How Does Injectable Hydrogel Fit in Current Regulatory Frameworks

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Injectable Hydrogel Regulatory Background and Objectives

Injectable hydrogels represent a significant advancement in biomedical technology, evolving from simple polymer solutions to sophisticated biomaterials capable of in situ gelation. The development trajectory of this technology spans several decades, beginning with rudimentary formulations in the 1960s and accelerating dramatically in the 1990s with the introduction of smart responsive systems. Recent years have witnessed exponential growth in research and applications, particularly in drug delivery, tissue engineering, and regenerative medicine.

The regulatory landscape governing injectable hydrogels has evolved alongside technological advancements, though often lagging behind innovation. Initially, these materials were primarily regulated under existing frameworks for medical devices or drug delivery systems, without specific consideration for their unique properties. The U.S. Food and Drug Administration (FDA) has historically classified hydrogels based on their primary mode of action, either as devices, drugs, biologics, or combination products, creating a complex regulatory pathway.

In Europe, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) implemented in 2017 have introduced more stringent requirements for all medical devices, including injectable hydrogels. These regulations emphasize post-market surveillance and clinical evidence, significantly impacting development timelines and costs for manufacturers.

The primary objective of this technical research report is to comprehensively analyze how injectable hydrogels fit within current regulatory frameworks globally. We aim to identify regulatory gaps, inconsistencies, and challenges that may impede innovation while ensuring patient safety. Additionally, we seek to forecast regulatory trends that might affect future development and commercialization of injectable hydrogel technologies.

A secondary objective is to evaluate the adequacy of existing classification systems for novel injectable hydrogel formulations, particularly those incorporating nanotechnology, stem cells, or gene therapy components. These hybrid technologies often blur traditional regulatory boundaries, creating uncertainty for developers and regulatory bodies alike.

Furthermore, this report intends to compare international regulatory approaches, identifying best practices and potential harmonization opportunities. Significant disparities exist between major markets including the United States, European Union, Japan, and China, creating challenges for global product development strategies.

Finally, we aim to provide strategic recommendations for both regulatory bodies and industry stakeholders to foster innovation while maintaining appropriate safety standards. This includes potential frameworks for evaluating novel injectable hydrogel technologies that better account for their unique characteristics and risk profiles.

The regulatory landscape governing injectable hydrogels has evolved alongside technological advancements, though often lagging behind innovation. Initially, these materials were primarily regulated under existing frameworks for medical devices or drug delivery systems, without specific consideration for their unique properties. The U.S. Food and Drug Administration (FDA) has historically classified hydrogels based on their primary mode of action, either as devices, drugs, biologics, or combination products, creating a complex regulatory pathway.

In Europe, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) implemented in 2017 have introduced more stringent requirements for all medical devices, including injectable hydrogels. These regulations emphasize post-market surveillance and clinical evidence, significantly impacting development timelines and costs for manufacturers.

The primary objective of this technical research report is to comprehensively analyze how injectable hydrogels fit within current regulatory frameworks globally. We aim to identify regulatory gaps, inconsistencies, and challenges that may impede innovation while ensuring patient safety. Additionally, we seek to forecast regulatory trends that might affect future development and commercialization of injectable hydrogel technologies.

A secondary objective is to evaluate the adequacy of existing classification systems for novel injectable hydrogel formulations, particularly those incorporating nanotechnology, stem cells, or gene therapy components. These hybrid technologies often blur traditional regulatory boundaries, creating uncertainty for developers and regulatory bodies alike.

Furthermore, this report intends to compare international regulatory approaches, identifying best practices and potential harmonization opportunities. Significant disparities exist between major markets including the United States, European Union, Japan, and China, creating challenges for global product development strategies.

Finally, we aim to provide strategic recommendations for both regulatory bodies and industry stakeholders to foster innovation while maintaining appropriate safety standards. This includes potential frameworks for evaluating novel injectable hydrogel technologies that better account for their unique characteristics and risk profiles.

Market Demand Analysis for Injectable Hydrogel Applications

The global market for injectable hydrogels has witnessed substantial growth in recent years, driven primarily by increasing applications in tissue engineering, drug delivery systems, and regenerative medicine. Current market valuations indicate that the injectable hydrogel sector is expanding at a compound annual growth rate of approximately 10-12%, with the global market expected to reach significant valuation by 2028.

Healthcare applications represent the largest segment for injectable hydrogels, particularly in wound healing, minimally invasive surgeries, and controlled drug release systems. The aging population worldwide has created heightened demand for advanced wound care solutions, where injectable hydrogels offer superior healing environments and reduced scarring compared to traditional methods.

In the pharmaceutical sector, injectable hydrogels are increasingly sought after for their ability to provide sustained and controlled drug release, enhancing therapeutic efficacy while reducing dosing frequency. This application is particularly valuable for chronic disease management, where patient compliance remains a significant challenge. Market research indicates that pharmaceutical companies are increasingly investing in hydrogel-based drug delivery platforms to extend patent lifecycles and improve treatment outcomes.

The cosmetic and aesthetic medicine market represents another rapidly growing segment for injectable hydrogels. With rising consumer preference for minimally invasive procedures, hydrogel-based dermal fillers and tissue augmentation products have seen substantial market penetration. This trend is particularly pronounced in developed economies across North America, Europe, and parts of Asia.

Orthopedic applications constitute a promising growth area, with injectable hydrogels being developed for cartilage repair, intervertebral disc regeneration, and as carriers for cell therapies. The increasing incidence of degenerative joint diseases and sports-related injuries is driving demand for innovative, minimally invasive treatment options in this space.

Regional analysis reveals that North America currently holds the largest market share for injectable hydrogels, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to experience the fastest growth rate due to improving healthcare infrastructure, increasing healthcare expenditure, and growing awareness about advanced treatment modalities.

Market challenges include cost concerns, particularly in emerging economies, and the need for more robust clinical evidence supporting long-term efficacy and safety. Additionally, regulatory hurdles vary significantly across different regions, creating complexities for global market players seeking multinational product launches.

Customer demand patterns indicate growing preference for biocompatible, biodegradable hydrogel formulations with tailored mechanical properties and degradation profiles. This has spurred innovation in material science, with manufacturers focusing on developing next-generation hydrogels with enhanced functionality and application-specific characteristics.

Healthcare applications represent the largest segment for injectable hydrogels, particularly in wound healing, minimally invasive surgeries, and controlled drug release systems. The aging population worldwide has created heightened demand for advanced wound care solutions, where injectable hydrogels offer superior healing environments and reduced scarring compared to traditional methods.

In the pharmaceutical sector, injectable hydrogels are increasingly sought after for their ability to provide sustained and controlled drug release, enhancing therapeutic efficacy while reducing dosing frequency. This application is particularly valuable for chronic disease management, where patient compliance remains a significant challenge. Market research indicates that pharmaceutical companies are increasingly investing in hydrogel-based drug delivery platforms to extend patent lifecycles and improve treatment outcomes.

The cosmetic and aesthetic medicine market represents another rapidly growing segment for injectable hydrogels. With rising consumer preference for minimally invasive procedures, hydrogel-based dermal fillers and tissue augmentation products have seen substantial market penetration. This trend is particularly pronounced in developed economies across North America, Europe, and parts of Asia.

Orthopedic applications constitute a promising growth area, with injectable hydrogels being developed for cartilage repair, intervertebral disc regeneration, and as carriers for cell therapies. The increasing incidence of degenerative joint diseases and sports-related injuries is driving demand for innovative, minimally invasive treatment options in this space.

Regional analysis reveals that North America currently holds the largest market share for injectable hydrogels, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to experience the fastest growth rate due to improving healthcare infrastructure, increasing healthcare expenditure, and growing awareness about advanced treatment modalities.

Market challenges include cost concerns, particularly in emerging economies, and the need for more robust clinical evidence supporting long-term efficacy and safety. Additionally, regulatory hurdles vary significantly across different regions, creating complexities for global market players seeking multinational product launches.

Customer demand patterns indicate growing preference for biocompatible, biodegradable hydrogel formulations with tailored mechanical properties and degradation profiles. This has spurred innovation in material science, with manufacturers focusing on developing next-generation hydrogels with enhanced functionality and application-specific characteristics.

Regulatory Challenges and Technical Barriers

Injectable hydrogels face significant regulatory challenges due to their hybrid nature, straddling the boundaries between medical devices, drugs, and biologics. Current regulatory frameworks in major markets like the US FDA, EU MDR, and NMPA in China were not specifically designed with these advanced biomaterials in mind, creating classification ambiguities. The FDA typically evaluates injectable hydrogels either as medical devices under the 510(k) pathway or as combination products, depending on their primary mode of action. However, this bifurcated approach often fails to address the unique characteristics of hydrogels that simultaneously provide structural support and deliver therapeutic agents.

Technical barriers compound these regulatory challenges. The complex viscoelastic properties of injectable hydrogels create difficulties in establishing standardized testing protocols. Current mechanical testing standards for biomaterials do not adequately capture the dynamic nature of hydrogels that transition from liquid to solid states in situ. This leads to inconsistent evaluation metrics across different regulatory jurisdictions, complicating multi-market approval strategies.

Biocompatibility assessment presents another significant hurdle. Traditional ISO 10993 testing protocols were developed primarily for permanent implants or transient contact materials, not for biodegradable matrices that interact with tissues over varying timeframes. The degradation products of hydrogels and their potential systemic effects require specialized toxicological evaluation approaches that current regulatory frameworks do not explicitly define.

Manufacturing consistency and quality control represent additional technical barriers. The complex chemistry of hydrogels makes batch-to-batch reproducibility challenging, particularly for those incorporating biological components or sensitive crosslinking mechanisms. Current Good Manufacturing Practice (cGMP) guidelines lack specific provisions for the unique production challenges of injectable hydrogels, creating uncertainty in quality assurance protocols.

Sterilization methods present further complications, as traditional approaches like ethylene oxide, gamma irradiation, or autoclaving can compromise the structural integrity or bioactivity of hydrogel components. This necessitates the development of novel sterilization techniques, which themselves require regulatory validation.

Long-term stability testing protocols are also inadequately defined for injectable hydrogels. Their shelf-life determination is complicated by potential changes in rheological properties over time and sensitivity to storage conditions. Current accelerated aging test protocols may not accurately predict the real-world performance of these materials.

These regulatory and technical barriers collectively slow the translation of promising injectable hydrogel technologies from laboratory to clinical application, creating a significant innovation gap in this rapidly evolving field.

Technical barriers compound these regulatory challenges. The complex viscoelastic properties of injectable hydrogels create difficulties in establishing standardized testing protocols. Current mechanical testing standards for biomaterials do not adequately capture the dynamic nature of hydrogels that transition from liquid to solid states in situ. This leads to inconsistent evaluation metrics across different regulatory jurisdictions, complicating multi-market approval strategies.

Biocompatibility assessment presents another significant hurdle. Traditional ISO 10993 testing protocols were developed primarily for permanent implants or transient contact materials, not for biodegradable matrices that interact with tissues over varying timeframes. The degradation products of hydrogels and their potential systemic effects require specialized toxicological evaluation approaches that current regulatory frameworks do not explicitly define.

Manufacturing consistency and quality control represent additional technical barriers. The complex chemistry of hydrogels makes batch-to-batch reproducibility challenging, particularly for those incorporating biological components or sensitive crosslinking mechanisms. Current Good Manufacturing Practice (cGMP) guidelines lack specific provisions for the unique production challenges of injectable hydrogels, creating uncertainty in quality assurance protocols.

Sterilization methods present further complications, as traditional approaches like ethylene oxide, gamma irradiation, or autoclaving can compromise the structural integrity or bioactivity of hydrogel components. This necessitates the development of novel sterilization techniques, which themselves require regulatory validation.

Long-term stability testing protocols are also inadequately defined for injectable hydrogels. Their shelf-life determination is complicated by potential changes in rheological properties over time and sensitivity to storage conditions. Current accelerated aging test protocols may not accurately predict the real-world performance of these materials.

These regulatory and technical barriers collectively slow the translation of promising injectable hydrogel technologies from laboratory to clinical application, creating a significant innovation gap in this rapidly evolving field.

Current Regulatory Pathways for Injectable Hydrogels

01 Composition and formulation of injectable hydrogels

Injectable hydrogels can be formulated using various polymers and cross-linking agents to create biocompatible matrices suitable for medical applications. These formulations typically include natural polymers (like hyaluronic acid, collagen, or alginate) or synthetic polymers that can form three-dimensional networks upon injection into the body. The composition can be tailored to control properties such as gelation time, mechanical strength, and degradation rate, making them versatile for different medical applications.- Composition and formulation of injectable hydrogels: Injectable hydrogels can be formulated using various polymers and cross-linking agents to create biocompatible matrices. These formulations typically include natural polymers (like hyaluronic acid, collagen, or alginate) or synthetic polymers (like polyethylene glycol) that can be cross-linked in situ after injection. The composition can be tailored to control properties such as gelation time, mechanical strength, and degradation rate, making them suitable for different biomedical applications.

- Drug delivery applications of injectable hydrogels: Injectable hydrogels serve as effective drug delivery systems due to their ability to encapsulate therapeutic agents and provide controlled release. These hydrogels can be designed to respond to specific stimuli such as pH, temperature, or enzymatic activity, allowing for targeted and sustained release of pharmaceuticals. The porous structure of hydrogels enables the incorporation of various drugs, proteins, or growth factors, making them versatile carriers for localized treatment of various conditions.

- Tissue engineering and regenerative medicine applications: Injectable hydrogels provide three-dimensional scaffolds that support cell growth, proliferation, and differentiation for tissue engineering applications. These biomaterials can be loaded with stem cells or growth factors to promote tissue regeneration in damaged areas. Their ability to conform to irregular tissue defects and solidify in situ makes them particularly valuable for minimally invasive procedures in regenerative medicine, including cartilage repair, bone regeneration, and wound healing.

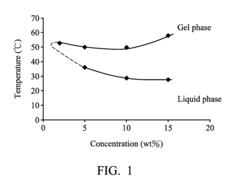

- Smart and stimuli-responsive injectable hydrogels: Advanced injectable hydrogels can respond to environmental stimuli such as temperature, pH, light, or electrical signals. These smart hydrogels undergo reversible sol-gel transitions or structural changes in response to specific triggers, enabling on-demand drug release or changes in mechanical properties. Thermo-responsive hydrogels that solidify at body temperature are particularly useful for clinical applications, as they can be injected as liquids and form solid gels once inside the body.

- Injectable hydrogels for aesthetic and cosmetic applications: Injectable hydrogels are widely used in aesthetic medicine and cosmetic procedures for soft tissue augmentation and facial rejuvenation. These hydrogels can be formulated to mimic the viscoelastic properties of natural tissues, providing natural-looking results for applications such as wrinkle filling, lip enhancement, and facial contouring. Biocompatible and biodegradable formulations ensure safety while providing temporary or semi-permanent aesthetic improvements.

02 Drug delivery applications of injectable hydrogels

Injectable hydrogels serve as effective drug delivery systems that can provide controlled release of therapeutic agents. These hydrogels can encapsulate various drugs, proteins, or growth factors and release them at controlled rates based on their network structure and degradation profile. The localized delivery minimizes systemic side effects while maintaining therapeutic concentrations at the target site. This approach is particularly valuable for delivering drugs with short half-lives or those requiring sustained release over extended periods.Expand Specific Solutions03 Tissue engineering and regenerative medicine applications

Injectable hydrogels provide three-dimensional scaffolds for tissue engineering and regenerative medicine. These hydrogels can support cell adhesion, proliferation, and differentiation, making them ideal for tissue repair and regeneration. They can be designed to mimic the extracellular matrix of specific tissues and can incorporate bioactive molecules to enhance tissue formation. Applications include cartilage repair, bone regeneration, wound healing, and neural tissue engineering.Expand Specific Solutions04 Stimuli-responsive injectable hydrogels

Stimuli-responsive injectable hydrogels can undergo sol-gel transitions in response to specific environmental triggers such as temperature, pH, light, or enzymatic activity. These smart materials can be injected as liquids and form gels in situ upon exposure to physiological conditions. This property enables minimally invasive administration and precise localization of the hydrogel. The responsive nature also allows for controlled drug release or degradation based on specific physiological or pathological conditions at the target site.Expand Specific Solutions05 Injectable hydrogels for aesthetic and cosmetic applications

Injectable hydrogels are widely used in aesthetic and cosmetic procedures for soft tissue augmentation and facial rejuvenation. These hydrogels can provide volume enhancement, wrinkle reduction, and skin rejuvenation effects. They are designed to be biocompatible, with appropriate viscoelastic properties that mimic natural tissues. Some formulations also incorporate additional bioactive components that can stimulate collagen production or provide other skin benefits beyond the volumizing effect.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

Injectable hydrogel technology is currently positioned at the intersection of rapid innovation and evolving regulatory frameworks. The market is in an early growth phase with increasing applications in drug delivery, tissue engineering, and minimally invasive procedures, projected to reach significant market value in the coming years. Regulatory oversight varies globally, with companies like Johnson & Johnson subsidiaries (AMO Groningen BV, Gelifex, Synthes GmbH), Contraline, and SentryX BV navigating different approval pathways. Academic institutions including MIT, Drexel University, and Fudan University are advancing fundamental research, while companies like Alcon AG and Carl Zeiss Meditec AG are exploring commercial applications. The technology faces classification challenges as it often spans multiple regulatory categories (drug/device/biologic), creating compliance complexity for developers seeking market approval across different jurisdictions.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced injectable hydrogel platforms that address regulatory challenges through innovative design approaches. Their technology focuses on shear-thinning hydrogels with self-healing properties that can be delivered minimally invasively while maintaining structural integrity post-injection. MIT researchers have engineered these materials to have predictable degradation profiles and controlled drug release kinetics, which aligns with FDA requirements for combination products. They've implemented standardized characterization methods for mechanical properties, gelation kinetics, and biocompatibility that satisfy both 510(k) and PMA regulatory pathways. MIT has also pioneered hydrogels with tunable mechanical properties that mimic native tissue environments, addressing the FDA's concerns about tissue integration and long-term performance[1][3]. Their regulatory strategy includes extensive preclinical validation using standardized animal models that demonstrate safety profiles consistent with ISO 10993 biocompatibility standards.

Strengths: Superior material engineering capabilities allowing precise control over gelation mechanisms and degradation profiles; extensive experience navigating regulatory pathways for combination devices; strong scientific foundation with comprehensive characterization protocols. Weaknesses: Complex manufacturing processes may present scale-up challenges for commercial production; potential variability in biological response across different patient populations may complicate regulatory approval processes.

Incept LLC

Technical Solution: Incept LLC has pioneered injectable hydrogel technologies specifically engineered to address regulatory challenges across multiple jurisdictions. Their approach focuses on hydrogels that form in situ through biocompatible crosslinking mechanisms, allowing for minimally invasive delivery while achieving precise mechanical properties post-injection. The company has developed a regulatory framework that strategically positions their hydrogels either as medical devices, combination products, or drug delivery systems depending on the specific application and intended use. Their technology platform incorporates synthetic polymers with well-documented safety profiles and controlled degradation characteristics, facilitating regulatory approval through established pathways. Incept has implemented comprehensive quality management systems that comply with ISO 13485 standards, ensuring consistent manufacturing processes that meet regulatory expectations[4]. Their regulatory strategy includes extensive physicochemical characterization, standardized biocompatibility testing according to ISO 10993, and controlled release studies that satisfy both FDA and international regulatory requirements. The company has successfully navigated the 510(k) pathway for certain applications by demonstrating substantial equivalence to predicate devices, while pursuing PMA routes for novel applications with no clear predicates.

Strengths: Extensive intellectual property portfolio covering various aspects of injectable hydrogel technology; demonstrated success in obtaining regulatory clearances across multiple product categories; sophisticated understanding of different regulatory frameworks globally. Weaknesses: Complex formulations may present challenges for consistent manufacturing at commercial scale; regulatory pathways may vary significantly between different applications, requiring substantial resources for each product line.

Critical Regulatory Guidelines and Scientific Literature

Hydrogels and method of making the same

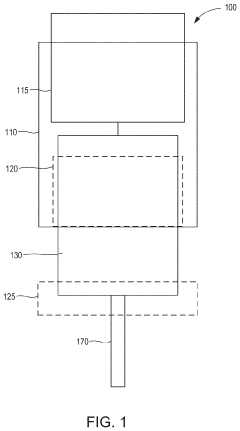

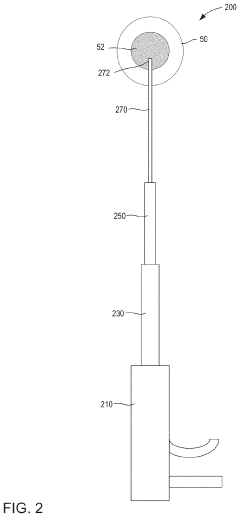

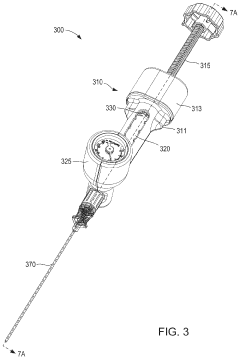

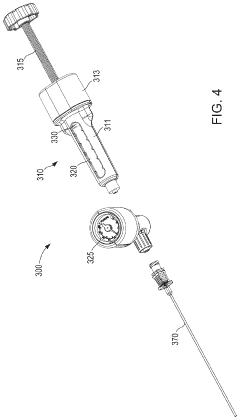

PatentActiveUS20200255601A1

Innovation

- Development of hydrogels that can be safely injected through fine gauge needles (15 gauge or smaller) at temperatures below 65°C, using a mixture of polyvinyl alcohol, polyvinylpyrrolidone, and polyethylene glycol, which solidify in situ to form a contiguous implant with a Young's modulus of 0.1 to 5.0 MPa, reducing the risk of expulsion and providing suitable mechanical support.

Hydrogel composition and method for using the same

PatentActiveUS20170106125A1

Innovation

- A temperature-sensitive hydrogel composition comprising a hydrophilic polyethylene glycol polymer and a hydrophobic polyester polymer with a bifunctional group monomer, combined with an anti-adhesion additive like carbohydrates or nitrogen-containing cyclic compounds, that transitions from a liquid to a gel at body temperature, allowing precise application and improved stability.

International Regulatory Harmonization Efforts

The global nature of medical device and pharmaceutical development necessitates coordinated regulatory approaches across different jurisdictions. For injectable hydrogels, which often straddle the boundary between devices and drugs, international harmonization efforts are particularly crucial. The International Medical Device Regulators Forum (IMDRF) has been instrumental in developing frameworks that can accommodate combination products like injectable hydrogels, building upon the foundation established by its predecessor, the Global Harmonization Task Force.

The European Union and the United States have made significant progress in mutual recognition agreements for certain aspects of medical product regulation, potentially streamlining the approval process for injectable hydrogels in both markets. These agreements focus on quality management system inspections and good manufacturing practice compliance, reducing duplicative regulatory burdens while maintaining safety standards.

ISO 13485 and ISO 10993 standards provide internationally recognized frameworks for quality management systems and biocompatibility testing, respectively. These standards are increasingly being adopted as reference points in regulatory frameworks worldwide, offering manufacturers of injectable hydrogels a more predictable path to multi-market approval.

The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) has developed guidelines that, while primarily focused on pharmaceuticals, have relevance for the drug components of injectable hydrogels. The ICH Q8 guideline on pharmaceutical development and Q9 on quality risk management provide valuable approaches that can be applied to the development and manufacturing of injectable hydrogels.

Emerging markets, particularly China and India, are increasingly aligning their regulatory frameworks with international standards, though significant differences remain. Both countries have recently updated their medical device regulations to better accommodate innovative technologies like injectable hydrogels, while still maintaining country-specific requirements that developers must navigate.

The World Health Organization's prequalification program, though primarily focused on medicines and vaccines for priority diseases, is exploring frameworks for combination products that could include certain types of injectable hydrogels, potentially facilitating access in low and middle-income countries.

Despite these harmonization efforts, significant challenges remain. Different classification systems across jurisdictions can lead to the same injectable hydrogel being regulated as a device in one country and a drug or combination product in another. Additionally, varying requirements for clinical evidence and post-market surveillance create complexity for global product launches and lifecycle management.

The European Union and the United States have made significant progress in mutual recognition agreements for certain aspects of medical product regulation, potentially streamlining the approval process for injectable hydrogels in both markets. These agreements focus on quality management system inspections and good manufacturing practice compliance, reducing duplicative regulatory burdens while maintaining safety standards.

ISO 13485 and ISO 10993 standards provide internationally recognized frameworks for quality management systems and biocompatibility testing, respectively. These standards are increasingly being adopted as reference points in regulatory frameworks worldwide, offering manufacturers of injectable hydrogels a more predictable path to multi-market approval.

The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) has developed guidelines that, while primarily focused on pharmaceuticals, have relevance for the drug components of injectable hydrogels. The ICH Q8 guideline on pharmaceutical development and Q9 on quality risk management provide valuable approaches that can be applied to the development and manufacturing of injectable hydrogels.

Emerging markets, particularly China and India, are increasingly aligning their regulatory frameworks with international standards, though significant differences remain. Both countries have recently updated their medical device regulations to better accommodate innovative technologies like injectable hydrogels, while still maintaining country-specific requirements that developers must navigate.

The World Health Organization's prequalification program, though primarily focused on medicines and vaccines for priority diseases, is exploring frameworks for combination products that could include certain types of injectable hydrogels, potentially facilitating access in low and middle-income countries.

Despite these harmonization efforts, significant challenges remain. Different classification systems across jurisdictions can lead to the same injectable hydrogel being regulated as a device in one country and a drug or combination product in another. Additionally, varying requirements for clinical evidence and post-market surveillance create complexity for global product launches and lifecycle management.

Safety and Efficacy Assessment Frameworks

The assessment of injectable hydrogels for safety and efficacy presents unique challenges within existing regulatory frameworks. Current assessment protocols typically follow a tiered approach, beginning with in vitro cytotoxicity testing to evaluate basic biocompatibility, followed by more complex in vivo studies examining tissue response, degradation profiles, and functional outcomes. These frameworks vary significantly between jurisdictions, with the FDA's 510(k) pathway in the United States requiring demonstration of substantial equivalence to predicate devices, while the EU's Medical Device Regulation (MDR) employs a risk-based classification system.

For injectable hydrogels specifically, regulatory bodies have established specialized testing requirements addressing their unique characteristics. These include rheological property assessments to ensure consistent gelation behavior under physiological conditions, mechanical stability testing to verify structural integrity post-injection, and controlled release kinetics evaluation when the hydrogel serves as a drug delivery vehicle. The viscoelastic nature of these materials necessitates specialized protocols beyond those used for conventional solid implants.

Long-term safety monitoring frameworks for injectable hydrogels focus on degradation byproducts and their potential systemic effects. Regulatory guidelines typically require comprehensive toxicokinetic studies tracking the fate of degradation products, with particular attention to potential accumulation in vital organs. The FDA's guidance on combination products provides specific direction when hydrogels incorporate active pharmaceutical ingredients, requiring additional pharmacokinetic and pharmacodynamic assessments.

Efficacy assessment for injectable hydrogels follows application-specific pathways. For tissue engineering applications, functional tissue formation metrics are primary endpoints, while drug delivery applications focus on release kinetics and therapeutic outcomes. The International Organization for Standardization (ISO) has developed several standards (including ISO 10993 series) that provide frameworks for biological evaluation, though these often require adaptation for the dynamic nature of hydrogel systems.

Emerging regulatory considerations include the development of standardized protocols for 3D bioprinting applications involving injectable hydrogels and the establishment of reference materials to enable cross-study comparisons. Regulatory science initiatives at major agencies are actively working to address these gaps, with collaborative efforts between the FDA, EMA, and academic institutions focused on developing hydrogel-specific testing paradigms that better predict clinical performance while minimizing animal testing through advanced in vitro models and computational approaches.

For injectable hydrogels specifically, regulatory bodies have established specialized testing requirements addressing their unique characteristics. These include rheological property assessments to ensure consistent gelation behavior under physiological conditions, mechanical stability testing to verify structural integrity post-injection, and controlled release kinetics evaluation when the hydrogel serves as a drug delivery vehicle. The viscoelastic nature of these materials necessitates specialized protocols beyond those used for conventional solid implants.

Long-term safety monitoring frameworks for injectable hydrogels focus on degradation byproducts and their potential systemic effects. Regulatory guidelines typically require comprehensive toxicokinetic studies tracking the fate of degradation products, with particular attention to potential accumulation in vital organs. The FDA's guidance on combination products provides specific direction when hydrogels incorporate active pharmaceutical ingredients, requiring additional pharmacokinetic and pharmacodynamic assessments.

Efficacy assessment for injectable hydrogels follows application-specific pathways. For tissue engineering applications, functional tissue formation metrics are primary endpoints, while drug delivery applications focus on release kinetics and therapeutic outcomes. The International Organization for Standardization (ISO) has developed several standards (including ISO 10993 series) that provide frameworks for biological evaluation, though these often require adaptation for the dynamic nature of hydrogel systems.

Emerging regulatory considerations include the development of standardized protocols for 3D bioprinting applications involving injectable hydrogels and the establishment of reference materials to enable cross-study comparisons. Regulatory science initiatives at major agencies are actively working to address these gaps, with collaborative efforts between the FDA, EMA, and academic institutions focused on developing hydrogel-specific testing paradigms that better predict clinical performance while minimizing animal testing through advanced in vitro models and computational approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!