Flexible Device Architectures For Wearable Thermoelectric Modules

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Thermoelectric Wearables: Background and Objectives

Thermoelectric wearable technology has evolved significantly over the past decade, transitioning from rigid, bulky devices to flexible, conformable systems that can adapt to the human body's contours. This evolution represents a convergence of materials science, electrical engineering, and thermal management principles, driven by the increasing demand for self-powered wearable electronics in healthcare, fitness, and consumer electronics sectors.

The fundamental principle behind thermoelectric wearables relies on the Seebeck effect, discovered in 1821, which enables direct conversion of temperature differentials into electrical energy. Early thermoelectric generators (TEGs) utilized rigid semiconductor materials with high figure of merit (ZT), primarily bismuth telluride (Bi2Te3) compounds. However, these traditional materials lacked the mechanical flexibility required for comfortable, long-term wearable applications.

Recent technological breakthroughs in flexible materials and manufacturing techniques have catalyzed the development of bendable, stretchable, and even textile-integrated thermoelectric modules. Key innovations include the development of organic thermoelectric materials, polymer-inorganic composites, and novel fabrication methods such as screen printing, inkjet printing, and roll-to-roll processing that enable large-area, cost-effective production of flexible thermoelectric devices.

The primary objective of flexible device architectures for wearable thermoelectric modules is to harvest body heat effectively while maintaining user comfort and device durability. This requires optimizing the thermal interface between the skin and the device, maximizing the temperature gradient across the thermoelectric elements, and ensuring mechanical resilience during repeated deformation cycles.

Secondary objectives include enhancing power density to support increasingly sophisticated wearable electronics, reducing manufacturing costs to enable mass-market adoption, and improving long-term reliability under real-world operating conditions including exposure to sweat, mechanical stress, and varying environmental temperatures.

The technology trajectory indicates a shift toward hybrid systems that combine thermoelectric energy harvesting with other power sources such as photovoltaics or piezoelectrics to create more robust and efficient energy solutions. Additionally, there is growing interest in self-powered wearable health monitoring systems that can operate continuously without battery replacement, particularly for remote patient monitoring and preventive healthcare applications.

As we look toward future developments, key research priorities include discovering novel flexible thermoelectric materials with higher ZT values, developing advanced thermal management strategies for wearable form factors, and creating standardized testing protocols to accurately assess the performance of flexible thermoelectric wearables under realistic usage conditions.

The fundamental principle behind thermoelectric wearables relies on the Seebeck effect, discovered in 1821, which enables direct conversion of temperature differentials into electrical energy. Early thermoelectric generators (TEGs) utilized rigid semiconductor materials with high figure of merit (ZT), primarily bismuth telluride (Bi2Te3) compounds. However, these traditional materials lacked the mechanical flexibility required for comfortable, long-term wearable applications.

Recent technological breakthroughs in flexible materials and manufacturing techniques have catalyzed the development of bendable, stretchable, and even textile-integrated thermoelectric modules. Key innovations include the development of organic thermoelectric materials, polymer-inorganic composites, and novel fabrication methods such as screen printing, inkjet printing, and roll-to-roll processing that enable large-area, cost-effective production of flexible thermoelectric devices.

The primary objective of flexible device architectures for wearable thermoelectric modules is to harvest body heat effectively while maintaining user comfort and device durability. This requires optimizing the thermal interface between the skin and the device, maximizing the temperature gradient across the thermoelectric elements, and ensuring mechanical resilience during repeated deformation cycles.

Secondary objectives include enhancing power density to support increasingly sophisticated wearable electronics, reducing manufacturing costs to enable mass-market adoption, and improving long-term reliability under real-world operating conditions including exposure to sweat, mechanical stress, and varying environmental temperatures.

The technology trajectory indicates a shift toward hybrid systems that combine thermoelectric energy harvesting with other power sources such as photovoltaics or piezoelectrics to create more robust and efficient energy solutions. Additionally, there is growing interest in self-powered wearable health monitoring systems that can operate continuously without battery replacement, particularly for remote patient monitoring and preventive healthcare applications.

As we look toward future developments, key research priorities include discovering novel flexible thermoelectric materials with higher ZT values, developing advanced thermal management strategies for wearable form factors, and creating standardized testing protocols to accurately assess the performance of flexible thermoelectric wearables under realistic usage conditions.

Market Analysis for Wearable Thermoelectric Applications

The wearable thermoelectric module market is experiencing significant growth, driven by increasing consumer demand for energy-efficient wearable devices. The global market for wearable technology was valued at approximately $61.3 billion in 2022 and is projected to reach $184.4 billion by 2030, with a compound annual growth rate (CAGR) of 14.6%. Within this broader market, thermoelectric wearables represent a rapidly expanding segment, expected to grow at a CAGR of 18.2% through 2028.

Healthcare applications dominate the current market landscape, accounting for nearly 45% of wearable thermoelectric module deployments. These applications include continuous health monitoring devices, temperature-regulated therapeutic wearables, and energy-harvesting medical implants. The consumer electronics sector follows closely, representing approximately 32% of the market, with applications in smartwatches, fitness trackers, and augmented reality devices.

Military and industrial applications constitute smaller but growing segments, collectively representing about 23% of the market. These sectors value the reliability and autonomous power generation capabilities of thermoelectric modules in harsh environments where traditional power sources may be impractical.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing manufacturing capabilities, growing consumer electronics markets, and substantial government investments in wearable technology research.

Key market drivers include the growing demand for self-powered wearable devices, increasing health consciousness among consumers, and technological advancements in flexible materials and manufacturing processes. The integration of Internet of Things (IoT) functionality into wearable devices is also accelerating market growth, as thermoelectric modules offer a sustainable power solution for always-connected devices.

Market challenges include high initial manufacturing costs, limited power generation efficiency (currently averaging 5-8% for commercial modules), and competition from alternative energy harvesting technologies such as photovoltaic and piezoelectric systems. Additionally, consumer concerns regarding comfort, aesthetics, and durability of wearable thermoelectric devices present significant market barriers.

Despite these challenges, the market outlook remains positive, with substantial opportunities for companies that can develop flexible, efficient, and aesthetically pleasing thermoelectric modules. Industry analysts predict that breakthroughs in flexible substrate materials and manufacturing techniques could potentially double the market size within the next decade.

Healthcare applications dominate the current market landscape, accounting for nearly 45% of wearable thermoelectric module deployments. These applications include continuous health monitoring devices, temperature-regulated therapeutic wearables, and energy-harvesting medical implants. The consumer electronics sector follows closely, representing approximately 32% of the market, with applications in smartwatches, fitness trackers, and augmented reality devices.

Military and industrial applications constitute smaller but growing segments, collectively representing about 23% of the market. These sectors value the reliability and autonomous power generation capabilities of thermoelectric modules in harsh environments where traditional power sources may be impractical.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing manufacturing capabilities, growing consumer electronics markets, and substantial government investments in wearable technology research.

Key market drivers include the growing demand for self-powered wearable devices, increasing health consciousness among consumers, and technological advancements in flexible materials and manufacturing processes. The integration of Internet of Things (IoT) functionality into wearable devices is also accelerating market growth, as thermoelectric modules offer a sustainable power solution for always-connected devices.

Market challenges include high initial manufacturing costs, limited power generation efficiency (currently averaging 5-8% for commercial modules), and competition from alternative energy harvesting technologies such as photovoltaic and piezoelectric systems. Additionally, consumer concerns regarding comfort, aesthetics, and durability of wearable thermoelectric devices present significant market barriers.

Despite these challenges, the market outlook remains positive, with substantial opportunities for companies that can develop flexible, efficient, and aesthetically pleasing thermoelectric modules. Industry analysts predict that breakthroughs in flexible substrate materials and manufacturing techniques could potentially double the market size within the next decade.

Technical Challenges in Flexible Thermoelectric Modules

Despite significant advancements in wearable thermoelectric technology, flexible thermoelectric modules (FTEMs) face several critical technical challenges that impede their widespread commercial adoption. The fundamental challenge lies in the inherent contradiction between flexibility and thermoelectric performance. Traditional high-performance thermoelectric materials such as bismuth telluride and lead telluride are rigid and brittle, making them unsuitable for applications requiring mechanical deformation.

Material selection presents a significant hurdle, as researchers must identify compounds that maintain high thermoelectric figure of merit (ZT) while offering mechanical flexibility. Current flexible thermoelectric materials typically exhibit ZT values below 0.3 at room temperature, considerably lower than rigid counterparts that can achieve ZT values exceeding 1.0. This performance gap represents a major limitation for practical energy harvesting applications.

Interface engineering between different materials in the module structure creates another substantial challenge. Thermal and electrical contact resistances at these interfaces can significantly degrade overall device performance. When flexible substrates undergo repeated bending and deformation, these interfaces experience mechanical stress that can lead to delamination, crack formation, and eventual device failure.

Heat management in flexible architectures presents unique difficulties compared to rigid modules. The thermal conductivity pathway must be carefully engineered to maintain temperature gradients while accommodating mechanical deformation. Flexible substrates often have poor thermal properties that can reduce the effective temperature difference across the thermoelectric elements, directly impacting power generation capability.

Manufacturing scalability remains problematic for flexible thermoelectric modules. Current fabrication techniques such as screen printing, inkjet printing, and vacuum deposition each have limitations in terms of material compatibility, dimensional control, and production throughput. The integration of multiple materials with different physical properties into a cohesive, reliable flexible structure requires sophisticated manufacturing processes that are not yet optimized for mass production.

Long-term reliability under mechanical stress constitutes a critical concern. Wearable applications demand modules that can withstand thousands of bending cycles while maintaining consistent performance. Current flexible modules typically show performance degradation after repeated mechanical deformation, with efficiency losses of 15-30% after 1000 bending cycles being commonly reported in research literature.

Power management electronics integration presents additional complexity, as the circuitry must also be flexible and efficiently handle the low-voltage output characteristic of thermoelectric generators. The development of flexible, efficient power conditioning circuits that can operate with variable input voltages remains an active research challenge.

Material selection presents a significant hurdle, as researchers must identify compounds that maintain high thermoelectric figure of merit (ZT) while offering mechanical flexibility. Current flexible thermoelectric materials typically exhibit ZT values below 0.3 at room temperature, considerably lower than rigid counterparts that can achieve ZT values exceeding 1.0. This performance gap represents a major limitation for practical energy harvesting applications.

Interface engineering between different materials in the module structure creates another substantial challenge. Thermal and electrical contact resistances at these interfaces can significantly degrade overall device performance. When flexible substrates undergo repeated bending and deformation, these interfaces experience mechanical stress that can lead to delamination, crack formation, and eventual device failure.

Heat management in flexible architectures presents unique difficulties compared to rigid modules. The thermal conductivity pathway must be carefully engineered to maintain temperature gradients while accommodating mechanical deformation. Flexible substrates often have poor thermal properties that can reduce the effective temperature difference across the thermoelectric elements, directly impacting power generation capability.

Manufacturing scalability remains problematic for flexible thermoelectric modules. Current fabrication techniques such as screen printing, inkjet printing, and vacuum deposition each have limitations in terms of material compatibility, dimensional control, and production throughput. The integration of multiple materials with different physical properties into a cohesive, reliable flexible structure requires sophisticated manufacturing processes that are not yet optimized for mass production.

Long-term reliability under mechanical stress constitutes a critical concern. Wearable applications demand modules that can withstand thousands of bending cycles while maintaining consistent performance. Current flexible modules typically show performance degradation after repeated mechanical deformation, with efficiency losses of 15-30% after 1000 bending cycles being commonly reported in research literature.

Power management electronics integration presents additional complexity, as the circuitry must also be flexible and efficiently handle the low-voltage output characteristic of thermoelectric generators. The development of flexible, efficient power conditioning circuits that can operate with variable input voltages remains an active research challenge.

Current Architectural Solutions for Wearable Thermoelectrics

01 Flexible substrate materials for wearable thermoelectric modules

Various flexible substrate materials can be used in wearable thermoelectric modules to achieve flexibility while maintaining performance. These materials include polymers, elastomers, and thin films that can bend and conform to body contours. The flexibility of these substrates allows the thermoelectric modules to maintain contact with the skin during movement, ensuring consistent energy harvesting or cooling functionality. These materials also provide mechanical support while allowing the device to stretch and flex with body movements.- Flexible substrate materials for wearable thermoelectric modules: Various flexible substrate materials can be used in wearable thermoelectric modules to achieve flexibility while maintaining performance. These materials include polymers, elastomers, and thin films that can bend and conform to body contours. The flexibility of these substrates allows the thermoelectric modules to maintain contact with the skin during movement, enhancing energy harvesting efficiency. These materials also provide mechanical support while allowing the necessary flexibility for wearable applications.

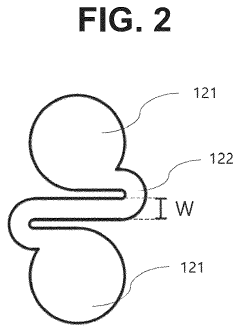

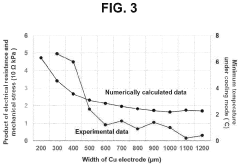

- Interconnect designs for flexible thermoelectric devices: Specialized interconnect designs enable flexibility in thermoelectric modules while maintaining electrical connectivity. These designs include serpentine, wavy, or mesh-like interconnect structures that can stretch and bend without breaking. By allowing movement between thermoelectric elements while preserving electrical pathways, these interconnect architectures enhance the overall flexibility and durability of wearable thermoelectric modules, making them suitable for applications involving body movement and contoured surfaces.

- Integration methods for flexible thermoelectric components: Various integration methods are employed to combine thermoelectric elements with flexible substrates and other components. These methods include transfer printing, direct deposition, and modular assembly techniques that preserve the flexibility of the overall device. Advanced bonding techniques ensure that connections remain intact during bending and stretching, while allowing for the integration of rigid thermoelectric materials into flexible architectures. These integration approaches are crucial for creating reliable wearable thermoelectric modules that can withstand repeated mechanical deformation.

- Structural designs for enhanced mechanical flexibility: Innovative structural designs enhance the mechanical flexibility of thermoelectric modules. These include segmented architectures, island-bridge configurations, and origami-inspired folding structures that distribute mechanical stress during bending and twisting. By strategically arranging rigid thermoelectric elements within flexible frameworks, these designs allow the modules to conform to complex three-dimensional surfaces while maintaining thermoelectric performance. Such structural approaches are essential for creating wearable devices that can adapt to body movements and contours.

- Materials for flexible thermoelectric elements: Advanced materials are developed specifically for flexible thermoelectric elements. These include organic thermoelectric materials, composite materials combining inorganic thermoelectric particles with flexible polymers, and thin-film thermoelectric materials that retain functionality when bent. These materials offer a balance between thermoelectric performance and mechanical flexibility, enabling the creation of wearable thermoelectric modules that can efficiently convert body heat into electricity while conforming to the body's natural movements and contours.

02 Interconnection techniques for flexible thermoelectric devices

Advanced interconnection techniques are essential for maintaining electrical connectivity in flexible thermoelectric modules during bending and stretching. These techniques include using serpentine or wavy interconnects, stretchable conductive materials, and novel bonding methods that can withstand repeated mechanical deformation. The interconnection designs allow for device flexibility while preserving the electrical pathways necessary for thermoelectric conversion. These approaches minimize stress concentration at connection points and prevent device failure during normal wear.Expand Specific Solutions03 Integration of thermoelectric materials with flexible platforms

Innovative methods for integrating rigid thermoelectric materials with flexible platforms enable the creation of wearable thermoelectric modules. These methods include thin-film deposition, printing techniques, and micro/nanofabrication approaches that allow thermoelectric materials to be incorporated onto flexible substrates. The integration techniques maintain the thermoelectric properties of the materials while enabling the mechanical flexibility required for wearable applications. This approach bridges the gap between high-performance thermoelectric materials and the mechanical requirements of wearable devices.Expand Specific Solutions04 Structural designs for enhancing flexibility in thermoelectric modules

Novel structural designs can enhance the flexibility of thermoelectric modules while preserving their energy conversion capabilities. These designs include segmented architectures, island-bridge configurations, and origami-inspired folding structures that allow the device to bend and conform to complex surfaces. The structural approaches distribute mechanical stress during deformation, preventing damage to the thermoelectric elements. These designs enable the modules to maintain performance even when subjected to various bending radii and deformation modes.Expand Specific Solutions05 Encapsulation methods for protecting flexible thermoelectric devices

Specialized encapsulation methods protect flexible thermoelectric modules from environmental factors while maintaining their mechanical flexibility. These methods include using stretchable polymers, breathable membranes, and multilayer encapsulation techniques that shield the device from moisture, sweat, and mechanical damage. The encapsulation approaches ensure the longevity and reliability of wearable thermoelectric modules in real-world conditions. These protective layers are designed to be flexible themselves, allowing the entire device to bend and conform without compromising the protection of sensitive components.Expand Specific Solutions

Industry Leaders in Flexible Thermoelectric Development

The flexible wearable thermoelectric module market is currently in its early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market is projected to expand significantly as wearable technology adoption rises, with estimates suggesting a compound annual growth rate exceeding 15% through 2028. Technologically, the field shows varying maturity levels, with companies like Tegway and LG Innotek leading commercial development of flexible thermoelectric solutions, while academic institutions such as KAIST, Tsinghua University, and MIT drive fundamental innovation. Established industrial players including 3M, BASF, and Sumitomo Chemical are leveraging their materials expertise to develop specialized components, while startups like Nimbus Materials focus on novel approaches. The ecosystem demonstrates strong industry-academia collaboration, particularly evident in technology transfers from research institutions to commercial entities.

Tegway Co. Ltd.

Technical Solution: Tegway has developed a proprietary flexible thermoelectric generator (TEG) technology called "ThermoReal" that utilizes thin-film thermoelectric materials deposited on flexible substrates. Their approach involves creating ultra-thin (less than 0.5mm) thermoelectric modules that can conform to curved surfaces while maintaining efficient energy conversion. The company employs a unique manufacturing process that allows for direct deposition of bismuth telluride-based compounds onto polymer substrates, creating a seamless integration between the rigid thermoelectric materials and flexible backing. This results in devices that can withstand over 100,000 bending cycles without significant performance degradation. Tegway's modules can generate power from temperature differentials as low as 1-2°C, making them particularly suitable for body heat harvesting applications in wearable devices.

Strengths: Exceptional flexibility and durability with proven bending endurance; ultra-thin profile suitable for integration into various wearable form factors; ability to harvest energy from minimal temperature gradients. Weaknesses: Lower power density compared to rigid thermoelectric modules; relatively high manufacturing costs; limited temperature operating range compared to ceramic-based alternatives.

LG Innotek Co., Ltd.

Technical Solution: LG Innotek has developed advanced flexible thermoelectric modules using a hybrid approach that combines rigid thermoelectric elements with flexible interconnects and substrates. Their technology employs segmented thermoelectric legs arranged in a novel serpentine configuration that allows for mechanical flexibility while maintaining electrical connectivity. The company utilizes proprietary polymer composites with enhanced thermal conductivity for the flexible substrate, which improves heat transfer while maintaining bendability. LG's manufacturing process incorporates automated precision placement of thermoelectric elements using pick-and-place technology, followed by a specialized low-temperature sintering process that preserves the integrity of the flexible components. Their modules achieve a power density of approximately 10-15 μW/cm² at temperature differentials typical of body-device interfaces (3-5°C), with demonstrated reliability over 50,000 flexing cycles.

Strengths: High manufacturing scalability leveraging existing semiconductor production infrastructure; good balance between flexibility and power generation efficiency; strong integration capabilities with other electronic components. Weaknesses: More complex manufacturing process compared to fully printed solutions; moderate thickness constraints limiting ultra-thin applications; performance degradation after repeated extreme bending.

Key Patents and Research in Flexible TE Module Design

Bidirectional stretchable and flexible wearable thermoelectric module

PatentActiveUS11839157B2

Innovation

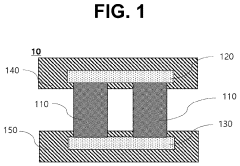

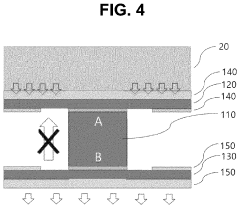

- A stretchable and flexible thermoelectric module is developed, comprising deformable electrodes and elastic composites with metal nano materials, allowing for both heating and cooling by reversing current direction, and featuring a specific electrode structure for improved thermal conductivity and mechanical flexibility.

Flexible thermoelectric device module and manufacturing method therefor

PatentWO2024101525A1

Innovation

- A flexible thermoelectric module design featuring N-type and P-type thermoelectric legs connected by a conductor, surrounded by an insulating metastructure with partial voids made of resin-based materials, which includes a metastructure pattern with negative or zero Poisson's ratio and air gaps, providing enhanced mechanical stability and thermal insulation.

Materials Science Advancements for Flexible Thermoelectrics

Recent advancements in materials science have significantly propelled the development of flexible thermoelectric modules for wearable applications. Traditional rigid thermoelectric materials like bismuth telluride (Bi2Te3) have been reimagined through novel processing techniques that enable flexibility while maintaining electrical conductivity and Seebeck coefficient values. Researchers have successfully developed thin-film deposition methods that allow for the creation of ultra-thin thermoelectric layers on flexible substrates, dramatically improving mechanical compliance without sacrificing performance.

Organic thermoelectric materials represent another breakthrough area, with conducting polymers such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) showing promising thermoelectric properties combined with inherent flexibility. These materials can be solution-processed at low temperatures, enabling compatibility with a wide range of flexible substrates including textiles and polymeric films. Recent modifications to these organic materials have achieved power factors approaching 100 μW/mK², marking significant progress toward commercially viable flexible thermoelectric generators.

Hybrid organic-inorganic composites have emerged as a compelling compromise between the high performance of inorganic materials and the flexibility of organic compounds. These composites typically incorporate nanoscale inorganic thermoelectric particles within a flexible organic matrix, creating materials that can bend and conform to irregular surfaces while maintaining reasonable thermoelectric conversion efficiency. Notable examples include graphene/PEDOT:PSS composites and tellurium nanowire/polymer blends that demonstrate enhanced mechanical durability under repeated flexing cycles.

Nanomaterial engineering has revolutionized flexible thermoelectrics through the development of one-dimensional structures like nanowires and nanotubes that possess inherent flexibility. These structures can be assembled into networks or arrays that maintain electrical pathways even when bent or stretched. Silver nanowire networks, carbon nanotube films, and tellurium nanowire meshes have all demonstrated promising combinations of electrical conductivity, thermal resistance, and mechanical flexibility essential for wearable applications.

Interface engineering between different material layers has proven critical for maintaining performance during mechanical deformation. Researchers have developed specialized adhesion layers and gradient interfaces that accommodate strain during bending while preserving electrical connections. Additionally, stretchable interconnects using serpentine patterns or liquid metal conductors have been integrated with thermoelectric elements to create fully functional modules that can withstand the dynamic movements associated with wearable applications.

Encapsulation technologies have also advanced significantly, with new barrier materials that protect sensitive thermoelectric components from environmental factors while remaining flexible. These developments collectively represent a transformative shift in thermoelectric material design, moving from rigid, brittle structures toward truly flexible, conformable systems suitable for next-generation wearable energy harvesting devices.

Organic thermoelectric materials represent another breakthrough area, with conducting polymers such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) showing promising thermoelectric properties combined with inherent flexibility. These materials can be solution-processed at low temperatures, enabling compatibility with a wide range of flexible substrates including textiles and polymeric films. Recent modifications to these organic materials have achieved power factors approaching 100 μW/mK², marking significant progress toward commercially viable flexible thermoelectric generators.

Hybrid organic-inorganic composites have emerged as a compelling compromise between the high performance of inorganic materials and the flexibility of organic compounds. These composites typically incorporate nanoscale inorganic thermoelectric particles within a flexible organic matrix, creating materials that can bend and conform to irregular surfaces while maintaining reasonable thermoelectric conversion efficiency. Notable examples include graphene/PEDOT:PSS composites and tellurium nanowire/polymer blends that demonstrate enhanced mechanical durability under repeated flexing cycles.

Nanomaterial engineering has revolutionized flexible thermoelectrics through the development of one-dimensional structures like nanowires and nanotubes that possess inherent flexibility. These structures can be assembled into networks or arrays that maintain electrical pathways even when bent or stretched. Silver nanowire networks, carbon nanotube films, and tellurium nanowire meshes have all demonstrated promising combinations of electrical conductivity, thermal resistance, and mechanical flexibility essential for wearable applications.

Interface engineering between different material layers has proven critical for maintaining performance during mechanical deformation. Researchers have developed specialized adhesion layers and gradient interfaces that accommodate strain during bending while preserving electrical connections. Additionally, stretchable interconnects using serpentine patterns or liquid metal conductors have been integrated with thermoelectric elements to create fully functional modules that can withstand the dynamic movements associated with wearable applications.

Encapsulation technologies have also advanced significantly, with new barrier materials that protect sensitive thermoelectric components from environmental factors while remaining flexible. These developments collectively represent a transformative shift in thermoelectric material design, moving from rigid, brittle structures toward truly flexible, conformable systems suitable for next-generation wearable energy harvesting devices.

Energy Harvesting Efficiency and Power Management Strategies

Energy harvesting efficiency in wearable thermoelectric modules represents a critical factor determining their practical utility in real-world applications. Current flexible thermoelectric generators (TEGs) typically demonstrate power densities ranging from 10-100 μW/cm² under body-ambient temperature differentials of 5-10K. This efficiency remains significantly below the theoretical maximum, primarily due to thermal interface losses, electrical resistance in flexible interconnects, and suboptimal thermal gradient maintenance across the device architecture.

Power management strategies have evolved substantially to address these limitations. Advanced DC-DC converters specifically designed for ultra-low voltage inputs (20-200mV) now achieve conversion efficiencies exceeding 80% for thermoelectric harvesting applications. These systems incorporate maximum power point tracking (MPPT) algorithms that dynamically adjust the electrical load to maintain optimal power extraction as temperature differentials fluctuate during wear.

Recent innovations in energy storage integration have yielded hybrid systems combining TEGs with thin-film supercapacitors or flexible lithium-ion batteries. These configurations enable efficient energy accumulation during periods of favorable thermal gradients, ensuring continuous power availability for wearable electronics despite the intermittent nature of harvested energy. Notably, silicon-based power management ICs have been miniaturized to dimensions below 4mm², facilitating seamless integration with flexible TEG architectures.

Thermal management represents another crucial aspect of efficiency optimization. Novel approaches include the implementation of thermally conductive polymer composites that direct heat flow while maintaining mechanical flexibility. These materials create preferential thermal pathways that maximize temperature differentials across thermoelectric elements while minimizing parasitic heat losses through the substrate and interconnect structures.

The integration of wireless power transfer capabilities with thermoelectric harvesting has emerged as a promising strategy for wearable applications. This approach enables supplementary charging during periods of insufficient thermal gradient, with intelligent switching circuits automatically selecting the optimal power source based on environmental conditions and device power requirements.

Looking forward, the development of self-adaptive thermoelectric systems represents a significant frontier. These systems incorporate microcontrollers that continuously monitor thermal conditions and reconfigure the thermoelectric array's electrical connections to optimize performance across varying temperature profiles, potentially increasing average power output by 30-45% compared to static configurations.

Power management strategies have evolved substantially to address these limitations. Advanced DC-DC converters specifically designed for ultra-low voltage inputs (20-200mV) now achieve conversion efficiencies exceeding 80% for thermoelectric harvesting applications. These systems incorporate maximum power point tracking (MPPT) algorithms that dynamically adjust the electrical load to maintain optimal power extraction as temperature differentials fluctuate during wear.

Recent innovations in energy storage integration have yielded hybrid systems combining TEGs with thin-film supercapacitors or flexible lithium-ion batteries. These configurations enable efficient energy accumulation during periods of favorable thermal gradients, ensuring continuous power availability for wearable electronics despite the intermittent nature of harvested energy. Notably, silicon-based power management ICs have been miniaturized to dimensions below 4mm², facilitating seamless integration with flexible TEG architectures.

Thermal management represents another crucial aspect of efficiency optimization. Novel approaches include the implementation of thermally conductive polymer composites that direct heat flow while maintaining mechanical flexibility. These materials create preferential thermal pathways that maximize temperature differentials across thermoelectric elements while minimizing parasitic heat losses through the substrate and interconnect structures.

The integration of wireless power transfer capabilities with thermoelectric harvesting has emerged as a promising strategy for wearable applications. This approach enables supplementary charging during periods of insufficient thermal gradient, with intelligent switching circuits automatically selecting the optimal power source based on environmental conditions and device power requirements.

Looking forward, the development of self-adaptive thermoelectric systems represents a significant frontier. These systems incorporate microcontrollers that continuously monitor thermal conditions and reconfigure the thermoelectric array's electrical connections to optimize performance across varying temperature profiles, potentially increasing average power output by 30-45% compared to static configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!