Exploring Vacuum Pump Use in Environmental Monitoring Devices

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution and Goals

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. Initially developed for scientific experiments, vacuum pumps have found diverse applications across industries, including environmental monitoring. The progression of vacuum pump technology has been driven by the need for improved efficiency, reliability, and miniaturization.

In the context of environmental monitoring devices, vacuum pumps play a crucial role in sample collection and analysis. The primary goal of incorporating vacuum pumps in these devices is to enable accurate and consistent sampling of air, water, or soil for contaminant detection and measurement. This technology aims to enhance the sensitivity and precision of environmental monitoring systems, allowing for real-time data collection and analysis in various settings.

The evolution of vacuum pump technology for environmental monitoring has been marked by several key advancements. Early environmental monitoring devices relied on manual sampling methods, which were time-consuming and prone to human error. The introduction of vacuum pumps automated the sampling process, significantly improving efficiency and reliability. Subsequent developments focused on reducing pump size and power consumption, enabling the creation of portable and battery-operated monitoring devices.

Recent technological goals in vacuum pump development for environmental monitoring include further miniaturization, increased energy efficiency, and enhanced durability in harsh environmental conditions. Researchers and engineers are working on developing micro-electromechanical systems (MEMS) based vacuum pumps, which promise significant size reduction while maintaining performance. Another important objective is to improve pump longevity and reduce maintenance requirements, ensuring continuous operation in remote or difficult-to-access locations.

Integration of smart technologies is another key goal in vacuum pump evolution for environmental monitoring. This includes the development of pumps with built-in sensors and communication capabilities, allowing for remote monitoring and control. Such advancements aim to create more intelligent and adaptive environmental monitoring systems that can adjust sampling parameters based on real-time data and environmental conditions.

Furthermore, there is a growing focus on developing vacuum pumps that are environmentally friendly and compliant with increasingly stringent regulations. This includes the use of materials and lubricants that have minimal environmental impact, as well as designs that reduce noise pollution – a critical factor in sensitive ecological monitoring applications.

As environmental concerns continue to grow globally, the evolution of vacuum pump technology in monitoring devices is expected to accelerate. Future goals may include the development of ultra-efficient pumps capable of operating on renewable energy sources, further expanding the reach and capabilities of environmental monitoring systems in remote and challenging environments.

In the context of environmental monitoring devices, vacuum pumps play a crucial role in sample collection and analysis. The primary goal of incorporating vacuum pumps in these devices is to enable accurate and consistent sampling of air, water, or soil for contaminant detection and measurement. This technology aims to enhance the sensitivity and precision of environmental monitoring systems, allowing for real-time data collection and analysis in various settings.

The evolution of vacuum pump technology for environmental monitoring has been marked by several key advancements. Early environmental monitoring devices relied on manual sampling methods, which were time-consuming and prone to human error. The introduction of vacuum pumps automated the sampling process, significantly improving efficiency and reliability. Subsequent developments focused on reducing pump size and power consumption, enabling the creation of portable and battery-operated monitoring devices.

Recent technological goals in vacuum pump development for environmental monitoring include further miniaturization, increased energy efficiency, and enhanced durability in harsh environmental conditions. Researchers and engineers are working on developing micro-electromechanical systems (MEMS) based vacuum pumps, which promise significant size reduction while maintaining performance. Another important objective is to improve pump longevity and reduce maintenance requirements, ensuring continuous operation in remote or difficult-to-access locations.

Integration of smart technologies is another key goal in vacuum pump evolution for environmental monitoring. This includes the development of pumps with built-in sensors and communication capabilities, allowing for remote monitoring and control. Such advancements aim to create more intelligent and adaptive environmental monitoring systems that can adjust sampling parameters based on real-time data and environmental conditions.

Furthermore, there is a growing focus on developing vacuum pumps that are environmentally friendly and compliant with increasingly stringent regulations. This includes the use of materials and lubricants that have minimal environmental impact, as well as designs that reduce noise pollution – a critical factor in sensitive ecological monitoring applications.

As environmental concerns continue to grow globally, the evolution of vacuum pump technology in monitoring devices is expected to accelerate. Future goals may include the development of ultra-efficient pumps capable of operating on renewable energy sources, further expanding the reach and capabilities of environmental monitoring systems in remote and challenging environments.

Environmental Monitoring Market Analysis

The environmental monitoring market has experienced significant growth in recent years, driven by increasing awareness of environmental issues, stringent regulations, and technological advancements. This market encompasses a wide range of devices and systems designed to measure, analyze, and monitor various environmental parameters, including air quality, water quality, soil contamination, and noise levels.

The global environmental monitoring market was valued at approximately $19.5 billion in 2020 and is projected to reach $28.9 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth is attributed to several factors, including the rising levels of pollution worldwide, growing public awareness about the health impacts of environmental degradation, and increasing government initiatives to protect the environment.

One of the key segments within this market is air quality monitoring, which has seen a surge in demand due to rising concerns over air pollution in urban areas and industrial zones. The air quality monitoring segment accounted for the largest share of the environmental monitoring market in 2020, driven by the need for real-time data on air pollutants such as particulate matter, nitrogen oxides, and volatile organic compounds.

Water quality monitoring is another crucial segment, with increasing concerns over water pollution and the need for safe drinking water driving market growth. The water quality monitoring segment is expected to witness the highest CAGR during the forecast period, fueled by stringent water quality regulations and the growing adoption of smart water management systems.

The market for environmental monitoring devices is characterized by a high degree of fragmentation, with numerous players offering a wide range of products and solutions. Key market players include Siemens AG, Thermo Fisher Scientific, Emerson Electric Co., and Honeywell International Inc. These companies are focusing on product innovation and strategic partnerships to maintain their competitive edge in the market.

Geographically, North America dominated the environmental monitoring market in 2020, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The integration of advanced technologies such as Internet of Things (IoT), artificial intelligence, and cloud computing is expected to revolutionize the environmental monitoring market. These technologies enable real-time data collection, analysis, and visualization, enhancing the accuracy and efficiency of environmental monitoring systems.

In conclusion, the environmental monitoring market presents significant opportunities for growth and innovation, particularly in the development of more efficient and cost-effective monitoring devices. The increasing demand for vacuum pumps in environmental monitoring devices aligns with the overall market trend towards more precise and reliable measurement technologies.

The global environmental monitoring market was valued at approximately $19.5 billion in 2020 and is projected to reach $28.9 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth is attributed to several factors, including the rising levels of pollution worldwide, growing public awareness about the health impacts of environmental degradation, and increasing government initiatives to protect the environment.

One of the key segments within this market is air quality monitoring, which has seen a surge in demand due to rising concerns over air pollution in urban areas and industrial zones. The air quality monitoring segment accounted for the largest share of the environmental monitoring market in 2020, driven by the need for real-time data on air pollutants such as particulate matter, nitrogen oxides, and volatile organic compounds.

Water quality monitoring is another crucial segment, with increasing concerns over water pollution and the need for safe drinking water driving market growth. The water quality monitoring segment is expected to witness the highest CAGR during the forecast period, fueled by stringent water quality regulations and the growing adoption of smart water management systems.

The market for environmental monitoring devices is characterized by a high degree of fragmentation, with numerous players offering a wide range of products and solutions. Key market players include Siemens AG, Thermo Fisher Scientific, Emerson Electric Co., and Honeywell International Inc. These companies are focusing on product innovation and strategic partnerships to maintain their competitive edge in the market.

Geographically, North America dominated the environmental monitoring market in 2020, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The integration of advanced technologies such as Internet of Things (IoT), artificial intelligence, and cloud computing is expected to revolutionize the environmental monitoring market. These technologies enable real-time data collection, analysis, and visualization, enhancing the accuracy and efficiency of environmental monitoring systems.

In conclusion, the environmental monitoring market presents significant opportunities for growth and innovation, particularly in the development of more efficient and cost-effective monitoring devices. The increasing demand for vacuum pumps in environmental monitoring devices aligns with the overall market trend towards more precise and reliable measurement technologies.

Vacuum Pump Challenges in Environmental Devices

Vacuum pumps play a crucial role in environmental monitoring devices, but their integration and operation present several significant challenges. One of the primary issues is the power consumption of vacuum pumps, which can be substantial in portable or remote monitoring systems. This high energy demand often necessitates larger batteries or more frequent charging, limiting the operational duration and deployment flexibility of environmental monitoring equipment.

Size and weight constraints pose another major challenge. Environmental monitoring devices are frequently designed for portability and ease of installation in various locations. Incorporating a vacuum pump without significantly increasing the overall dimensions or weight of the device requires careful engineering and may involve trade-offs in pump performance or efficiency.

Noise and vibration generated by vacuum pumps can interfere with sensitive measurements and potentially impact the accuracy of environmental data collection. This is particularly problematic in applications where minimal disturbance to the surrounding environment is crucial, such as wildlife monitoring or air quality assessments in urban areas.

Reliability and maintenance requirements present ongoing challenges. Vacuum pumps in environmental monitoring devices often operate in harsh conditions, exposed to dust, moisture, and temperature fluctuations. Ensuring consistent performance and minimizing the need for frequent maintenance or replacement is essential for long-term deployment and data integrity.

The need for precise flow control and pressure regulation adds complexity to vacuum pump integration. Many environmental monitoring applications require specific air or gas flow rates and pressures for accurate sampling. Achieving and maintaining these conditions across varying environmental parameters demands sophisticated control systems and pump designs.

Contamination risks associated with vacuum pumps can compromise sample integrity. Oil-based pumps may introduce hydrocarbon contaminants, while dry pumps might generate particles from wear. Developing pumps that minimize these risks without sacrificing performance is an ongoing challenge in environmental monitoring applications.

Cost considerations also play a significant role in vacuum pump selection for environmental devices. High-performance, low-maintenance pumps suitable for environmental monitoring can be expensive, potentially limiting the widespread adoption of advanced monitoring technologies, especially in resource-constrained settings or large-scale deployment scenarios.

Addressing these challenges requires innovative approaches in pump design, materials science, and system integration. Ongoing research focuses on developing more efficient, compact, and environmentally robust vacuum pump solutions tailored to the specific needs of environmental monitoring applications.

Size and weight constraints pose another major challenge. Environmental monitoring devices are frequently designed for portability and ease of installation in various locations. Incorporating a vacuum pump without significantly increasing the overall dimensions or weight of the device requires careful engineering and may involve trade-offs in pump performance or efficiency.

Noise and vibration generated by vacuum pumps can interfere with sensitive measurements and potentially impact the accuracy of environmental data collection. This is particularly problematic in applications where minimal disturbance to the surrounding environment is crucial, such as wildlife monitoring or air quality assessments in urban areas.

Reliability and maintenance requirements present ongoing challenges. Vacuum pumps in environmental monitoring devices often operate in harsh conditions, exposed to dust, moisture, and temperature fluctuations. Ensuring consistent performance and minimizing the need for frequent maintenance or replacement is essential for long-term deployment and data integrity.

The need for precise flow control and pressure regulation adds complexity to vacuum pump integration. Many environmental monitoring applications require specific air or gas flow rates and pressures for accurate sampling. Achieving and maintaining these conditions across varying environmental parameters demands sophisticated control systems and pump designs.

Contamination risks associated with vacuum pumps can compromise sample integrity. Oil-based pumps may introduce hydrocarbon contaminants, while dry pumps might generate particles from wear. Developing pumps that minimize these risks without sacrificing performance is an ongoing challenge in environmental monitoring applications.

Cost considerations also play a significant role in vacuum pump selection for environmental devices. High-performance, low-maintenance pumps suitable for environmental monitoring can be expensive, potentially limiting the widespread adoption of advanced monitoring technologies, especially in resource-constrained settings or large-scale deployment scenarios.

Addressing these challenges requires innovative approaches in pump design, materials science, and system integration. Ongoing research focuses on developing more efficient, compact, and environmentally robust vacuum pump solutions tailored to the specific needs of environmental monitoring applications.

Current Vacuum Pump Integration Solutions

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to impeller shapes, housing configurations, or the integration of multiple stages for better vacuum generation.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.

- Vacuum pump control systems: Advanced control systems for vacuum pumps focus on optimizing performance, energy efficiency, and maintenance schedules. These systems may incorporate sensors, microprocessors, and software algorithms to monitor and adjust pump operation in real-time.

- Specialized vacuum pumps for specific applications: Vacuum pumps designed for specific industries or applications, such as semiconductor manufacturing, medical devices, or food processing. These pumps may have unique features or materials to meet the requirements of their intended use.

- Energy-efficient vacuum pump technologies: Innovations focused on reducing energy consumption in vacuum pumps, including the use of variable speed drives, regenerative technologies, or alternative power sources. These advancements aim to lower operational costs and environmental impact.

- Maintenance and reliability improvements: Developments in vacuum pump design and materials to enhance durability, extend service intervals, and simplify maintenance procedures. These improvements may include self-diagnostic capabilities, modular designs for easy part replacement, or corrosion-resistant components.

02 Energy-efficient vacuum pump systems

Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining or improving pumping performance. This may involve advanced motor designs, optimized control systems, or the use of energy recovery mechanisms.Expand Specific Solutions03 Vacuum pump cooling and lubrication

Innovations in cooling and lubrication systems for vacuum pumps aim to extend operational life, reduce maintenance requirements, and improve overall reliability. These may include advanced heat dissipation methods or novel lubrication techniques.Expand Specific Solutions04 Specialized vacuum pumps for specific applications

Development of vacuum pumps tailored for specific industries or applications, such as semiconductor manufacturing, medical devices, or food processing. These pumps may have unique features or materials to meet the requirements of their intended use.Expand Specific Solutions05 Smart vacuum pump control systems

Integration of advanced control systems and sensors in vacuum pumps to enable real-time monitoring, predictive maintenance, and automated operation. These smart systems may improve efficiency, reduce downtime, and optimize performance based on specific operating conditions.Expand Specific Solutions

Key Environmental Monitoring Device Manufacturers

The vacuum pump market for environmental monitoring devices is in a growth phase, driven by increasing environmental concerns and regulatory requirements. The market size is expanding, with a diverse range of players competing for market share. Technologically, the field is moderately mature, with established companies like Edwards Ltd., Pfeiffer Vacuum Technology AG, and Agilent Technologies leading innovation. However, there's room for advancement, particularly in miniaturization and energy efficiency. Emerging players such as SKY Technology Development Co., Ltd. CAS and Youngshin Precision Co. Ltd. are also contributing to technological progress, while research institutions like the Korea Research Institute of Standards & Science are pushing the boundaries of precision and reliability in environmental monitoring applications.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for environmental monitoring devices. Their innovative approach includes the integration of dry pumping technology, which eliminates the need for oil and reduces contamination risks in sensitive environmental samples[1]. The company's GXS dry screw pump series offers high pumping speeds and low power consumption, making it ideal for continuous operation in environmental monitoring stations[2]. Edwards has also implemented smart pump control systems that allow for remote monitoring and adjustment of pump parameters, ensuring optimal performance in various environmental conditions[3]. Their vacuum pumps are designed with corrosion-resistant materials to withstand exposure to diverse atmospheric pollutants, enhancing longevity and reliability in field deployments[4].

Strengths: Oil-free operation reduces sample contamination; energy-efficient designs for long-term deployment; smart control systems for remote management. Weaknesses: Higher initial cost compared to traditional pumps; may require specialized maintenance.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a range of vacuum pumps specifically designed for environmental monitoring applications. Their IDP-3 dry scroll pump technology offers oil-free operation, crucial for preventing sample contamination in sensitive environmental analyses[1]. Agilent's pumps feature advanced materials that resist corrosion from aggressive environmental samples, ensuring long-term reliability in field deployments[2]. The company has also integrated smart control systems that allow for precise vacuum regulation and remote monitoring, optimizing performance for various environmental sampling techniques[3]. Agilent's vacuum solutions are designed to operate quietly and with low vibration, minimizing disruption in sensitive monitoring environments[4]. Additionally, their pumps are engineered for energy efficiency, reducing power consumption and operational costs for long-term environmental monitoring projects[5].

Strengths: Oil-free operation ensures sample purity; corrosion-resistant materials for durability; smart control systems for precise operation. Weaknesses: May have higher upfront costs; specialized maintenance requirements.

Innovative Vacuum Pump Designs for Monitoring

Monitoring device of the gas recirculation system in gas stations

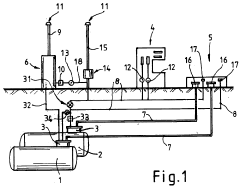

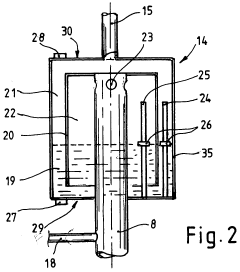

PatentWO2009086569A1

Innovation

- A monitoring device with a gas mass flow meter and controller measures the gas delivery rate from vacuum pumps, compares it with the number of active pumps, and uses check valves and level indicators to control a hydrocarbon scrubber, ensuring proper gas recirculation and system tightness, with an emergency vent line for pressure compensation.

Monitoring device of the gas recirculation system in gas stations

PatentInactiveEP2391574A1

Innovation

- A monitoring device with a gas mass flow meter, check valve, and controller is used to measure and compare gas delivery rates with active vacuum pumps, and a hydrocarbon scrubber is activated or shut off based on pressure and flow data, ensuring proper operation and system tightness, with additional safety features like emergency vent lines and level indicators.

Regulatory Framework for Environmental Monitoring

The regulatory framework for environmental monitoring plays a crucial role in ensuring the effectiveness and compliance of monitoring devices, including those utilizing vacuum pump technology. This framework encompasses a complex web of international, national, and local regulations that govern the design, deployment, and operation of environmental monitoring equipment.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and standards for environmental monitoring. These guidelines often serve as a foundation for national and regional regulatory bodies to develop more specific regulations tailored to their local contexts.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body responsible for setting standards and enforcing regulations related to environmental monitoring. The EPA's regulations cover a wide range of environmental parameters, including air quality, water quality, and soil contamination. These regulations often specify the required monitoring frequencies, measurement accuracies, and reporting procedures for various environmental pollutants.

The European Union has established its own comprehensive regulatory framework for environmental monitoring through directives such as the Air Quality Directive (2008/50/EC) and the Water Framework Directive (2000/60/EC). These directives set out specific requirements for member states to implement monitoring programs and report on environmental quality.

Many countries have also developed their own national environmental monitoring regulations, which may be more stringent than international standards. For example, Japan's Air Pollution Control Law and Water Pollution Control Law establish detailed requirements for monitoring and reporting environmental quality data.

Regulatory frameworks often include specific provisions for the calibration and maintenance of monitoring equipment, including vacuum pumps used in sampling and analysis processes. These regulations may specify the frequency of calibration, acceptable error margins, and documentation requirements to ensure the reliability and accuracy of monitoring data.

As environmental monitoring technologies continue to evolve, regulatory frameworks must adapt to accommodate new methodologies and equipment. This includes addressing the use of vacuum pumps in novel monitoring applications, such as continuous emissions monitoring systems (CEMS) or portable air quality monitors.

Compliance with these regulatory frameworks is essential for manufacturers and operators of environmental monitoring devices. Failure to meet regulatory standards can result in legal penalties, loss of operating permits, and reputational damage. Therefore, understanding and adhering to the relevant regulatory requirements is a critical aspect of developing and implementing environmental monitoring solutions that incorporate vacuum pump technology.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and standards for environmental monitoring. These guidelines often serve as a foundation for national and regional regulatory bodies to develop more specific regulations tailored to their local contexts.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body responsible for setting standards and enforcing regulations related to environmental monitoring. The EPA's regulations cover a wide range of environmental parameters, including air quality, water quality, and soil contamination. These regulations often specify the required monitoring frequencies, measurement accuracies, and reporting procedures for various environmental pollutants.

The European Union has established its own comprehensive regulatory framework for environmental monitoring through directives such as the Air Quality Directive (2008/50/EC) and the Water Framework Directive (2000/60/EC). These directives set out specific requirements for member states to implement monitoring programs and report on environmental quality.

Many countries have also developed their own national environmental monitoring regulations, which may be more stringent than international standards. For example, Japan's Air Pollution Control Law and Water Pollution Control Law establish detailed requirements for monitoring and reporting environmental quality data.

Regulatory frameworks often include specific provisions for the calibration and maintenance of monitoring equipment, including vacuum pumps used in sampling and analysis processes. These regulations may specify the frequency of calibration, acceptable error margins, and documentation requirements to ensure the reliability and accuracy of monitoring data.

As environmental monitoring technologies continue to evolve, regulatory frameworks must adapt to accommodate new methodologies and equipment. This includes addressing the use of vacuum pumps in novel monitoring applications, such as continuous emissions monitoring systems (CEMS) or portable air quality monitors.

Compliance with these regulatory frameworks is essential for manufacturers and operators of environmental monitoring devices. Failure to meet regulatory standards can result in legal penalties, loss of operating permits, and reputational damage. Therefore, understanding and adhering to the relevant regulatory requirements is a critical aspect of developing and implementing environmental monitoring solutions that incorporate vacuum pump technology.

Energy Efficiency in Vacuum Pump Systems

Energy efficiency in vacuum pump systems is a critical consideration for environmental monitoring devices, particularly in the context of exploring vacuum pump use. The optimization of energy consumption in these systems not only reduces operational costs but also aligns with sustainability goals, making it a key focus area for manufacturers and end-users alike.

Vacuum pumps are essential components in many environmental monitoring devices, used for tasks such as air sampling, gas analysis, and particle collection. However, these pumps can be significant energy consumers, often accounting for a substantial portion of the device's overall power requirements. As such, improving their energy efficiency has become a priority in the field.

One of the primary approaches to enhancing energy efficiency in vacuum pump systems is through the implementation of variable speed drives (VSDs). These drives allow the pump to adjust its speed and power consumption based on the actual demand, rather than operating at full capacity continuously. This dynamic adjustment can lead to significant energy savings, especially in applications where the vacuum requirements fluctuate over time.

Another strategy involves the use of advanced materials and coatings in pump construction. Low-friction coatings and high-performance bearings can reduce mechanical losses, thereby improving overall efficiency. Additionally, the integration of more efficient motors, such as permanent magnet synchronous motors (PMSMs), can further reduce energy consumption compared to traditional induction motors.

Heat recovery systems represent another avenue for improving energy efficiency in vacuum pump systems. The heat generated during pump operation, which is typically wasted, can be captured and repurposed for other processes or for maintaining optimal operating temperatures in the monitoring devices. This approach not only reduces energy waste but can also contribute to the overall thermal management of the system.

Intelligent control systems and predictive maintenance algorithms are increasingly being employed to optimize vacuum pump performance. These systems can monitor operating conditions in real-time, adjusting pump parameters for maximum efficiency and predicting maintenance needs to prevent energy-wasting malfunctions. By ensuring that pumps operate at peak efficiency and undergo timely maintenance, these smart systems can significantly reduce energy consumption over the long term.

The design of vacuum chambers and piping systems also plays a crucial role in energy efficiency. Minimizing leaks, optimizing pipe diameters, and reducing unnecessary bends or restrictions in the vacuum network can lower the pump's workload, leading to reduced energy consumption. Furthermore, the selection of appropriate pump sizes and types for specific applications prevents oversizing, which is a common cause of energy inefficiency in vacuum systems.

As environmental monitoring devices continue to evolve, the integration of energy-efficient vacuum pump systems becomes increasingly important. This focus on efficiency not only improves the devices' portability and field operation time but also contributes to their overall environmental impact reduction. The ongoing research and development in this area promise further advancements, potentially revolutionizing the energy footprint of environmental monitoring technologies.

Vacuum pumps are essential components in many environmental monitoring devices, used for tasks such as air sampling, gas analysis, and particle collection. However, these pumps can be significant energy consumers, often accounting for a substantial portion of the device's overall power requirements. As such, improving their energy efficiency has become a priority in the field.

One of the primary approaches to enhancing energy efficiency in vacuum pump systems is through the implementation of variable speed drives (VSDs). These drives allow the pump to adjust its speed and power consumption based on the actual demand, rather than operating at full capacity continuously. This dynamic adjustment can lead to significant energy savings, especially in applications where the vacuum requirements fluctuate over time.

Another strategy involves the use of advanced materials and coatings in pump construction. Low-friction coatings and high-performance bearings can reduce mechanical losses, thereby improving overall efficiency. Additionally, the integration of more efficient motors, such as permanent magnet synchronous motors (PMSMs), can further reduce energy consumption compared to traditional induction motors.

Heat recovery systems represent another avenue for improving energy efficiency in vacuum pump systems. The heat generated during pump operation, which is typically wasted, can be captured and repurposed for other processes or for maintaining optimal operating temperatures in the monitoring devices. This approach not only reduces energy waste but can also contribute to the overall thermal management of the system.

Intelligent control systems and predictive maintenance algorithms are increasingly being employed to optimize vacuum pump performance. These systems can monitor operating conditions in real-time, adjusting pump parameters for maximum efficiency and predicting maintenance needs to prevent energy-wasting malfunctions. By ensuring that pumps operate at peak efficiency and undergo timely maintenance, these smart systems can significantly reduce energy consumption over the long term.

The design of vacuum chambers and piping systems also plays a crucial role in energy efficiency. Minimizing leaks, optimizing pipe diameters, and reducing unnecessary bends or restrictions in the vacuum network can lower the pump's workload, leading to reduced energy consumption. Furthermore, the selection of appropriate pump sizes and types for specific applications prevents oversizing, which is a common cause of energy inefficiency in vacuum systems.

As environmental monitoring devices continue to evolve, the integration of energy-efficient vacuum pump systems becomes increasingly important. This focus on efficiency not only improves the devices' portability and field operation time but also contributes to their overall environmental impact reduction. The ongoing research and development in this area promise further advancements, potentially revolutionizing the energy footprint of environmental monitoring technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!