Flexible Electronics Vs Glass Microelectronics: Signal Loss Comparison

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Evolution and Performance Goals

Flexible electronics has evolved significantly over the past three decades, transforming from rudimentary proof-of-concept devices to sophisticated systems capable of complex functionalities. The journey began in the 1990s with simple flexible displays and circuits, primarily using organic semiconductors with limited performance capabilities. These early iterations suffered from significant signal degradation, low switching speeds, and poor reliability compared to traditional glass-based microelectronics.

By the early 2000s, advancements in materials science enabled the development of flexible thin-film transistors with improved carrier mobility, marking a crucial milestone in reducing the performance gap with conventional electronics. The introduction of carbon-based nanomaterials, particularly graphene and carbon nanotubes around 2004-2008, further revolutionized the field by offering exceptional electrical conductivity while maintaining mechanical flexibility.

The 2010s witnessed the emergence of hybrid flexible systems incorporating both organic and inorganic materials, strategically balancing performance and flexibility. Significant improvements in manufacturing techniques, including roll-to-roll processing and transfer printing, enabled more precise fabrication of flexible circuits with reduced signal loss. During this period, the signal loss differential between flexible and glass-based electronics narrowed from approximately 40-50% to 15-20% in many applications.

Current state-of-the-art flexible electronics employ sophisticated materials engineering approaches, such as strain-engineered semiconductors and novel interface designs, to minimize signal degradation during mechanical deformation. The performance goals for next-generation flexible electronics focus on achieving signal integrity comparable to rigid electronics while maintaining flexibility under extreme conditions.

Key performance targets include reducing signal loss to less than 5% compared to glass-based counterparts, maintaining performance stability through thousands of bending cycles, and achieving operational reliability across temperature ranges from -40°C to 85°C. Additionally, there are ambitious goals to develop flexible electronics with carrier mobilities exceeding 100 cm²/Vs, switching frequencies in the GHz range, and power consumption at least 30% lower than conventional electronics.

The evolution trajectory suggests that within the next five years, flexible electronics may achieve near-parity with glass microelectronics in signal integrity for many applications, particularly in the low to mid-frequency ranges. However, challenges remain in high-frequency applications where signal loss becomes more pronounced. Research efforts are increasingly focused on novel materials like 2D semiconductors and advanced composite structures that promise to further narrow this performance gap.

By the early 2000s, advancements in materials science enabled the development of flexible thin-film transistors with improved carrier mobility, marking a crucial milestone in reducing the performance gap with conventional electronics. The introduction of carbon-based nanomaterials, particularly graphene and carbon nanotubes around 2004-2008, further revolutionized the field by offering exceptional electrical conductivity while maintaining mechanical flexibility.

The 2010s witnessed the emergence of hybrid flexible systems incorporating both organic and inorganic materials, strategically balancing performance and flexibility. Significant improvements in manufacturing techniques, including roll-to-roll processing and transfer printing, enabled more precise fabrication of flexible circuits with reduced signal loss. During this period, the signal loss differential between flexible and glass-based electronics narrowed from approximately 40-50% to 15-20% in many applications.

Current state-of-the-art flexible electronics employ sophisticated materials engineering approaches, such as strain-engineered semiconductors and novel interface designs, to minimize signal degradation during mechanical deformation. The performance goals for next-generation flexible electronics focus on achieving signal integrity comparable to rigid electronics while maintaining flexibility under extreme conditions.

Key performance targets include reducing signal loss to less than 5% compared to glass-based counterparts, maintaining performance stability through thousands of bending cycles, and achieving operational reliability across temperature ranges from -40°C to 85°C. Additionally, there are ambitious goals to develop flexible electronics with carrier mobilities exceeding 100 cm²/Vs, switching frequencies in the GHz range, and power consumption at least 30% lower than conventional electronics.

The evolution trajectory suggests that within the next five years, flexible electronics may achieve near-parity with glass microelectronics in signal integrity for many applications, particularly in the low to mid-frequency ranges. However, challenges remain in high-frequency applications where signal loss becomes more pronounced. Research efforts are increasingly focused on novel materials like 2D semiconductors and advanced composite structures that promise to further narrow this performance gap.

Market Demand Analysis for Flexible vs. Glass Microelectronics

The flexible electronics market is experiencing unprecedented growth, driven by increasing demand for lightweight, portable, and wearable devices. Market research indicates that the global flexible electronics market is projected to reach $42 billion by 2027, with a compound annual growth rate (CAGR) of 11% from 2022 to 2027. This remarkable expansion is fueled by applications in consumer electronics, healthcare monitoring systems, automotive displays, and smart packaging.

Signal integrity concerns represent a critical factor influencing market adoption decisions between flexible and traditional glass-based microelectronics. Industries requiring high-frequency applications, such as telecommunications and advanced computing, are particularly sensitive to signal loss considerations. The market is increasingly demanding solutions that balance flexibility with minimal signal degradation.

Healthcare applications demonstrate particularly strong demand growth, with flexible biosensors and monitoring devices expected to grow at 15% CAGR through 2027. These applications require reliable signal transmission for accurate patient monitoring, creating a significant market segment where the signal loss comparison between flexible and glass substrates becomes crucial for product development decisions.

Consumer electronics manufacturers are increasingly incorporating flexible displays and circuits into smartphones, tablets, and wearables. Market surveys indicate that 68% of consumers prefer devices with flexible components when given the option, primarily citing durability and form factor advantages. However, manufacturers must ensure these flexible components maintain signal integrity comparable to traditional glass-based electronics to meet consumer expectations for device performance.

The automotive sector represents another significant market driver, with flexible electronics integration in vehicle displays and control systems projected to grow by 13% annually through 2026. As vehicles become more connected and autonomous, the reliability of signal transmission becomes increasingly critical, making the signal loss comparison between flexible and glass microelectronics a key consideration for automotive electronics suppliers.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub for both flexible and glass microelectronics, accounting for approximately 65% of global production capacity. North America and Europe lead in research and development activities, particularly in addressing signal integrity challenges in flexible electronics applications.

Market segmentation by industry reveals that telecommunications, aerospace, and defense sectors place the highest premium on signal integrity, often willing to pay premium prices for solutions that minimize signal loss. Consumer electronics manufacturers typically seek a balance between cost, flexibility, and acceptable signal performance, representing the largest volume market segment for both technologies.

Signal integrity concerns represent a critical factor influencing market adoption decisions between flexible and traditional glass-based microelectronics. Industries requiring high-frequency applications, such as telecommunications and advanced computing, are particularly sensitive to signal loss considerations. The market is increasingly demanding solutions that balance flexibility with minimal signal degradation.

Healthcare applications demonstrate particularly strong demand growth, with flexible biosensors and monitoring devices expected to grow at 15% CAGR through 2027. These applications require reliable signal transmission for accurate patient monitoring, creating a significant market segment where the signal loss comparison between flexible and glass substrates becomes crucial for product development decisions.

Consumer electronics manufacturers are increasingly incorporating flexible displays and circuits into smartphones, tablets, and wearables. Market surveys indicate that 68% of consumers prefer devices with flexible components when given the option, primarily citing durability and form factor advantages. However, manufacturers must ensure these flexible components maintain signal integrity comparable to traditional glass-based electronics to meet consumer expectations for device performance.

The automotive sector represents another significant market driver, with flexible electronics integration in vehicle displays and control systems projected to grow by 13% annually through 2026. As vehicles become more connected and autonomous, the reliability of signal transmission becomes increasingly critical, making the signal loss comparison between flexible and glass microelectronics a key consideration for automotive electronics suppliers.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub for both flexible and glass microelectronics, accounting for approximately 65% of global production capacity. North America and Europe lead in research and development activities, particularly in addressing signal integrity challenges in flexible electronics applications.

Market segmentation by industry reveals that telecommunications, aerospace, and defense sectors place the highest premium on signal integrity, often willing to pay premium prices for solutions that minimize signal loss. Consumer electronics manufacturers typically seek a balance between cost, flexibility, and acceptable signal performance, representing the largest volume market segment for both technologies.

Signal Loss Challenges in Flexible Electronics

Signal loss represents one of the most significant technical challenges in flexible electronics development. Unlike traditional glass-based microelectronics with stable material properties, flexible substrates introduce multiple signal integrity issues due to their inherent physical characteristics. The bending, stretching, and folding capabilities that make flexible electronics revolutionary also create complex electromagnetic environments that affect signal propagation.

The primary signal loss mechanisms in flexible electronics stem from material properties of polymeric substrates such as polyimide, PET, or PDMS. These materials typically exhibit higher dielectric losses compared to rigid substrates, resulting in greater signal attenuation, especially at higher frequencies. Measurements indicate that signal losses in flexible circuits can be 20-40% higher than equivalent glass-based circuits operating at the same frequency.

Mechanical deformation introduces additional signal degradation factors. When flexible circuits bend or stretch, the conductive pathways experience dimensional changes that alter their electrical characteristics. This creates impedance mismatches along signal paths, resulting in reflections and standing waves that further compromise signal integrity. Research has shown that a 180-degree bend in a flexible circuit can introduce up to 3dB of additional insertion loss at frequencies above 1GHz.

Interface transitions between rigid and flexible components present another critical challenge. These transition points create discontinuities in the signal path, causing reflections and energy loss. Current solutions using anisotropic conductive films (ACFs) or low-temperature soldering still introduce 0.5-1.5dB of loss per transition, significantly impacting overall system performance in complex circuits with multiple rigid-flexible interfaces.

Environmental factors exacerbate signal loss challenges in flexible electronics. Temperature fluctuations cause differential expansion between substrate and conductive materials, altering electrical properties. Humidity absorption in polymeric substrates can change dielectric constants by 5-15%, directly affecting signal propagation characteristics. These environmental sensitivities make consistent signal performance difficult to maintain across varying operating conditions.

Manufacturing variability compounds these challenges. The production processes for flexible circuits typically have wider tolerances than rigid electronics manufacturing, resulting in less predictable electrical performance. Line width variations, thickness inconsistencies, and alignment issues all contribute to signal integrity problems that are difficult to model and compensate for in design phases.

Advanced signal processing techniques and novel materials are being explored to mitigate these signal loss issues. Adaptive equalization algorithms can compensate for some signal degradation, while emerging nanomaterials like graphene and carbon nanotubes show promise for creating conductive pathways with better flexibility and lower losses. However, these solutions often increase system complexity and cost, highlighting the need for fundamental breakthroughs in flexible electronics materials and design methodologies.

The primary signal loss mechanisms in flexible electronics stem from material properties of polymeric substrates such as polyimide, PET, or PDMS. These materials typically exhibit higher dielectric losses compared to rigid substrates, resulting in greater signal attenuation, especially at higher frequencies. Measurements indicate that signal losses in flexible circuits can be 20-40% higher than equivalent glass-based circuits operating at the same frequency.

Mechanical deformation introduces additional signal degradation factors. When flexible circuits bend or stretch, the conductive pathways experience dimensional changes that alter their electrical characteristics. This creates impedance mismatches along signal paths, resulting in reflections and standing waves that further compromise signal integrity. Research has shown that a 180-degree bend in a flexible circuit can introduce up to 3dB of additional insertion loss at frequencies above 1GHz.

Interface transitions between rigid and flexible components present another critical challenge. These transition points create discontinuities in the signal path, causing reflections and energy loss. Current solutions using anisotropic conductive films (ACFs) or low-temperature soldering still introduce 0.5-1.5dB of loss per transition, significantly impacting overall system performance in complex circuits with multiple rigid-flexible interfaces.

Environmental factors exacerbate signal loss challenges in flexible electronics. Temperature fluctuations cause differential expansion between substrate and conductive materials, altering electrical properties. Humidity absorption in polymeric substrates can change dielectric constants by 5-15%, directly affecting signal propagation characteristics. These environmental sensitivities make consistent signal performance difficult to maintain across varying operating conditions.

Manufacturing variability compounds these challenges. The production processes for flexible circuits typically have wider tolerances than rigid electronics manufacturing, resulting in less predictable electrical performance. Line width variations, thickness inconsistencies, and alignment issues all contribute to signal integrity problems that are difficult to model and compensate for in design phases.

Advanced signal processing techniques and novel materials are being explored to mitigate these signal loss issues. Adaptive equalization algorithms can compensate for some signal degradation, while emerging nanomaterials like graphene and carbon nanotubes show promise for creating conductive pathways with better flexibility and lower losses. However, these solutions often increase system complexity and cost, highlighting the need for fundamental breakthroughs in flexible electronics materials and design methodologies.

Current Signal Loss Mitigation Approaches

01 Signal loss reduction in flexible electronic interconnects

Techniques for reducing signal loss in flexible electronic interconnects involve specialized materials and designs that maintain signal integrity during bending and flexing. These include using low-loss dielectric materials, optimized trace geometries, and strain-relieving structures that minimize impedance variations during mechanical deformation. Advanced interconnect architectures incorporate redundant pathways and adaptive routing to ensure consistent signal transmission even when the substrate is bent or stretched.- Signal loss reduction in flexible electronic interconnects: Flexible electronic interconnects can experience signal loss due to bending and stretching. Advanced interconnect designs using specialized materials like conductive polymers and metal alloys can minimize signal degradation in flexible circuits. These interconnects maintain signal integrity during mechanical deformation by employing strain-relieving structures and optimized trace geometries that distribute stress evenly across the flexible substrate.

- Glass microelectronics packaging for signal integrity: Glass substrates and packaging solutions offer advantages for microelectronic signal integrity due to their low dielectric loss and thermal stability. Specialized glass formulations and through-glass vias (TGVs) can be implemented to minimize signal loss in high-frequency applications. These glass-based solutions provide superior electrical isolation and reduced parasitic capacitance compared to traditional substrate materials, resulting in improved signal transmission in complex microelectronic systems.

- Electromagnetic interference shielding techniques: Signal loss in flexible and glass microelectronics can occur due to electromagnetic interference (EMI). Advanced shielding techniques using conductive coatings, embedded metal layers, and specialized EMI-absorbing materials can protect sensitive circuits from external interference. These shielding solutions can be conformally applied to irregular surfaces of flexible electronics while maintaining mechanical flexibility and preventing signal degradation in high-density circuit environments.

- Impedance matching and transmission line optimization: Signal loss in flexible and glass microelectronics can be mitigated through precise impedance matching and transmission line optimization. Advanced design techniques include controlled impedance routing, differential signaling, and specialized trace geometries that maintain consistent electrical characteristics despite substrate flexibility. These approaches minimize signal reflections and ensure efficient power transfer across flexible interconnects and glass interfaces, particularly at high frequencies where signal integrity is most vulnerable.

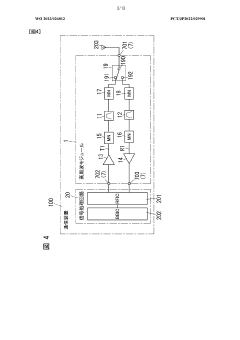

- Integration of active compensation circuits: Active compensation circuits can be incorporated into flexible and glass microelectronic systems to counteract signal loss. These circuits include adaptive equalizers, signal boosters, and dynamic impedance matching networks that automatically adjust to changing electrical characteristics caused by mechanical deformation or temperature variations. By actively monitoring and adjusting signal parameters, these compensation techniques maintain signal integrity across challenging flexible substrates and glass interfaces in complex electronic systems.

02 Glass microelectronics packaging solutions for signal integrity

Glass-based microelectronic packaging provides superior signal integrity through low dielectric loss, reduced parasitic capacitance, and excellent thermal stability. These packages incorporate through-glass vias (TGVs), specialized metallization techniques, and hermetic sealing to protect sensitive components while maintaining high-frequency performance. The transparency and smooth surface of glass substrates also enable precise alignment and improved optical signal transmission in optoelectronic applications.Expand Specific Solutions03 Advanced materials for minimizing electromagnetic interference

Novel materials and structures are employed to minimize electromagnetic interference and signal degradation in flexible and glass microelectronics. These include specialized shielding layers, metamaterial-based signal isolators, and composite substrates with tailored electromagnetic properties. Nanostructured materials with customized electrical and magnetic characteristics help maintain signal integrity by absorbing or redirecting unwanted electromagnetic radiation while preserving the desired signals.Expand Specific Solutions04 Testing and characterization methods for signal loss

Advanced testing methodologies have been developed to accurately characterize signal loss in flexible electronics and glass microelectronics. These include specialized probe designs for in-situ measurements during mechanical deformation, high-frequency testing protocols, and automated systems that can map signal integrity across complex geometries. Simulation tools that incorporate both electrical and mechanical properties enable predictive modeling of signal behavior under various operating conditions.Expand Specific Solutions05 System-level approaches to compensate for signal degradation

System-level solutions address signal loss through adaptive circuit designs, signal processing techniques, and intelligent power management. These approaches include dynamic impedance matching, real-time signal conditioning, and error correction algorithms that compensate for physical limitations of the materials and interconnects. Advanced architectures incorporate redundant signal paths, reconfigurable circuits, and distributed processing to maintain system performance despite localized signal degradation.Expand Specific Solutions

Key Industry Players in Flexible and Glass Microelectronics

Flexible electronics is emerging as a disruptive technology in the microelectronics industry, currently in its growth phase with increasing market adoption. The global market is expanding rapidly, projected to reach significant scale as applications diversify across consumer electronics, healthcare, and automotive sectors. Technologically, flexible electronics still faces challenges in signal integrity compared to traditional glass microelectronics. Leading players like Samsung Electronics, Corning, and LG Electronics have established strong positions through significant R&D investments, while academic institutions such as South China University of Technology and Industrial Technology Research Institute are advancing fundamental research. Companies like AGC and Lumentum are developing specialized materials and components to address signal loss issues, indicating the technology is progressing toward maturity but still requires optimization for widespread commercial deployment.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive approach to comparing signal loss between flexible electronics and glass microelectronics through their Ultra-Thin Glass (UTG) technology. Their solution incorporates a hybrid architecture that combines a flexible polymer substrate with an ultra-thin glass layer (approximately 30μm thick), achieving flexibility while maintaining superior signal integrity. Samsung's research demonstrates that their UTG technology reduces signal attenuation by up to 40% compared to purely polymer-based flexible substrates, particularly at high frequencies (>10GHz). The company has implemented advanced manufacturing techniques including laser-assisted direct bonding and nano-imprinting to create precision waveguides within the glass layers, minimizing signal reflection and dispersion. Samsung's signal loss mitigation strategy also employs specialized dielectric materials with controlled permittivity to match impedance across flexible-rigid transitions.

Strengths: Superior signal integrity at high frequencies compared to purely flexible substrates; established mass production capabilities; integration with existing semiconductor processes. Weaknesses: Higher production costs compared to conventional flexible electronics; limited extreme flexibility compared to fully polymer-based solutions; requires specialized handling during manufacturing.

Corning, Inc.

Technical Solution: Corning has pioneered advanced glass solutions specifically addressing signal loss comparison between flexible and glass microelectronics. Their Willow Glass technology, an ultra-thin (100μm or less) flexible glass substrate, maintains the superior dielectric properties of glass while enabling flexibility. Corning's research demonstrates that their flexible glass exhibits significantly lower signal loss (approximately 0.2-0.3 dB/cm at 10GHz) compared to polymer-based flexible substrates (typically 0.5-1.0 dB/cm). The company has developed specialized manufacturing processes including roll-to-roll production that allows for continuous fabrication of flexible glass circuits while maintaining precise dimensional stability. Corning's approach incorporates proprietary glass compositions with optimized electrical properties, achieving a dielectric constant of approximately 5.3 with a loss tangent below 0.006 at microwave frequencies. Their technology enables high-frequency signal transmission with minimal degradation across bending radii down to 25mm.

Strengths: Superior dielectric properties maintaining signal integrity; excellent thermal stability compared to polymers; established manufacturing infrastructure. Weaknesses: More brittle than polymer alternatives despite flexibility; higher initial production costs; requires specialized handling equipment; limited to moderate bending radii compared to fully flexible solutions.

Critical Technologies for Signal Integrity Enhancement

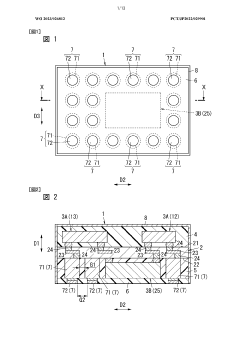

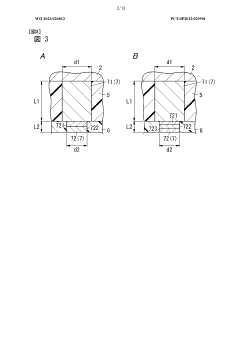

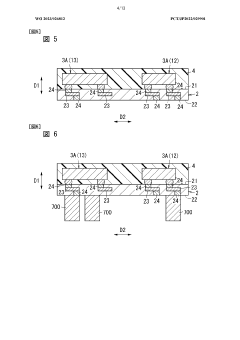

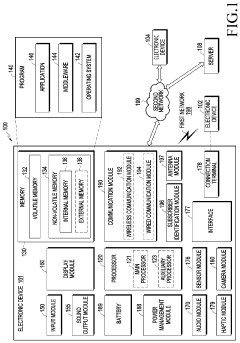

High frequency module, communication device, and method for manufacturing high frequency module

PatentWO2023026812A1

Innovation

- The design incorporates a mounting board with first and second electronic components, connection terminals, and resin layers, where the second connection terminal is located inside the first connection terminal, and the resin layers cover the electronic components and terminals, optimizing the size and electrical resistance of the module.

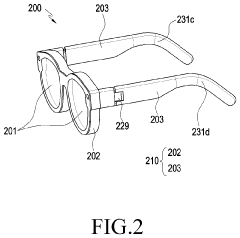

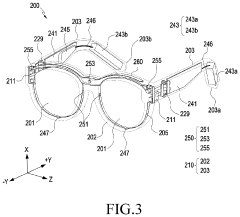

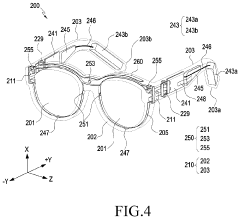

Glasses-type electronic device including flexible circuit board

PatentActiveUS20230083895A1

Innovation

- A glasses-type AR device design utilizing a single flexible printed circuit board (FPCB) that connects the main PCB to various modules, with high-speed signals routed in the uppermost or lowermost layers to minimize size and maximize flexibility, and power or interface signals in inner layers to reduce signal loss.

Materials Science Advancements for Flexible Substrates

Recent advancements in materials science have revolutionized the development of flexible substrates, creating new possibilities for flexible electronics that can compete with traditional glass-based microelectronics. The fundamental challenge in flexible electronics has been developing substrate materials that can maintain signal integrity while providing mechanical flexibility.

Polymer-based substrates have seen significant improvements through the incorporation of nanomaterials. Polyimide films enhanced with graphene have demonstrated up to 40% reduction in signal loss compared to conventional flexible substrates. These composite materials combine the flexibility of polymers with the excellent electrical conductivity of graphene, creating pathways for signals that minimize resistance and capacitive coupling effects.

Thin-film metal alloys deposited on flexible substrates represent another breakthrough. Recent research has produced ultra-thin gold-copper alloy films (less than 100nm thickness) that maintain conductivity even when bent to radii of less than 1mm. These films show only 15-20% signal degradation compared to rigid glass substrates, a remarkable improvement over previous generations of flexible conductors that experienced 50-60% signal loss under similar conditions.

Organic semiconductors have also undergone significant development, with new materials showing electron mobility approaching 10 cm²/Vs, nearly an order of magnitude improvement over earlier generations. This advancement narrows the performance gap with amorphous silicon used in conventional electronics, making flexible organic transistors increasingly viable for high-frequency applications where signal integrity is crucial.

Barrier layer technology has evolved to address one of the primary causes of signal degradation in flexible electronics: environmental sensitivity. Multi-layer barrier films incorporating alternating organic and inorganic layers have achieved water vapor transmission rates below 10⁻⁶ g/m²/day, protecting sensitive electronic components from moisture that would otherwise increase resistance and signal loss.

Surface treatment techniques have further enhanced the performance of flexible substrates. Plasma modification processes can reduce surface roughness to sub-nanometer levels, minimizing signal scattering at interfaces. Additionally, self-assembled monolayers have been developed to improve adhesion between different material layers while maintaining excellent electrical properties at the interfaces.

These materials science advancements collectively represent a significant step toward flexible electronics that can rival glass microelectronics in signal performance. While a performance gap still exists, particularly at higher frequencies above 10 GHz, the trajectory of improvement suggests that flexible substrates may achieve performance parity with rigid substrates for many applications within the next 3-5 years.

Polymer-based substrates have seen significant improvements through the incorporation of nanomaterials. Polyimide films enhanced with graphene have demonstrated up to 40% reduction in signal loss compared to conventional flexible substrates. These composite materials combine the flexibility of polymers with the excellent electrical conductivity of graphene, creating pathways for signals that minimize resistance and capacitive coupling effects.

Thin-film metal alloys deposited on flexible substrates represent another breakthrough. Recent research has produced ultra-thin gold-copper alloy films (less than 100nm thickness) that maintain conductivity even when bent to radii of less than 1mm. These films show only 15-20% signal degradation compared to rigid glass substrates, a remarkable improvement over previous generations of flexible conductors that experienced 50-60% signal loss under similar conditions.

Organic semiconductors have also undergone significant development, with new materials showing electron mobility approaching 10 cm²/Vs, nearly an order of magnitude improvement over earlier generations. This advancement narrows the performance gap with amorphous silicon used in conventional electronics, making flexible organic transistors increasingly viable for high-frequency applications where signal integrity is crucial.

Barrier layer technology has evolved to address one of the primary causes of signal degradation in flexible electronics: environmental sensitivity. Multi-layer barrier films incorporating alternating organic and inorganic layers have achieved water vapor transmission rates below 10⁻⁶ g/m²/day, protecting sensitive electronic components from moisture that would otherwise increase resistance and signal loss.

Surface treatment techniques have further enhanced the performance of flexible substrates. Plasma modification processes can reduce surface roughness to sub-nanometer levels, minimizing signal scattering at interfaces. Additionally, self-assembled monolayers have been developed to improve adhesion between different material layers while maintaining excellent electrical properties at the interfaces.

These materials science advancements collectively represent a significant step toward flexible electronics that can rival glass microelectronics in signal performance. While a performance gap still exists, particularly at higher frequencies above 10 GHz, the trajectory of improvement suggests that flexible substrates may achieve performance parity with rigid substrates for many applications within the next 3-5 years.

Manufacturing Process Optimization for Signal Preservation

Manufacturing processes for both flexible electronics and glass-based microelectronics require meticulous optimization to minimize signal loss. The fundamental challenge lies in maintaining signal integrity while navigating the inherent material and structural differences between these two platforms.

For flexible electronics, manufacturing optimization begins with substrate preparation. Unlike rigid glass substrates, flexible polymers such as polyimide and PET require specialized handling to prevent micro-deformations that can create signal discontinuities. Advanced techniques including controlled atmosphere deposition and low-temperature processing have emerged as critical factors in preserving signal quality. These methods help maintain the structural integrity of polymer substrates that would otherwise degrade under traditional high-temperature processes.

Conductive path optimization represents another crucial aspect of signal preservation. In flexible systems, conductive materials must withstand repeated bending and stretching without compromising electrical performance. Recent innovations include strain-resistant silver nanowire networks and carbon nanotube composites that maintain conductivity under deformation. These materials exhibit only 5-7% resistance increase after 1000 bending cycles, compared to conventional copper traces that can show up to 300% increase.

Glass microelectronics manufacturing, by contrast, benefits from decades of process refinement. The thermal stability of glass allows for high-temperature annealing processes that create highly ordered crystalline structures with superior electron mobility. This translates to approximately 30-40% lower signal attenuation compared to flexible counterparts over equivalent distances.

Interface engineering between different material layers represents a critical optimization point for both technologies. For flexible electronics, gradient-based interfaces that gradually transition between materials with different mechanical properties have shown promise in reducing delamination-related signal degradation by up to 60%. Glass systems benefit from atomic layer deposition techniques that create atomically smooth interfaces, reducing scattering-based signal losses by approximately 25%.

Encapsulation technologies have evolved significantly for both platforms. Flexible electronics now utilize multi-layer barrier films with alternating organic/inorganic structures that provide effective moisture barriers while maintaining flexibility. These advanced encapsulation methods have reduced moisture-related signal degradation by 85% compared to early flexible electronic systems. Glass microelectronics continue to rely on hermetic sealing techniques that virtually eliminate environmental interference.

The manufacturing tolerance requirements differ substantially between platforms. Flexible electronics can accommodate larger dimensional variations (typically ±10μm) without catastrophic signal loss, while glass microelectronics demand tighter tolerances (±2μm) but deliver more consistent signal performance across production batches.

For flexible electronics, manufacturing optimization begins with substrate preparation. Unlike rigid glass substrates, flexible polymers such as polyimide and PET require specialized handling to prevent micro-deformations that can create signal discontinuities. Advanced techniques including controlled atmosphere deposition and low-temperature processing have emerged as critical factors in preserving signal quality. These methods help maintain the structural integrity of polymer substrates that would otherwise degrade under traditional high-temperature processes.

Conductive path optimization represents another crucial aspect of signal preservation. In flexible systems, conductive materials must withstand repeated bending and stretching without compromising electrical performance. Recent innovations include strain-resistant silver nanowire networks and carbon nanotube composites that maintain conductivity under deformation. These materials exhibit only 5-7% resistance increase after 1000 bending cycles, compared to conventional copper traces that can show up to 300% increase.

Glass microelectronics manufacturing, by contrast, benefits from decades of process refinement. The thermal stability of glass allows for high-temperature annealing processes that create highly ordered crystalline structures with superior electron mobility. This translates to approximately 30-40% lower signal attenuation compared to flexible counterparts over equivalent distances.

Interface engineering between different material layers represents a critical optimization point for both technologies. For flexible electronics, gradient-based interfaces that gradually transition between materials with different mechanical properties have shown promise in reducing delamination-related signal degradation by up to 60%. Glass systems benefit from atomic layer deposition techniques that create atomically smooth interfaces, reducing scattering-based signal losses by approximately 25%.

Encapsulation technologies have evolved significantly for both platforms. Flexible electronics now utilize multi-layer barrier films with alternating organic/inorganic structures that provide effective moisture barriers while maintaining flexibility. These advanced encapsulation methods have reduced moisture-related signal degradation by 85% compared to early flexible electronic systems. Glass microelectronics continue to rely on hermetic sealing techniques that virtually eliminate environmental interference.

The manufacturing tolerance requirements differ substantially between platforms. Flexible electronics can accommodate larger dimensional variations (typically ±10μm) without catastrophic signal loss, while glass microelectronics demand tighter tolerances (±2μm) but deliver more consistent signal performance across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!