Flexible Electronics Vs Polycarbonate Sheets: Crack Resistance Analysis

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics and Polycarbonate Evolution

Flexible electronics technology has evolved significantly over the past three decades, transforming from basic concepts to sophisticated applications across multiple industries. The journey began in the 1990s with rudimentary flexible displays and circuits, primarily using organic semiconductors on plastic substrates. These early implementations suffered from poor durability and limited functionality but established the foundational principles for future development.

The 2000s marked a period of rapid advancement with the introduction of new materials and fabrication techniques. Researchers developed improved conductive polymers, nanomaterials like carbon nanotubes, and metal nanowires that offered enhanced electrical properties while maintaining flexibility. Concurrently, polycarbonate sheet technology underwent its own evolution from rigid, brittle structures to increasingly flexible and durable formulations.

By the 2010s, flexible electronics had matured significantly with the commercial introduction of flexible displays in consumer electronics. Companies like Samsung and LG pioneered curved OLED screens, while medical device manufacturers began incorporating flexible circuits into wearable health monitors. During this same period, polycarbonate manufacturing techniques advanced to produce thinner sheets with improved impact resistance and optical clarity.

The convergence of these technologies occurred around 2015-2018, when researchers began specifically addressing crack resistance challenges at the interface between electronic components and polycarbonate substrates. This period saw the development of specialized adhesives, interface layers, and strain-distribution architectures designed to prevent crack propagation under mechanical stress.

Recent developments (2019-2023) have focused on intrinsically stretchable electronics that can withstand significant deformation without cracking. These include liquid metal circuits embedded in elastomers, kirigami-inspired structural designs that distribute strain, and self-healing materials that can repair microcracks autonomously. Simultaneously, polycarbonate formulations have evolved to incorporate nanocomposite reinforcements and gradient structures that resist crack initiation.

The current technological frontier (2023-present) explores biomimetic approaches inspired by natural structures like spider silk and plant stems that exhibit exceptional flexibility and crack resistance. Researchers are developing hierarchical composite structures that can dissipate energy across multiple scales, preventing catastrophic failure even under extreme bending conditions. Machine learning algorithms are now being employed to optimize material compositions and structural designs for specific applications, accelerating the pace of innovation in this field.

The 2000s marked a period of rapid advancement with the introduction of new materials and fabrication techniques. Researchers developed improved conductive polymers, nanomaterials like carbon nanotubes, and metal nanowires that offered enhanced electrical properties while maintaining flexibility. Concurrently, polycarbonate sheet technology underwent its own evolution from rigid, brittle structures to increasingly flexible and durable formulations.

By the 2010s, flexible electronics had matured significantly with the commercial introduction of flexible displays in consumer electronics. Companies like Samsung and LG pioneered curved OLED screens, while medical device manufacturers began incorporating flexible circuits into wearable health monitors. During this same period, polycarbonate manufacturing techniques advanced to produce thinner sheets with improved impact resistance and optical clarity.

The convergence of these technologies occurred around 2015-2018, when researchers began specifically addressing crack resistance challenges at the interface between electronic components and polycarbonate substrates. This period saw the development of specialized adhesives, interface layers, and strain-distribution architectures designed to prevent crack propagation under mechanical stress.

Recent developments (2019-2023) have focused on intrinsically stretchable electronics that can withstand significant deformation without cracking. These include liquid metal circuits embedded in elastomers, kirigami-inspired structural designs that distribute strain, and self-healing materials that can repair microcracks autonomously. Simultaneously, polycarbonate formulations have evolved to incorporate nanocomposite reinforcements and gradient structures that resist crack initiation.

The current technological frontier (2023-present) explores biomimetic approaches inspired by natural structures like spider silk and plant stems that exhibit exceptional flexibility and crack resistance. Researchers are developing hierarchical composite structures that can dissipate energy across multiple scales, preventing catastrophic failure even under extreme bending conditions. Machine learning algorithms are now being employed to optimize material compositions and structural designs for specific applications, accelerating the pace of innovation in this field.

Market Demand for Crack-Resistant Materials

The global market for crack-resistant materials has witnessed substantial growth in recent years, driven primarily by the increasing adoption of flexible electronics across various industries. The demand for materials that can withstand repeated bending, folding, and stretching without developing cracks has become paramount, especially in consumer electronics, healthcare devices, automotive displays, and wearable technology sectors.

Consumer electronics represents the largest market segment, with an estimated annual growth rate exceeding 20% for flexible display technologies. Manufacturers are increasingly transitioning from rigid glass substrates to more durable alternatives, creating a significant market opportunity for advanced crack-resistant materials. The smartphone industry alone consumes substantial quantities of these materials, with over 1.5 billion devices shipped annually requiring some form of crack-resistant protection.

Healthcare applications present another rapidly expanding market segment. Medical devices incorporating flexible electronics demand exceptional crack resistance due to their critical applications and frequent handling. The market for flexible biomedical sensors is projected to grow substantially as remote patient monitoring and wearable health devices become more prevalent in healthcare delivery systems worldwide.

Automotive displays represent a particularly demanding application environment, requiring materials that can withstand extreme temperature variations, vibration, and potential impact while maintaining optical clarity. The transition toward larger, curved displays in vehicle interiors has accelerated demand for crack-resistant polycarbonate solutions that can conform to complex interior geometries while maintaining structural integrity.

Geographically, Asia-Pacific dominates the market for crack-resistant materials, with major manufacturing hubs in China, South Korea, Japan, and Taiwan driving demand. North America and Europe follow, with significant research activities and premium applications in aerospace, defense, and high-end consumer products.

Industry surveys indicate that manufacturers are willing to pay premium prices for materials offering superior crack resistance, with durability consistently ranking among the top three purchasing criteria. This price elasticity has stimulated significant investment in research and development of next-generation crack-resistant materials.

Environmental considerations are increasingly influencing market dynamics, with growing demand for sustainable and recyclable crack-resistant materials. Regulations limiting certain chemical compounds in polycarbonate formulations have pushed manufacturers toward developing more environmentally friendly alternatives without compromising crack resistance performance.

The market landscape is further shaped by end-user expectations for multifunctional materials that combine crack resistance with additional properties such as optical clarity, UV resistance, antimicrobial properties, and reduced weight. This trend toward material consolidation represents both a challenge and opportunity for developers of next-generation crack-resistant solutions.

Consumer electronics represents the largest market segment, with an estimated annual growth rate exceeding 20% for flexible display technologies. Manufacturers are increasingly transitioning from rigid glass substrates to more durable alternatives, creating a significant market opportunity for advanced crack-resistant materials. The smartphone industry alone consumes substantial quantities of these materials, with over 1.5 billion devices shipped annually requiring some form of crack-resistant protection.

Healthcare applications present another rapidly expanding market segment. Medical devices incorporating flexible electronics demand exceptional crack resistance due to their critical applications and frequent handling. The market for flexible biomedical sensors is projected to grow substantially as remote patient monitoring and wearable health devices become more prevalent in healthcare delivery systems worldwide.

Automotive displays represent a particularly demanding application environment, requiring materials that can withstand extreme temperature variations, vibration, and potential impact while maintaining optical clarity. The transition toward larger, curved displays in vehicle interiors has accelerated demand for crack-resistant polycarbonate solutions that can conform to complex interior geometries while maintaining structural integrity.

Geographically, Asia-Pacific dominates the market for crack-resistant materials, with major manufacturing hubs in China, South Korea, Japan, and Taiwan driving demand. North America and Europe follow, with significant research activities and premium applications in aerospace, defense, and high-end consumer products.

Industry surveys indicate that manufacturers are willing to pay premium prices for materials offering superior crack resistance, with durability consistently ranking among the top three purchasing criteria. This price elasticity has stimulated significant investment in research and development of next-generation crack-resistant materials.

Environmental considerations are increasingly influencing market dynamics, with growing demand for sustainable and recyclable crack-resistant materials. Regulations limiting certain chemical compounds in polycarbonate formulations have pushed manufacturers toward developing more environmentally friendly alternatives without compromising crack resistance performance.

The market landscape is further shaped by end-user expectations for multifunctional materials that combine crack resistance with additional properties such as optical clarity, UV resistance, antimicrobial properties, and reduced weight. This trend toward material consolidation represents both a challenge and opportunity for developers of next-generation crack-resistant solutions.

Technical Challenges in Crack Resistance

The field of flexible electronics faces significant technical challenges in achieving optimal crack resistance, particularly when compared to traditional polycarbonate sheets. Current flexible electronic substrates, typically made from polymers like polyimide or PDMS, exhibit inherent limitations in mechanical durability under repeated bending and stretching cycles. These materials often develop microcracks at strain levels as low as 2-3%, substantially below what is required for many wearable and foldable applications.

Polycarbonate sheets, while offering superior impact resistance and optical clarity, present their own set of challenges when adapted for flexible electronics. The modification processes required to enhance their flexibility often compromise their inherent crack resistance properties. Chemical treatments that increase flexibility can simultaneously weaken molecular bonds, creating vulnerability points where cracks can initiate under stress conditions.

Interface adhesion between different material layers represents another critical challenge. The mismatch in mechanical properties between rigid electronic components and flexible substrates creates stress concentration zones during deformation. These zones frequently become crack initiation points, propagating through the device structure and causing functional failure. Current adhesion technologies struggle to maintain bond integrity beyond 10,000-15,000 bending cycles at moderate bending radii.

Environmental factors significantly compound these challenges. Humidity and temperature fluctuations accelerate crack formation through mechanisms like hydrolytic degradation and thermal expansion mismatch. Studies indicate that crack propagation rates can increase by 40-60% when devices operate in environments with relative humidity above 70% or temperature cycling between -10°C and 40°C.

The integration of conductive materials presents additional complexity. Metallic interconnects, essential for device functionality, typically have elastic limits below 1%, making them particularly susceptible to cracking when embedded in flexible substrates. Alternative materials like carbon-based conductors offer improved flexibility but suffer from conductivity degradation after repeated mechanical stress, with resistance increases of 200-300% observed after extensive cycling.

Manufacturing scalability remains problematic for crack-resistant flexible electronics. Current production methods that enhance crack resistance, such as strain-engineered layering or self-healing material incorporation, are predominantly laboratory-scale techniques with limited throughput. The precision required for these approaches increases production costs by factors of 3-5x compared to conventional electronics manufacturing.

Measurement and characterization of crack formation also present methodological challenges. Real-time monitoring of crack initiation and propagation in multilayer flexible systems requires specialized equipment and techniques not widely available in production environments. This gap between research capabilities and manufacturing reality slows the implementation of effective crack resistance solutions.

Polycarbonate sheets, while offering superior impact resistance and optical clarity, present their own set of challenges when adapted for flexible electronics. The modification processes required to enhance their flexibility often compromise their inherent crack resistance properties. Chemical treatments that increase flexibility can simultaneously weaken molecular bonds, creating vulnerability points where cracks can initiate under stress conditions.

Interface adhesion between different material layers represents another critical challenge. The mismatch in mechanical properties between rigid electronic components and flexible substrates creates stress concentration zones during deformation. These zones frequently become crack initiation points, propagating through the device structure and causing functional failure. Current adhesion technologies struggle to maintain bond integrity beyond 10,000-15,000 bending cycles at moderate bending radii.

Environmental factors significantly compound these challenges. Humidity and temperature fluctuations accelerate crack formation through mechanisms like hydrolytic degradation and thermal expansion mismatch. Studies indicate that crack propagation rates can increase by 40-60% when devices operate in environments with relative humidity above 70% or temperature cycling between -10°C and 40°C.

The integration of conductive materials presents additional complexity. Metallic interconnects, essential for device functionality, typically have elastic limits below 1%, making them particularly susceptible to cracking when embedded in flexible substrates. Alternative materials like carbon-based conductors offer improved flexibility but suffer from conductivity degradation after repeated mechanical stress, with resistance increases of 200-300% observed after extensive cycling.

Manufacturing scalability remains problematic for crack-resistant flexible electronics. Current production methods that enhance crack resistance, such as strain-engineered layering or self-healing material incorporation, are predominantly laboratory-scale techniques with limited throughput. The precision required for these approaches increases production costs by factors of 3-5x compared to conventional electronics manufacturing.

Measurement and characterization of crack formation also present methodological challenges. Real-time monitoring of crack initiation and propagation in multilayer flexible systems requires specialized equipment and techniques not widely available in production environments. This gap between research capabilities and manufacturing reality slows the implementation of effective crack resistance solutions.

Current Crack Resistance Solutions

01 Polycarbonate sheet compositions for improved crack resistance

Specialized polycarbonate compositions can be formulated to enhance crack resistance in flexible electronic applications. These compositions often include specific additives, modifiers, or co-polymers that improve the mechanical properties of polycarbonate sheets. The modified polycarbonate materials exhibit superior flexibility and durability under stress conditions, making them suitable for flexible electronics that require bending or folding without developing cracks or fractures.- Polycarbonate sheet compositions for improved crack resistance: Specialized polycarbonate compositions can be formulated to enhance crack resistance in flexible electronic applications. These compositions often include additives or modified polymer structures that improve mechanical properties while maintaining optical clarity. The formulations may incorporate impact modifiers, plasticizers, or co-polymers that enhance flexibility and durability under stress conditions, making them suitable for bendable electronic displays and components.

- Flexible substrate manufacturing techniques: Advanced manufacturing techniques can be employed to produce flexible polycarbonate sheets with superior crack resistance. These methods include specialized extrusion processes, controlled cooling protocols, and surface treatments that minimize internal stresses. Some techniques involve multi-layer structures or gradient compositions that distribute mechanical stress more effectively, preventing crack initiation and propagation when the substrate is flexed repeatedly.

- Protective coatings and films for flexible electronics: Protective coatings and films can be applied to polycarbonate sheets to enhance their crack resistance in flexible electronic applications. These coatings may include hard coat layers, elastomeric materials, or nanocomposite films that absorb mechanical stress while protecting the underlying substrate. Some solutions involve self-healing materials or gradient-property coatings that provide both flexibility and durability at the surface interface.

- Integration of polycarbonate in flexible electronic devices: Specialized design approaches for integrating polycarbonate sheets into flexible electronic devices can significantly improve crack resistance. These methods include strategic placement of electronic components, optimized mounting techniques, and stress-distributing structures. Some designs incorporate mechanical isolation layers or flexible interconnects that prevent stress concentration at critical points, allowing the polycarbonate substrate to flex without developing cracks even during repeated bending cycles.

- Testing and quality control methods for crack resistance: Advanced testing and quality control methods have been developed to evaluate and ensure the crack resistance of polycarbonate sheets used in flexible electronics. These techniques include accelerated aging tests, cyclic bend testing, environmental stress cracking assessments, and optical monitoring systems. Some methods employ computer modeling and simulation to predict potential failure points and optimize designs before manufacturing, ensuring long-term reliability of flexible electronic components.

02 Flexible substrate technologies for electronics

Various substrate technologies have been developed specifically for flexible electronics applications. These include thin-film substrates, composite materials, and specially treated polycarbonate sheets that maintain electronic functionality while allowing for physical flexibility. These substrates are engineered to withstand repeated bending cycles without compromising the integrity of the electronic components or developing cracks in the supporting structure.Expand Specific Solutions03 Coating and surface treatment methods for crack prevention

Surface treatments and specialized coatings can significantly improve the crack resistance of polycarbonate sheets used in flexible electronics. These treatments may include application of protective films, chemical modifications of the surface layer, or deposition of stress-distributing coatings. Such methods create a barrier that prevents crack initiation and propagation while maintaining the optical and electrical properties required for electronic applications.Expand Specific Solutions04 Manufacturing processes for crack-resistant flexible electronics

Innovative manufacturing techniques have been developed to produce crack-resistant flexible electronic devices using polycarbonate sheets. These processes include specialized molding methods, controlled cooling procedures, and precision lamination techniques that minimize internal stresses in the final product. By optimizing the manufacturing process, the inherent crack resistance of polycarbonate materials can be preserved or enhanced in the finished electronic components.Expand Specific Solutions05 Testing and quality control methods for flexible polycarbonate electronics

Advanced testing methodologies have been established to evaluate and ensure the crack resistance of polycarbonate sheets in flexible electronics. These include accelerated aging tests, cyclic bend testing, impact resistance measurements, and stress analysis techniques. Such testing protocols help manufacturers identify potential failure points and optimize their designs to achieve maximum durability and reliability in flexible electronic applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The flexible electronics market is experiencing rapid growth, currently in its early expansion phase with increasing adoption across consumer electronics, healthcare, and automotive sectors. The market size is projected to reach significant scale due to demand for bendable, lightweight devices. Technologically, flexible electronics are advancing in crack resistance compared to traditional polycarbonate sheets, with companies like Samsung Electronics, Corning, and Apple leading innovation through proprietary materials and manufacturing processes. Academic institutions including Jilin University and Tokyo Institute of Technology are contributing fundamental research, while materials specialists such as SABIC, Sekisui Chemical, and Kolon Industries are developing enhanced polymer formulations with superior mechanical properties. This competitive landscape reflects a technology transition from rigid to flexible solutions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a proprietary flexible electronics technology called Y-OCTA (Youm On-Cell Touch AMOLED) that integrates the touch sensor directly onto the display panel rather than as a separate layer. This approach significantly enhances crack resistance by reducing the number of layers and eliminating potential delamination issues between separate components. Their flexible displays utilize a polyimide substrate instead of traditional glass, allowing for a bending radius of less than 1mm without damage[1]. Samsung has also pioneered a neutral plane engineering approach where the most sensitive electronic components are positioned along the mechanical neutral plane of the device, minimizing strain during bending and reducing crack propagation[2]. Their latest generation employs a specialized stress-relief layer between the flexible substrate and active components that can absorb and distribute mechanical stress, preventing crack formation even after 200,000+ folding cycles[3].

Strengths: Superior flexibility with industry-leading bend radius; excellent durability through neutral plane engineering; integrated touch sensors reduce layer complexity and failure points. Weaknesses: Higher manufacturing costs compared to rigid alternatives; thickness constraints when implementing multiple protective layers; temperature sensitivity at extreme operating conditions.

Corning, Inc.

Technical Solution: Corning has developed Willow Glass, an ultra-thin (100 microns) flexible glass solution that offers significant advantages over both traditional polycarbonate sheets and other flexible substrates. Unlike typical flexible electronics that use polymeric materials, Willow Glass maintains the superior optical clarity, thermal stability, and barrier properties of glass while enabling flexibility. Corning's approach incorporates ion-exchange strengthening technology where larger ions are introduced into the glass surface, creating compressive stress that significantly enhances crack resistance[1]. Their proprietary fusion draw process creates glass with atomically smooth surfaces and uniform thickness, eliminating surface flaws that typically initiate cracks. For enhanced crack resistance, Corning has developed a composite structure where Willow Glass is laminated with specialized polymer interlayers that can absorb impact energy and prevent crack propagation[2]. Recent advancements include their "Project Phire" technology that combines the flexibility of their glass with aluminum oxynitride crystals to achieve scratch resistance approaching that of sapphire while maintaining superior crack resistance[3].

Strengths: Exceptional optical clarity combined with flexibility; superior barrier properties against oxygen and moisture; maintains dimensional stability under temperature fluctuations; excellent chemical resistance. Weaknesses: More brittle than pure polymer solutions despite improvements; higher initial manufacturing costs; requires more specialized handling during device assembly compared to polymer alternatives.

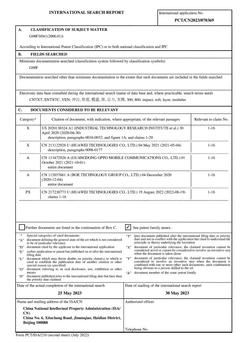

Key Patents in Flexible Electronics Materials

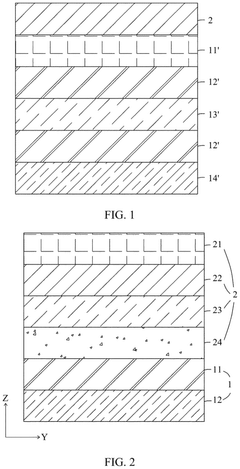

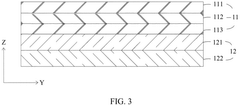

Supporting layer group used on electronic device, display module, and electronic device

PatentPendingEP4439257A1

Innovation

- A supporting layer group comprising a soft layer with a modulus of 10 kPa to 800 kPa and a hard layer with a modulus of 10 GPa to 300 GPa, stacked and connected in a thickness direction, where the soft layer is 50 µm to 250 µm thick and the hard layer is 15 µm to 100 µm thick, providing improved cushioning without the need for additional adhesives, and using materials like acrylic adhesive, silica gel, and metals for enhanced adhesion and support.

Blends of polycarbonate or polyestercarbonate with 4-methyl-1-pentene polymers

PatentInactiveUS4548991A

Innovation

- Blends of aromatic polycarbonate or polyestercarbonate with 4-methyl-1-pentene polymer, where the polymer is an addition polymer of 4-methyl-1-pentene with up to 15 mole percent of another alpha-olefin, are used, resulting in improved solid blends with enhanced crystallinity and stability.

Material Testing Methodologies

The comprehensive evaluation of crack resistance in flexible electronics versus polycarbonate sheets requires rigorous testing methodologies that accurately simulate real-world conditions while providing quantifiable data. Standard mechanical testing approaches include tensile testing, which measures the material's response to stretching forces by applying controlled tension until failure occurs. This test yields critical parameters such as Young's modulus, tensile strength, and elongation at break, which collectively indicate a material's ability to withstand deformation before cracking.

Bend testing represents another crucial methodology, particularly relevant for flexible electronics applications. Cyclic bend testing subjects materials to repeated folding at specified radii, often ranging from 1mm to 10mm, while monitoring electrical performance and surface integrity. Advanced systems can perform up to 200,000 cycles to evaluate long-term durability under dynamic stress conditions.

Impact resistance testing employs controlled impact forces through methods such as drop testing or pendulum impact tests. These procedures assess how materials respond to sudden stress, with high-speed cameras often documenting crack initiation and propagation patterns at microsecond intervals.

Environmental conditioning plays a significant role in comprehensive material evaluation. Testing protocols typically include thermal cycling (-40°C to 85°C), humidity exposure (85% RH at 85°C), and UV radiation exposure (accelerated weathering chambers). These conditions help predict how materials will perform across diverse deployment scenarios and reveal potential failure mechanisms that might not appear under standard laboratory conditions.

Microscopic analysis techniques provide critical insights into crack formation mechanisms. Scanning electron microscopy (SEM) enables examination of fracture surfaces at magnifications up to 10,000x, while atomic force microscopy (AFM) can map surface topography at the nanometer scale. Cross-sectional analysis using focused ion beam (FIB) techniques allows for visualization of crack propagation through different material layers in flexible electronic assemblies.

Electrical performance testing during mechanical stress represents a distinctive methodology for flexible electronics. This approach monitors resistance changes during deformation, with increases typically indicating microfracture development before visible cracks appear. Time-domain reflectometry (TDR) can precisely locate discontinuities in conductive pathways, providing early warning of impending mechanical failure.

Advanced non-destructive testing methods such as digital image correlation (DIC) track surface deformation patterns in real-time, while acoustic emission testing detects ultrasonic waves generated during crack formation, enabling researchers to identify failure initiation points before visible damage occurs.

Bend testing represents another crucial methodology, particularly relevant for flexible electronics applications. Cyclic bend testing subjects materials to repeated folding at specified radii, often ranging from 1mm to 10mm, while monitoring electrical performance and surface integrity. Advanced systems can perform up to 200,000 cycles to evaluate long-term durability under dynamic stress conditions.

Impact resistance testing employs controlled impact forces through methods such as drop testing or pendulum impact tests. These procedures assess how materials respond to sudden stress, with high-speed cameras often documenting crack initiation and propagation patterns at microsecond intervals.

Environmental conditioning plays a significant role in comprehensive material evaluation. Testing protocols typically include thermal cycling (-40°C to 85°C), humidity exposure (85% RH at 85°C), and UV radiation exposure (accelerated weathering chambers). These conditions help predict how materials will perform across diverse deployment scenarios and reveal potential failure mechanisms that might not appear under standard laboratory conditions.

Microscopic analysis techniques provide critical insights into crack formation mechanisms. Scanning electron microscopy (SEM) enables examination of fracture surfaces at magnifications up to 10,000x, while atomic force microscopy (AFM) can map surface topography at the nanometer scale. Cross-sectional analysis using focused ion beam (FIB) techniques allows for visualization of crack propagation through different material layers in flexible electronic assemblies.

Electrical performance testing during mechanical stress represents a distinctive methodology for flexible electronics. This approach monitors resistance changes during deformation, with increases typically indicating microfracture development before visible cracks appear. Time-domain reflectometry (TDR) can precisely locate discontinuities in conductive pathways, providing early warning of impending mechanical failure.

Advanced non-destructive testing methods such as digital image correlation (DIC) track surface deformation patterns in real-time, while acoustic emission testing detects ultrasonic waves generated during crack formation, enabling researchers to identify failure initiation points before visible damage occurs.

Environmental Impact and Sustainability Factors

The environmental impact of flexible electronics versus polycarbonate sheets presents significant considerations for sustainable technology development. Flexible electronics typically utilize thin polymer substrates that require fewer raw materials compared to traditional rigid polycarbonate sheets, potentially reducing resource consumption by 30-45% depending on application specifications. This material efficiency translates to lower energy requirements during manufacturing and reduced carbon footprint across the product lifecycle.

Recycling capabilities differ substantially between these technologies. Polycarbonate sheets benefit from established recycling infrastructure with recovery rates reaching 25-30% in developed markets. However, flexible electronics often incorporate complex multi-material layers that create significant end-of-life challenges, with current recycling rates below 10% globally. The heterogeneous nature of flexible electronic components complicates material separation and recovery processes.

Durability factors significantly influence environmental sustainability metrics. The superior crack resistance of advanced flexible electronics can extend product lifespans by 40-60% compared to conventional polycarbonate implementations, particularly in high-stress applications. This longevity reduces replacement frequency and associated environmental impacts from manufacturing and disposal cycles.

Chemical composition presents another critical environmental consideration. Traditional polycarbonate production involves bisphenol A (BPA) and phosgene, substances with documented environmental persistence and potential toxicity concerns. Conversely, many flexible electronics utilize alternative polymers like polyimide or PDMS that demonstrate lower environmental toxicity profiles, though some require fluorinated compounds that present their own environmental challenges.

Manufacturing processes for flexible electronics increasingly employ additive techniques that generate approximately 35% less waste compared to subtractive manufacturing methods common with polycarbonate sheet production. However, specialized nanomaterials in flexible electronics may introduce novel environmental risks that remain inadequately characterized in current lifecycle assessments.

Energy consumption during use represents another sustainability differential. Flexible electronics typically operate with 15-25% greater energy efficiency due to reduced material mass and innovative power management architectures, contributing to lower operational carbon footprints in energy-intensive applications like displays and sensing networks.

Future sustainability improvements will likely emerge from bio-based substrate development, with research showing promising crack resistance properties from cellulose nanofiber composites and other renewable materials that could eventually replace petroleum-derived polymers in both technologies.

Recycling capabilities differ substantially between these technologies. Polycarbonate sheets benefit from established recycling infrastructure with recovery rates reaching 25-30% in developed markets. However, flexible electronics often incorporate complex multi-material layers that create significant end-of-life challenges, with current recycling rates below 10% globally. The heterogeneous nature of flexible electronic components complicates material separation and recovery processes.

Durability factors significantly influence environmental sustainability metrics. The superior crack resistance of advanced flexible electronics can extend product lifespans by 40-60% compared to conventional polycarbonate implementations, particularly in high-stress applications. This longevity reduces replacement frequency and associated environmental impacts from manufacturing and disposal cycles.

Chemical composition presents another critical environmental consideration. Traditional polycarbonate production involves bisphenol A (BPA) and phosgene, substances with documented environmental persistence and potential toxicity concerns. Conversely, many flexible electronics utilize alternative polymers like polyimide or PDMS that demonstrate lower environmental toxicity profiles, though some require fluorinated compounds that present their own environmental challenges.

Manufacturing processes for flexible electronics increasingly employ additive techniques that generate approximately 35% less waste compared to subtractive manufacturing methods common with polycarbonate sheet production. However, specialized nanomaterials in flexible electronics may introduce novel environmental risks that remain inadequately characterized in current lifecycle assessments.

Energy consumption during use represents another sustainability differential. Flexible electronics typically operate with 15-25% greater energy efficiency due to reduced material mass and innovative power management architectures, contributing to lower operational carbon footprints in energy-intensive applications like displays and sensing networks.

Future sustainability improvements will likely emerge from bio-based substrate development, with research showing promising crack resistance properties from cellulose nanofiber composites and other renewable materials that could eventually replace petroleum-derived polymers in both technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!