydrogels incorporate reinforcing components or novel cross-linking mechanisms to enhance their mechanical properties while maintaining injectability. The improved mechanical stability allows these hydrogels to withstand physiological stresses and maintain their function over extended periods in the body.Expand Specific Solutions05 Self-healing injectable hydrogels for biomedical applications

Self-healing hydrogels possess the ability to recover their structural integrity after injection-induced shear stress or damage. These advanced materials incorporate dynamic bonds that can reform after disruption, providing enhanced durability and longevity in vivo. Self-healing properties are particularly valuable for applications requiring prolonged presence in the body, such as sustained drug release or long-term tissue support.Expand Specific Solutions

Key Industry Players in Agricultural Hydrogel Development

The injectable hydrogel market for crop protection formulations is currently in a growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 8-12%. Major agrochemical companies including Bayer CropScience, BASF, and Syngenta are leading innovation in this space, with DuPont and Jiangsu Rotam Chemistry also making significant investments. The technology is approaching commercial maturity, with advanced formulations moving from R&D to field trials. Companies like UPL and American Soil Technologies are developing specialized applications for controlled release of pesticides and nutrients, while research institutions such as Utrecht University and Newcastle University are advancing fundamental hydrogel science. The competitive landscape is characterized by increasing patent activity and strategic partnerships between material science specialists and agricultural incumbents.

Bayer CropScience LP

Technical Solution: Bayer CropScience has developed advanced injectable hydrogel formulations for controlled release of crop protection agents. Their technology utilizes cross-linked polymeric networks that respond to environmental triggers such as soil pH, temperature, and moisture levels. The company's proprietary hydrogel matrices incorporate active ingredients through physical entrapment or chemical bonding, allowing for sustained release over extended periods (typically 2-8 weeks depending on formulation). Bayer's systems employ biodegradable polymers including modified cellulose derivatives and polyacrylamides that gradually degrade in soil environments, releasing encapsulated pesticides or nutrients at optimal rates. Their formulations have demonstrated up to 40% reduction in application frequency while maintaining efficacy comparable to conventional treatments. Recent innovations include stimuli-responsive hydrogels that can modulate release rates based on specific environmental conditions, such as accelerating release during pest outbreaks triggered by temperature changes.

Strengths: Superior controlled-release profiles with demonstrated field efficacy; biodegradable formulations reducing environmental impact; extensive field testing data across diverse crops and conditions. Weaknesses: Higher initial production costs compared to conventional formulations; potential variability in release kinetics under extreme environmental conditions; requires specialized application equipment in some formulations.

BASF Corp.

Technical Solution: BASF has pioneered injectable hydrogel systems for crop protection using their proprietary "Smart Formulation Technology" platform. Their approach utilizes responsive polymer networks that can be injected as low-viscosity solutions that subsequently form stable hydrogels in situ. These formulations incorporate active ingredients through various mechanisms including ionic complexation and hydrophobic interactions. BASF's hydrogels feature multi-phase release profiles, with an initial burst release followed by sustained delivery over 30-60 days. The company has developed specialized cross-linking chemistries that respond to soil microbiome activity, allowing for targeted breakdown in specific agricultural environments. Their formulations incorporate natural polysaccharides combined with synthetic polymers to optimize both performance and environmental compatibility. BASF has demonstrated field results showing up to 35% reduction in active ingredient requirements while maintaining equivalent pest control compared to conventional formulations, particularly effective in drought conditions where traditional formulations often fail.

Strengths: Advanced polymer chemistry expertise allowing precise control of release kinetics; formulations optimized for compatibility with existing application equipment; strong environmental profile with reduced leaching potential. Weaknesses: Some formulations show sensitivity to extreme temperature fluctuations; higher manufacturing complexity leading to increased production costs; limited efficacy data in tropical agricultural systems.

Critical Patents and Research in Injectable Hydrogel Technology

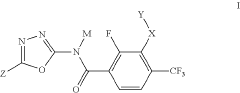

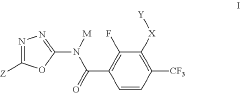

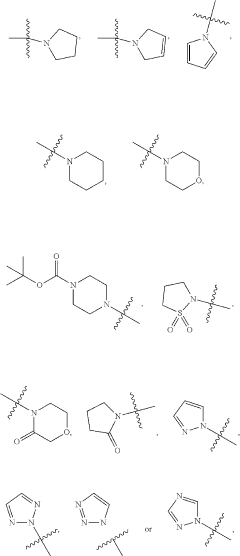

N-(1,3,4-oxadiazol-2-yl)arylcarboxamides or salts thereof, preparation methods, herbicidal compositions and uses thereof

PatentPendingUS20230041563A1

Innovation

- The development of an N-(1,3,4-oxadiazol-2-yl)arylcarboxamide compound or its salt, which exhibits low dosage requirements, high herbicidal activity, and excellent crop safety, particularly selective for rice, offering a sulfur-containing chiral herbicide with broad-spectrum weed control.

Use of alkoxylated compounds as nonionic emulsifiers in crop protection formulations

PatentInactiveCA1162409A

Innovation

- Development of alkoxylated compounds as nonionic emulsifiers, specifically those of the formula Rl-CH2-CH-CH2-R2, where R1 and R2 are phenoxy or naphthoxy radicals, which are used alone or in combination with anionic surfactants to create stable oil-in-water emulsions suitable for crop protection formulations, preventing creaming and sedimentation.

Environmental Impact Assessment of Hydrogel Applications

The environmental impact of hydrogel applications in agriculture represents a critical area of assessment as these materials gain prominence in crop protection formulations. Injectable hydrogels, while offering significant benefits for controlled release of agrochemicals, introduce various environmental considerations that must be thoroughly evaluated.

Hydrogels in agricultural applications interact directly with soil ecosystems, potentially altering soil structure, water retention capabilities, and microbial communities. Research indicates that biodegradable hydrogels can enhance soil quality by improving water retention and reducing irrigation requirements by up to 30-50% in arid regions. This water conservation aspect represents a significant positive environmental impact, particularly in drought-prone agricultural areas.

However, concerns exist regarding the persistence of synthetic hydrogels in soil environments. Non-biodegradable formulations may accumulate over repeated applications, potentially introducing microplastics into agricultural soils. Studies have detected residual acrylamide-based hydrogel particles persisting for 3-5 years in field conditions, raising questions about long-term soil health impacts.

The biodegradation pathways of various hydrogel formulations show significant variation based on their chemical composition. Natural polymer-based hydrogels (alginate, chitosan, cellulose derivatives) typically demonstrate superior environmental compatibility, with complete degradation occurring within 6-18 months under field conditions. In contrast, synthetic variants may require specialized degradation conditions or exhibit prolonged persistence.

Leaching potential represents another critical environmental consideration. Research indicates that hydrogel-encapsulated agrochemicals demonstrate reduced leaching into groundwater by 40-60% compared to conventional formulations. This reduction in chemical runoff provides substantial protection for aquatic ecosystems and drinking water sources.

Ecotoxicological assessments of hydrogel degradation products have yielded mixed results. While natural polymer derivatives generally demonstrate minimal ecotoxicity, certain synthetic hydrogel breakdown components have shown potential for bioaccumulation in soil organisms. Comprehensive lifecycle assessments indicate that the environmental footprint of hydrogel applications must consider both production inputs and end-of-life impacts.

Regulatory frameworks for evaluating hydrogel environmental impacts remain inconsistent globally, with the European Union implementing the most stringent requirements for biodegradability and ecotoxicity testing. The development of standardized protocols for assessing the environmental fate of agricultural hydrogels represents an ongoing challenge for the industry and regulatory bodies.

Hydrogels in agricultural applications interact directly with soil ecosystems, potentially altering soil structure, water retention capabilities, and microbial communities. Research indicates that biodegradable hydrogels can enhance soil quality by improving water retention and reducing irrigation requirements by up to 30-50% in arid regions. This water conservation aspect represents a significant positive environmental impact, particularly in drought-prone agricultural areas.

However, concerns exist regarding the persistence of synthetic hydrogels in soil environments. Non-biodegradable formulations may accumulate over repeated applications, potentially introducing microplastics into agricultural soils. Studies have detected residual acrylamide-based hydrogel particles persisting for 3-5 years in field conditions, raising questions about long-term soil health impacts.

The biodegradation pathways of various hydrogel formulations show significant variation based on their chemical composition. Natural polymer-based hydrogels (alginate, chitosan, cellulose derivatives) typically demonstrate superior environmental compatibility, with complete degradation occurring within 6-18 months under field conditions. In contrast, synthetic variants may require specialized degradation conditions or exhibit prolonged persistence.

Leaching potential represents another critical environmental consideration. Research indicates that hydrogel-encapsulated agrochemicals demonstrate reduced leaching into groundwater by 40-60% compared to conventional formulations. This reduction in chemical runoff provides substantial protection for aquatic ecosystems and drinking water sources.

Ecotoxicological assessments of hydrogel degradation products have yielded mixed results. While natural polymer derivatives generally demonstrate minimal ecotoxicity, certain synthetic hydrogel breakdown components have shown potential for bioaccumulation in soil organisms. Comprehensive lifecycle assessments indicate that the environmental footprint of hydrogel applications must consider both production inputs and end-of-life impacts.

Regulatory frameworks for evaluating hydrogel environmental impacts remain inconsistent globally, with the European Union implementing the most stringent requirements for biodegradability and ecotoxicity testing. The development of standardized protocols for assessing the environmental fate of agricultural hydrogels represents an ongoing challenge for the industry and regulatory bodies.

Regulatory Framework for Agricultural Hydrogel Products

The regulatory landscape for agricultural hydrogel products represents a complex framework that varies significantly across global jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates injectable hydrogels used in crop protection formulations primarily under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). These products must undergo rigorous safety assessments focusing on environmental fate, toxicological profiles, and potential ecological impacts before receiving market authorization.

The European Union implements a more stringent approach through the European Chemicals Agency (ECHA) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Additionally, agricultural hydrogels must comply with the Plant Protection Products Regulation (EC) No 1107/2009, which demands comprehensive data packages demonstrating efficacy, safety, and environmental compatibility. The EU's precautionary principle often results in longer approval timelines compared to other regions.

In Asia, regulatory frameworks show considerable variation. Japan's Ministry of Agriculture, Forestry and Fisheries (MAFF) has established specific guidelines for biodegradable agricultural materials, including hydrogels, with particular emphasis on soil impact assessments. China's regulatory system, administered by the Institute for the Control of Agrochemicals (ICAMA), has recently updated its requirements for novel delivery systems in crop protection, including specific provisions for polymer-based formulations.

Data requirements across these jurisdictions typically include physical-chemical properties, degradation pathways, leaching potential, effects on non-target organisms, and residue profiles. For injectable hydrogels specifically, regulators increasingly focus on polymer degradation products and their environmental persistence. The novelty of these delivery systems often necessitates case-by-case evaluations that extend beyond standard regulatory frameworks.

Emerging regulatory trends indicate a shift toward more comprehensive life-cycle assessments for agricultural inputs. Several jurisdictions are developing specialized frameworks for "biostimulants" and "plant strengtheners," categories where some hydrogel formulations may be classified. These frameworks typically impose less stringent requirements than conventional pesticide regulations while still ensuring environmental safety.

Industry stakeholders face significant challenges navigating these diverse regulatory landscapes, particularly when developing products for global markets. Regulatory harmonization initiatives, such as the OECD's Guidelines for the Testing of Chemicals, provide some standardization but substantial regional differences persist. Companies developing injectable hydrogel crop protection formulations must therefore adopt strategic regulatory planning that accounts for these jurisdictional variations.

The European Union implements a more stringent approach through the European Chemicals Agency (ECHA) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Additionally, agricultural hydrogels must comply with the Plant Protection Products Regulation (EC) No 1107/2009, which demands comprehensive data packages demonstrating efficacy, safety, and environmental compatibility. The EU's precautionary principle often results in longer approval timelines compared to other regions.

In Asia, regulatory frameworks show considerable variation. Japan's Ministry of Agriculture, Forestry and Fisheries (MAFF) has established specific guidelines for biodegradable agricultural materials, including hydrogels, with particular emphasis on soil impact assessments. China's regulatory system, administered by the Institute for the Control of Agrochemicals (ICAMA), has recently updated its requirements for novel delivery systems in crop protection, including specific provisions for polymer-based formulations.

Data requirements across these jurisdictions typically include physical-chemical properties, degradation pathways, leaching potential, effects on non-target organisms, and residue profiles. For injectable hydrogels specifically, regulators increasingly focus on polymer degradation products and their environmental persistence. The novelty of these delivery systems often necessitates case-by-case evaluations that extend beyond standard regulatory frameworks.

Emerging regulatory trends indicate a shift toward more comprehensive life-cycle assessments for agricultural inputs. Several jurisdictions are developing specialized frameworks for "biostimulants" and "plant strengtheners," categories where some hydrogel formulations may be classified. These frameworks typically impose less stringent requirements than conventional pesticide regulations while still ensuring environmental safety.

Industry stakeholders face significant challenges navigating these diverse regulatory landscapes, particularly when developing products for global markets. Regulatory harmonization initiatives, such as the OECD's Guidelines for the Testing of Chemicals, provide some standardization but substantial regional differences persist. Companies developing injectable hydrogel crop protection formulations must therefore adopt strategic regulatory planning that accounts for these jurisdictional variations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!