Flexible Electronics Vs Flexible Coatings: Performance Variances

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics and Coatings Background and Objectives

Flexible electronics and flexible coatings represent two distinct yet complementary technological domains that have evolved significantly over the past few decades. Flexible electronics emerged in the 1990s with the development of organic semiconductors and has since expanded to include various materials and fabrication techniques. This technology enables electronic circuits to be built on flexible substrates, allowing them to bend, fold, and stretch while maintaining functionality. Meanwhile, flexible coatings have evolved from traditional protective layers to sophisticated functional materials that can adapt to substrate movement while providing specific properties such as conductivity, thermal management, or environmental protection.

The evolution of these technologies has been driven by increasing demands for wearable devices, foldable displays, medical implants, and Internet of Things (IoT) applications. Market research indicates a compound annual growth rate exceeding 15% for flexible electronics, with projections suggesting a market value surpassing $40 billion by 2027. This growth trajectory reflects the transformative potential of these technologies across multiple industries.

Technical advancements in flexible electronics have progressed from simple flexible circuits to complex systems incorporating sensors, displays, and energy harvesting components. Key milestones include the development of organic light-emitting diodes (OLEDs) for flexible displays, printed electronics manufacturing techniques, and stretchable interconnects that maintain conductivity under mechanical stress. Concurrently, flexible coatings have evolved from basic polymeric materials to advanced nanocomposites with tunable properties and multi-functional capabilities.

The primary objective of current research in this field is to address the performance variances between flexible electronics and flexible coatings under different operational conditions. While flexible electronics offer dynamic functionality and interactive capabilities, they often face challenges related to durability, environmental stability, and manufacturing scalability. Conversely, flexible coatings typically provide superior environmental protection and simpler manufacturing processes but have traditionally offered limited electronic functionality.

Understanding these performance variances is crucial for developing next-generation devices that combine the advantages of both technologies. Research aims to bridge the gap between electronic functionality and protective capabilities, potentially leading to integrated systems where flexible coatings serve not only as protective layers but also as functional components of electronic systems. This convergence could enable new applications in healthcare monitoring, structural health monitoring, and sustainable energy systems.

The technical goals include developing materials and manufacturing processes that optimize the balance between flexibility, functionality, durability, and cost-effectiveness across both domains. This requires interdisciplinary approaches combining materials science, electrical engineering, chemistry, and manufacturing technology to create solutions that overcome current limitations and exploit the complementary strengths of flexible electronics and coatings.

The evolution of these technologies has been driven by increasing demands for wearable devices, foldable displays, medical implants, and Internet of Things (IoT) applications. Market research indicates a compound annual growth rate exceeding 15% for flexible electronics, with projections suggesting a market value surpassing $40 billion by 2027. This growth trajectory reflects the transformative potential of these technologies across multiple industries.

Technical advancements in flexible electronics have progressed from simple flexible circuits to complex systems incorporating sensors, displays, and energy harvesting components. Key milestones include the development of organic light-emitting diodes (OLEDs) for flexible displays, printed electronics manufacturing techniques, and stretchable interconnects that maintain conductivity under mechanical stress. Concurrently, flexible coatings have evolved from basic polymeric materials to advanced nanocomposites with tunable properties and multi-functional capabilities.

The primary objective of current research in this field is to address the performance variances between flexible electronics and flexible coatings under different operational conditions. While flexible electronics offer dynamic functionality and interactive capabilities, they often face challenges related to durability, environmental stability, and manufacturing scalability. Conversely, flexible coatings typically provide superior environmental protection and simpler manufacturing processes but have traditionally offered limited electronic functionality.

Understanding these performance variances is crucial for developing next-generation devices that combine the advantages of both technologies. Research aims to bridge the gap between electronic functionality and protective capabilities, potentially leading to integrated systems where flexible coatings serve not only as protective layers but also as functional components of electronic systems. This convergence could enable new applications in healthcare monitoring, structural health monitoring, and sustainable energy systems.

The technical goals include developing materials and manufacturing processes that optimize the balance between flexibility, functionality, durability, and cost-effectiveness across both domains. This requires interdisciplinary approaches combining materials science, electrical engineering, chemistry, and manufacturing technology to create solutions that overcome current limitations and exploit the complementary strengths of flexible electronics and coatings.

Market Demand Analysis for Flexible Electronic Solutions

The flexible electronics market has witnessed substantial growth in recent years, driven by increasing demand for lightweight, portable, and adaptable electronic solutions across various industries. Current market analysis indicates that the global flexible electronics market is projected to reach $42.2 billion by 2027, growing at a CAGR of 11.3% from 2020. This remarkable growth trajectory is fueled by the expanding applications in consumer electronics, healthcare, automotive, and aerospace sectors.

Consumer electronics remains the dominant application segment, accounting for approximately 35% of the market share. The demand for flexible displays, bendable smartphones, and wearable technology continues to surge as consumers increasingly prefer devices that offer enhanced portability and durability. Major smartphone manufacturers have already introduced foldable displays, signaling a shift toward more flexible form factors in mainstream consumer products.

Healthcare represents another significant growth sector for flexible electronics, particularly in medical wearables and implantable devices. The market for flexible biomedical sensors is expanding rapidly, with applications ranging from continuous glucose monitoring to smart bandages that track wound healing. This segment is expected to grow at 15.7% annually through 2026, outpacing the overall market growth rate.

When comparing flexible electronics with flexible coatings, market research indicates distinct consumer preferences and performance expectations. While flexible coatings primarily address protective and aesthetic functions, flexible electronics deliver interactive functionality that commands premium pricing. The average price premium for flexible electronic solutions versus traditional rigid alternatives stands at 30-45%, reflecting the higher perceived value and manufacturing complexity.

Regional analysis reveals Asia-Pacific as the largest market for flexible electronics, accounting for 42% of global demand, followed by North America (28%) and Europe (22%). China, South Korea, and Japan lead manufacturing capacity, while North America dominates in research innovation and patent activity. The fastest growth is anticipated in emerging markets like India and Brazil, where increasing smartphone penetration and healthcare modernization are creating new demand vectors.

Industry surveys indicate that durability remains the primary concern for end-users, with 68% of consumers citing reliability under repeated flexing as their top consideration when purchasing flexible electronic products. Performance consistency across temperature variations ranks second (54%), followed by power efficiency (47%). These consumer priorities are directly influencing R&D focus areas, with manufacturers increasingly investing in materials science to address these specific performance requirements.

Consumer electronics remains the dominant application segment, accounting for approximately 35% of the market share. The demand for flexible displays, bendable smartphones, and wearable technology continues to surge as consumers increasingly prefer devices that offer enhanced portability and durability. Major smartphone manufacturers have already introduced foldable displays, signaling a shift toward more flexible form factors in mainstream consumer products.

Healthcare represents another significant growth sector for flexible electronics, particularly in medical wearables and implantable devices. The market for flexible biomedical sensors is expanding rapidly, with applications ranging from continuous glucose monitoring to smart bandages that track wound healing. This segment is expected to grow at 15.7% annually through 2026, outpacing the overall market growth rate.

When comparing flexible electronics with flexible coatings, market research indicates distinct consumer preferences and performance expectations. While flexible coatings primarily address protective and aesthetic functions, flexible electronics deliver interactive functionality that commands premium pricing. The average price premium for flexible electronic solutions versus traditional rigid alternatives stands at 30-45%, reflecting the higher perceived value and manufacturing complexity.

Regional analysis reveals Asia-Pacific as the largest market for flexible electronics, accounting for 42% of global demand, followed by North America (28%) and Europe (22%). China, South Korea, and Japan lead manufacturing capacity, while North America dominates in research innovation and patent activity. The fastest growth is anticipated in emerging markets like India and Brazil, where increasing smartphone penetration and healthcare modernization are creating new demand vectors.

Industry surveys indicate that durability remains the primary concern for end-users, with 68% of consumers citing reliability under repeated flexing as their top consideration when purchasing flexible electronic products. Performance consistency across temperature variations ranks second (54%), followed by power efficiency (47%). These consumer priorities are directly influencing R&D focus areas, with manufacturers increasingly investing in materials science to address these specific performance requirements.

Current Technical Challenges in Flexible Technologies

The field of flexible technologies faces significant technical challenges that differentiate the performance of flexible electronics from flexible coatings. One of the primary challenges is durability under repeated mechanical stress. While flexible electronics must maintain electrical conductivity through thousands of bending cycles, flexible coatings primarily need to prevent cracking and delamination. Testing has shown that flexible electronics typically fail after 10,000-50,000 bending cycles depending on the substrate material, whereas high-performance flexible coatings can withstand up to 100,000 cycles before showing significant degradation.

Temperature stability presents another critical challenge. Flexible electronics often incorporate temperature-sensitive components that limit their operational range to -20°C to 60°C. In contrast, advanced flexible coatings can maintain performance across a broader temperature spectrum (-40°C to 150°C), making them more suitable for extreme environment applications. This performance gap necessitates additional thermal management systems for flexible electronics, increasing complexity and cost.

Manufacturing scalability remains problematic for flexible electronics, which typically require clean room environments and precise deposition techniques. Current roll-to-roll manufacturing processes for flexible electronics achieve yields of 60-85%, significantly lower than the 90-98% yields common in flexible coating applications. This efficiency gap translates directly to cost differentials, with flexible electronics costing 3-10 times more per square meter than comparable flexible coatings.

Environmental resistance varies substantially between these technologies. Flexible coatings generally offer superior protection against moisture, chemicals, and UV radiation due to their inherent barrier properties. Flexible electronics require additional encapsulation layers that add thickness and reduce flexibility, creating a design trade-off between protection and performance. Recent accelerated weathering tests demonstrate that unprotected flexible electronics degrade within 500-1000 hours of exposure, while specialized flexible coatings maintain performance for 3000-5000 hours under identical conditions.

Power requirements represent another significant variance. Flexible electronics demand power sources that must themselves be flexible or strategically placed to avoid compromising the system's flexibility. Current flexible battery technologies offer energy densities of only 10-30% compared to rigid counterparts, severely limiting operational duration. Flexible coatings, being passive in nature, avoid this constraint entirely, allowing for simpler implementation in energy-constrained applications.

Integration complexity also differs markedly between these technologies. Flexible electronics require sophisticated interconnection strategies to maintain functionality during deformation, with current techniques achieving reliability rates of 85-95% after 1000 flexing cycles. Flexible coatings present fewer integration challenges but struggle with consistent thickness control across complex geometries, with thickness variations typically ranging from 5-15% across curved surfaces.

Temperature stability presents another critical challenge. Flexible electronics often incorporate temperature-sensitive components that limit their operational range to -20°C to 60°C. In contrast, advanced flexible coatings can maintain performance across a broader temperature spectrum (-40°C to 150°C), making them more suitable for extreme environment applications. This performance gap necessitates additional thermal management systems for flexible electronics, increasing complexity and cost.

Manufacturing scalability remains problematic for flexible electronics, which typically require clean room environments and precise deposition techniques. Current roll-to-roll manufacturing processes for flexible electronics achieve yields of 60-85%, significantly lower than the 90-98% yields common in flexible coating applications. This efficiency gap translates directly to cost differentials, with flexible electronics costing 3-10 times more per square meter than comparable flexible coatings.

Environmental resistance varies substantially between these technologies. Flexible coatings generally offer superior protection against moisture, chemicals, and UV radiation due to their inherent barrier properties. Flexible electronics require additional encapsulation layers that add thickness and reduce flexibility, creating a design trade-off between protection and performance. Recent accelerated weathering tests demonstrate that unprotected flexible electronics degrade within 500-1000 hours of exposure, while specialized flexible coatings maintain performance for 3000-5000 hours under identical conditions.

Power requirements represent another significant variance. Flexible electronics demand power sources that must themselves be flexible or strategically placed to avoid compromising the system's flexibility. Current flexible battery technologies offer energy densities of only 10-30% compared to rigid counterparts, severely limiting operational duration. Flexible coatings, being passive in nature, avoid this constraint entirely, allowing for simpler implementation in energy-constrained applications.

Integration complexity also differs markedly between these technologies. Flexible electronics require sophisticated interconnection strategies to maintain functionality during deformation, with current techniques achieving reliability rates of 85-95% after 1000 flexing cycles. Flexible coatings present fewer integration challenges but struggle with consistent thickness control across complex geometries, with thickness variations typically ranging from 5-15% across curved surfaces.

Comparative Analysis of Current Flexible Technology Solutions

01 Flexible electronic devices and manufacturing methods

Flexible electronic devices incorporate bendable components and substrates that can withstand mechanical stress while maintaining functionality. These devices use specialized manufacturing techniques to create circuits on flexible materials like polymers or thin metal foils. The flexibility allows for applications in wearable technology, curved displays, and conformable sensors. Manufacturing methods include roll-to-roll processing, direct printing of electronic components, and specialized bonding techniques that maintain electrical connectivity during bending or stretching.- Flexible electronic devices with bendable substrates: Flexible electronic devices are constructed using bendable substrates that allow for folding, rolling, or twisting without compromising functionality. These devices incorporate specialized materials that maintain electrical conductivity while being subjected to mechanical stress. The flexibility enables applications in wearable technology, curved displays, and portable electronics that conform to non-flat surfaces. These innovations address the limitations of traditional rigid electronics by providing durability against physical deformation.

- Protective flexible coatings for electronic components: Protective flexible coatings are applied to electronic components to enhance durability while maintaining flexibility. These coatings provide resistance against environmental factors such as moisture, chemicals, and temperature fluctuations. The formulations typically include elastomeric polymers that can stretch and recover without cracking or delaminating from the substrate. These coatings are essential for preserving the performance and extending the lifespan of flexible electronic devices in various operating conditions.

- Conductive materials for flexible circuits: Specialized conductive materials are developed for flexible circuit applications that maintain electrical performance under bending and stretching conditions. These materials include metal nanowires, conductive polymers, carbon-based materials like graphene, and liquid metal alloys. The formulations are designed to provide stable electrical conductivity while accommodating mechanical deformation. These innovative materials enable the creation of stretchable interconnects and sensors that can be integrated into textiles, medical devices, and consumer electronics.

- Manufacturing techniques for flexible electronic systems: Advanced manufacturing techniques are employed to produce flexible electronic systems with consistent performance characteristics. These methods include roll-to-roll processing, direct printing of electronic components, laser patterning, and transfer printing. The manufacturing processes are designed to create thin, lightweight devices that maintain functionality when bent or folded. These techniques enable mass production of flexible electronics while ensuring reliability and performance under mechanical stress.

- Testing and performance evaluation of flexible electronics: Specialized testing methodologies are developed to evaluate the performance of flexible electronics under various mechanical and environmental conditions. These tests include cyclic bending, folding endurance, environmental stress testing, and accelerated aging. The evaluation protocols assess electrical performance, mechanical durability, and coating adhesion during and after deformation. These testing approaches help ensure that flexible electronic products meet reliability standards and maintain functionality throughout their intended lifecycle.

02 Protective flexible coatings for electronic components

Protective coatings for flexible electronics provide environmental resistance while maintaining device flexibility. These specialized formulations protect against moisture, chemicals, and physical damage without compromising the bendable nature of the underlying components. The coatings typically consist of polymer-based materials with additives that enhance durability, adhesion, and flexibility. Some formulations incorporate self-healing properties or nanoparticles to improve performance characteristics such as scratch resistance and thermal management while preserving electrical functionality.Expand Specific Solutions03 Stretchable conductive materials and interconnects

Stretchable conductive materials enable electronics to not only bend but also stretch while maintaining electrical conductivity. These materials typically combine elastic substrates with conductive elements arranged in patterns that accommodate stretching without breaking electrical connections. Innovations include wavy or serpentine metal traces, conductive polymers with elastomeric properties, and composite materials incorporating conductive nanoparticles within stretchable matrices. These technologies are crucial for applications requiring conformability to complex surfaces or dynamic movement, such as medical monitoring devices and soft robotics.Expand Specific Solutions04 Thermal management in flexible electronics

Thermal management solutions for flexible electronics address the challenge of heat dissipation in bendable devices. Unlike rigid electronics with conventional heat sinks, flexible devices require innovative approaches to prevent overheating while maintaining flexibility. These solutions include thermally conductive yet flexible materials, specialized thermal interface materials, and novel heat spreading designs. Some approaches incorporate phase change materials or microfluidic cooling channels that can bend with the device while efficiently removing heat from sensitive components, thereby improving device reliability and performance.Expand Specific Solutions05 Durability and reliability testing methods

Testing methodologies for flexible electronics evaluate performance under various mechanical stresses and environmental conditions. These methods assess the durability and reliability of flexible devices through repeated bending, folding, or stretching cycles while monitoring electrical performance. Environmental testing exposes devices to temperature extremes, humidity, and chemical exposure to evaluate coating effectiveness and material stability. Advanced techniques include in-situ monitoring during deformation, accelerated aging tests, and specialized fixtures that simulate real-world usage scenarios. These testing protocols help predict device lifespan and identify failure modes specific to flexible electronic systems.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The flexible electronics market is currently in a growth phase, with increasing adoption across consumer electronics, healthcare, and automotive sectors. The global market size is projected to reach significant value by 2030, driven by demand for bendable displays and wearable technology. While flexible electronics offer advantages in form factor and durability, flexible coatings provide enhanced protection and functionality at potentially lower manufacturing costs. Leading companies like Samsung Electronics, LG Display, and BOE Technology are advancing flexible display technologies, while materials specialists such as DuPont Electronics and Liquid Wire are developing innovative conductive materials. Academic institutions including Northwestern University and Fudan University are contributing fundamental research, creating a competitive landscape where performance trade-offs between complete flexible systems and coated conventional electronics continue to evolve.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible OLED display technology utilizing thin-film encapsulation (TFE) rather than traditional glass substrates. Their approach combines flexible electronics with specialized barrier coatings to achieve bendable displays. Samsung's technology employs a multi-layer structure with alternating inorganic (SiNx) and organic polymer layers that provide effective moisture barriers while maintaining flexibility. Their latest innovations include Ultra-Thin Glass (UTG) technology for foldable devices, which offers a balance between flexibility and durability through a proprietary glass thinning and strengthening process. Samsung has also pioneered stretchable display technology with elastic interconnects that can withstand repeated deformation while maintaining electrical performance.

Strengths: Industry-leading production capacity for flexible displays; proprietary UTG technology offers superior surface hardness compared to polymer alternatives; vertical integration allows control over entire supply chain. Weaknesses: Higher manufacturing costs compared to rigid electronics; limited fold cycle durability in current commercial products; thickness constraints when balancing flexibility and durability.

DuPont Electronics, Inc.

Technical Solution: DuPont has developed advanced flexible electronic materials through their Intexar™ technology platform, which integrates electronic functionality directly into stretchable fabrics and substrates. Their approach differs significantly from coating-based solutions by embedding conductive materials within elastic polymers to create truly stretchable circuits. DuPont's technology utilizes silver-based conductive inks printed on thermoplastic polyurethane (TPU) substrates, which can withstand repeated stretching up to 100% while maintaining electrical performance. For protective coatings, DuPont offers Kapton® polyimide films that provide exceptional thermal stability (functioning from -269°C to 400°C) and chemical resistance while maintaining flexibility. Their materials demonstrate superior performance in harsh environments compared to traditional flexible coatings.

Strengths: Extensive materials science expertise; products maintain electrical performance under extreme mechanical stress; solutions integrate seamlessly with existing textile manufacturing processes. Weaknesses: Higher initial cost compared to conventional electronics; requires specialized manufacturing equipment; limited transparency options for display applications.

Critical Patents and Technical Innovations Review

Rigid-flexible printed circuit bord fabrication using inkjet printing

PatentActiveUS20200037451A1

Innovation

- The use of a multi-head inkjet printing system with flexible and rigid conductive and dielectric ink compositions, allowing for direct printing of rigid-flexible electronic objects, which includes a combination of print heads for resin, metallic, and conductive inks, controlled by a computer-aided manufacturing module for precise layer formation and curing.

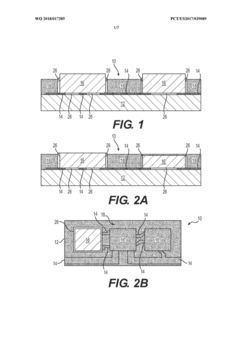

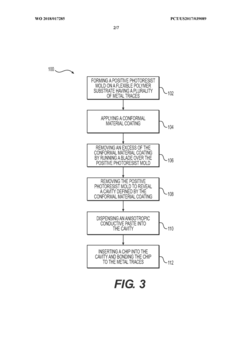

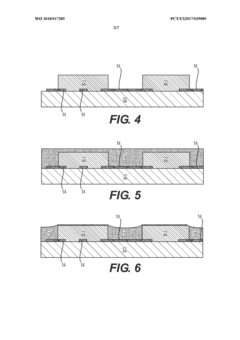

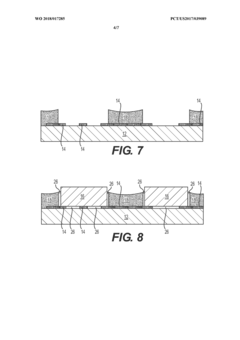

Method of manufacturing flexible electronic circuits having conformal material coatings

PatentWO2018017285A1

Innovation

- The method involves forming a positive photoresist mold or using a screen with porous and blocked portions to apply a conformal material coating, allowing for precise control over coating thickness by removing excess material with a blade, and then dispensing anisotropic conductive paste into cavities created within the coating to bond chips to metal traces.

Material Science Advancements for Flexibility Enhancement

Recent advancements in material science have revolutionized the development of flexible technologies, creating a significant divergence between flexible electronics and flexible coatings. The fundamental materials research has focused on enhancing mechanical properties while maintaining electrical performance in flexible electronics, whereas flexible coatings prioritize durability and environmental resistance while preserving flexibility.

Polymer science has contributed substantially to both fields, with the development of conductive polymers like PEDOT:PSS for electronics and high-performance elastomers for coatings. These materials exhibit remarkable elastic deformation capabilities while maintaining their functional properties under strain. The incorporation of nanomaterials has further enhanced flexibility characteristics, with carbon nanotubes and graphene providing exceptional mechanical flexibility and electrical conductivity for electronics applications.

Composite material engineering has emerged as a critical advancement area, combining organic and inorganic components to achieve synergistic properties. For flexible electronics, these composites often feature conductive fillers dispersed in flexible polymer matrices, creating materials that can withstand repeated bending cycles without performance degradation. In contrast, flexible coating composites typically incorporate self-healing components and UV-resistant additives to extend service life under environmental exposure.

Surface modification techniques have evolved to address the interface challenges in both technologies. Plasma treatment and chemical functionalization methods have improved adhesion between flexible substrates and functional layers, reducing delamination risks during flexing. These techniques have proven particularly valuable for flexible coatings, where interfacial strength determines overall system durability.

Molecular engineering approaches have enabled precise control over material properties at the nanoscale. Self-assembling materials and supramolecular structures provide unique flexibility mechanisms that conventional materials cannot achieve. These advanced materials often exhibit dynamic bonding capabilities, allowing for reversible deformation without permanent structural damage.

Manufacturing process innovations have complemented material advancements, with solution processing techniques enabling the deposition of flexible materials on various substrates. Roll-to-roll manufacturing has become particularly important for scaling production while maintaining material flexibility properties. The development of low-temperature processing methods has expanded the range of compatible substrate materials, further enhancing design flexibility.

Cross-disciplinary research combining materials science with mechanical engineering and electronics has accelerated innovation in flexibility enhancement. Computational modeling of material behavior under mechanical stress has guided experimental work, reducing development cycles and enabling more targeted material design approaches for specific flexibility requirements in both electronics and coatings applications.

Polymer science has contributed substantially to both fields, with the development of conductive polymers like PEDOT:PSS for electronics and high-performance elastomers for coatings. These materials exhibit remarkable elastic deformation capabilities while maintaining their functional properties under strain. The incorporation of nanomaterials has further enhanced flexibility characteristics, with carbon nanotubes and graphene providing exceptional mechanical flexibility and electrical conductivity for electronics applications.

Composite material engineering has emerged as a critical advancement area, combining organic and inorganic components to achieve synergistic properties. For flexible electronics, these composites often feature conductive fillers dispersed in flexible polymer matrices, creating materials that can withstand repeated bending cycles without performance degradation. In contrast, flexible coating composites typically incorporate self-healing components and UV-resistant additives to extend service life under environmental exposure.

Surface modification techniques have evolved to address the interface challenges in both technologies. Plasma treatment and chemical functionalization methods have improved adhesion between flexible substrates and functional layers, reducing delamination risks during flexing. These techniques have proven particularly valuable for flexible coatings, where interfacial strength determines overall system durability.

Molecular engineering approaches have enabled precise control over material properties at the nanoscale. Self-assembling materials and supramolecular structures provide unique flexibility mechanisms that conventional materials cannot achieve. These advanced materials often exhibit dynamic bonding capabilities, allowing for reversible deformation without permanent structural damage.

Manufacturing process innovations have complemented material advancements, with solution processing techniques enabling the deposition of flexible materials on various substrates. Roll-to-roll manufacturing has become particularly important for scaling production while maintaining material flexibility properties. The development of low-temperature processing methods has expanded the range of compatible substrate materials, further enhancing design flexibility.

Cross-disciplinary research combining materials science with mechanical engineering and electronics has accelerated innovation in flexibility enhancement. Computational modeling of material behavior under mechanical stress has guided experimental work, reducing development cycles and enabling more targeted material design approaches for specific flexibility requirements in both electronics and coatings applications.

Durability and Reliability Testing Methodologies

The durability and reliability testing of flexible electronics and flexible coatings require distinct methodologies due to their fundamental structural differences. For flexible electronics, testing protocols typically focus on mechanical stress resistance during repeated bending, folding, and stretching operations. Industry standards such as ASTM D2176 (folding endurance) and IEC 62715-6-1 (mechanical durability for flexible displays) provide frameworks for evaluating performance under mechanical strain. These tests often employ cyclic bending apparatus that can perform thousands of bend cycles while monitoring electrical performance parameters in real-time.

Flexible coatings, conversely, undergo testing regimens centered on adhesion strength, abrasion resistance, and chemical stability. Methods such as ASTM D3359 (tape test) and ASTM D4060 (abrasion resistance) are commonly utilized to evaluate coating integrity under physical stress. Environmental chamber testing is crucial for both technologies but with different emphasis points - flexible electronics require temperature cycling combined with mechanical stress, while coatings focus on UV exposure, humidity cycling, and chemical resistance.

Accelerated aging tests represent another critical evaluation dimension, with flexible electronics typically subjected to combined thermal-mechanical stress tests that simulate years of use in compressed timeframes. The IEC 61215 standard, though originally developed for photovoltaics, has been adapted for flexible electronics reliability assessment. For coatings, salt spray tests (ASTM B117) and weatherometer exposure tests provide insights into long-term environmental durability.

Failure analysis techniques also differ significantly between these technologies. Flexible electronics employ electrical performance monitoring during stress testing, with parameters such as resistance changes, capacitance drift, and signal integrity serving as key indicators. Advanced imaging techniques including scanning electron microscopy and infrared thermography help identify failure modes at the micro and nanoscale. For coatings, spectroscopic analysis (FTIR, Raman) tracks chemical degradation, while mechanical testing focuses on delamination, cracking, and loss of flexibility.

The integration of in-situ monitoring systems represents the cutting edge of reliability testing for both technologies. For flexible electronics, impedance spectroscopy during mechanical cycling provides real-time degradation data, while for coatings, embedded sensors that detect moisture ingress or chemical changes offer early warning of potential failures. These advanced methodologies enable more accurate lifetime predictions and help identify failure mechanisms that might otherwise remain undetected until catastrophic failure occurs.

Flexible coatings, conversely, undergo testing regimens centered on adhesion strength, abrasion resistance, and chemical stability. Methods such as ASTM D3359 (tape test) and ASTM D4060 (abrasion resistance) are commonly utilized to evaluate coating integrity under physical stress. Environmental chamber testing is crucial for both technologies but with different emphasis points - flexible electronics require temperature cycling combined with mechanical stress, while coatings focus on UV exposure, humidity cycling, and chemical resistance.

Accelerated aging tests represent another critical evaluation dimension, with flexible electronics typically subjected to combined thermal-mechanical stress tests that simulate years of use in compressed timeframes. The IEC 61215 standard, though originally developed for photovoltaics, has been adapted for flexible electronics reliability assessment. For coatings, salt spray tests (ASTM B117) and weatherometer exposure tests provide insights into long-term environmental durability.

Failure analysis techniques also differ significantly between these technologies. Flexible electronics employ electrical performance monitoring during stress testing, with parameters such as resistance changes, capacitance drift, and signal integrity serving as key indicators. Advanced imaging techniques including scanning electron microscopy and infrared thermography help identify failure modes at the micro and nanoscale. For coatings, spectroscopic analysis (FTIR, Raman) tracks chemical degradation, while mechanical testing focuses on delamination, cracking, and loss of flexibility.

The integration of in-situ monitoring systems represents the cutting edge of reliability testing for both technologies. For flexible electronics, impedance spectroscopy during mechanical cycling provides real-time degradation data, while for coatings, embedded sensors that detect moisture ingress or chemical changes offer early warning of potential failures. These advanced methodologies enable more accurate lifetime predictions and help identify failure mechanisms that might otherwise remain undetected until catastrophic failure occurs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!