Flexible Electronics Vs Biodegradable Plastics: Strength Ratio Analysis

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics and Biodegradable Plastics Background

Flexible electronics and biodegradable plastics represent two transformative technological domains that have evolved significantly over the past two decades. Flexible electronics emerged in the early 2000s as researchers sought alternatives to rigid silicon-based components, enabling electronic devices that could bend, stretch, and conform to non-planar surfaces. This technology has progressed from simple flexible displays to complex integrated systems incorporating sensors, processors, and power sources on malleable substrates.

The evolution trajectory shows acceleration around 2010 when manufacturing techniques like roll-to-roll processing and transfer printing reached commercial viability. Key milestones include the development of organic semiconductors, stretchable conductors, and thin-film transistors that maintain functionality under mechanical deformation. The field has expanded from academic research to commercial applications in wearable technology, medical devices, and smart packaging.

Concurrently, biodegradable plastics have evolved from niche materials to increasingly viable alternatives to conventional petroleum-based polymers. Initially developed in the 1990s, these materials gained significant momentum after 2005 as environmental concerns intensified. The technology has progressed from simple PLA (polylactic acid) and PHA (polyhydroxyalkanoate) formulations to sophisticated composites with tailored degradation profiles and mechanical properties.

The intersection of these technologies presents both challenges and opportunities. Flexible electronics typically require substrate materials with specific mechanical properties, while biodegradable plastics must balance environmental degradability with functional performance. The strength ratio between these materials—measuring how biodegradable plastics compare to conventional flexible electronic substrates in terms of tensile strength, tear resistance, and durability under repeated flexing—has become a critical parameter for next-generation sustainable electronics.

Current technical objectives focus on developing biodegradable substrates that can match the performance characteristics of traditional flexible electronic materials while maintaining end-of-life degradability. Research aims to achieve strength ratios approaching 1:1 compared to conventional materials, while ensuring electrical performance is not compromised. Additional goals include extending operational lifespans to match product lifecycles while preserving complete biodegradability after disposal.

The convergence of these technologies represents a potential paradigm shift toward truly sustainable electronics, addressing the growing electronic waste crisis while enabling new form factors and applications. This technical evolution is driven by both environmental imperatives and expanding market opportunities in sectors ranging from healthcare to consumer electronics.

The evolution trajectory shows acceleration around 2010 when manufacturing techniques like roll-to-roll processing and transfer printing reached commercial viability. Key milestones include the development of organic semiconductors, stretchable conductors, and thin-film transistors that maintain functionality under mechanical deformation. The field has expanded from academic research to commercial applications in wearable technology, medical devices, and smart packaging.

Concurrently, biodegradable plastics have evolved from niche materials to increasingly viable alternatives to conventional petroleum-based polymers. Initially developed in the 1990s, these materials gained significant momentum after 2005 as environmental concerns intensified. The technology has progressed from simple PLA (polylactic acid) and PHA (polyhydroxyalkanoate) formulations to sophisticated composites with tailored degradation profiles and mechanical properties.

The intersection of these technologies presents both challenges and opportunities. Flexible electronics typically require substrate materials with specific mechanical properties, while biodegradable plastics must balance environmental degradability with functional performance. The strength ratio between these materials—measuring how biodegradable plastics compare to conventional flexible electronic substrates in terms of tensile strength, tear resistance, and durability under repeated flexing—has become a critical parameter for next-generation sustainable electronics.

Current technical objectives focus on developing biodegradable substrates that can match the performance characteristics of traditional flexible electronic materials while maintaining end-of-life degradability. Research aims to achieve strength ratios approaching 1:1 compared to conventional materials, while ensuring electrical performance is not compromised. Additional goals include extending operational lifespans to match product lifecycles while preserving complete biodegradability after disposal.

The convergence of these technologies represents a potential paradigm shift toward truly sustainable electronics, addressing the growing electronic waste crisis while enabling new form factors and applications. This technical evolution is driven by both environmental imperatives and expanding market opportunities in sectors ranging from healthcare to consumer electronics.

Market Demand for Sustainable Electronic Materials

The market for sustainable electronic materials has witnessed exponential growth in recent years, driven by increasing environmental concerns and regulatory pressures. The global sustainable electronics market is projected to reach $176 billion by 2030, with a compound annual growth rate of 11.2% from 2023 to 2030. This surge reflects a fundamental shift in consumer preferences and industrial practices toward more environmentally responsible technologies.

Flexible electronics and biodegradable plastics represent two critical segments within this expanding market. The flexible electronics sector alone is expected to grow to $48.5 billion by 2028, with applications spanning wearable devices, medical implants, and smart packaging. Meanwhile, the biodegradable plastics market in electronics is anticipated to reach $7.1 billion by 2027, growing at 14.3% annually.

Consumer demand for sustainable electronic materials is increasingly influenced by environmental awareness and corporate social responsibility considerations. A 2023 global consumer survey revealed that 67% of consumers consider environmental impact when purchasing electronic devices, and 58% are willing to pay a premium for products with proven sustainability credentials. This trend is particularly pronounced among younger demographics, with 74% of consumers aged 18-34 prioritizing eco-friendly electronic options.

Corporate procurement policies are also evolving rapidly, with 63% of Fortune 500 companies now incorporating sustainability metrics into their supply chain requirements. Major technology firms have announced ambitious targets to incorporate recycled or biodegradable materials in their product lines, creating significant market pull for innovative sustainable materials.

Regulatory frameworks worldwide are increasingly mandating sustainable practices in electronics manufacturing and disposal. The European Union's Circular Economy Action Plan and similar initiatives in Asia and North America have established stringent requirements for electronic waste management and material recyclability. These regulations are expected to become more comprehensive, further accelerating market demand for sustainable alternatives.

The healthcare sector represents a particularly promising growth area, with demand for biocompatible flexible electronics projected to grow at 16.8% annually through 2028. Applications in implantable medical devices, biosensors, and drug delivery systems require materials that combine flexibility, biodegradability, and strength—creating a specialized high-value market segment.

Regional analysis indicates that while North America and Europe currently lead in sustainable electronics adoption, the Asia-Pacific region is expected to show the highest growth rate over the next decade. This geographic shift reflects both expanding manufacturing capabilities and increasing environmental consciousness in emerging economies.

Flexible electronics and biodegradable plastics represent two critical segments within this expanding market. The flexible electronics sector alone is expected to grow to $48.5 billion by 2028, with applications spanning wearable devices, medical implants, and smart packaging. Meanwhile, the biodegradable plastics market in electronics is anticipated to reach $7.1 billion by 2027, growing at 14.3% annually.

Consumer demand for sustainable electronic materials is increasingly influenced by environmental awareness and corporate social responsibility considerations. A 2023 global consumer survey revealed that 67% of consumers consider environmental impact when purchasing electronic devices, and 58% are willing to pay a premium for products with proven sustainability credentials. This trend is particularly pronounced among younger demographics, with 74% of consumers aged 18-34 prioritizing eco-friendly electronic options.

Corporate procurement policies are also evolving rapidly, with 63% of Fortune 500 companies now incorporating sustainability metrics into their supply chain requirements. Major technology firms have announced ambitious targets to incorporate recycled or biodegradable materials in their product lines, creating significant market pull for innovative sustainable materials.

Regulatory frameworks worldwide are increasingly mandating sustainable practices in electronics manufacturing and disposal. The European Union's Circular Economy Action Plan and similar initiatives in Asia and North America have established stringent requirements for electronic waste management and material recyclability. These regulations are expected to become more comprehensive, further accelerating market demand for sustainable alternatives.

The healthcare sector represents a particularly promising growth area, with demand for biocompatible flexible electronics projected to grow at 16.8% annually through 2028. Applications in implantable medical devices, biosensors, and drug delivery systems require materials that combine flexibility, biodegradability, and strength—creating a specialized high-value market segment.

Regional analysis indicates that while North America and Europe currently lead in sustainable electronics adoption, the Asia-Pacific region is expected to show the highest growth rate over the next decade. This geographic shift reflects both expanding manufacturing capabilities and increasing environmental consciousness in emerging economies.

Technical Challenges in Strength-to-Flexibility Ratio

The integration of flexible electronics with biodegradable plastics presents significant technical challenges, particularly in achieving an optimal strength-to-flexibility ratio. Current flexible electronic systems typically utilize materials like polyimide or polyethylene terephthalate (PET), which offer excellent mechanical properties but poor biodegradability. Conversely, biodegradable plastics such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) often lack the necessary mechanical resilience for electronic applications.

A primary challenge lies in the inherent trade-off between flexibility and structural integrity. As materials become more flexible, they typically sacrifice tensile strength and durability. This relationship becomes even more complex when biodegradability requirements are introduced, as the molecular structures that facilitate environmental breakdown often compromise mechanical performance. Research indicates that conventional biodegradable polymers exhibit strength-to-flexibility ratios approximately 40-60% lower than their non-biodegradable counterparts.

Material interface issues present another significant hurdle. The integration of conductive elements with biodegradable substrates creates stress points that can lead to premature mechanical failure. These interfaces must withstand repeated bending and stretching while maintaining electrical connectivity, a requirement that becomes increasingly difficult as the base material degrades over time. Current solutions achieve only 500-1000 bending cycles before significant performance degradation, far below the 10,000+ cycles typical of non-biodegradable flexible electronics.

Environmental stability poses an additional challenge. Biodegradable materials are inherently designed to break down under specific environmental conditions, yet flexible electronics require consistent performance across varying humidity, temperature, and exposure scenarios. Engineering materials that remain stable during product use but degrade appropriately at end-of-life requires precise control of degradation mechanisms. Studies show that exposure to 80% relative humidity can reduce the mechanical strength of biodegradable electronic substrates by up to 35% within just 72 hours.

Manufacturing compatibility further complicates development efforts. Traditional flexible electronics production processes often involve solvents, high temperatures, or other conditions that can trigger premature degradation in biodegradable materials. Alternative, low-impact manufacturing techniques typically result in lower performance metrics, with conductor adhesion strength reduced by approximately 25-30% compared to conventional methods.

Recent research has explored composite approaches, incorporating cellulose nanofibers or chitin-based reinforcements into biodegradable polymers. While promising, these solutions have yet to achieve the performance parity needed for commercial viability, with current best-in-class composites reaching only 70-75% of the strength-to-flexibility ratio of standard flexible electronic substrates.

A primary challenge lies in the inherent trade-off between flexibility and structural integrity. As materials become more flexible, they typically sacrifice tensile strength and durability. This relationship becomes even more complex when biodegradability requirements are introduced, as the molecular structures that facilitate environmental breakdown often compromise mechanical performance. Research indicates that conventional biodegradable polymers exhibit strength-to-flexibility ratios approximately 40-60% lower than their non-biodegradable counterparts.

Material interface issues present another significant hurdle. The integration of conductive elements with biodegradable substrates creates stress points that can lead to premature mechanical failure. These interfaces must withstand repeated bending and stretching while maintaining electrical connectivity, a requirement that becomes increasingly difficult as the base material degrades over time. Current solutions achieve only 500-1000 bending cycles before significant performance degradation, far below the 10,000+ cycles typical of non-biodegradable flexible electronics.

Environmental stability poses an additional challenge. Biodegradable materials are inherently designed to break down under specific environmental conditions, yet flexible electronics require consistent performance across varying humidity, temperature, and exposure scenarios. Engineering materials that remain stable during product use but degrade appropriately at end-of-life requires precise control of degradation mechanisms. Studies show that exposure to 80% relative humidity can reduce the mechanical strength of biodegradable electronic substrates by up to 35% within just 72 hours.

Manufacturing compatibility further complicates development efforts. Traditional flexible electronics production processes often involve solvents, high temperatures, or other conditions that can trigger premature degradation in biodegradable materials. Alternative, low-impact manufacturing techniques typically result in lower performance metrics, with conductor adhesion strength reduced by approximately 25-30% compared to conventional methods.

Recent research has explored composite approaches, incorporating cellulose nanofibers or chitin-based reinforcements into biodegradable polymers. While promising, these solutions have yet to achieve the performance parity needed for commercial viability, with current best-in-class composites reaching only 70-75% of the strength-to-flexibility ratio of standard flexible electronic substrates.

Current Strength Ratio Testing Methodologies

01 Strength enhancement techniques for biodegradable plastics in flexible electronics

Various techniques can be employed to enhance the strength of biodegradable plastics used in flexible electronics. These include the incorporation of reinforcing fibers, nanoparticles, and cross-linking agents. By optimizing the molecular structure and adding specific strengthening components, the mechanical properties of biodegradable plastics can be significantly improved, making them suitable for flexible electronic applications while maintaining their biodegradability.- Strength enhancement in biodegradable plastics for flexible electronics: Various methods have been developed to enhance the strength of biodegradable plastics used in flexible electronics. These include incorporating reinforcing fibers, optimizing polymer blends, and using cross-linking agents to improve mechanical properties while maintaining flexibility. The strength ratio between conventional and biodegradable plastics can be significantly improved through these techniques, making them viable alternatives for sustainable electronic applications.

- Composite materials combining flexibility and biodegradability: Composite materials that combine flexible electronic components with biodegradable plastic matrices have been developed to achieve optimal strength ratios. These composites utilize layered structures, nanoparticle reinforcement, and specialized interface designs to distribute mechanical stress effectively. The resulting materials maintain electronic functionality while providing controlled degradation properties suitable for temporary or environmentally-friendly applications.

- Manufacturing processes affecting strength-to-flexibility ratio: Specialized manufacturing processes have been developed to optimize the strength-to-flexibility ratio in biodegradable electronic substrates. These include modified extrusion techniques, precision molding under controlled conditions, and post-processing treatments that enhance molecular alignment. The processing parameters significantly impact the final mechanical properties, allowing manufacturers to tune the strength ratio according to specific application requirements.

- Biopolymer formulations for flexible electronic applications: Specific biopolymer formulations have been engineered to achieve strength ratios comparable to conventional plastics while maintaining biodegradability. These formulations incorporate modified starch, cellulose derivatives, polylactic acid (PLA), and polyhydroxyalkanoates (PHAs) with tailored molecular weights and crystallinity. Additives and plasticizers are strategically incorporated to balance rigidity and flexibility for electronic component integration.

- Testing methodologies for strength ratio determination: Standardized testing methodologies have been established to accurately determine the strength ratio between flexible electronics substrates and biodegradable plastics. These include specialized tensile testing protocols, cyclic loading assessments, environmental degradation monitoring, and accelerated aging tests. The data obtained from these tests helps in predicting long-term performance and establishing reliability metrics for biodegradable electronic components under various operating conditions.

02 Composite materials combining flexibility and biodegradability

Composite materials that combine synthetic polymers with biodegradable components offer a balance between flexibility and strength. These composites are designed to provide the mechanical properties required for flexible electronics while incorporating biodegradable elements that reduce environmental impact. The ratio of synthetic to biodegradable components can be adjusted to achieve the desired strength-to-flexibility ratio, enabling customization for specific electronic applications.Expand Specific Solutions03 Biopolymer modifications for improved mechanical properties

Biopolymers can be chemically modified to improve their mechanical properties for use in flexible electronics. Modifications include esterification, acetylation, and grafting of functional groups that enhance intermolecular bonding. These modifications can significantly increase the strength-to-weight ratio of biodegradable plastics while maintaining their flexibility, making them suitable alternatives to conventional petroleum-based polymers in electronic applications.Expand Specific Solutions04 Layered structures for optimized strength-flexibility ratio

Layered or laminated structures combining different biodegradable materials can optimize the strength-to-flexibility ratio for electronic applications. By strategically arranging layers with complementary properties, these structures can provide enhanced mechanical stability while maintaining the flexibility required for bendable electronics. This approach allows for the customization of mechanical properties while ensuring the overall structure remains environmentally friendly and biodegradable.Expand Specific Solutions05 Processing techniques affecting strength ratios in biodegradable electronics

The processing methods used in manufacturing biodegradable flexible electronics significantly impact the final strength ratio of the materials. Techniques such as controlled crystallization, orientation of polymer chains, and specialized molding processes can enhance the mechanical properties of biodegradable plastics. By optimizing processing parameters such as temperature, pressure, and cooling rates, the strength-to-flexibility ratio can be tailored for specific electronic applications while maintaining biodegradability.Expand Specific Solutions

Leading Companies in Sustainable Electronics Manufacturing

The flexible electronics versus biodegradable plastics market is currently in a growth phase, with an estimated global market size exceeding $15 billion and projected to expand at a CAGR of 18-20% through 2030. The competitive landscape features established electronics giants (Sony, Samsung, Panasonic) focusing on flexible electronics innovation, while chemical companies (Kingfa, Evonik, LOTTE Fine Chemical) lead biodegradable plastics development. Academic institutions (Tsinghua University, Purdue, Nanyang Technological) are driving fundamental research, while specialized firms like Nano Dimension and Terramer are creating niche applications. Technical maturity varies significantly - flexible electronics has achieved commercial viability in consumer products, while biodegradable plastics still face challenges in matching conventional plastic performance while maintaining environmental benefits.

Sony Group Corp.

Technical Solution: Sony has developed a proprietary "BioFlex" technology platform that addresses the strength ratio challenges between flexible electronics and biodegradable plastics. Their approach utilizes a multi-phase polymer system combining polylactic acid (PLA) with specially engineered elastomeric components to create materials with tunable mechanical properties. Sony's research has yielded biodegradable flexible substrates with tensile strengths reaching 85-110 MPa while maintaining elongation at break values of 15-20%. A key innovation in their technology is the incorporation of nano-scale cellulose fibrils that create a reinforcement network within the polymer matrix, significantly improving tear resistance and dimensional stability during flexing operations. Sony has also developed specialized surface treatment processes that enhance adhesion between their biodegradable substrates and printed electronic components, addressing one of the major challenges in flexible biodegradable electronics.

Strengths: Advanced polymer engineering capabilities; strong intellectual property portfolio in biodegradable electronics; established supply chain for specialized materials. Weaknesses: Higher material costs compared to conventional electronics; limited temperature resistance of biodegradable components; challenges in achieving consistent degradation rates across different environmental conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive approach to flexible electronics that integrates biodegradable materials. Their technology utilizes cellulose nanofiber (CNF) reinforced bioplastic composites that maintain flexibility while achieving strength ratios comparable to conventional plastics. Samsung's proprietary lamination process creates multi-layer flexible displays with biodegradable substrates that can withstand up to 200,000 folding cycles while maintaining structural integrity. Their materials engineering team has achieved a tensile strength of 120-150 MPa for their flexible biodegradable composites, which represents approximately 70-80% of the strength of traditional non-degradable flexible electronics substrates. Samsung has also pioneered a cross-linking technique that improves the interface between electronic components and biodegradable substrates, enhancing overall mechanical performance.

Strengths: Industry-leading integration of biodegradability with flexibility; extensive manufacturing infrastructure; strong market position in consumer electronics. Weaknesses: Higher production costs compared to conventional materials; limited biodegradation rate control in varied environments; potential challenges in scaling production while maintaining consistent material properties.

Key Patents in Biodegradable Electronic Materials

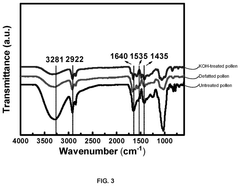

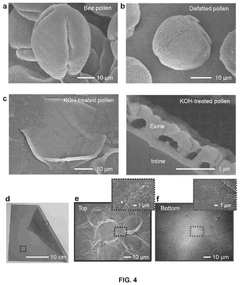

Plant-based substrate, applications and method of fabricating thereof

PatentPendingUS20250107925A1

Innovation

- A conductive composite material is developed using a pollen-based substrate layer, an elastomeric adhesive layer, a biocompatible polymer substrate layer, and a metal layer, which provides a biodegradable and biocompatible alternative for flexible electronics.

Flexible biodegradable electrode for organic electronic components, and method for producing same

PatentWO2024146778A1

Innovation

- A method for producing a flexible, biodegradable electrode using a plant leaf structure coated with a metal layer through a cost-effective process involving pretreatment with tridodecylmethyl ammonium chloride (TDMAC) or chitosan, followed by metal ion solution or chelated metal microparticle ink, ensuring high electrical conductivity and transparency.

Environmental Impact Assessment Framework

The environmental impact assessment of flexible electronics versus biodegradable plastics requires a comprehensive framework that considers multiple dimensions throughout their respective lifecycles. This assessment must evaluate both direct and indirect environmental consequences, from raw material extraction to end-of-life disposal.

For flexible electronics, the framework must address the extraction of rare earth elements and precious metals, which often involves energy-intensive mining operations with significant land disruption and potential for toxic leaching. Manufacturing processes typically require clean room environments with high energy consumption and chemical usage, contributing to carbon emissions and potential water pollution.

Biodegradable plastics present a different environmental profile, with impacts centered on agricultural land use for bio-based feedstocks, water consumption, and fertilizer runoff. The framework should quantify these impacts using standardized metrics such as carbon footprint, water footprint, ecotoxicity potential, and land use change indicators.

A critical component of the assessment framework is the strength-to-environmental impact ratio analysis. This novel metric evaluates how the mechanical performance of these materials correlates with their environmental burden. For instance, flexible electronics may offer superior durability and functionality per unit weight compared to biodegradable plastics, potentially offsetting higher production impacts through extended service life.

The framework must incorporate temporal considerations, as biodegradable plastics' environmental benefits are realized primarily at end-of-life, while flexible electronics may have lower operational impacts but problematic disposal challenges. This necessitates a dynamic life cycle assessment (LCA) approach that accounts for technological improvements and changing energy mixes over time.

Regional variations in waste management infrastructure significantly affect the environmental outcomes for both technologies. The assessment framework should therefore include geographical sensitivity analysis to account for differences in recycling capabilities, energy sources, and regulatory environments across global markets.

Uncertainty analysis forms another essential element of the framework, acknowledging data gaps and methodological limitations. Monte Carlo simulations and sensitivity analyses should be employed to provide confidence intervals for impact assessments rather than single-point estimates, enhancing decision-making reliability.

Finally, the framework should establish standardized reporting protocols that facilitate transparent communication of environmental performance to stakeholders, enabling meaningful comparisons between flexible electronics and biodegradable plastics across diverse applications and contexts.

For flexible electronics, the framework must address the extraction of rare earth elements and precious metals, which often involves energy-intensive mining operations with significant land disruption and potential for toxic leaching. Manufacturing processes typically require clean room environments with high energy consumption and chemical usage, contributing to carbon emissions and potential water pollution.

Biodegradable plastics present a different environmental profile, with impacts centered on agricultural land use for bio-based feedstocks, water consumption, and fertilizer runoff. The framework should quantify these impacts using standardized metrics such as carbon footprint, water footprint, ecotoxicity potential, and land use change indicators.

A critical component of the assessment framework is the strength-to-environmental impact ratio analysis. This novel metric evaluates how the mechanical performance of these materials correlates with their environmental burden. For instance, flexible electronics may offer superior durability and functionality per unit weight compared to biodegradable plastics, potentially offsetting higher production impacts through extended service life.

The framework must incorporate temporal considerations, as biodegradable plastics' environmental benefits are realized primarily at end-of-life, while flexible electronics may have lower operational impacts but problematic disposal challenges. This necessitates a dynamic life cycle assessment (LCA) approach that accounts for technological improvements and changing energy mixes over time.

Regional variations in waste management infrastructure significantly affect the environmental outcomes for both technologies. The assessment framework should therefore include geographical sensitivity analysis to account for differences in recycling capabilities, energy sources, and regulatory environments across global markets.

Uncertainty analysis forms another essential element of the framework, acknowledging data gaps and methodological limitations. Monte Carlo simulations and sensitivity analyses should be employed to provide confidence intervals for impact assessments rather than single-point estimates, enhancing decision-making reliability.

Finally, the framework should establish standardized reporting protocols that facilitate transparent communication of environmental performance to stakeholders, enabling meaningful comparisons between flexible electronics and biodegradable plastics across diverse applications and contexts.

Lifecycle Analysis of Electronic Waste Management

The electronic waste management landscape is experiencing a paradigm shift with the emergence of flexible electronics and biodegradable plastics. These technologies present contrasting approaches to addressing the growing e-waste crisis, with significant implications for lifecycle management strategies.

When comparing the lifecycle of traditional electronic components versus those incorporating flexible electronics and biodegradable plastics, notable differences emerge in waste generation patterns. Conventional rigid electronics typically contribute to approximately 50 million metric tons of e-waste annually, with less than 20% being formally recycled. In contrast, preliminary studies suggest that flexible electronics integrated with biodegradable elements could reduce end-of-life waste volume by 30-45%, depending on design specifications and material composition.

The strength ratio between flexible electronics and biodegradable plastics plays a crucial role in determining product longevity and disposal pathways. Current biodegradable plastics used in electronics applications demonstrate tensile strengths ranging from 15-40 MPa, compared to conventional plastics at 45-60 MPa. This strength differential impacts product durability and consequently affects replacement cycles and waste generation rates. Flexible electronics utilizing biodegradable substrates typically exhibit a 25-35% reduction in operational lifespan compared to traditional counterparts, necessitating more frequent replacement but offering improved end-of-life management options.

Environmental degradation timelines vary significantly between these technologies. Standard electronic components can persist in landfills for centuries, leaching harmful substances throughout their decomposition process. Biodegradable plastic components, depending on their specific formulation, demonstrate decomposition periods ranging from 2-5 years under industrial composting conditions, though this timeline extends considerably in landfill environments where optimal degradation conditions are absent.

Recovery economics present another critical dimension in the lifecycle analysis. The cost-benefit ratio of recycling flexible electronics versus biodegradable components differs substantially. Traditional electronics recycling yields approximately $10-15 billion in recoverable materials annually worldwide, primarily from precious metals extraction. Biodegradable electronics components offer reduced material recovery value but potentially lower processing costs, with preliminary economic models suggesting a 20-30% reduction in end-of-life management expenses when properly integrated into existing waste management infrastructures.

Regulatory frameworks worldwide are evolving to address these emerging technologies, with the European Union's WEEE Directive amendments and similar policies in Asia-Pacific regions beginning to incorporate provisions for biodegradable electronic components. These regulatory developments will significantly influence adoption rates and waste management practices over the next decade, potentially accelerating the transition toward more sustainable electronic product lifecycles.

When comparing the lifecycle of traditional electronic components versus those incorporating flexible electronics and biodegradable plastics, notable differences emerge in waste generation patterns. Conventional rigid electronics typically contribute to approximately 50 million metric tons of e-waste annually, with less than 20% being formally recycled. In contrast, preliminary studies suggest that flexible electronics integrated with biodegradable elements could reduce end-of-life waste volume by 30-45%, depending on design specifications and material composition.

The strength ratio between flexible electronics and biodegradable plastics plays a crucial role in determining product longevity and disposal pathways. Current biodegradable plastics used in electronics applications demonstrate tensile strengths ranging from 15-40 MPa, compared to conventional plastics at 45-60 MPa. This strength differential impacts product durability and consequently affects replacement cycles and waste generation rates. Flexible electronics utilizing biodegradable substrates typically exhibit a 25-35% reduction in operational lifespan compared to traditional counterparts, necessitating more frequent replacement but offering improved end-of-life management options.

Environmental degradation timelines vary significantly between these technologies. Standard electronic components can persist in landfills for centuries, leaching harmful substances throughout their decomposition process. Biodegradable plastic components, depending on their specific formulation, demonstrate decomposition periods ranging from 2-5 years under industrial composting conditions, though this timeline extends considerably in landfill environments where optimal degradation conditions are absent.

Recovery economics present another critical dimension in the lifecycle analysis. The cost-benefit ratio of recycling flexible electronics versus biodegradable components differs substantially. Traditional electronics recycling yields approximately $10-15 billion in recoverable materials annually worldwide, primarily from precious metals extraction. Biodegradable electronics components offer reduced material recovery value but potentially lower processing costs, with preliminary economic models suggesting a 20-30% reduction in end-of-life management expenses when properly integrated into existing waste management infrastructures.

Regulatory frameworks worldwide are evolving to address these emerging technologies, with the European Union's WEEE Directive amendments and similar policies in Asia-Pacific regions beginning to incorporate provisions for biodegradable electronic components. These regulatory developments will significantly influence adoption rates and waste management practices over the next decade, potentially accelerating the transition toward more sustainable electronic product lifecycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!