Exploring Vacuum Pump Use in High-Energy Particle Physics

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Particle Physics Vacuum Pump Evolution and Objectives

Vacuum pump technology has played a crucial role in the evolution of high-energy particle physics, enabling researchers to create and maintain the ultra-high vacuum environments necessary for particle acceleration and collision experiments. The development of vacuum pumps in this field has been driven by the increasing demands for higher vacuum levels, larger volumes, and more efficient operation.

The history of vacuum pump use in particle physics can be traced back to the early 20th century, with the invention of the diffusion pump by Wolfgang Gaede in 1915. This innovation marked a significant improvement over mechanical pumps, allowing for the creation of lower pressures. As particle accelerators grew in size and complexity, the need for more advanced vacuum technologies became apparent.

In the mid-20th century, the introduction of turbomolecular pumps revolutionized vacuum technology in particle physics. These pumps, capable of achieving ultra-high vacuum levels, became essential components in accelerator facilities worldwide. Concurrently, the development of cryogenic pumping techniques further enhanced vacuum capabilities, particularly in superconducting accelerators.

The objectives of vacuum pump technology in high-energy particle physics have evolved alongside the field's progress. Initially, the primary goal was simply to achieve the lowest possible pressure. However, as experiments became more sophisticated, additional objectives emerged. These include maintaining stable vacuum conditions over extended periods, minimizing contamination, and scaling up vacuum systems to accommodate larger accelerators.

Current objectives focus on improving energy efficiency, reducing maintenance requirements, and developing pumps capable of handling the extreme conditions present in cutting-edge experiments. There is also a growing emphasis on developing vacuum systems that can operate in the presence of intense radiation and magnetic fields, which are common in particle physics environments.

Looking forward, the field of particle physics continues to push the boundaries of vacuum technology. Future objectives include the development of novel pumping mechanisms, such as non-evaporable getter (NEG) coatings, which can maintain ultra-high vacuum conditions with minimal power consumption. Additionally, there is a drive towards creating more compact and integrated vacuum systems to support the next generation of particle accelerators and detectors.

The evolution of vacuum pump technology in particle physics reflects a constant interplay between scientific ambition and technological innovation. As researchers strive to explore new frontiers in particle physics, the demands placed on vacuum systems continue to grow, spurring further advancements in pump design and performance.

The history of vacuum pump use in particle physics can be traced back to the early 20th century, with the invention of the diffusion pump by Wolfgang Gaede in 1915. This innovation marked a significant improvement over mechanical pumps, allowing for the creation of lower pressures. As particle accelerators grew in size and complexity, the need for more advanced vacuum technologies became apparent.

In the mid-20th century, the introduction of turbomolecular pumps revolutionized vacuum technology in particle physics. These pumps, capable of achieving ultra-high vacuum levels, became essential components in accelerator facilities worldwide. Concurrently, the development of cryogenic pumping techniques further enhanced vacuum capabilities, particularly in superconducting accelerators.

The objectives of vacuum pump technology in high-energy particle physics have evolved alongside the field's progress. Initially, the primary goal was simply to achieve the lowest possible pressure. However, as experiments became more sophisticated, additional objectives emerged. These include maintaining stable vacuum conditions over extended periods, minimizing contamination, and scaling up vacuum systems to accommodate larger accelerators.

Current objectives focus on improving energy efficiency, reducing maintenance requirements, and developing pumps capable of handling the extreme conditions present in cutting-edge experiments. There is also a growing emphasis on developing vacuum systems that can operate in the presence of intense radiation and magnetic fields, which are common in particle physics environments.

Looking forward, the field of particle physics continues to push the boundaries of vacuum technology. Future objectives include the development of novel pumping mechanisms, such as non-evaporable getter (NEG) coatings, which can maintain ultra-high vacuum conditions with minimal power consumption. Additionally, there is a drive towards creating more compact and integrated vacuum systems to support the next generation of particle accelerators and detectors.

The evolution of vacuum pump technology in particle physics reflects a constant interplay between scientific ambition and technological innovation. As researchers strive to explore new frontiers in particle physics, the demands placed on vacuum systems continue to grow, spurring further advancements in pump design and performance.

Market Analysis for High-Energy Physics Equipment

The market for high-energy physics equipment, particularly vacuum pumps used in particle accelerators and detectors, has shown significant growth in recent years. This expansion is driven by increased investments in fundamental research, advancements in particle physics, and the growing number of large-scale scientific facilities worldwide.

The global market for high-energy physics equipment is estimated to be in the billions of dollars, with vacuum pumps representing a substantial portion of this market. The demand for these specialized pumps is primarily fueled by the construction and upgrading of particle accelerators, such as those at CERN, Fermilab, and other major research institutions.

Key market segments for vacuum pumps in high-energy physics include turbomolecular pumps, cryogenic pumps, and ion pumps. These pumps are essential for maintaining the ultra-high vacuum conditions required in particle accelerators and detectors. The market is characterized by a high degree of technological sophistication and stringent performance requirements.

Geographically, North America and Europe dominate the market due to the presence of major research facilities and equipment manufacturers. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing investments in scientific research and the construction of new particle physics facilities in countries like China and Japan.

The market is highly concentrated, with a few specialized manufacturers dominating the supply of vacuum pumps for high-energy physics applications. These companies often have long-standing relationships with research institutions and possess proprietary technologies that meet the exacting standards of particle physics experiments.

Growth drivers for the market include ongoing upgrades to existing facilities, the planning and construction of new particle accelerators, and the increasing complexity of experiments requiring more advanced vacuum systems. Additionally, spin-off applications of high-energy physics technologies in industries such as semiconductor manufacturing and medical imaging contribute to market expansion.

Challenges in the market include the high cost of equipment, long development cycles, and the cyclical nature of funding for large-scale scientific projects. However, the critical role of vacuum pumps in enabling cutting-edge research in particle physics ensures a stable long-term demand for these specialized products.

The global market for high-energy physics equipment is estimated to be in the billions of dollars, with vacuum pumps representing a substantial portion of this market. The demand for these specialized pumps is primarily fueled by the construction and upgrading of particle accelerators, such as those at CERN, Fermilab, and other major research institutions.

Key market segments for vacuum pumps in high-energy physics include turbomolecular pumps, cryogenic pumps, and ion pumps. These pumps are essential for maintaining the ultra-high vacuum conditions required in particle accelerators and detectors. The market is characterized by a high degree of technological sophistication and stringent performance requirements.

Geographically, North America and Europe dominate the market due to the presence of major research facilities and equipment manufacturers. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing investments in scientific research and the construction of new particle physics facilities in countries like China and Japan.

The market is highly concentrated, with a few specialized manufacturers dominating the supply of vacuum pumps for high-energy physics applications. These companies often have long-standing relationships with research institutions and possess proprietary technologies that meet the exacting standards of particle physics experiments.

Growth drivers for the market include ongoing upgrades to existing facilities, the planning and construction of new particle accelerators, and the increasing complexity of experiments requiring more advanced vacuum systems. Additionally, spin-off applications of high-energy physics technologies in industries such as semiconductor manufacturing and medical imaging contribute to market expansion.

Challenges in the market include the high cost of equipment, long development cycles, and the cyclical nature of funding for large-scale scientific projects. However, the critical role of vacuum pumps in enabling cutting-edge research in particle physics ensures a stable long-term demand for these specialized products.

Current Vacuum Pump Technology in Particle Accelerators

Vacuum pump technology plays a crucial role in particle accelerators, enabling the creation and maintenance of high-vacuum environments essential for particle beam propagation. Current vacuum pump systems in particle accelerators employ a combination of different pump types to achieve and sustain ultra-high vacuum conditions.

The primary vacuum pumps used in modern particle accelerators include turbomolecular pumps, ion pumps, and cryogenic pumps. Turbomolecular pumps are widely utilized for their high pumping speeds and ability to handle large gas loads. These pumps operate by imparting momentum to gas molecules through rapidly rotating blades, effectively removing them from the vacuum chamber.

Ion pumps, also known as sputter-ion pumps, are extensively employed in particle accelerators due to their ability to maintain ultra-high vacuum conditions without moving parts. These pumps ionize gas molecules and accelerate them towards a titanium cathode, where they are trapped through chemical reactions or physical adsorption.

Cryogenic pumps, or cryopumps, are another essential component of vacuum systems in particle accelerators. These pumps utilize extremely low temperatures to condense and trap gas molecules on cold surfaces. Cryopumps are particularly effective in removing water vapor and other condensable gases, contributing significantly to achieving ultra-high vacuum levels.

In addition to these primary pump types, getter pumps and sublimation pumps are often used as complementary technologies. Getter pumps employ highly reactive materials to chemically bind residual gas molecules, while sublimation pumps use evaporated titanium to trap gases through chemisorption.

The vacuum pump systems in particle accelerators are typically arranged in a cascaded configuration, with different pump types working in tandem to achieve optimal performance. Roughing pumps, such as scroll pumps or rotary vane pumps, are used initially to reduce pressure from atmospheric levels. Once a suitable base pressure is reached, turbomolecular pumps take over to further lower the pressure. Finally, ion pumps and cryopumps are activated to achieve and maintain ultra-high vacuum conditions.

Advanced control systems and monitoring equipment are integral to modern vacuum pump technology in particle accelerators. These systems ensure precise pressure regulation, pump sequencing, and fault detection. Residual gas analyzers are commonly employed to monitor gas composition within the vacuum chamber, allowing for real-time adjustments and optimization of pump performance.

The primary vacuum pumps used in modern particle accelerators include turbomolecular pumps, ion pumps, and cryogenic pumps. Turbomolecular pumps are widely utilized for their high pumping speeds and ability to handle large gas loads. These pumps operate by imparting momentum to gas molecules through rapidly rotating blades, effectively removing them from the vacuum chamber.

Ion pumps, also known as sputter-ion pumps, are extensively employed in particle accelerators due to their ability to maintain ultra-high vacuum conditions without moving parts. These pumps ionize gas molecules and accelerate them towards a titanium cathode, where they are trapped through chemical reactions or physical adsorption.

Cryogenic pumps, or cryopumps, are another essential component of vacuum systems in particle accelerators. These pumps utilize extremely low temperatures to condense and trap gas molecules on cold surfaces. Cryopumps are particularly effective in removing water vapor and other condensable gases, contributing significantly to achieving ultra-high vacuum levels.

In addition to these primary pump types, getter pumps and sublimation pumps are often used as complementary technologies. Getter pumps employ highly reactive materials to chemically bind residual gas molecules, while sublimation pumps use evaporated titanium to trap gases through chemisorption.

The vacuum pump systems in particle accelerators are typically arranged in a cascaded configuration, with different pump types working in tandem to achieve optimal performance. Roughing pumps, such as scroll pumps or rotary vane pumps, are used initially to reduce pressure from atmospheric levels. Once a suitable base pressure is reached, turbomolecular pumps take over to further lower the pressure. Finally, ion pumps and cryopumps are activated to achieve and maintain ultra-high vacuum conditions.

Advanced control systems and monitoring equipment are integral to modern vacuum pump technology in particle accelerators. These systems ensure precise pressure regulation, pump sequencing, and fault detection. Residual gas analyzers are commonly employed to monitor gas composition within the vacuum chamber, allowing for real-time adjustments and optimization of pump performance.

Existing Vacuum Solutions for Particle Accelerators

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of multiple stages for better vacuum generation.

- Energy-efficient vacuum pump systems: Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining or improving pumping performance. This may involve the use of advanced motor technologies, optimized control systems, or innovative cooling mechanisms.

- Vacuum pump control and monitoring: Advanced control and monitoring systems for vacuum pumps enable precise operation, fault detection, and predictive maintenance. These systems may incorporate sensors, data analytics, and remote monitoring capabilities to optimize pump performance and reliability.

- Specialized vacuum pumps for specific applications: Development of vacuum pumps tailored for specific industries or applications, such as semiconductor manufacturing, food processing, or medical devices. These specialized pumps may incorporate unique features or materials to meet specific requirements of the target application.

- Multi-stage vacuum pump systems: Design and implementation of multi-stage vacuum pump systems that combine different pump types or technologies to achieve higher vacuum levels or improved efficiency across a wide pressure range. These systems may integrate roughing pumps, turbomolecular pumps, or cryogenic pumps in various configurations.

02 Vacuum pump control systems

Advanced control systems for vacuum pumps focus on optimizing operation, energy efficiency, and performance. These systems may include sensors, microprocessors, and software algorithms to monitor and adjust pump parameters in real-time, ensuring optimal functioning across various applications.Expand Specific Solutions03 Specialized vacuum pumps for specific applications

Vacuum pumps designed for specific industries or applications, such as semiconductor manufacturing, medical devices, or aerospace, incorporate unique features to meet the particular requirements of these fields. These specialized pumps may have customized materials, geometries, or operating principles tailored to their intended use.Expand Specific Solutions04 Vacuum pump maintenance and reliability improvements

Innovations focused on enhancing the longevity, reliability, and ease of maintenance of vacuum pumps. These may include self-diagnostic features, modular designs for easy component replacement, or the use of wear-resistant materials to extend the operational life of the pump.Expand Specific Solutions05 Energy-efficient vacuum pump technologies

Development of vacuum pump technologies that prioritize energy efficiency and reduced environmental impact. These may include the use of variable speed drives, regenerative designs, or innovative cooling systems to minimize power consumption while maintaining high performance.Expand Specific Solutions

Key Players in Particle Physics Vacuum Technology

The vacuum pump market in high-energy particle physics is in a mature stage, with established players and ongoing technological advancements. The global market size is substantial, driven by increasing demand for precision instruments in scientific research and industrial applications. Technologically, the field is advanced, with companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and LEYBOLD AG leading innovation. These firms, along with others such as Agilent Technologies and MKS, Inc., are continuously improving pump efficiency, reliability, and performance to meet the exacting requirements of particle physics experiments. The competitive landscape is characterized by a mix of specialized vacuum technology companies and diversified scientific instrument manufacturers, all vying for market share through product differentiation and research partnerships.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pumps specifically designed for high-energy particle physics applications. Their GXS dry screw vacuum pumps offer high pumping speeds up to 3400 m³/h and ultimate pressures down to 5 x 10⁻³ mbar[1]. These pumps utilize a unique screw mechanism that provides efficient pumping across a wide pressure range. For ultra-high vacuum requirements in particle accelerators, Edwards has engineered their nEXT turbomolecular pumps, capable of achieving pressures as low as 10⁻¹¹ mbar[2]. The company has also introduced their new GXS2000 pump, specifically optimized for large-scale physics research facilities, offering improved reliability and reduced maintenance needs[3].

Strengths: Specialized pumps for particle physics, high pumping speeds, ultra-low ultimate pressures. Weaknesses: High initial cost, complexity in maintenance for some models.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed the HiPace turbomolecular pumps series, specifically tailored for high-energy particle physics applications. These pumps can achieve ultimate pressures below 10⁻¹⁰ mbar and offer pumping speeds up to 3000 l/s[4]. For backing pumps, Pfeiffer's ACP multi-stage Roots pumps provide oil-free vacuum with high robustness against particle contamination. The company has also introduced their innovative HiLobe Roots pumps, which combine high pumping speed with a compact design, ideal for space-constrained accelerator environments[5]. Pfeiffer's vacuum solutions are equipped with advanced control systems that allow for remote operation and integration with facility-wide control networks, crucial for large-scale physics experiments[6].

Strengths: High pumping efficiency, contamination-resistant designs, advanced control systems. Weaknesses: Higher power consumption in some models, potential for increased heat generation.

Core Innovations in High-Energy Physics Vacuum Systems

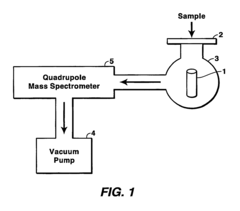

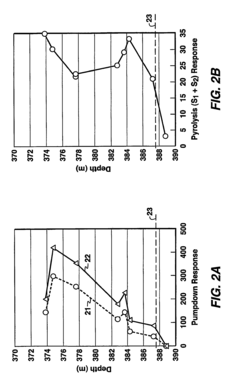

Method for measuring adsorbed and interstitial fluids

PatentInactiveEP1461821B1

Innovation

- A method involving placing a rock sample in an evacuated chamber connected to a vacuum pump and a mass spectrometer to measure the detection rate of molecular constituents over time, allowing for the estimation of rock properties like permeability by comparing the results with known samples, thereby providing more current and relevant information.

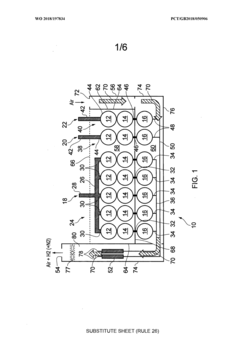

Vacuum pumping system

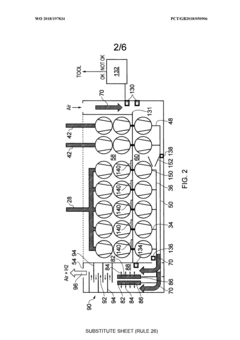

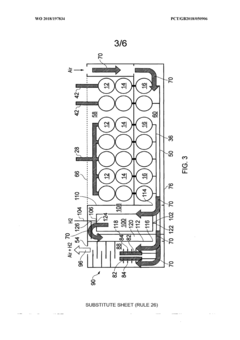

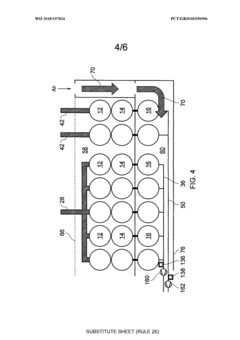

PatentWO2018197834A1

Innovation

- A vacuum pumping system that dilutes flammable gases with air to below their lower flammability limit, using a housing with distinct pressure regions and airflow generators to mix air with the gas stream, preventing ignition and allowing safe emission, and incorporating hydrogen recovery systems to recycle valuable gases.

Energy Efficiency in High-Vacuum Systems

Energy efficiency in high-vacuum systems is a critical consideration in the field of high-energy particle physics. The operation of vacuum pumps, essential for maintaining the ultra-low pressures required in particle accelerators and detectors, consumes significant amounts of energy. As experiments in particle physics become more complex and energy-intensive, optimizing the efficiency of vacuum systems has become a paramount concern for researchers and facility managers alike.

One of the primary approaches to improving energy efficiency in high-vacuum systems is the implementation of advanced pump designs. Modern turbomolecular pumps, for instance, utilize magnetic bearings and optimized blade geometries to reduce friction and power consumption while maintaining high pumping speeds. These innovations have led to pumps that can achieve ultimate pressures in the range of 10^-11 mbar with significantly lower energy input compared to their predecessors.

Another key strategy involves the intelligent control and operation of vacuum systems. Adaptive pumping algorithms can adjust the speed and power of pumps based on real-time pressure measurements, ensuring that energy is not wasted on unnecessary pumping when stable vacuum conditions are achieved. Furthermore, the integration of smart sensors and IoT technologies allows for predictive maintenance, reducing downtime and optimizing overall system efficiency.

The use of cryogenic pumping techniques has also shown promise in enhancing energy efficiency. By employing surfaces cooled to extremely low temperatures, typically using liquid helium or nitrogen, these systems can effectively trap gas molecules without the need for continuous mechanical pumping. While the initial cooling process requires energy, the long-term operation can be more efficient, especially for maintaining ultra-high vacuums over extended periods.

Researchers are also exploring novel materials and surface treatments to reduce outgassing and improve vacuum quality without increasing pumping requirements. Advanced getter materials, which can absorb residual gases, are being developed to complement traditional pumping methods, potentially reducing the overall energy demand of vacuum systems.

Energy recovery systems are another area of focus. The heat generated by vacuum pumps, particularly in large-scale facilities, can be substantial. By implementing heat exchangers and thermal management systems, this waste heat can be recaptured and used for other purposes within the facility, such as heating or powering auxiliary systems, thereby improving overall energy efficiency.

As the field of high-energy particle physics continues to push the boundaries of scientific exploration, the demand for more efficient high-vacuum systems will only increase. The ongoing research and development in this area not only benefits particle physics experiments but also has wide-ranging applications in other fields that rely on vacuum technology, such as semiconductor manufacturing and space simulation chambers.

One of the primary approaches to improving energy efficiency in high-vacuum systems is the implementation of advanced pump designs. Modern turbomolecular pumps, for instance, utilize magnetic bearings and optimized blade geometries to reduce friction and power consumption while maintaining high pumping speeds. These innovations have led to pumps that can achieve ultimate pressures in the range of 10^-11 mbar with significantly lower energy input compared to their predecessors.

Another key strategy involves the intelligent control and operation of vacuum systems. Adaptive pumping algorithms can adjust the speed and power of pumps based on real-time pressure measurements, ensuring that energy is not wasted on unnecessary pumping when stable vacuum conditions are achieved. Furthermore, the integration of smart sensors and IoT technologies allows for predictive maintenance, reducing downtime and optimizing overall system efficiency.

The use of cryogenic pumping techniques has also shown promise in enhancing energy efficiency. By employing surfaces cooled to extremely low temperatures, typically using liquid helium or nitrogen, these systems can effectively trap gas molecules without the need for continuous mechanical pumping. While the initial cooling process requires energy, the long-term operation can be more efficient, especially for maintaining ultra-high vacuums over extended periods.

Researchers are also exploring novel materials and surface treatments to reduce outgassing and improve vacuum quality without increasing pumping requirements. Advanced getter materials, which can absorb residual gases, are being developed to complement traditional pumping methods, potentially reducing the overall energy demand of vacuum systems.

Energy recovery systems are another area of focus. The heat generated by vacuum pumps, particularly in large-scale facilities, can be substantial. By implementing heat exchangers and thermal management systems, this waste heat can be recaptured and used for other purposes within the facility, such as heating or powering auxiliary systems, thereby improving overall energy efficiency.

As the field of high-energy particle physics continues to push the boundaries of scientific exploration, the demand for more efficient high-vacuum systems will only increase. The ongoing research and development in this area not only benefits particle physics experiments but also has wide-ranging applications in other fields that rely on vacuum technology, such as semiconductor manufacturing and space simulation chambers.

Safety Protocols in Particle Physics Facilities

Safety protocols in particle physics facilities are of paramount importance due to the high-energy environments and potential hazards associated with experimental setups. These protocols encompass a wide range of measures designed to protect personnel, equipment, and the environment from potential risks inherent in particle physics research.

One of the primary safety concerns in these facilities is radiation exposure. Strict guidelines are implemented to monitor and limit radiation levels, including the use of personal dosimeters, radiation shielding, and controlled access to high-radiation areas. Regular radiation surveys and real-time monitoring systems are employed to ensure that exposure levels remain within acceptable limits.

Electrical safety is another critical aspect, given the high-voltage equipment used in particle accelerators and detectors. Comprehensive grounding systems, insulation protocols, and lockout-tagout procedures are essential to prevent electrical accidents. Regular inspections and maintenance of electrical systems are conducted to identify and address potential hazards.

Cryogenic safety measures are crucial in facilities that utilize superconducting magnets and detectors. Proper handling and storage of cryogenic fluids, such as liquid helium and nitrogen, are essential. Safety systems include oxygen depletion monitors, ventilation systems, and emergency shutdown procedures to mitigate risks associated with cryogenic leaks or spills.

Fire safety is a significant concern due to the presence of flammable materials and high-energy equipment. Advanced fire detection and suppression systems are installed throughout the facility, along with clearly marked evacuation routes and regular fire drills. Special attention is given to areas with a higher risk of fire, such as power supply rooms and experimental halls.

Vacuum systems, including those utilizing vacuum pumps, require specific safety protocols. These include proper venting procedures, pressure relief systems, and safeguards against implosion risks. Regular maintenance and inspection of vacuum components are essential to prevent leaks or failures that could compromise safety.

Laser safety protocols are implemented in facilities using high-power lasers for research or calibration purposes. These include controlled access to laser areas, proper eye protection, and interlocking systems to prevent accidental exposure.

Emergency response planning is a critical component of safety protocols. This includes detailed procedures for various scenarios, such as power outages, equipment failures, or accidents. Regular drills and training sessions ensure that all personnel are familiar with emergency procedures and their roles during an incident.

Personal protective equipment (PPE) requirements are strictly enforced, with specific gear mandated for different areas and activities within the facility. This may include hard hats, safety glasses, hearing protection, and specialized clothing for certain experimental areas.

One of the primary safety concerns in these facilities is radiation exposure. Strict guidelines are implemented to monitor and limit radiation levels, including the use of personal dosimeters, radiation shielding, and controlled access to high-radiation areas. Regular radiation surveys and real-time monitoring systems are employed to ensure that exposure levels remain within acceptable limits.

Electrical safety is another critical aspect, given the high-voltage equipment used in particle accelerators and detectors. Comprehensive grounding systems, insulation protocols, and lockout-tagout procedures are essential to prevent electrical accidents. Regular inspections and maintenance of electrical systems are conducted to identify and address potential hazards.

Cryogenic safety measures are crucial in facilities that utilize superconducting magnets and detectors. Proper handling and storage of cryogenic fluids, such as liquid helium and nitrogen, are essential. Safety systems include oxygen depletion monitors, ventilation systems, and emergency shutdown procedures to mitigate risks associated with cryogenic leaks or spills.

Fire safety is a significant concern due to the presence of flammable materials and high-energy equipment. Advanced fire detection and suppression systems are installed throughout the facility, along with clearly marked evacuation routes and regular fire drills. Special attention is given to areas with a higher risk of fire, such as power supply rooms and experimental halls.

Vacuum systems, including those utilizing vacuum pumps, require specific safety protocols. These include proper venting procedures, pressure relief systems, and safeguards against implosion risks. Regular maintenance and inspection of vacuum components are essential to prevent leaks or failures that could compromise safety.

Laser safety protocols are implemented in facilities using high-power lasers for research or calibration purposes. These include controlled access to laser areas, proper eye protection, and interlocking systems to prevent accidental exposure.

Emergency response planning is a critical component of safety protocols. This includes detailed procedures for various scenarios, such as power outages, equipment failures, or accidents. Regular drills and training sessions ensure that all personnel are familiar with emergency procedures and their roles during an incident.

Personal protective equipment (PPE) requirements are strictly enforced, with specific gear mandated for different areas and activities within the facility. This may include hard hats, safety glasses, hearing protection, and specialized clothing for certain experimental areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!