Flexible Electronics Vs Advanced Polymer Films: Performance Lifeline

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Evolution and Objectives

Flexible electronics represents a revolutionary shift in electronic device architecture, evolving from rigid silicon-based components to malleable systems capable of bending, stretching, and conforming to non-planar surfaces. This technological trajectory began in the 1960s with the development of thin-film transistors, but gained significant momentum in the early 2000s when researchers successfully demonstrated functional electronic circuits on flexible substrates.

The evolution of flexible electronics has been characterized by several distinct phases. Initially, the focus was on creating basic flexible displays and simple sensing elements. This progressed to the development of more complex integrated circuits on flexible substrates, followed by the current phase emphasizing complete flexible electronic systems with enhanced functionality and reliability.

Advanced polymer films have played a pivotal role in this evolution, transitioning from passive substrates to active components that directly influence device performance. The symbiotic relationship between flexible electronics and polymer film technology has accelerated innovation in both fields, with improvements in one domain catalyzing advancements in the other.

The primary objectives driving flexible electronics development include achieving mechanical robustness under repeated deformation cycles, maintaining electrical performance stability during bending and stretching, and extending operational lifetimes under various environmental conditions. These objectives directly address the fundamental challenge of balancing flexibility with functionality – a persistent tension in the field.

Current research aims to develop flexible electronic systems that can withstand thousands of bending cycles without performance degradation, operate reliably in diverse environments including high humidity and temperature fluctuations, and maintain stable electrical characteristics despite mechanical stress. The performance lifeline of these devices is increasingly dependent on the properties of their polymer film components.

Looking forward, the field is moving toward bio-integrated electronics, energy-autonomous flexible systems, and large-area flexible electronics for smart infrastructure. These applications demand unprecedented levels of mechanical compliance, environmental stability, and operational longevity from both the electronic components and their polymer substrates.

The convergence of nanotechnology, materials science, and electronic engineering continues to push the boundaries of what's possible in flexible electronics. Emerging techniques such as direct-write fabrication, solution processing, and hybrid integration are enabling new device architectures that were previously unattainable, further expanding the application landscape for this transformative technology.

The evolution of flexible electronics has been characterized by several distinct phases. Initially, the focus was on creating basic flexible displays and simple sensing elements. This progressed to the development of more complex integrated circuits on flexible substrates, followed by the current phase emphasizing complete flexible electronic systems with enhanced functionality and reliability.

Advanced polymer films have played a pivotal role in this evolution, transitioning from passive substrates to active components that directly influence device performance. The symbiotic relationship between flexible electronics and polymer film technology has accelerated innovation in both fields, with improvements in one domain catalyzing advancements in the other.

The primary objectives driving flexible electronics development include achieving mechanical robustness under repeated deformation cycles, maintaining electrical performance stability during bending and stretching, and extending operational lifetimes under various environmental conditions. These objectives directly address the fundamental challenge of balancing flexibility with functionality – a persistent tension in the field.

Current research aims to develop flexible electronic systems that can withstand thousands of bending cycles without performance degradation, operate reliably in diverse environments including high humidity and temperature fluctuations, and maintain stable electrical characteristics despite mechanical stress. The performance lifeline of these devices is increasingly dependent on the properties of their polymer film components.

Looking forward, the field is moving toward bio-integrated electronics, energy-autonomous flexible systems, and large-area flexible electronics for smart infrastructure. These applications demand unprecedented levels of mechanical compliance, environmental stability, and operational longevity from both the electronic components and their polymer substrates.

The convergence of nanotechnology, materials science, and electronic engineering continues to push the boundaries of what's possible in flexible electronics. Emerging techniques such as direct-write fabrication, solution processing, and hybrid integration are enabling new device architectures that were previously unattainable, further expanding the application landscape for this transformative technology.

Market Analysis for Flexible Electronic Applications

The flexible electronics market has experienced remarkable growth over the past decade, expanding from a niche technology to a significant industry segment. Current market valuations place the global flexible electronics sector at approximately $42 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 11-13% through 2030. This growth trajectory significantly outpaces traditional rigid electronics markets, which typically see 3-5% annual growth.

Consumer electronics represents the largest application segment, accounting for roughly 38% of the flexible electronics market. Wearable devices, particularly health monitoring systems and smart watches, have emerged as primary drivers within this segment. The healthcare sector follows closely, with medical devices incorporating flexible electronic components growing at nearly 15% annually, driven by demand for non-invasive monitoring solutions and smart bandages.

Advanced polymer films serve as critical enabling materials for flexible electronics, with the market for specialized polymer substrates reaching $3.8 billion in 2023. Polyimide continues to dominate with approximately 45% market share due to its excellent thermal stability and mechanical properties, though newer materials like polyethylene naphthalate (PEN) and polyethylene terephthalate (PET) are gaining traction in less demanding applications.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for over 60% of global production capacity. South Korea, Japan, and Taiwan lead in display technologies, while China has rapidly expanded its manufacturing capabilities across multiple application areas. North America and Europe maintain competitive advantages in specialized applications and materials innovation, particularly in medical devices and automotive implementations.

Market challenges include price sensitivity, as flexible electronics typically command a 30-40% premium over rigid alternatives. This price differential has limited penetration in cost-sensitive consumer segments. Additionally, performance longevity remains a significant concern, with flexible devices typically demonstrating 30-50% shorter operational lifespans than their rigid counterparts.

Future market expansion will likely be driven by emerging applications in energy harvesting (particularly flexible photovoltaics), automotive interfaces, and smart packaging. The integration of flexible electronics with Internet of Things (IoT) infrastructure presents particularly promising growth opportunities, with market forecasts suggesting this convergence could generate an additional $15 billion in market value by 2028.

Consumer electronics represents the largest application segment, accounting for roughly 38% of the flexible electronics market. Wearable devices, particularly health monitoring systems and smart watches, have emerged as primary drivers within this segment. The healthcare sector follows closely, with medical devices incorporating flexible electronic components growing at nearly 15% annually, driven by demand for non-invasive monitoring solutions and smart bandages.

Advanced polymer films serve as critical enabling materials for flexible electronics, with the market for specialized polymer substrates reaching $3.8 billion in 2023. Polyimide continues to dominate with approximately 45% market share due to its excellent thermal stability and mechanical properties, though newer materials like polyethylene naphthalate (PEN) and polyethylene terephthalate (PET) are gaining traction in less demanding applications.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for over 60% of global production capacity. South Korea, Japan, and Taiwan lead in display technologies, while China has rapidly expanded its manufacturing capabilities across multiple application areas. North America and Europe maintain competitive advantages in specialized applications and materials innovation, particularly in medical devices and automotive implementations.

Market challenges include price sensitivity, as flexible electronics typically command a 30-40% premium over rigid alternatives. This price differential has limited penetration in cost-sensitive consumer segments. Additionally, performance longevity remains a significant concern, with flexible devices typically demonstrating 30-50% shorter operational lifespans than their rigid counterparts.

Future market expansion will likely be driven by emerging applications in energy harvesting (particularly flexible photovoltaics), automotive interfaces, and smart packaging. The integration of flexible electronics with Internet of Things (IoT) infrastructure presents particularly promising growth opportunities, with market forecasts suggesting this convergence could generate an additional $15 billion in market value by 2028.

Current Challenges in Polymer Film Technology

Despite significant advancements in polymer film technology, several critical challenges continue to impede the full realization of flexible electronics potential. The foremost challenge lies in achieving optimal balance between flexibility and durability. Current polymer films often demonstrate a trade-off relationship where increased flexibility typically results in compromised mechanical strength and vice versa, creating a fundamental engineering dilemma for applications requiring both properties simultaneously.

Thermal stability presents another significant hurdle. Many polymer films exhibit performance degradation when exposed to elevated temperatures during manufacturing processes or operational conditions. This thermal vulnerability limits their application in high-temperature environments and complicates integration with traditional electronic components that generate substantial heat during operation.

Barrier properties constitute a persistent technical obstacle. Polymer films generally demonstrate inferior oxygen and moisture barrier capabilities compared to traditional rigid substrates like glass. This permeability accelerates oxidation of sensitive electronic components, substantially reducing device lifespan, particularly in organic electronics where exposure to environmental elements can rapidly degrade performance.

Manufacturing scalability remains problematic. While laboratory-scale production of high-performance polymer films has shown promising results, transitioning to cost-effective mass production while maintaining consistent quality presents significant challenges. Current manufacturing processes often introduce defects, thickness variations, and structural inconsistencies that compromise performance reliability.

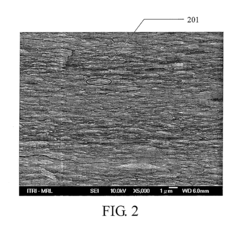

Surface roughness and dimensional stability issues further complicate integration with electronic components. Many polymer films exhibit micro-scale surface irregularities and dimensional changes under varying environmental conditions, creating difficulties in achieving precise patterning and reliable electrical connections necessary for complex electronic circuits.

Adhesion between polymer films and deposited electronic materials represents another technical barrier. Poor interfacial bonding leads to delamination during flexing cycles, creating electrical discontinuities and device failure. Current adhesion promotion techniques often involve chemical treatments that may compromise other film properties.

Long-term reliability under repeated mechanical stress constitutes perhaps the most significant challenge. Polymer films typically demonstrate performance degradation after multiple bending cycles, with microscopic crack formation and propagation leading to electrical pathway disruption. This fatigue behavior severely limits practical application lifespans in devices requiring frequent flexing.

Additionally, environmental stability concerns persist, as many advanced polymer films remain susceptible to UV degradation, chemical exposure, and humidity-induced property changes, necessitating protective encapsulation that often compromises flexibility and adds manufacturing complexity.

Thermal stability presents another significant hurdle. Many polymer films exhibit performance degradation when exposed to elevated temperatures during manufacturing processes or operational conditions. This thermal vulnerability limits their application in high-temperature environments and complicates integration with traditional electronic components that generate substantial heat during operation.

Barrier properties constitute a persistent technical obstacle. Polymer films generally demonstrate inferior oxygen and moisture barrier capabilities compared to traditional rigid substrates like glass. This permeability accelerates oxidation of sensitive electronic components, substantially reducing device lifespan, particularly in organic electronics where exposure to environmental elements can rapidly degrade performance.

Manufacturing scalability remains problematic. While laboratory-scale production of high-performance polymer films has shown promising results, transitioning to cost-effective mass production while maintaining consistent quality presents significant challenges. Current manufacturing processes often introduce defects, thickness variations, and structural inconsistencies that compromise performance reliability.

Surface roughness and dimensional stability issues further complicate integration with electronic components. Many polymer films exhibit micro-scale surface irregularities and dimensional changes under varying environmental conditions, creating difficulties in achieving precise patterning and reliable electrical connections necessary for complex electronic circuits.

Adhesion between polymer films and deposited electronic materials represents another technical barrier. Poor interfacial bonding leads to delamination during flexing cycles, creating electrical discontinuities and device failure. Current adhesion promotion techniques often involve chemical treatments that may compromise other film properties.

Long-term reliability under repeated mechanical stress constitutes perhaps the most significant challenge. Polymer films typically demonstrate performance degradation after multiple bending cycles, with microscopic crack formation and propagation leading to electrical pathway disruption. This fatigue behavior severely limits practical application lifespans in devices requiring frequent flexing.

Additionally, environmental stability concerns persist, as many advanced polymer films remain susceptible to UV degradation, chemical exposure, and humidity-induced property changes, necessitating protective encapsulation that often compromises flexibility and adds manufacturing complexity.

Polymer Film Solutions for Flexible Electronics

01 Flexible electronic devices with polymer substrates

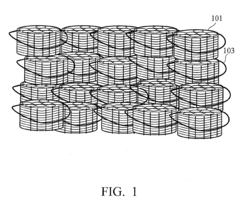

Flexible electronic devices utilize advanced polymer films as substrates to enable bendability and conformability. These polymer substrates provide mechanical flexibility while maintaining electronic functionality, allowing for applications in wearable technology, medical devices, and consumer electronics. The polymer films serve as a foundation for mounting electronic components and circuits, creating devices that can adapt to various shapes and surfaces.- Flexible electronic devices with polymer substrates: Flexible electronic devices utilize advanced polymer films as substrates to enable bendability and conformability while maintaining electronic functionality. These polymer substrates provide mechanical support while allowing the device to flex, bend, or stretch without compromising performance. The integration of electronic components on these flexible substrates enables applications in wearable technology, medical devices, and portable electronics where traditional rigid electronics would be unsuitable.

- Advanced polymer films for medical and healthcare applications: Advanced polymer films are utilized in medical and healthcare applications to create flexible, biocompatible devices that can interface with the human body. These films serve as substrates for biosensors, drug delivery systems, and monitoring devices that conform to body contours. The polymer materials are engineered to be biocompatible, maintain performance in physiological conditions, and provide reliable functionality for extended periods, enhancing patient comfort and treatment efficacy.

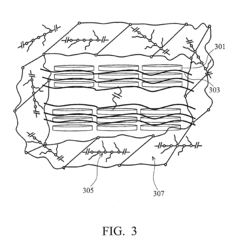

- Durability and performance enhancement of polymer films: Various techniques are employed to enhance the durability and performance of polymer films used in flexible electronics. These include surface treatments, addition of reinforcing materials, and specialized coating processes that improve resistance to environmental factors, mechanical stress, and repeated flexing. Enhanced polymer films demonstrate improved barrier properties against moisture and oxygen, increased thermal stability, and better adhesion to electronic components, extending the operational lifetime of flexible electronic devices.

- Manufacturing processes for flexible electronic systems: Specialized manufacturing processes have been developed for integrating electronic components with flexible polymer films. These include roll-to-roll processing, direct printing of electronic circuits on polymer substrates, and novel bonding techniques that maintain flexibility while ensuring reliable electrical connections. These manufacturing approaches enable mass production of flexible electronic systems with consistent performance characteristics while minimizing production costs and material waste.

- Smart polymer films with integrated sensing capabilities: Advanced polymer films can be engineered with integrated sensing capabilities to create smart materials that respond to environmental stimuli. These films incorporate conductive elements, piezoelectric materials, or other functional components that enable detection of pressure, temperature, chemical exposure, or mechanical deformation. The sensing capabilities are maintained even when the film is flexed or stretched, allowing for applications in structural health monitoring, smart packaging, and interactive consumer products.

02 Polymer films for medical and healthcare applications

Advanced polymer films are utilized in medical and healthcare applications to create flexible, biocompatible devices. These films enable the development of wearable health monitors, implantable electronics, and therapeutic devices that conform to body contours. The polymer materials provide essential properties such as biocompatibility, durability, and flexibility needed for extended contact with the human body while maintaining electronic performance.Expand Specific Solutions03 Conductive polymer composites for flexible circuits

Conductive polymer composites combine the flexibility of polymers with electrical conductivity needed for flexible electronics. These materials incorporate conductive elements such as carbon nanotubes, metallic nanoparticles, or conductive polymers into flexible film matrices. The resulting composites enable the creation of stretchable circuits, sensors, and interconnects that maintain electrical performance even when bent or stretched, extending the lifetime and reliability of flexible electronic systems.Expand Specific Solutions04 Environmental protection and durability enhancements

Advanced polymer films provide critical environmental protection for flexible electronic components, shielding them from moisture, oxygen, and mechanical damage. These protective layers extend the operational lifetime of flexible electronics by preventing degradation of sensitive components. Specialized barrier films with multiple layers can achieve ultra-low permeation rates while maintaining flexibility, ensuring long-term performance reliability in various environmental conditions.Expand Specific Solutions05 Manufacturing techniques for flexible polymer electronics

Innovative manufacturing techniques enable the production of high-performance flexible electronics using advanced polymer films. These methods include roll-to-roll processing, direct printing of electronic components onto polymer substrates, and laser patterning. Such manufacturing approaches allow for cost-effective mass production of flexible electronic devices while maintaining precise control over material properties and device performance, creating a sustainable production lifeline for next-generation electronics.Expand Specific Solutions

Leading Companies in Flexible Electronics Industry

The flexible electronics market is experiencing rapid growth, positioned at the early-mainstream stage of industry development with a projected market size exceeding $30 billion by 2030. While advanced polymer films from established players like FUJIFILM, Toyobo, and LG Chem offer superior barrier properties and thermal stability, emerging flexible electronics technologies from research institutions (Tsinghua University, MIT) and innovative companies (Samsung Electronics, 3M) are challenging traditional materials with enhanced performance characteristics. The competitive landscape shows a convergence between chemical giants focusing on high-performance films and electronics manufacturers developing integrated flexible solutions, with Asian companies (particularly from Japan, South Korea, and China) demonstrating technological leadership through strategic R&D investments and cross-industry collaborations.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed proprietary flexible electronics technology utilizing their expertise in film manufacturing. Their approach combines ultra-thin polyimide substrates with specialized coating technologies to create flexible electronic components with exceptional durability. FUJIFILM's solution incorporates their EXCLEAR transparent conductive film technology, which uses silver nanowire networks embedded in polymer matrices to maintain conductivity even under repeated bending and folding conditions. This technology achieves bend radii of less than 3mm while maintaining over 90% of original conductivity after 100,000 flex cycles. Additionally, FUJIFILM has integrated their advanced polymer film expertise to develop moisture barrier films with water vapor transmission rates below 10^-6 g/m²/day, addressing one of the critical challenges in flexible electronics longevity.

Strengths: Superior durability under mechanical stress with minimal performance degradation; excellent barrier properties against environmental factors; leverages established manufacturing infrastructure. Weaknesses: Higher production costs compared to conventional rigid electronics; limited to specific application areas where flexibility justifies premium pricing; requires specialized integration techniques for system-level implementation.

Toyobo Co., Ltd.

Technical Solution: Toyobo has pioneered COSMOSHINE® polymer film technology specifically engineered for flexible electronics applications. Their solution utilizes biaxially oriented polyester films with proprietary surface treatment processes that enhance adhesion properties while maintaining optical clarity. Toyobo's approach incorporates nano-scale surface modification techniques that create controlled surface roughness (Ra < 5nm) to optimize the interface between the polymer substrate and conductive layers. Their films demonstrate exceptional dimensional stability with thermal shrinkage below 0.1% at 150°C, critical for maintaining circuit integrity during manufacturing processes. Toyobo has also developed specialized barrier films with oxygen transmission rates below 0.1 cc/m²/day and water vapor transmission rates under 0.01 g/m²/day, significantly extending the operational lifetime of flexible electronic devices in variable environmental conditions.

Strengths: Exceptional dimensional stability under thermal stress; superior optical properties with >90% light transmission; excellent chemical resistance against common solvents used in electronics manufacturing. Weaknesses: Higher material costs compared to standard polymer films; requires specialized handling during device assembly; limited bendability compared to some competing flexible substrate technologies.

Key Patents in Advanced Polymer Film Technology

Transparent flexible film and fabrication method thereof

PatentInactiveUS20090149564A1

Innovation

- A transparent flexible film is developed using a composition comprising 40-75 parts by weight of clay, 15-45 parts by weight of a water-soluble polymer, 1-10 parts by weight of a mono-functional acrylic oligomer, and 10-45 parts by weight of a bi-functional acrylic oligomer, with the clay being delaminated and oriented properly through a method involving a suspension, drying, and UV curing, eliminating the need for organic solvents.

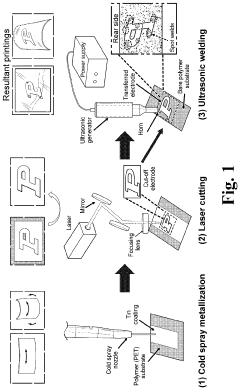

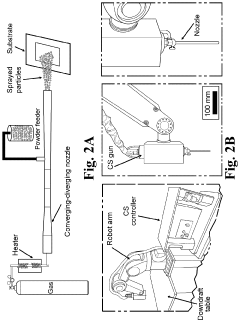

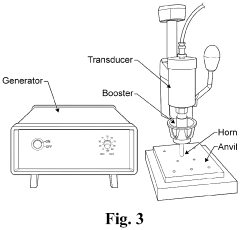

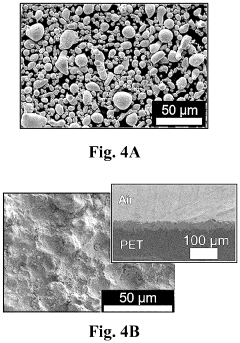

Cold spray printed flexible electronics and method for manufacturing the same

PatentPendingUS20240194377A1

Innovation

- A cold spray technique combined with femtosecond laser machining and ultrasonic welding is used for direct conductive metallization on flexible polymers, enabling high-resolution, high-conductivity, and high-adhesion flexible electronics without the need for high-temperature post-sintering processes.

Environmental Impact and Sustainability Considerations

The environmental footprint of flexible electronics and advanced polymer films represents a critical consideration in their development and deployment. Traditional electronic manufacturing processes involve significant resource consumption, toxic chemicals, and generate substantial waste. In contrast, flexible electronics manufacturing can potentially reduce material usage through thinner substrates and more efficient production methods, resulting in lower energy consumption during fabrication phases.

Advanced polymer films offer notable environmental advantages through their lightweight properties, which translate to reduced transportation emissions and energy requirements throughout the supply chain. Many modern polymer formulations are designed with end-of-life considerations, incorporating biodegradable components or recyclable materials that minimize landfill impact. However, challenges remain in creating truly sustainable polymer systems that maintain performance while reducing environmental harm.

The recyclability of these technologies presents a complex landscape. While conventional rigid electronics contain valuable recoverable materials like gold and copper, their recovery processes often involve hazardous chemicals. Flexible electronics introduce new recycling challenges due to the intimate integration of different materials, making separation difficult. Recent innovations in delamination techniques and solvent-based recovery systems show promise for improving the circular economy potential of these technologies.

Energy efficiency during operation represents another significant environmental dimension. Flexible electronics typically consume less power than their rigid counterparts due to lower operating temperatures and more efficient material interfaces. Advanced polymer films contribute to this efficiency through superior thermal management and electrical insulation properties, extending device lifespans and reducing replacement frequency.

Manufacturing sustainability initiatives are gaining momentum across the industry. Leading manufacturers have implemented closed-loop water systems, solvent recovery processes, and renewable energy integration in production facilities. These approaches significantly reduce the carbon footprint of both flexible electronics and advanced polymer films, though implementation remains inconsistent across global manufacturing centers.

Regulatory frameworks increasingly influence development trajectories, with policies like the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives driving innovation toward more environmentally responsible materials and designs. Forward-thinking companies are proactively developing compliance roadmaps that anticipate stricter future regulations, positioning sustainability as a competitive advantage rather than merely a compliance requirement.

Advanced polymer films offer notable environmental advantages through their lightweight properties, which translate to reduced transportation emissions and energy requirements throughout the supply chain. Many modern polymer formulations are designed with end-of-life considerations, incorporating biodegradable components or recyclable materials that minimize landfill impact. However, challenges remain in creating truly sustainable polymer systems that maintain performance while reducing environmental harm.

The recyclability of these technologies presents a complex landscape. While conventional rigid electronics contain valuable recoverable materials like gold and copper, their recovery processes often involve hazardous chemicals. Flexible electronics introduce new recycling challenges due to the intimate integration of different materials, making separation difficult. Recent innovations in delamination techniques and solvent-based recovery systems show promise for improving the circular economy potential of these technologies.

Energy efficiency during operation represents another significant environmental dimension. Flexible electronics typically consume less power than their rigid counterparts due to lower operating temperatures and more efficient material interfaces. Advanced polymer films contribute to this efficiency through superior thermal management and electrical insulation properties, extending device lifespans and reducing replacement frequency.

Manufacturing sustainability initiatives are gaining momentum across the industry. Leading manufacturers have implemented closed-loop water systems, solvent recovery processes, and renewable energy integration in production facilities. These approaches significantly reduce the carbon footprint of both flexible electronics and advanced polymer films, though implementation remains inconsistent across global manufacturing centers.

Regulatory frameworks increasingly influence development trajectories, with policies like the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives driving innovation toward more environmentally responsible materials and designs. Forward-thinking companies are proactively developing compliance roadmaps that anticipate stricter future regulations, positioning sustainability as a competitive advantage rather than merely a compliance requirement.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of flexible electronics versus advanced polymer films presents significant contrasts in production methodologies and economic viability. Current flexible electronics manufacturing predominantly relies on roll-to-roll (R2R) processing, which enables continuous production of electronic components on flexible substrates. However, this approach faces yield challenges when scaling to industrial volumes, with defect rates typically ranging from 5-15% depending on complexity, significantly higher than the 1-3% observed in traditional rigid electronics manufacturing.

Advanced polymer films, conversely, benefit from decades of industrial optimization in production processes. Major manufacturers like DuPont, 3M, and BASF have established high-throughput production lines capable of producing millions of square meters annually with consistent quality. The manufacturing maturity translates to production costs of $2-8 per square meter for advanced polymer films, compared to $15-100 for flexible electronic components of similar dimensions.

Capital expenditure requirements further differentiate these technologies. A new flexible electronics production facility typically requires investment of $50-200 million, whereas polymer film production line expansions can be implemented for $20-80 million with higher output capacity. This cost disparity creates significant barriers to market entry for new flexible electronics manufacturers.

Energy consumption metrics also favor polymer film production, with requirements of 2-5 kWh per square meter versus 8-20 kWh for flexible electronics. This efficiency gap impacts both operational costs and environmental sustainability profiles, with flexible electronics carrying a carbon footprint approximately 2.5 times larger per unit area.

Supply chain considerations reveal additional challenges for flexible electronics scaling. The industry relies on specialized materials including indium tin oxide, silver nanowires, and organic semiconductors—many facing supply constraints and price volatility. Advanced polymer films utilize more established chemical supply chains with multiple sourcing options, reducing production disruption risks.

Recent innovations in hybrid manufacturing approaches show promise for addressing these disparities. Integration of additive manufacturing techniques with traditional polymer processing has demonstrated potential cost reductions of 30-40% for flexible electronic components while improving production consistency. These developments suggest convergence pathways that may eventually narrow the manufacturing gap between these competing technologies.

Advanced polymer films, conversely, benefit from decades of industrial optimization in production processes. Major manufacturers like DuPont, 3M, and BASF have established high-throughput production lines capable of producing millions of square meters annually with consistent quality. The manufacturing maturity translates to production costs of $2-8 per square meter for advanced polymer films, compared to $15-100 for flexible electronic components of similar dimensions.

Capital expenditure requirements further differentiate these technologies. A new flexible electronics production facility typically requires investment of $50-200 million, whereas polymer film production line expansions can be implemented for $20-80 million with higher output capacity. This cost disparity creates significant barriers to market entry for new flexible electronics manufacturers.

Energy consumption metrics also favor polymer film production, with requirements of 2-5 kWh per square meter versus 8-20 kWh for flexible electronics. This efficiency gap impacts both operational costs and environmental sustainability profiles, with flexible electronics carrying a carbon footprint approximately 2.5 times larger per unit area.

Supply chain considerations reveal additional challenges for flexible electronics scaling. The industry relies on specialized materials including indium tin oxide, silver nanowires, and organic semiconductors—many facing supply constraints and price volatility. Advanced polymer films utilize more established chemical supply chains with multiple sourcing options, reducing production disruption risks.

Recent innovations in hybrid manufacturing approaches show promise for addressing these disparities. Integration of additive manufacturing techniques with traditional polymer processing has demonstrated potential cost reductions of 30-40% for flexible electronic components while improving production consistency. These developments suggest convergence pathways that may eventually narrow the manufacturing gap between these competing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!