Exploring Vacuum Pump Integration in Quantum Computing Hardware

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Computing Vacuum Pump Integration Goals

The integration of vacuum pumps in quantum computing hardware represents a critical technological goal aimed at enhancing the performance and reliability of quantum systems. This objective stems from the fundamental requirement of maintaining a pristine environment for quantum operations, free from external interference and contamination.

One primary goal is to achieve and sustain ultra-high vacuum conditions within quantum computing chambers. This is essential for minimizing decoherence and maintaining quantum coherence for extended periods. By integrating advanced vacuum pump technologies, researchers aim to reach vacuum levels in the range of 10^-10 to 10^-12 Torr, which is crucial for the proper functioning of superconducting qubits and other quantum components.

Another key objective is to develop compact and efficient vacuum systems that can be seamlessly integrated into quantum computing architectures. As quantum processors grow in complexity and scale, there is a pressing need for vacuum solutions that do not compromise the overall system design or introduce additional sources of noise or vibration. This goal encompasses the development of miniaturized vacuum pumps and innovative pumping configurations that can be incorporated into the limited space available in quantum computing setups.

Reliability and longevity of vacuum systems in quantum computing environments are also paramount. The aim is to create vacuum pump solutions that can operate continuously for extended periods without maintenance, ensuring uninterrupted quantum computations. This involves improving pump durability, reducing wear and tear, and implementing intelligent monitoring systems to predict and prevent potential failures.

Furthermore, there is a focus on developing vacuum pumps that are compatible with cryogenic environments. Many quantum computing systems operate at extremely low temperatures, often near absolute zero. The goal is to design vacuum pumps that can function effectively in these conditions without introducing thermal loads or compromising the cryogenic setup.

Energy efficiency is another crucial aspect of vacuum pump integration goals. As quantum computers scale up, the power consumption of auxiliary systems, including vacuum pumps, becomes increasingly significant. Researchers are working towards developing energy-efficient pumping solutions that minimize the overall power requirements of quantum computing systems, contributing to their practical scalability and operational cost-effectiveness.

Lastly, there is an ongoing effort to enhance the cleanliness of vacuum systems in quantum computing. The goal is to eliminate any potential sources of contamination that could interfere with quantum operations. This includes developing advanced materials and coatings for vacuum components, as well as implementing sophisticated filtration and purification techniques to ensure the highest level of cleanliness within the quantum computing environment.

One primary goal is to achieve and sustain ultra-high vacuum conditions within quantum computing chambers. This is essential for minimizing decoherence and maintaining quantum coherence for extended periods. By integrating advanced vacuum pump technologies, researchers aim to reach vacuum levels in the range of 10^-10 to 10^-12 Torr, which is crucial for the proper functioning of superconducting qubits and other quantum components.

Another key objective is to develop compact and efficient vacuum systems that can be seamlessly integrated into quantum computing architectures. As quantum processors grow in complexity and scale, there is a pressing need for vacuum solutions that do not compromise the overall system design or introduce additional sources of noise or vibration. This goal encompasses the development of miniaturized vacuum pumps and innovative pumping configurations that can be incorporated into the limited space available in quantum computing setups.

Reliability and longevity of vacuum systems in quantum computing environments are also paramount. The aim is to create vacuum pump solutions that can operate continuously for extended periods without maintenance, ensuring uninterrupted quantum computations. This involves improving pump durability, reducing wear and tear, and implementing intelligent monitoring systems to predict and prevent potential failures.

Furthermore, there is a focus on developing vacuum pumps that are compatible with cryogenic environments. Many quantum computing systems operate at extremely low temperatures, often near absolute zero. The goal is to design vacuum pumps that can function effectively in these conditions without introducing thermal loads or compromising the cryogenic setup.

Energy efficiency is another crucial aspect of vacuum pump integration goals. As quantum computers scale up, the power consumption of auxiliary systems, including vacuum pumps, becomes increasingly significant. Researchers are working towards developing energy-efficient pumping solutions that minimize the overall power requirements of quantum computing systems, contributing to their practical scalability and operational cost-effectiveness.

Lastly, there is an ongoing effort to enhance the cleanliness of vacuum systems in quantum computing. The goal is to eliminate any potential sources of contamination that could interfere with quantum operations. This includes developing advanced materials and coatings for vacuum components, as well as implementing sophisticated filtration and purification techniques to ensure the highest level of cleanliness within the quantum computing environment.

Market Demand for Advanced Quantum Hardware

The quantum computing hardware market is experiencing a significant surge in demand, driven by the potential of quantum technologies to revolutionize various industries. As quantum systems become more sophisticated, the need for advanced hardware components, including vacuum pumps, is growing exponentially. This demand is fueled by both academic research institutions and commercial entities seeking to harness the power of quantum computing for complex problem-solving and optimization tasks.

The market for quantum computing hardware is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 30% through 2025. This growth is primarily attributed to increased investments in quantum research and development by governments, tech giants, and startups worldwide. The integration of vacuum pumps in quantum computing systems is a critical aspect of this market expansion, as these components play a vital role in maintaining the ultra-low temperatures and high vacuum environments necessary for quantum operations.

Industries such as finance, pharmaceuticals, and logistics are showing particular interest in quantum computing capabilities, driving demand for more robust and efficient hardware solutions. Financial institutions are exploring quantum algorithms for portfolio optimization and risk analysis, while pharmaceutical companies are leveraging quantum simulations for drug discovery processes. The logistics sector is investigating quantum-based optimization techniques for supply chain management and route planning.

The demand for advanced quantum hardware is also being propelled by the race for quantum supremacy among leading tech companies. As these firms strive to develop more powerful quantum processors with increasing qubit counts, the requirements for supporting hardware, including sophisticated vacuum systems, become more stringent. This competitive landscape is fostering innovation in quantum hardware design and manufacturing, with a focus on improving coherence times and reducing error rates.

Government initiatives and funding programs are playing a crucial role in stimulating market demand for quantum computing hardware. Many countries have launched national quantum strategies, allocating substantial resources to advance their quantum capabilities. These initiatives not only support basic research but also encourage collaboration between academia and industry, further accelerating the development and adoption of advanced quantum technologies.

As the quantum computing ecosystem matures, there is a growing emphasis on scalability and reliability in hardware components. End-users are seeking quantum systems that can operate consistently over extended periods, necessitating high-performance vacuum pumps and other critical infrastructure. This trend is driving innovation in vacuum technology, with manufacturers focusing on developing pumps that can maintain ultra-high vacuum levels with minimal vibration and noise, crucial for preserving quantum coherence.

The market for quantum computing hardware is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 30% through 2025. This growth is primarily attributed to increased investments in quantum research and development by governments, tech giants, and startups worldwide. The integration of vacuum pumps in quantum computing systems is a critical aspect of this market expansion, as these components play a vital role in maintaining the ultra-low temperatures and high vacuum environments necessary for quantum operations.

Industries such as finance, pharmaceuticals, and logistics are showing particular interest in quantum computing capabilities, driving demand for more robust and efficient hardware solutions. Financial institutions are exploring quantum algorithms for portfolio optimization and risk analysis, while pharmaceutical companies are leveraging quantum simulations for drug discovery processes. The logistics sector is investigating quantum-based optimization techniques for supply chain management and route planning.

The demand for advanced quantum hardware is also being propelled by the race for quantum supremacy among leading tech companies. As these firms strive to develop more powerful quantum processors with increasing qubit counts, the requirements for supporting hardware, including sophisticated vacuum systems, become more stringent. This competitive landscape is fostering innovation in quantum hardware design and manufacturing, with a focus on improving coherence times and reducing error rates.

Government initiatives and funding programs are playing a crucial role in stimulating market demand for quantum computing hardware. Many countries have launched national quantum strategies, allocating substantial resources to advance their quantum capabilities. These initiatives not only support basic research but also encourage collaboration between academia and industry, further accelerating the development and adoption of advanced quantum technologies.

As the quantum computing ecosystem matures, there is a growing emphasis on scalability and reliability in hardware components. End-users are seeking quantum systems that can operate consistently over extended periods, necessitating high-performance vacuum pumps and other critical infrastructure. This trend is driving innovation in vacuum technology, with manufacturers focusing on developing pumps that can maintain ultra-high vacuum levels with minimal vibration and noise, crucial for preserving quantum coherence.

Vacuum Technology in Quantum Computing: Status and Challenges

Vacuum technology plays a crucial role in the development and operation of quantum computing hardware. The integration of advanced vacuum systems is essential for maintaining the delicate quantum states necessary for quantum computations. Currently, the field faces several significant challenges in implementing and optimizing vacuum technology for quantum computing applications.

One of the primary challenges is achieving and maintaining ultra-high vacuum (UHV) conditions within quantum computing systems. UHV environments, typically characterized by pressures below 10^-9 mbar, are necessary to minimize particle interactions that can lead to decoherence of quantum states. However, creating and sustaining such low pressures in complex quantum computing architectures presents substantial technical difficulties.

The design and integration of vacuum pumps suitable for quantum computing hardware pose another major challenge. Traditional vacuum pumps often introduce vibrations and electromagnetic interference, which can disrupt the sensitive quantum operations. Developing pumps that are both highly efficient and compatible with the stringent requirements of quantum systems is an ongoing area of research and development.

Vacuum sealing and materials selection also present significant hurdles. The materials used in quantum computing hardware must be carefully chosen to minimize outgassing, which can compromise vacuum quality. Additionally, these materials must be compatible with cryogenic temperatures often required in quantum systems, further complicating the design process.

Scalability is another critical challenge in vacuum technology for quantum computing. As quantum processors grow in size and complexity, maintaining uniform and stable vacuum conditions across larger volumes becomes increasingly difficult. This scalability issue is particularly relevant for efforts to develop practical, large-scale quantum computers.

Cryogenic compatibility adds another layer of complexity to vacuum technology in quantum computing. Many quantum computing architectures operate at extremely low temperatures, often near absolute zero. Integrating vacuum systems that can function effectively at these temperatures without introducing heat or vibrations is a significant engineering challenge.

Monitoring and control systems for vacuum environments in quantum computing also require advancement. Developing sensors and feedback mechanisms that can operate accurately at extreme conditions without interfering with quantum operations is crucial for maintaining the stability and reliability of quantum systems.

As the field of quantum computing continues to evolve, addressing these challenges in vacuum technology will be essential for realizing the full potential of quantum computers. Ongoing research and innovation in vacuum pump design, materials science, and system integration will play a vital role in overcoming these obstacles and advancing the capabilities of quantum computing hardware.

One of the primary challenges is achieving and maintaining ultra-high vacuum (UHV) conditions within quantum computing systems. UHV environments, typically characterized by pressures below 10^-9 mbar, are necessary to minimize particle interactions that can lead to decoherence of quantum states. However, creating and sustaining such low pressures in complex quantum computing architectures presents substantial technical difficulties.

The design and integration of vacuum pumps suitable for quantum computing hardware pose another major challenge. Traditional vacuum pumps often introduce vibrations and electromagnetic interference, which can disrupt the sensitive quantum operations. Developing pumps that are both highly efficient and compatible with the stringent requirements of quantum systems is an ongoing area of research and development.

Vacuum sealing and materials selection also present significant hurdles. The materials used in quantum computing hardware must be carefully chosen to minimize outgassing, which can compromise vacuum quality. Additionally, these materials must be compatible with cryogenic temperatures often required in quantum systems, further complicating the design process.

Scalability is another critical challenge in vacuum technology for quantum computing. As quantum processors grow in size and complexity, maintaining uniform and stable vacuum conditions across larger volumes becomes increasingly difficult. This scalability issue is particularly relevant for efforts to develop practical, large-scale quantum computers.

Cryogenic compatibility adds another layer of complexity to vacuum technology in quantum computing. Many quantum computing architectures operate at extremely low temperatures, often near absolute zero. Integrating vacuum systems that can function effectively at these temperatures without introducing heat or vibrations is a significant engineering challenge.

Monitoring and control systems for vacuum environments in quantum computing also require advancement. Developing sensors and feedback mechanisms that can operate accurately at extreme conditions without interfering with quantum operations is crucial for maintaining the stability and reliability of quantum systems.

As the field of quantum computing continues to evolve, addressing these challenges in vacuum technology will be essential for realizing the full potential of quantum computers. Ongoing research and innovation in vacuum pump design, materials science, and system integration will play a vital role in overcoming these obstacles and advancing the capabilities of quantum computing hardware.

Current Vacuum Pump Integration Solutions

01 Vacuum pump design and efficiency improvements

Advancements in vacuum pump design focus on improving efficiency, reducing energy consumption, and enhancing overall performance. These improvements may include optimized rotor configurations, advanced sealing technologies, and innovative cooling systems to maintain optimal operating temperatures.- Vacuum pump design and efficiency improvements: Innovations in vacuum pump design focus on enhancing efficiency and performance. This includes optimizing pump geometry, improving sealing mechanisms, and developing advanced rotor designs. These improvements aim to increase pumping speed, reduce power consumption, and extend the operational life of vacuum pumps.

- Integration of vacuum pumps in specific applications: Vacuum pumps are integrated into various specialized systems, such as refrigeration units, semiconductor manufacturing equipment, and medical devices. The integration process involves adapting pump designs to meet specific application requirements, ensuring compatibility with other system components, and optimizing overall system performance.

- Control systems for vacuum pump operation: Advanced control systems are developed to manage vacuum pump operation more effectively. These systems incorporate sensors, microprocessors, and software algorithms to monitor pump performance, adjust operating parameters in real-time, and optimize energy consumption. They also enable remote monitoring and predictive maintenance capabilities.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump configurations are designed to achieve higher vacuum levels and improved pumping efficiency. These systems combine different types of pumps in series or parallel arrangements, each optimized for specific pressure ranges. This approach allows for better overall system performance and flexibility in handling various vacuum requirements.

- Vacuum pump noise reduction and vibration control: Techniques are developed to reduce noise and vibration in vacuum pump systems. This includes the use of advanced materials, improved mounting systems, and innovative pump designs that minimize mechanical vibrations. These enhancements contribute to quieter operation and reduced wear on pump components, leading to increased reliability and longer service life.

02 Integration of vacuum pumps in specific applications

Vacuum pumps are integrated into various systems and applications, such as refrigeration units, semiconductor manufacturing equipment, and medical devices. The integration process involves customizing pump designs to meet specific requirements of each application, including size constraints, noise reduction, and compatibility with other components.Expand Specific Solutions03 Control systems for vacuum pump operation

Advanced control systems are developed to optimize vacuum pump operation, including automated pressure regulation, flow control, and fault detection. These systems may incorporate sensors, microprocessors, and software algorithms to ensure efficient and reliable pump performance across various operating conditions.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump configurations are designed to achieve higher vacuum levels and improved pumping speeds. These systems may combine different types of pumps, such as rotary vane and turbomolecular pumps, to optimize performance across a wide range of pressure conditions and applications.Expand Specific Solutions05 Vacuum pump maintenance and monitoring systems

Innovative maintenance and monitoring systems are developed to enhance the reliability and longevity of vacuum pumps. These may include real-time condition monitoring, predictive maintenance algorithms, and easy-access designs for simplified servicing and component replacement.Expand Specific Solutions

Key Players in Quantum Computing and Vacuum Technology

The quantum computing hardware integration landscape is evolving rapidly, with the market in its early growth stage. Major players like Intel, IBM, and Google are investing heavily in this emerging field, while specialized companies such as Zapata Computing and Equal1 Labs are developing innovative solutions. The market size is expanding, driven by increasing demand for advanced computing capabilities across industries. Technological maturity varies, with companies like Rigetti & Co. and IQM Finland leading in full-stack quantum computing solutions. Established firms like Applied Materials and Texas Instruments are leveraging their semiconductor expertise to contribute to quantum hardware development. As the technology progresses, collaboration between academia, research institutions, and industry players is becoming crucial for advancing quantum computing integration.

Google LLC

Technical Solution: Google's approach to vacuum pump integration in quantum computing hardware focuses on their superconducting qubit architecture. They have developed a modular quantum computing system called Sycamore, which utilizes a sophisticated cryogenic setup with multiple vacuum stages. Google's design incorporates a combination of turbo-molecular pumps and ion pumps to achieve and maintain the ultra-high vacuum conditions necessary for qubit operation[3]. The company has also made advancements in the miniaturization of vacuum components, working towards more compact and efficient quantum processors. Google's recent efforts have been directed towards improving the reliability and longevity of their vacuum systems, with a focus on reducing maintenance requirements and increasing overall system uptime[4].

Strengths: Advanced superconducting qubit technology, innovative modular design, and progress in system miniaturization. Weaknesses: Complexity of vacuum system integration in modular architecture, potential challenges in scaling to larger qubit counts.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive approach to vacuum pump integration in quantum computing hardware. Their solution involves using cryogenic pumps and ultra-high vacuum systems to maintain the extremely low temperatures and pressures required for quantum operations. IBM's quantum computers utilize a dilution refrigerator system that incorporates multiple stages of cooling, with vacuum pumps playing a crucial role in each stage[1]. The company has also innovated in the field of ion trapping, where precise vacuum control is essential for maintaining quantum coherence. Their trapped-ion quantum computers use specialized vacuum chambers and pumping systems to achieve ultra-low pressures, typically in the range of 10^-11 to 10^-12 torr[2].

Strengths: Extensive experience in quantum hardware development, advanced cryogenic systems, and precise vacuum control. Weaknesses: High costs associated with maintaining complex vacuum systems, potential scalability challenges for larger quantum processors.

Innovations in Quantum-Compatible Vacuum Systems

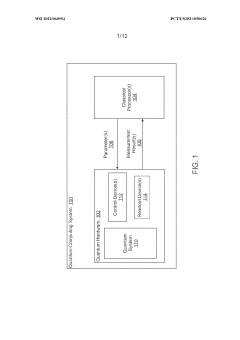

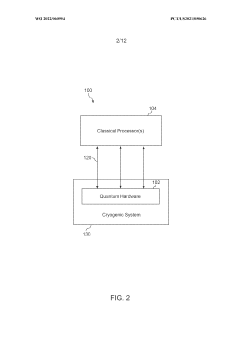

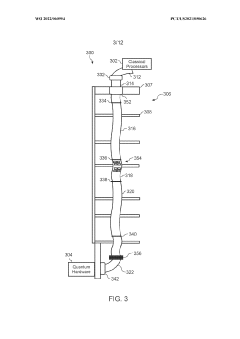

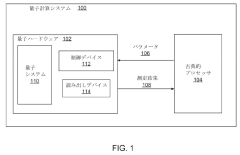

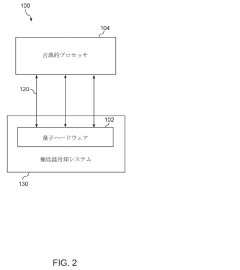

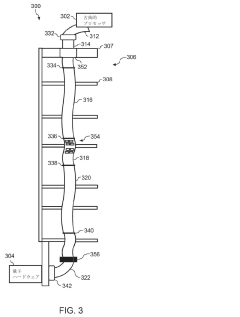

Quantum computing system having flex circuit boards for improved signal transmissions and method of operating the same

PatentWO2022060954A1

Innovation

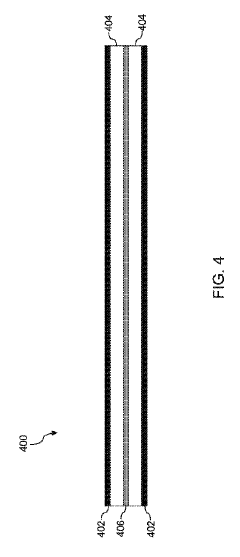

- The implementation of flex circuit boards with signal lines that are superconducting and have low thermal conductivity, allowing for improved signal transmission and isolation, reducing noise and thermal interference, and enabling efficient coupling of classical processors to quantum hardware within a vacuum chamber.

Quantum computing system with flex circuit board for improved signal transmission

PatentActiveJP2023542893A

Innovation

- The implementation of flex circuit boards with multiple signal lines that provide improved signal transmission, isolation, and reduced thermal conductivity, coupled with a vacuum chamber creating a cooling gradient, to manage communication between classical processors and quantum hardware, using materials like copper, niobium, and superconducting materials to maintain low thermal loads and minimize interference.

Cryogenic Considerations for Quantum Vacuum Systems

Cryogenic environments are crucial for maintaining the delicate quantum states necessary for quantum computing operations. When integrating vacuum pumps into quantum computing hardware, several critical cryogenic considerations must be addressed to ensure optimal performance and reliability.

The primary challenge lies in maintaining ultra-low temperatures while simultaneously achieving high vacuum levels. Cryogenic temperatures, typically below 4 Kelvin, are essential for reducing thermal noise and preserving quantum coherence. However, these extreme conditions pose unique challenges for vacuum pump operation and integration.

Material selection becomes paramount in cryogenic vacuum systems. Components must be carefully chosen to withstand thermal contraction and expansion cycles without compromising vacuum integrity. Materials such as stainless steel, copper, and certain polymers are often employed due to their low outgassing properties and thermal stability at cryogenic temperatures.

Thermal management is another critical aspect of cryogenic vacuum systems in quantum computing. Heat loads introduced by vacuum pumps must be minimized to prevent unwanted warming of the quantum components. This often necessitates the use of multi-stage cooling systems and sophisticated thermal isolation techniques.

Cryogenic-compatible vacuum seals and feedthroughs require special attention. Traditional elastomeric seals become brittle and ineffective at extremely low temperatures, necessitating the use of metal seals or specialized cryogenic gaskets. Careful design of thermal gradients along sealing surfaces is essential to maintain vacuum integrity across temperature transitions.

The choice of vacuum pump technology for cryogenic applications is crucial. Cryopumps, which operate by condensing gases on cold surfaces, are particularly well-suited for quantum computing environments. However, their integration requires careful consideration of regeneration cycles and potential contamination risks.

Vibration isolation is another critical factor in cryogenic quantum vacuum systems. Mechanical vibrations from vacuum pumps can disrupt quantum states and degrade system performance. Advanced vibration dampening techniques and strategic pump placement are essential to mitigate these effects.

Lastly, the design of cryogenic vacuum systems must account for the unique behavior of gases at ultra-low temperatures. Phenomena such as cryosorption and thermal transpiration can significantly impact vacuum performance and must be carefully managed through appropriate system design and operational protocols.

The primary challenge lies in maintaining ultra-low temperatures while simultaneously achieving high vacuum levels. Cryogenic temperatures, typically below 4 Kelvin, are essential for reducing thermal noise and preserving quantum coherence. However, these extreme conditions pose unique challenges for vacuum pump operation and integration.

Material selection becomes paramount in cryogenic vacuum systems. Components must be carefully chosen to withstand thermal contraction and expansion cycles without compromising vacuum integrity. Materials such as stainless steel, copper, and certain polymers are often employed due to their low outgassing properties and thermal stability at cryogenic temperatures.

Thermal management is another critical aspect of cryogenic vacuum systems in quantum computing. Heat loads introduced by vacuum pumps must be minimized to prevent unwanted warming of the quantum components. This often necessitates the use of multi-stage cooling systems and sophisticated thermal isolation techniques.

Cryogenic-compatible vacuum seals and feedthroughs require special attention. Traditional elastomeric seals become brittle and ineffective at extremely low temperatures, necessitating the use of metal seals or specialized cryogenic gaskets. Careful design of thermal gradients along sealing surfaces is essential to maintain vacuum integrity across temperature transitions.

The choice of vacuum pump technology for cryogenic applications is crucial. Cryopumps, which operate by condensing gases on cold surfaces, are particularly well-suited for quantum computing environments. However, their integration requires careful consideration of regeneration cycles and potential contamination risks.

Vibration isolation is another critical factor in cryogenic quantum vacuum systems. Mechanical vibrations from vacuum pumps can disrupt quantum states and degrade system performance. Advanced vibration dampening techniques and strategic pump placement are essential to mitigate these effects.

Lastly, the design of cryogenic vacuum systems must account for the unique behavior of gases at ultra-low temperatures. Phenomena such as cryosorption and thermal transpiration can significantly impact vacuum performance and must be carefully managed through appropriate system design and operational protocols.

Scalability and Efficiency of Integrated Vacuum Solutions

The integration of vacuum pumps in quantum computing hardware presents significant challenges and opportunities for scalability and efficiency. As quantum systems grow in complexity and size, maintaining the required ultra-high vacuum conditions becomes increasingly demanding. Traditional external vacuum systems often struggle to meet these escalating requirements, necessitating innovative approaches to vacuum integration.

One key aspect of scalable vacuum solutions is the miniaturization of pump components. By developing compact, high-performance vacuum pumps that can be directly integrated into quantum computing modules, researchers aim to reduce the overall system footprint and improve vacuum distribution. This approach allows for more localized vacuum control, potentially enhancing the stability of quantum states and reducing decoherence effects.

Efficiency improvements in integrated vacuum solutions focus on several areas. Advanced materials and coatings are being explored to minimize outgassing and improve pump longevity. Novel pump designs, such as those utilizing micro-electromechanical systems (MEMS) technology, show promise in achieving higher pumping speeds while consuming less power. These developments are crucial for scaling up quantum systems without proportionally increasing their energy demands.

Another critical factor in scalability is the ability to maintain consistent vacuum levels across larger quantum chip arrays. Integrated vacuum networks, featuring strategically placed pumps and sophisticated pressure monitoring systems, are being developed to ensure uniform vacuum conditions. This uniformity is essential for maintaining coherence across multiple qubits and enabling reliable large-scale quantum operations.

The integration of vacuum pumps also opens up possibilities for more dynamic vacuum control. Adaptive pumping systems, capable of adjusting their operation based on real-time pressure measurements, could optimize vacuum conditions for different quantum computing operations. This flexibility could lead to more efficient use of resources and potentially extend the operational lifetime of quantum hardware.

However, challenges remain in achieving the desired level of integration without introducing new sources of noise or interference. Careful design considerations are necessary to isolate the quantum components from the mechanical and electromagnetic effects of the integrated pumps. Ongoing research is focused on developing pump technologies that are compatible with the extreme sensitivity of quantum systems.

As quantum computing hardware continues to evolve, the scalability and efficiency of integrated vacuum solutions will play a crucial role in determining the practical limits of quantum processor size and performance. The successful development of these technologies could significantly contribute to the realization of large-scale, fault-tolerant quantum computers capable of tackling complex real-world problems.

One key aspect of scalable vacuum solutions is the miniaturization of pump components. By developing compact, high-performance vacuum pumps that can be directly integrated into quantum computing modules, researchers aim to reduce the overall system footprint and improve vacuum distribution. This approach allows for more localized vacuum control, potentially enhancing the stability of quantum states and reducing decoherence effects.

Efficiency improvements in integrated vacuum solutions focus on several areas. Advanced materials and coatings are being explored to minimize outgassing and improve pump longevity. Novel pump designs, such as those utilizing micro-electromechanical systems (MEMS) technology, show promise in achieving higher pumping speeds while consuming less power. These developments are crucial for scaling up quantum systems without proportionally increasing their energy demands.

Another critical factor in scalability is the ability to maintain consistent vacuum levels across larger quantum chip arrays. Integrated vacuum networks, featuring strategically placed pumps and sophisticated pressure monitoring systems, are being developed to ensure uniform vacuum conditions. This uniformity is essential for maintaining coherence across multiple qubits and enabling reliable large-scale quantum operations.

The integration of vacuum pumps also opens up possibilities for more dynamic vacuum control. Adaptive pumping systems, capable of adjusting their operation based on real-time pressure measurements, could optimize vacuum conditions for different quantum computing operations. This flexibility could lead to more efficient use of resources and potentially extend the operational lifetime of quantum hardware.

However, challenges remain in achieving the desired level of integration without introducing new sources of noise or interference. Careful design considerations are necessary to isolate the quantum components from the mechanical and electromagnetic effects of the integrated pumps. Ongoing research is focused on developing pump technologies that are compatible with the extreme sensitivity of quantum systems.

As quantum computing hardware continues to evolve, the scalability and efficiency of integrated vacuum solutions will play a crucial role in determining the practical limits of quantum processor size and performance. The successful development of these technologies could significantly contribute to the realization of large-scale, fault-tolerant quantum computers capable of tackling complex real-world problems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!