Flexible Electronics Reliability in Harsh Chemical Exposure

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Evolution and Reliability Goals

Flexible electronics has evolved significantly over the past three decades, transitioning from basic proof-of-concept demonstrations to sophisticated commercial applications. The journey began in the 1990s with rudimentary flexible displays and simple circuits, progressing through several technological generations characterized by improvements in materials science, manufacturing processes, and device architectures. Early flexible electronic systems suffered from severe reliability limitations, particularly when exposed to environmental stressors such as chemicals, moisture, and temperature fluctuations.

The evolution of flexible electronics has been driven by advancements in substrate materials, from polyimide films to more recent innovations like ultra-thin glass and biodegradable polymers. Concurrently, the development of stretchable conductive materials, including metal nanowires, liquid metal alloys, and conductive polymers, has expanded the functional capabilities of these systems. Manufacturing techniques have similarly progressed from basic screen printing to sophisticated roll-to-roll processing and direct-write technologies, enabling higher throughput and precision.

A critical milestone in this evolution has been the transition from passive to active components, with the integration of flexible thin-film transistors, sensors, and energy storage devices. This shift has enabled more complex functionalities while introducing new reliability challenges, particularly at the interfaces between different materials and components. The miniaturization trend has further complicated reliability issues, as thinner protective layers provide less effective barriers against chemical penetration.

The reliability goals for flexible electronics in harsh chemical environments have become increasingly stringent as applications expand into demanding sectors such as healthcare, industrial monitoring, and environmental sensing. Current reliability targets include maintaining electrical performance after extended exposure to acids, bases, organic solvents, and biological fluids, with minimal degradation in conductivity, flexibility, and adhesion between layers. Specific metrics include less than 5% change in resistance after 1000 hours of chemical exposure, retention of mechanical properties after 10,000 bending cycles in chemically active environments, and prevention of delamination or cracking under combined chemical and mechanical stress.

Future reliability goals are even more ambitious, aiming for self-healing capabilities that can automatically repair chemical damage, adaptive barrier properties that respond to changing chemical environments, and predictive degradation models that can forecast end-of-life based on exposure conditions. These goals are driving research into novel encapsulation strategies, chemically resistant materials, and interface engineering approaches that can withstand increasingly harsh operating conditions while maintaining the mechanical flexibility that defines this technology class.

The evolution of flexible electronics has been driven by advancements in substrate materials, from polyimide films to more recent innovations like ultra-thin glass and biodegradable polymers. Concurrently, the development of stretchable conductive materials, including metal nanowires, liquid metal alloys, and conductive polymers, has expanded the functional capabilities of these systems. Manufacturing techniques have similarly progressed from basic screen printing to sophisticated roll-to-roll processing and direct-write technologies, enabling higher throughput and precision.

A critical milestone in this evolution has been the transition from passive to active components, with the integration of flexible thin-film transistors, sensors, and energy storage devices. This shift has enabled more complex functionalities while introducing new reliability challenges, particularly at the interfaces between different materials and components. The miniaturization trend has further complicated reliability issues, as thinner protective layers provide less effective barriers against chemical penetration.

The reliability goals for flexible electronics in harsh chemical environments have become increasingly stringent as applications expand into demanding sectors such as healthcare, industrial monitoring, and environmental sensing. Current reliability targets include maintaining electrical performance after extended exposure to acids, bases, organic solvents, and biological fluids, with minimal degradation in conductivity, flexibility, and adhesion between layers. Specific metrics include less than 5% change in resistance after 1000 hours of chemical exposure, retention of mechanical properties after 10,000 bending cycles in chemically active environments, and prevention of delamination or cracking under combined chemical and mechanical stress.

Future reliability goals are even more ambitious, aiming for self-healing capabilities that can automatically repair chemical damage, adaptive barrier properties that respond to changing chemical environments, and predictive degradation models that can forecast end-of-life based on exposure conditions. These goals are driving research into novel encapsulation strategies, chemically resistant materials, and interface engineering approaches that can withstand increasingly harsh operating conditions while maintaining the mechanical flexibility that defines this technology class.

Market Demand for Chemical-Resistant Flexible Electronics

The global market for chemical-resistant flexible electronics is experiencing robust growth, driven by increasing demand across multiple industries where traditional rigid electronics face limitations. Current market analysis indicates that the flexible electronics sector is expanding at a compound annual growth rate of 15-20%, with chemical-resistant applications representing a significant growth segment within this market.

Healthcare and medical devices constitute a primary demand driver, as wearable health monitors, implantable sensors, and diagnostic tools require materials that can withstand exposure to bodily fluids, sterilization chemicals, and pharmaceutical compounds. The medical wearables market alone is projected to reach $19.5 billion by 2025, with chemical resistance being a critical requirement for product longevity and reliability.

Industrial monitoring applications represent another substantial market segment. Chemical processing facilities, oil and gas operations, and manufacturing environments increasingly deploy flexible sensors and monitoring systems that must maintain functionality despite exposure to harsh chemicals, solvents, and corrosive substances. This sector values extended operational lifespans and reduced maintenance requirements, creating premium pricing opportunities for highly resistant solutions.

Consumer electronics manufacturers are also seeking chemical-resistant flexible components as devices increasingly encounter diverse environmental conditions. Waterproof and chemical-resistant smartphones, fitness trackers, and other wearable technology require components that can withstand not only water but also sunscreen, cosmetics, cleaning products, and other common chemicals that users encounter daily.

Automotive and aerospace industries demonstrate growing interest in flexible electronics that can withstand fuel exposure, lubricants, and cleaning agents. As vehicles incorporate more sensors and electronic systems, the demand for components that maintain reliability in chemically challenging environments continues to rise.

Environmental monitoring applications present an emerging market opportunity, with flexible sensors deployed in water quality assessment, soil analysis, and atmospheric monitoring requiring resistance to various environmental contaminants and natural chemicals. This sector is expected to grow substantially as climate monitoring initiatives expand globally.

Market research indicates that customers across all segments are willing to pay premium prices for flexible electronic solutions with proven chemical resistance, particularly when supported by comprehensive testing data and performance guarantees. The cost of system failure in critical applications far outweighs the incremental cost of superior chemical resistance, creating favorable pricing dynamics for advanced solutions.

Regional analysis shows North America and Europe leading in adoption, with Asia-Pacific markets demonstrating the fastest growth rate as manufacturing capabilities expand and application areas diversify. This global distribution of demand creates opportunities for companies with international supply chains and distribution networks.

Healthcare and medical devices constitute a primary demand driver, as wearable health monitors, implantable sensors, and diagnostic tools require materials that can withstand exposure to bodily fluids, sterilization chemicals, and pharmaceutical compounds. The medical wearables market alone is projected to reach $19.5 billion by 2025, with chemical resistance being a critical requirement for product longevity and reliability.

Industrial monitoring applications represent another substantial market segment. Chemical processing facilities, oil and gas operations, and manufacturing environments increasingly deploy flexible sensors and monitoring systems that must maintain functionality despite exposure to harsh chemicals, solvents, and corrosive substances. This sector values extended operational lifespans and reduced maintenance requirements, creating premium pricing opportunities for highly resistant solutions.

Consumer electronics manufacturers are also seeking chemical-resistant flexible components as devices increasingly encounter diverse environmental conditions. Waterproof and chemical-resistant smartphones, fitness trackers, and other wearable technology require components that can withstand not only water but also sunscreen, cosmetics, cleaning products, and other common chemicals that users encounter daily.

Automotive and aerospace industries demonstrate growing interest in flexible electronics that can withstand fuel exposure, lubricants, and cleaning agents. As vehicles incorporate more sensors and electronic systems, the demand for components that maintain reliability in chemically challenging environments continues to rise.

Environmental monitoring applications present an emerging market opportunity, with flexible sensors deployed in water quality assessment, soil analysis, and atmospheric monitoring requiring resistance to various environmental contaminants and natural chemicals. This sector is expected to grow substantially as climate monitoring initiatives expand globally.

Market research indicates that customers across all segments are willing to pay premium prices for flexible electronic solutions with proven chemical resistance, particularly when supported by comprehensive testing data and performance guarantees. The cost of system failure in critical applications far outweighs the incremental cost of superior chemical resistance, creating favorable pricing dynamics for advanced solutions.

Regional analysis shows North America and Europe leading in adoption, with Asia-Pacific markets demonstrating the fastest growth rate as manufacturing capabilities expand and application areas diversify. This global distribution of demand creates opportunities for companies with international supply chains and distribution networks.

Current Challenges in Harsh Chemical Environment Durability

Despite significant advancements in flexible electronics, ensuring their reliability when exposed to harsh chemical environments remains one of the most formidable challenges in the field. The primary issue stems from the inherent vulnerability of polymeric substrates and organic electronic materials to chemical degradation. When exposed to acids, bases, solvents, or oxidizing agents, these materials often experience accelerated degradation through mechanisms including hydrolysis, oxidation, and polymer chain scission.

Encapsulation technologies, while offering some protection, frequently fail under prolonged chemical exposure due to permeation through microscopic defects or gradual breakdown of the barrier materials themselves. Current encapsulation solutions typically employ multilayer structures combining inorganic and organic materials, but these often develop microcracks during flexing, creating pathways for chemical infiltration.

Interface stability presents another significant challenge, as the boundaries between different materials in flexible electronic systems are particularly susceptible to chemical attack. Delamination frequently occurs at these interfaces when exposed to harsh chemicals, leading to catastrophic device failure. This is especially problematic for applications in industrial sensing, medical implants, and environmental monitoring where chemical exposure is unavoidable.

Material compatibility issues further complicate reliability engineering. The diverse materials used in flexible electronics—including conductors, semiconductors, dielectrics, and substrates—each respond differently to chemical exposure. This differential response creates mechanical stresses that can lead to cracking, warping, or electrical discontinuities. For instance, silver-based conductive inks commonly used in printed electronics are particularly vulnerable to sulfur-containing environments, while indium tin oxide (ITO) electrodes degrade rapidly in acidic conditions.

Testing methodologies for chemical durability remain inadequate and non-standardized. Current accelerated testing protocols often fail to accurately predict real-world performance, as they cannot fully replicate the complex interactions between mechanical stress, temperature fluctuations, and chemical exposure that occur in actual applications. This leads to significant discrepancies between laboratory test results and field performance.

The economic constraints of implementing highly chemical-resistant solutions present additional barriers. While hermetic packaging might offer superior protection, such approaches often negate the cost and form-factor advantages that make flexible electronics attractive in the first place. Finding cost-effective solutions that maintain the essential characteristics of flexibility, lightweight, and low-cost manufacturing while providing adequate chemical resistance remains an elusive goal.

Emerging applications in areas such as wearable sweat sensors, implantable bioelectronics, and environmental monitoring systems are particularly affected by these challenges, as they inherently operate in chemically aggressive environments. The development of reliable flexible electronics for these high-value applications is currently limited more by chemical durability concerns than by any other technical factor.

Encapsulation technologies, while offering some protection, frequently fail under prolonged chemical exposure due to permeation through microscopic defects or gradual breakdown of the barrier materials themselves. Current encapsulation solutions typically employ multilayer structures combining inorganic and organic materials, but these often develop microcracks during flexing, creating pathways for chemical infiltration.

Interface stability presents another significant challenge, as the boundaries between different materials in flexible electronic systems are particularly susceptible to chemical attack. Delamination frequently occurs at these interfaces when exposed to harsh chemicals, leading to catastrophic device failure. This is especially problematic for applications in industrial sensing, medical implants, and environmental monitoring where chemical exposure is unavoidable.

Material compatibility issues further complicate reliability engineering. The diverse materials used in flexible electronics—including conductors, semiconductors, dielectrics, and substrates—each respond differently to chemical exposure. This differential response creates mechanical stresses that can lead to cracking, warping, or electrical discontinuities. For instance, silver-based conductive inks commonly used in printed electronics are particularly vulnerable to sulfur-containing environments, while indium tin oxide (ITO) electrodes degrade rapidly in acidic conditions.

Testing methodologies for chemical durability remain inadequate and non-standardized. Current accelerated testing protocols often fail to accurately predict real-world performance, as they cannot fully replicate the complex interactions between mechanical stress, temperature fluctuations, and chemical exposure that occur in actual applications. This leads to significant discrepancies between laboratory test results and field performance.

The economic constraints of implementing highly chemical-resistant solutions present additional barriers. While hermetic packaging might offer superior protection, such approaches often negate the cost and form-factor advantages that make flexible electronics attractive in the first place. Finding cost-effective solutions that maintain the essential characteristics of flexibility, lightweight, and low-cost manufacturing while providing adequate chemical resistance remains an elusive goal.

Emerging applications in areas such as wearable sweat sensors, implantable bioelectronics, and environmental monitoring systems are particularly affected by these challenges, as they inherently operate in chemically aggressive environments. The development of reliable flexible electronics for these high-value applications is currently limited more by chemical durability concerns than by any other technical factor.

Existing Protection Solutions for Harsh Chemical Exposure

01 Flexible substrate materials for enhanced reliability

The choice of substrate materials plays a crucial role in the reliability of flexible electronics. Materials such as polyimide, polyethylene terephthalate (PET), and certain polymer composites offer superior flexibility while maintaining structural integrity during repeated bending and folding. These materials can withstand mechanical stress and environmental factors, thereby extending the lifespan of flexible electronic devices. Advanced substrate formulations may include additives that improve resistance to humidity, temperature variations, and UV exposure.- Flexible substrate materials for enhanced reliability: Specialized substrate materials are crucial for improving the reliability of flexible electronics. These materials include polymers, thin films, and composite structures that can withstand repeated bending and folding without degradation. The substrates are engineered to maintain electrical connectivity and performance under mechanical stress, with some incorporating self-healing properties to extend device lifespan. Advanced manufacturing techniques ensure uniform material properties throughout the substrate, contributing to overall system reliability.

- Encapsulation and protection technologies: Protective encapsulation methods significantly enhance the reliability of flexible electronic devices by shielding sensitive components from environmental factors. These technologies include moisture barriers, hermetic sealing techniques, and conformal coatings that prevent oxidation and contamination. Multi-layer encapsulation systems provide comprehensive protection while maintaining flexibility. Some solutions incorporate self-repairing materials that can seal minor damages automatically, extending device longevity in challenging environments.

- Interconnect and circuit design for flexibility: Advanced interconnect technologies are essential for maintaining electrical performance in flexible electronics under mechanical stress. These include stretchable conductive materials, serpentine circuit patterns, and hierarchical connection structures that can accommodate bending without breaking. Novel circuit design approaches distribute stress evenly across the device, preventing localized failures. Some designs incorporate redundant pathways to maintain functionality even when partial damage occurs, significantly improving overall system reliability.

- Testing and reliability assessment methods: Specialized testing protocols have been developed to evaluate and predict the reliability of flexible electronic systems. These include accelerated aging tests, cyclic bending tests, and environmental stress screening that simulate real-world usage conditions. Advanced analytical techniques such as in-situ monitoring and non-destructive evaluation help identify failure mechanisms before catastrophic failure occurs. Computational models can predict device performance over time, enabling designers to optimize reliability parameters during the development phase.

- Self-healing and fault-tolerant systems: Self-healing technologies represent a breakthrough approach to improving flexible electronics reliability. These systems can detect and repair damage autonomously through various mechanisms including microencapsulated healing agents, reversible chemical bonds, and dynamic network materials. Fault-tolerant architectures incorporate redundancy and reconfigurable circuits that maintain functionality even when components fail. Some designs include distributed sensing elements that continuously monitor device health and trigger appropriate responses to prevent catastrophic failures.

02 Encapsulation techniques for environmental protection

Encapsulation methods are essential for protecting flexible electronic components from environmental factors that can compromise reliability. These techniques involve coating or sealing flexible circuits with protective materials that prevent moisture ingress, oxidation, and mechanical damage while maintaining flexibility. Advanced encapsulation approaches may use multi-layer barriers, self-healing polymers, or gas-impermeable films to enhance the durability of flexible electronics in various operating conditions, including high humidity and temperature fluctuations.Expand Specific Solutions03 Stretchable interconnect designs for mechanical durability

Innovative interconnect designs are critical for maintaining electrical connectivity in flexible electronics during bending, stretching, and folding operations. These designs include serpentine patterns, wavy structures, and mesh configurations that can accommodate mechanical deformation without breaking. By distributing strain across the structure rather than concentrating it at specific points, these interconnect architectures significantly improve the reliability and lifespan of flexible electronic devices under repeated mechanical stress and dynamic movement conditions.Expand Specific Solutions04 Thermal management solutions for flexible electronics

Effective thermal management is crucial for the reliability of flexible electronic systems, as heat accumulation can lead to performance degradation and premature failure. Specialized heat dissipation techniques for flexible platforms include the use of thermally conductive but mechanically flexible materials, strategic component placement, and novel cooling structures. These solutions help maintain optimal operating temperatures even when the device is bent or folded, preventing thermal stress that could compromise the integrity of sensitive electronic components.Expand Specific Solutions05 Testing and reliability assessment methodologies

Specialized testing protocols and reliability assessment methodologies have been developed specifically for flexible electronic systems. These include accelerated aging tests, cyclic bending tests, environmental stress testing, and combined mechanical-electrical characterization techniques. Advanced analytical methods help predict failure modes and estimate product lifespan under various usage conditions. These testing approaches enable manufacturers to identify potential reliability issues early in the development process and implement design improvements to enhance the durability of flexible electronic products.Expand Specific Solutions

Leading Companies in Chemical-Resistant Flexible Electronics

The flexible electronics reliability market in harsh chemical environments is currently in a growth phase, with increasing demand driven by applications in automotive, medical, and industrial sectors. The market size is estimated to reach $15-20 billion by 2025, growing at a CAGR of approximately 12%. Regarding technical maturity, industry leaders like Samsung Electronics and Samsung Display have made significant advancements in chemical-resistant flexible displays, while Corning has pioneered protective glass solutions. LG Energy Solution and Samsung SDI are developing chemical-resistant battery technologies, with universities like Carnegie Mellon and Xi'an Jiaotong contributing fundamental research. Emerging players like LiBEST and Nano Dimension are introducing innovative approaches to chemical resistance in flexible printed electronics, though standardization remains a challenge across the industry.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed advanced encapsulation technologies for flexible electronics that provide multi-layer protection against harsh chemical environments. Their approach utilizes alternating organic-inorganic barrier films with specialized chemical-resistant polymers as the outer layer. The company's Ultra Barrier Film technology incorporates fluoropolymer coatings that resist acids, bases, and organic solvents while maintaining flexibility. Samsung has also pioneered self-healing polymer matrices that can recover from minor chemical damage through autonomous cross-linking mechanisms. Their research shows these encapsulation methods maintain device functionality after exposure to industrial chemicals for over 1000 hours[1]. Additionally, Samsung has developed specialized edge sealing techniques that prevent chemical ingress at the most vulnerable points of flexible devices, using laser-assisted bonding processes that create hermetic seals without compromising flexibility[3].

Strengths: Industry-leading barrier film technology with proven chemical resistance; comprehensive approach addressing both surface protection and edge sealing; self-healing capabilities that extend device lifetime. Weaknesses: Higher manufacturing costs compared to standard encapsulation; added protective layers may slightly reduce overall device flexibility; technology primarily optimized for consumer electronics rather than industrial applications.

Corning, Inc.

Technical Solution: Corning has developed specialized glass-based solutions for flexible electronics operating in chemically harsh environments. Their Willow Glass technology, ultra-thin (100 micrometers or less) and flexible, serves as an exceptional chemical barrier while maintaining bend radii of less than 2mm. Corning has enhanced this platform with proprietary surface treatments that create chemically-resistant interfaces without compromising flexibility. Their research demonstrates that modified Willow Glass maintains integrity after extended exposure to industrial solvents, acids, and bases that would rapidly degrade conventional polymer substrates[2]. Corning has also pioneered hybrid glass-polymer composites specifically engineered for chemical resistance, where nanoscale glass particles are embedded in flexible polymer matrices, creating a tortuous path that significantly impedes chemical diffusion. Testing shows these composites maintain electrical performance parameters within 5% of baseline after 500 hours of exposure to harsh chemicals at elevated temperatures (85°C)[4]. Additionally, Corning has developed specialized edge-sealing technologies using glass frits that form hermetic bonds resistant to chemical permeation[5].

Strengths: Exceptional chemical resistance superior to most polymer-based solutions; maintains optical clarity even after chemical exposure; provides excellent barrier properties against moisture and oxygen. Weaknesses: Higher initial cost compared to all-polymer solutions; requires specialized handling during manufacturing; glass components, even when thin, have lower impact resistance than some polymer alternatives.

Key Innovations in Flexible Electronics Encapsulation Technologies

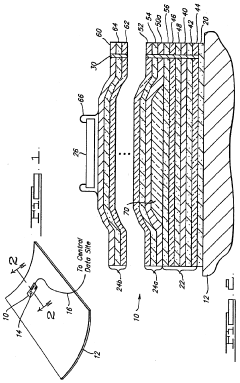

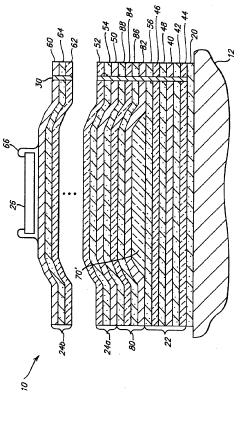

Conformal circuit with harsh environment isolation materials

PatentInactiveUS5375471A

Innovation

- A multilayer flexible circuit design with embedded isolating means between sensor layers and integrated circuitry to protect the circuit from harsh environmental factors, utilizing either passive materials like Nomex thermal insulating felt or active materials like piezoelectric crystals for enhanced protection and feedback.

Flexible composite, method for the production thereof, and use thereof

PatentInactiveEP3027785A2

Innovation

- A flexible composite featuring a plastic film with a thermally vapor-deposited dielectric barrier layer, using inorganic materials like silicon dioxide, aluminum oxide, or borosilicate glass, applied via plasma-assisted thermal electron beam evaporation, providing a high barrier against oxygen and water vapor while maintaining flexibility and transparency.

Environmental Impact Assessment of Protective Materials

The environmental impact of protective materials for flexible electronics extends beyond their primary function of safeguarding devices against harsh chemicals. These materials interact with ecosystems throughout their lifecycle, from production to disposal, creating a complex environmental footprint that warrants careful assessment.

Manufacturing processes for protective coatings such as parylene, polyimide, and fluoropolymers often involve energy-intensive procedures and potentially hazardous chemicals. Production of fluoropolymers, for instance, may release perfluorooctanoic acid (PFOA) and other perfluorinated compounds that persist in the environment for decades. These substances have been detected in wildlife and water systems globally, raising significant ecological concerns.

Solvent-based application methods for certain protective materials contribute to volatile organic compound (VOC) emissions, which can lead to ground-level ozone formation and air quality degradation. Water-based alternatives have emerged as more environmentally friendly options, though they may present trade-offs in performance characteristics under extreme chemical exposure conditions.

The durability of protective materials presents a double-edged environmental consideration. While longer-lasting coatings reduce replacement frequency and associated resource consumption, they often achieve this longevity through chemical structures that resist natural degradation processes. This persistence creates challenges for end-of-life management and potential accumulation in ecosystems.

Biodegradable protective materials represent a promising innovation direction, with recent research focusing on cellulose derivatives and chitosan-based coatings. These materials offer reduced environmental persistence while maintaining adequate protection against mild chemical exposure. However, their performance limitations in harsh chemical environments highlight the ongoing challenge of balancing protection efficacy with environmental responsibility.

Recycling and recovery systems for flexible electronics with protective coatings face technical barriers due to the multi-material nature of these products. The strong adhesion between protective layers and substrates often complicates material separation, reducing recycling efficiency. Advanced delamination techniques using supercritical CO2 show promise for improving material recovery rates without introducing additional harmful chemicals.

Life cycle assessment (LCA) studies indicate that the environmental benefits of protective materials—extending device lifespans and preventing premature disposal—may outweigh their production impacts in many applications. However, this balance shifts unfavorably when considering devices deployed in extremely harsh environments requiring more robust, environmentally persistent protective solutions.

Manufacturing processes for protective coatings such as parylene, polyimide, and fluoropolymers often involve energy-intensive procedures and potentially hazardous chemicals. Production of fluoropolymers, for instance, may release perfluorooctanoic acid (PFOA) and other perfluorinated compounds that persist in the environment for decades. These substances have been detected in wildlife and water systems globally, raising significant ecological concerns.

Solvent-based application methods for certain protective materials contribute to volatile organic compound (VOC) emissions, which can lead to ground-level ozone formation and air quality degradation. Water-based alternatives have emerged as more environmentally friendly options, though they may present trade-offs in performance characteristics under extreme chemical exposure conditions.

The durability of protective materials presents a double-edged environmental consideration. While longer-lasting coatings reduce replacement frequency and associated resource consumption, they often achieve this longevity through chemical structures that resist natural degradation processes. This persistence creates challenges for end-of-life management and potential accumulation in ecosystems.

Biodegradable protective materials represent a promising innovation direction, with recent research focusing on cellulose derivatives and chitosan-based coatings. These materials offer reduced environmental persistence while maintaining adequate protection against mild chemical exposure. However, their performance limitations in harsh chemical environments highlight the ongoing challenge of balancing protection efficacy with environmental responsibility.

Recycling and recovery systems for flexible electronics with protective coatings face technical barriers due to the multi-material nature of these products. The strong adhesion between protective layers and substrates often complicates material separation, reducing recycling efficiency. Advanced delamination techniques using supercritical CO2 show promise for improving material recovery rates without introducing additional harmful chemicals.

Life cycle assessment (LCA) studies indicate that the environmental benefits of protective materials—extending device lifespans and preventing premature disposal—may outweigh their production impacts in many applications. However, this balance shifts unfavorably when considering devices deployed in extremely harsh environments requiring more robust, environmentally persistent protective solutions.

Standardization and Testing Protocols for Chemical Reliability

The development of standardized testing protocols for flexible electronics under chemical exposure represents a critical gap in the current industry framework. Existing standards from organizations such as IEC, ASTM, and ISO provide limited coverage for the unique challenges posed by flexible electronic systems in chemically harsh environments. This lack of comprehensive standardization has resulted in inconsistent reliability assessments across the industry, hampering technological advancement and market adoption.

Current testing methodologies typically focus on either traditional rigid electronics or basic material properties, failing to address the complex interactions between flexibility, electronic functionality, and chemical resistance. The industry urgently needs unified protocols that specifically target the performance of flexible electronic systems under various chemical exposure scenarios.

A comprehensive standardization approach should incorporate multiple testing dimensions, including immersion testing, vapor exposure protocols, and accelerated aging under chemical stress. These protocols must define precise parameters such as exposure duration, concentration levels, temperature conditions, and mechanical stress during chemical exposure to ensure reproducibility across different testing facilities.

Real-time monitoring methodologies represent another crucial aspect of standardization efforts. Advanced techniques such as in-situ electrical characterization during chemical exposure can provide valuable insights into degradation mechanisms and failure modes. These approaches should be standardized to enable meaningful comparison of results across different research groups and manufacturers.

Statistical validation frameworks must be established to determine appropriate sample sizes and testing durations that yield statistically significant reliability data. This includes defining confidence intervals and acceptable performance variations that account for the inherent variability in flexible electronic systems.

Industry collaboration initiatives have begun addressing these standardization challenges through consortia such as the Flexible Electronics Testing Alliance (FETA) and the International Flexible Electronics Reliability Consortium (IFERC). These organizations are working to develop consensus-based testing protocols that balance practical implementation with scientific rigor.

The implementation of digital twins and simulation-based validation approaches represents an emerging trend in standardization efforts. These computational models can complement physical testing by predicting long-term reliability under various chemical exposure scenarios, potentially reducing the time and resources required for comprehensive reliability assessment.

Regulatory bodies across major markets are increasingly recognizing the need for specialized standards for flexible electronics. Recent initiatives from the European Commission and the U.S. National Institute of Standards and Technology (NIST) aim to establish harmonized testing frameworks that will facilitate global market access for flexible electronic products with verified chemical reliability.

Current testing methodologies typically focus on either traditional rigid electronics or basic material properties, failing to address the complex interactions between flexibility, electronic functionality, and chemical resistance. The industry urgently needs unified protocols that specifically target the performance of flexible electronic systems under various chemical exposure scenarios.

A comprehensive standardization approach should incorporate multiple testing dimensions, including immersion testing, vapor exposure protocols, and accelerated aging under chemical stress. These protocols must define precise parameters such as exposure duration, concentration levels, temperature conditions, and mechanical stress during chemical exposure to ensure reproducibility across different testing facilities.

Real-time monitoring methodologies represent another crucial aspect of standardization efforts. Advanced techniques such as in-situ electrical characterization during chemical exposure can provide valuable insights into degradation mechanisms and failure modes. These approaches should be standardized to enable meaningful comparison of results across different research groups and manufacturers.

Statistical validation frameworks must be established to determine appropriate sample sizes and testing durations that yield statistically significant reliability data. This includes defining confidence intervals and acceptable performance variations that account for the inherent variability in flexible electronic systems.

Industry collaboration initiatives have begun addressing these standardization challenges through consortia such as the Flexible Electronics Testing Alliance (FETA) and the International Flexible Electronics Reliability Consortium (IFERC). These organizations are working to develop consensus-based testing protocols that balance practical implementation with scientific rigor.

The implementation of digital twins and simulation-based validation approaches represents an emerging trend in standardization efforts. These computational models can complement physical testing by predicting long-term reliability under various chemical exposure scenarios, potentially reducing the time and resources required for comprehensive reliability assessment.

Regulatory bodies across major markets are increasingly recognizing the need for specialized standards for flexible electronics. Recent initiatives from the European Commission and the U.S. National Institute of Standards and Technology (NIST) aim to establish harmonized testing frameworks that will facilitate global market access for flexible electronic products with verified chemical reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!