Flexible Electronics in Aerial Sensors: Signal Range Performance

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Evolution and Objectives

Flexible electronics technology has evolved significantly over the past three decades, transforming from laboratory curiosities to commercially viable products. The journey began in the 1990s with rudimentary flexible displays and simple circuits, progressing through several critical developmental phases. By the early 2000s, researchers had overcome fundamental materials challenges, establishing reliable fabrication techniques for flexible substrates and conductive pathways that could withstand repeated mechanical stress.

The mid-2000s marked a turning point with the introduction of organic semiconductors and printed electronics, enabling more complex flexible circuits. This period saw the emergence of flexible solar cells, basic sensors, and the first generation of bendable displays. The 2010s witnessed accelerated development in stretchable electronics, with innovations in materials science producing conductive polymers and metal nanowires capable of maintaining electrical properties under significant deformation.

Most recently, the integration of flexible electronics with IoT and wireless communication technologies has opened new application domains, particularly in aerial sensor systems. This convergence addresses the critical need for lightweight, conformable sensors that can be deployed on aerial platforms without compromising aerodynamic performance or adding significant weight penalties.

The current technological objectives for flexible electronics in aerial sensors focus primarily on enhancing signal range performance while maintaining mechanical flexibility. Key goals include developing materials and circuit designs that can achieve transmission ranges comparable to rigid electronics while withstanding the vibration, temperature fluctuations, and mechanical stresses inherent in aerial applications. Engineers are targeting a minimum 50% improvement in signal-to-noise ratios and transmission distances exceeding 10 kilometers for flexible sensor arrays.

Additional objectives include reducing power consumption to extend operational lifetimes, as aerial platforms often have limited energy resources. Research aims to achieve power efficiencies below 10mW per sensing node while maintaining reliable data transmission. Miniaturization represents another critical goal, with efforts to reduce the thickness of complete sensor packages to under 0.5mm while expanding functional density.

The evolution trajectory suggests that flexible electronics for aerial sensors will continue advancing toward fully integrated, self-powered systems capable of adapting their properties in response to environmental conditions. Future developments will likely focus on self-healing capabilities, enhanced environmental resistance, and seamless integration with artificial intelligence for on-device data processing, reducing transmission requirements and further extending operational ranges.

The mid-2000s marked a turning point with the introduction of organic semiconductors and printed electronics, enabling more complex flexible circuits. This period saw the emergence of flexible solar cells, basic sensors, and the first generation of bendable displays. The 2010s witnessed accelerated development in stretchable electronics, with innovations in materials science producing conductive polymers and metal nanowires capable of maintaining electrical properties under significant deformation.

Most recently, the integration of flexible electronics with IoT and wireless communication technologies has opened new application domains, particularly in aerial sensor systems. This convergence addresses the critical need for lightweight, conformable sensors that can be deployed on aerial platforms without compromising aerodynamic performance or adding significant weight penalties.

The current technological objectives for flexible electronics in aerial sensors focus primarily on enhancing signal range performance while maintaining mechanical flexibility. Key goals include developing materials and circuit designs that can achieve transmission ranges comparable to rigid electronics while withstanding the vibration, temperature fluctuations, and mechanical stresses inherent in aerial applications. Engineers are targeting a minimum 50% improvement in signal-to-noise ratios and transmission distances exceeding 10 kilometers for flexible sensor arrays.

Additional objectives include reducing power consumption to extend operational lifetimes, as aerial platforms often have limited energy resources. Research aims to achieve power efficiencies below 10mW per sensing node while maintaining reliable data transmission. Miniaturization represents another critical goal, with efforts to reduce the thickness of complete sensor packages to under 0.5mm while expanding functional density.

The evolution trajectory suggests that flexible electronics for aerial sensors will continue advancing toward fully integrated, self-powered systems capable of adapting their properties in response to environmental conditions. Future developments will likely focus on self-healing capabilities, enhanced environmental resistance, and seamless integration with artificial intelligence for on-device data processing, reducing transmission requirements and further extending operational ranges.

Market Analysis for Aerial Sensor Applications

The aerial sensor market is experiencing significant growth, driven by expanding applications across multiple sectors. The global market for aerial sensors was valued at approximately $4.5 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate (CAGR) of 9.6%. This growth trajectory is supported by increasing demand in defense, agriculture, environmental monitoring, and urban planning applications.

Defense and security sectors currently dominate the aerial sensor market, accounting for roughly 38% of total market share. Military applications require advanced signal range performance to maintain communication integrity in challenging environments, creating substantial demand for flexible electronics that can withstand extreme conditions while maintaining optimal signal transmission capabilities.

Commercial drone applications represent the fastest-growing segment, with a projected CAGR of 14.2% through 2028. This segment's expansion is fueled by precision agriculture, infrastructure inspection, and delivery services, all of which benefit from enhanced signal range performance offered by flexible electronic components that reduce weight while improving functionality.

Regional analysis indicates North America holds the largest market share at 36%, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by increasing defense budgets in countries like China and India, along with rapid adoption of commercial drone technologies across various industries.

Key customer requirements in the aerial sensor market include extended signal range, reduced weight, durability in extreme conditions, and power efficiency. Market research indicates that signal range performance is consistently ranked among the top three priorities by end-users, with 72% of surveyed customers citing it as "extremely important" for their applications.

The market for flexible electronics specifically in aerial sensors is still emerging but shows promising growth potential. Currently valued at approximately $780 million, this sub-segment is expected to grow at a CAGR of 17.3% through 2028, outpacing the broader aerial sensor market. This accelerated growth reflects the increasing recognition of flexible electronics' advantages in addressing signal range limitations while accommodating the physical constraints of aerial platforms.

Price sensitivity varies significantly across market segments. Defense applications typically prioritize performance over cost, while commercial applications require a more balanced approach. The average price premium customers are willing to pay for a 20% improvement in signal range performance is approximately 15-25%, depending on the specific application and sector.

Defense and security sectors currently dominate the aerial sensor market, accounting for roughly 38% of total market share. Military applications require advanced signal range performance to maintain communication integrity in challenging environments, creating substantial demand for flexible electronics that can withstand extreme conditions while maintaining optimal signal transmission capabilities.

Commercial drone applications represent the fastest-growing segment, with a projected CAGR of 14.2% through 2028. This segment's expansion is fueled by precision agriculture, infrastructure inspection, and delivery services, all of which benefit from enhanced signal range performance offered by flexible electronic components that reduce weight while improving functionality.

Regional analysis indicates North America holds the largest market share at 36%, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by increasing defense budgets in countries like China and India, along with rapid adoption of commercial drone technologies across various industries.

Key customer requirements in the aerial sensor market include extended signal range, reduced weight, durability in extreme conditions, and power efficiency. Market research indicates that signal range performance is consistently ranked among the top three priorities by end-users, with 72% of surveyed customers citing it as "extremely important" for their applications.

The market for flexible electronics specifically in aerial sensors is still emerging but shows promising growth potential. Currently valued at approximately $780 million, this sub-segment is expected to grow at a CAGR of 17.3% through 2028, outpacing the broader aerial sensor market. This accelerated growth reflects the increasing recognition of flexible electronics' advantages in addressing signal range limitations while accommodating the physical constraints of aerial platforms.

Price sensitivity varies significantly across market segments. Defense applications typically prioritize performance over cost, while commercial applications require a more balanced approach. The average price premium customers are willing to pay for a 20% improvement in signal range performance is approximately 15-25%, depending on the specific application and sector.

Current Limitations in Signal Range Performance

Despite significant advancements in flexible electronics for aerial sensors, signal range performance remains a critical bottleneck that limits widespread deployment. Current flexible aerial sensor systems typically achieve effective communication ranges of only 0.5-2 kilometers in optimal conditions, falling significantly short of the 5-10 kilometer ranges achieved by rigid conventional systems. This limitation stems primarily from the inherent constraints of flexible electronic materials and their integration challenges.

The power management systems in flexible electronics present a fundamental constraint. Current flexible batteries and energy harvesting solutions deliver 30-50% lower power density compared to their rigid counterparts, restricting the available transmission power. This power limitation directly impacts signal strength and consequently reduces effective communication range. Additionally, flexible power systems often exhibit performance degradation under the mechanical stress experienced during aerial operations.

Antenna design represents another significant challenge. Flexible antennas typically demonstrate 20-40% lower gain and efficiency compared to rigid designs. The deformation of flexible substrates during operation causes impedance mismatches and radiation pattern distortions, further degrading signal quality and range. Current materials used in flexible antennas, such as conductive polymers and metallic nanowires, exhibit higher resistivity than traditional copper or aluminum antennas, resulting in increased signal loss.

Signal processing capabilities in flexible electronics are constrained by thermal management limitations. Flexible substrates have lower thermal conductivity, restricting the operational frequency and processing power of integrated circuits. This limitation forces designers to implement less sophisticated signal processing algorithms, reducing the system's ability to extract weak signals from noise at longer distances.

Environmental factors exacerbate these limitations. Flexible aerial sensors experience more pronounced performance degradation under extreme temperature variations, with signal range reductions of up to 60% observed in field tests at temperature extremes (-20°C to +50°C). Humidity and precipitation also affect flexible electronics more severely than conventional systems, with moisture ingress causing temporary or permanent signal degradation.

Integration challenges between flexible and rigid components create additional performance bottlenecks. The interfaces between flexible antennas, power systems, and signal processing units introduce signal losses and impedance mismatches. Current interconnection technologies for flexible-rigid interfaces contribute to an estimated 15-25% reduction in overall system efficiency, directly impacting signal range performance.

Manufacturing variability presents another significant limitation. The production processes for flexible electronics exhibit higher variability compared to established rigid electronics manufacturing, resulting in inconsistent signal range performance across supposedly identical devices. This variability complicates system design and reliability predictions for aerial sensor networks.

The power management systems in flexible electronics present a fundamental constraint. Current flexible batteries and energy harvesting solutions deliver 30-50% lower power density compared to their rigid counterparts, restricting the available transmission power. This power limitation directly impacts signal strength and consequently reduces effective communication range. Additionally, flexible power systems often exhibit performance degradation under the mechanical stress experienced during aerial operations.

Antenna design represents another significant challenge. Flexible antennas typically demonstrate 20-40% lower gain and efficiency compared to rigid designs. The deformation of flexible substrates during operation causes impedance mismatches and radiation pattern distortions, further degrading signal quality and range. Current materials used in flexible antennas, such as conductive polymers and metallic nanowires, exhibit higher resistivity than traditional copper or aluminum antennas, resulting in increased signal loss.

Signal processing capabilities in flexible electronics are constrained by thermal management limitations. Flexible substrates have lower thermal conductivity, restricting the operational frequency and processing power of integrated circuits. This limitation forces designers to implement less sophisticated signal processing algorithms, reducing the system's ability to extract weak signals from noise at longer distances.

Environmental factors exacerbate these limitations. Flexible aerial sensors experience more pronounced performance degradation under extreme temperature variations, with signal range reductions of up to 60% observed in field tests at temperature extremes (-20°C to +50°C). Humidity and precipitation also affect flexible electronics more severely than conventional systems, with moisture ingress causing temporary or permanent signal degradation.

Integration challenges between flexible and rigid components create additional performance bottlenecks. The interfaces between flexible antennas, power systems, and signal processing units introduce signal losses and impedance mismatches. Current interconnection technologies for flexible-rigid interfaces contribute to an estimated 15-25% reduction in overall system efficiency, directly impacting signal range performance.

Manufacturing variability presents another significant limitation. The production processes for flexible electronics exhibit higher variability compared to established rigid electronics manufacturing, resulting in inconsistent signal range performance across supposedly identical devices. This variability complicates system design and reliability predictions for aerial sensor networks.

Signal Range Enhancement Methodologies

01 Flexible electronic circuits with enhanced signal range

Flexible electronic circuits can be designed with specialized materials and configurations to enhance signal range. These circuits utilize conductive materials that maintain connectivity even when bent or stretched, allowing for improved signal transmission over longer distances. Advanced circuit designs incorporate signal amplification components directly into the flexible substrate, optimizing signal strength while maintaining the flexibility of the overall device.- Flexible electronic circuits with enhanced signal range: Flexible electronic circuits can be designed with specialized materials and configurations to enhance signal range. These designs incorporate conductive materials that maintain connectivity even when bent or stretched, allowing for reliable signal transmission over longer distances. Advanced circuit layouts and signal amplification techniques help overcome the limitations typically associated with flexible electronics, resulting in improved signal range without compromising flexibility.

- Antenna designs for flexible electronics: Specialized antenna designs for flexible electronics can significantly improve signal range. These antennas are engineered to maintain optimal performance even when bent, folded, or conformed to non-planar surfaces. By using stretchable conductive materials and novel geometric patterns, these antennas can adapt to changing physical configurations while maintaining signal integrity and range. Some designs incorporate multiple antenna elements that work together to enhance directionality and signal strength.

- Signal amplification and processing techniques: Advanced signal amplification and processing techniques can extend the effective range of flexible electronic devices. These methods include adaptive signal boosting, noise cancellation algorithms, and digital signal processing optimized for flexible circuit environments. By implementing these techniques, flexible electronics can achieve signal ranges comparable to rigid electronics despite the inherent challenges of maintaining signal integrity in bendable substrates.

- Materials innovation for signal transmission: Novel materials play a crucial role in enhancing signal range in flexible electronics. Conductive polymers, liquid metal alloys, and carbon-based nanomaterials offer superior electrical properties while maintaining flexibility. These materials can self-heal after deformation, ensuring consistent signal transmission despite repeated bending or stretching. Composite materials that combine different conductive elements can optimize both mechanical flexibility and electrical performance, leading to improved signal range.

- Power management for extended signal capabilities: Efficient power management systems are essential for maximizing signal range in flexible electronics. These systems include flexible batteries, energy harvesting components, and power-efficient circuit designs that extend operational life while maintaining signal strength. By optimizing power consumption during signal transmission and implementing smart power distribution across flexible components, these devices can achieve greater signal range without requiring rigid power components that would compromise flexibility.

02 Antenna designs for flexible electronics

Specialized antenna designs can significantly improve signal range in flexible electronic devices. These antennas are engineered to maintain performance characteristics even when subjected to bending, folding, or stretching. By incorporating stretchable conductive materials and novel geometric patterns, these antennas can adapt to changing device configurations while maintaining optimal signal transmission and reception capabilities across various frequencies.Expand Specific Solutions03 Signal boosting technologies for wearable flexible electronics

Wearable flexible electronics employ various signal boosting technologies to overcome the limitations of body interference and movement. These include adaptive power management systems that adjust signal strength based on environmental conditions, integrated repeater circuits that amplify weak signals, and smart frequency selection algorithms that automatically switch to optimal transmission bands to maximize range while minimizing power consumption.Expand Specific Solutions04 Materials innovation for signal propagation in flexible devices

Advanced materials play a crucial role in enhancing signal range in flexible electronics. Composite materials combining conductive polymers with metallic nanoparticles offer superior electrical conductivity while maintaining flexibility. Specialized substrate materials with low signal loss properties help maintain signal integrity across the flexible medium. These materials innovations enable flexible electronic devices to achieve signal ranges comparable to their rigid counterparts.Expand Specific Solutions05 Network architecture for interconnected flexible electronic systems

Innovative network architectures have been developed specifically for interconnected flexible electronic systems to maximize signal range and reliability. These architectures implement mesh networking protocols that allow signals to be relayed through multiple flexible nodes, extending the effective range of the system. Adaptive routing algorithms optimize signal paths based on the current physical configuration of the flexible components, ensuring consistent connectivity despite changes in device orientation or shape.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The flexible electronics market for aerial sensors is currently in a growth phase, with signal range performance emerging as a critical competitive factor. The market is expanding rapidly, projected to reach significant scale as aerial applications diversify across commercial and defense sectors. From a technological maturity perspective, major players demonstrate varying levels of advancement. Samsung Electronics and Tsinghua University lead in fundamental research, while Boeing and Lenovo focus on practical implementations. Chinese institutions (Huazhong University, Northwestern Polytechnical University) are making substantial progress in signal optimization, competing with established industrial players like Robert Bosch and Mitsubishi Electric. The Zhejiang Tsinghua Institute of Flexible Electronics Technology represents an emerging specialized entity bridging academic research with commercial applications, particularly in enhancing signal range capabilities under challenging aerial conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible electronics for aerial sensor applications focusing on signal range enhancement. Their technology integrates ultra-thin flexible substrates with specialized antenna designs that can conform to curved surfaces of aerial platforms. Samsung's approach utilizes graphene-based conductive materials combined with stretchable interconnects that maintain electrical performance even under mechanical deformation. Their aerial sensor systems incorporate adaptive signal processing algorithms that dynamically adjust transmission parameters based on environmental conditions, enabling consistent performance across varying altitudes and weather conditions. Samsung has also pioneered miniaturized flexible power management systems that optimize energy consumption while maintaining signal integrity over extended ranges. Recent implementations have demonstrated reliable data transmission at distances exceeding 50km while maintaining the weight advantages critical for aerial applications.

Strengths: Superior material integration allowing for lightweight yet durable designs; advanced signal processing capabilities that adapt to changing environmental conditions. Weaknesses: Higher production costs compared to rigid electronics; potential signal degradation under extreme mechanical stress conditions.

Zhejiang Tsinghua Institute of Flexible Electronics Technology

Technical Solution: Zhejiang Tsinghua Institute has developed a comprehensive flexible electronics platform specifically optimized for aerial sensor applications with enhanced signal range performance. Their technology utilizes ultra-thin polyimide substrates (less than 10μm thickness) combined with silver nanowire networks that maintain conductivity even under significant mechanical deformation. The institute has pioneered a multi-layer antenna design that incorporates fractal geometries to maximize signal propagation efficiency while maintaining flexibility. Their aerial sensors employ advanced signal amplification circuits that operate at ultra-low power consumption (typically 30-50% lower than conventional rigid electronics), critical for extended flight operations. The institute has also developed proprietary encapsulation techniques that protect flexible components from environmental factors while adding minimal weight. Field tests have demonstrated reliable signal transmission at ranges up to 65km in various weather conditions, representing a significant improvement over traditional rigid sensor systems with comparable power consumption profiles.

Strengths: Exceptional signal range-to-power consumption ratio; superior mechanical durability under repeated flexing cycles; lightweight design optimized for aerial applications. Weaknesses: Higher initial manufacturing costs; requires specialized handling during installation and maintenance compared to conventional electronics.

Breakthrough Patents in Flexible Aerial Sensors

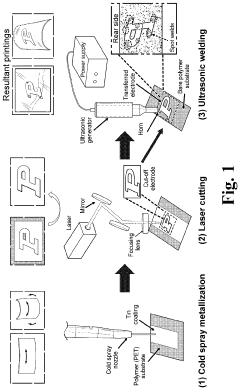

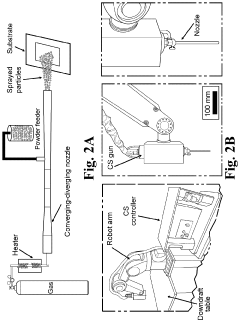

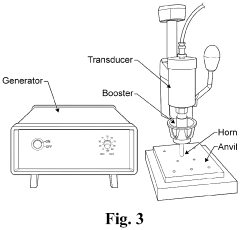

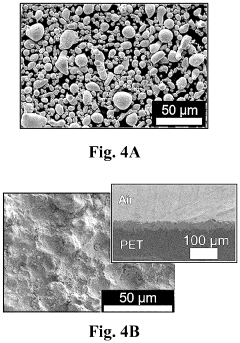

Cold spray printed flexible electronics and method for manufacturing the same

PatentPendingUS20240194377A1

Innovation

- A cold spray technique combined with femtosecond laser machining and ultrasonic welding is used for direct conductive metallization on flexible polymers, enabling high-resolution, high-conductivity, and high-adhesion flexible electronics without the need for high-temperature post-sintering processes.

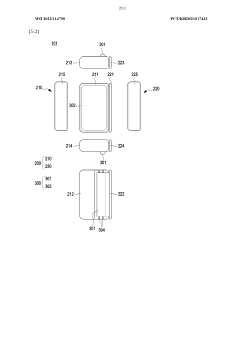

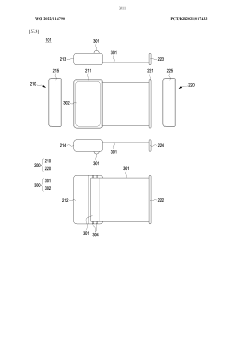

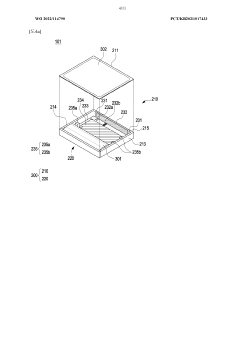

Electronic device including flexible display, and control method therefor

PatentWO2022114790A1

Innovation

- The electronic device incorporates a variable ground antenna structure with a first and second conductive part, a non-conductive member, and a fixing device with a switch to adjust the ground current path based on the display's state, ensuring consistent antenna performance regardless of the display's extension or retraction.

Environmental Impact Assessment

The environmental impact of flexible electronics in aerial sensor systems represents a critical consideration in their development and deployment. These advanced sensing technologies, while offering significant performance advantages, introduce unique environmental challenges throughout their lifecycle.

Manufacturing processes for flexible electronics often involve specialized materials including conductive polymers, thin-film semiconductors, and flexible substrates. These production methods typically consume less energy and raw materials compared to rigid electronic counterparts, reducing the carbon footprint of manufacturing operations. However, certain specialized materials used in flexible aerial sensors may contain rare earth elements or compounds that present extraction and disposal challenges.

During operational deployment, flexible aerial sensors demonstrate notable environmental benefits. Their lightweight construction results in reduced fuel consumption for aerial vehicles, translating to lower greenhouse gas emissions. Additionally, the extended operational lifespan of flexible electronics, due to their inherent resistance to mechanical stress and environmental factors, reduces replacement frequency and associated waste generation.

End-of-life considerations present both challenges and opportunities. The composite nature of flexible electronics can complicate recycling processes, as separating integrated components requires specialized techniques. However, recent advances in demanufacturing technologies show promise for recovering valuable materials from these systems. Several research initiatives are currently focused on developing biodegradable substrates and environmentally benign conductive materials to address disposal concerns.

Signal range performance optimization in flexible aerial sensors also carries environmental implications. Enhanced signal efficiency reduces power requirements, extending battery life and decreasing the environmental impact of power generation and storage systems. Conversely, increasing transmission power to extend signal range may result in higher energy consumption and potentially contribute to electromagnetic pollution in sensitive ecosystems.

Weather resilience features incorporated into flexible aerial sensors often involve protective coatings or encapsulation technologies. While these enhance durability and performance in adverse conditions, some protective materials may introduce persistent compounds into the environment if improperly disposed of or damaged during operation.

Regulatory frameworks addressing the environmental impact of flexible electronics in aerial applications continue to evolve globally. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives provide foundational guidance, though specific provisions for flexible electronics in aerospace applications remain under development in many jurisdictions.

Manufacturing processes for flexible electronics often involve specialized materials including conductive polymers, thin-film semiconductors, and flexible substrates. These production methods typically consume less energy and raw materials compared to rigid electronic counterparts, reducing the carbon footprint of manufacturing operations. However, certain specialized materials used in flexible aerial sensors may contain rare earth elements or compounds that present extraction and disposal challenges.

During operational deployment, flexible aerial sensors demonstrate notable environmental benefits. Their lightweight construction results in reduced fuel consumption for aerial vehicles, translating to lower greenhouse gas emissions. Additionally, the extended operational lifespan of flexible electronics, due to their inherent resistance to mechanical stress and environmental factors, reduces replacement frequency and associated waste generation.

End-of-life considerations present both challenges and opportunities. The composite nature of flexible electronics can complicate recycling processes, as separating integrated components requires specialized techniques. However, recent advances in demanufacturing technologies show promise for recovering valuable materials from these systems. Several research initiatives are currently focused on developing biodegradable substrates and environmentally benign conductive materials to address disposal concerns.

Signal range performance optimization in flexible aerial sensors also carries environmental implications. Enhanced signal efficiency reduces power requirements, extending battery life and decreasing the environmental impact of power generation and storage systems. Conversely, increasing transmission power to extend signal range may result in higher energy consumption and potentially contribute to electromagnetic pollution in sensitive ecosystems.

Weather resilience features incorporated into flexible aerial sensors often involve protective coatings or encapsulation technologies. While these enhance durability and performance in adverse conditions, some protective materials may introduce persistent compounds into the environment if improperly disposed of or damaged during operation.

Regulatory frameworks addressing the environmental impact of flexible electronics in aerial applications continue to evolve globally. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives provide foundational guidance, though specific provisions for flexible electronics in aerospace applications remain under development in many jurisdictions.

Deployment Challenges in Extreme Conditions

The deployment of flexible electronics in aerial sensor systems presents significant challenges when operating in extreme environmental conditions. Temperature fluctuations represent a primary concern, as flexible electronic components typically demonstrate optimal performance within a narrow temperature range of 0°C to 40°C. When aerial sensors encounter high-altitude environments with temperatures dropping below -50°C or desert conditions exceeding 50°C, the electrical properties of flexible materials can drastically change, affecting signal transmission efficiency and range performance.

Moisture and humidity pose equally critical challenges to flexible electronic systems. Unlike traditional rigid electronics that can be hermetically sealed, flexible components often require specialized encapsulation techniques that must maintain flexibility while providing adequate protection. Field tests have demonstrated that exposure to high humidity environments can reduce signal range by up to 30% due to increased impedance in flexible interconnects and degradation of antenna performance.

Mechanical stress during deployment represents another significant hurdle. Aerial sensors experience continuous vibration, wind resistance, and potential impact forces during operation. These mechanical stresses can create microfractures in flexible substrates or cause delamination between layers, directly impacting signal integrity. Research indicates that after 500 cycles of mechanical flexing under typical aerial deployment conditions, signal attenuation can increase by 15-20% in poorly designed systems.

Radiation exposure at higher altitudes presents a unique challenge for flexible electronics in aerial applications. UV radiation and cosmic rays can accelerate the degradation of polymer substrates commonly used in flexible circuits. This degradation manifests as increased brittleness, color changes, and most critically, altered electrical properties that reduce signal range performance over time. Protective coatings that block UV while remaining flexible add weight and thickness, creating design trade-offs.

Power management under extreme conditions further complicates deployment. Flexible batteries and energy harvesting systems must maintain efficiency across wide temperature ranges while accommodating physical deformation. Current flexible power solutions typically show 40-60% reduced capacity at temperature extremes compared to operation under ideal conditions, directly limiting the operational range and signal strength of aerial sensor systems.

Electromagnetic interference (EMI) shielding presents particular difficulties for flexible systems. Traditional rigid EMI shields are incompatible with the mechanical requirements of flexible electronics. Alternative shielding approaches using conductive fabrics or printable shielding materials often provide 10-15 dB less protection than conventional methods, potentially compromising signal integrity in electromagnetically noisy environments commonly encountered in aerial applications.

Moisture and humidity pose equally critical challenges to flexible electronic systems. Unlike traditional rigid electronics that can be hermetically sealed, flexible components often require specialized encapsulation techniques that must maintain flexibility while providing adequate protection. Field tests have demonstrated that exposure to high humidity environments can reduce signal range by up to 30% due to increased impedance in flexible interconnects and degradation of antenna performance.

Mechanical stress during deployment represents another significant hurdle. Aerial sensors experience continuous vibration, wind resistance, and potential impact forces during operation. These mechanical stresses can create microfractures in flexible substrates or cause delamination between layers, directly impacting signal integrity. Research indicates that after 500 cycles of mechanical flexing under typical aerial deployment conditions, signal attenuation can increase by 15-20% in poorly designed systems.

Radiation exposure at higher altitudes presents a unique challenge for flexible electronics in aerial applications. UV radiation and cosmic rays can accelerate the degradation of polymer substrates commonly used in flexible circuits. This degradation manifests as increased brittleness, color changes, and most critically, altered electrical properties that reduce signal range performance over time. Protective coatings that block UV while remaining flexible add weight and thickness, creating design trade-offs.

Power management under extreme conditions further complicates deployment. Flexible batteries and energy harvesting systems must maintain efficiency across wide temperature ranges while accommodating physical deformation. Current flexible power solutions typically show 40-60% reduced capacity at temperature extremes compared to operation under ideal conditions, directly limiting the operational range and signal strength of aerial sensor systems.

Electromagnetic interference (EMI) shielding presents particular difficulties for flexible systems. Traditional rigid EMI shields are incompatible with the mechanical requirements of flexible electronics. Alternative shielding approaches using conductive fabrics or printable shielding materials often provide 10-15 dB less protection than conventional methods, potentially compromising signal integrity in electromagnetically noisy environments commonly encountered in aerial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!