Future Trends in Ethylene Vinyl Acetate for Medical Devices

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Medical Devices Evolution and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a crucial material in the medical device industry, with its evolution closely tied to advancements in healthcare technology. The journey of EVA in medical applications began in the 1960s when its biocompatibility and versatility were first recognized. Since then, it has undergone significant developments to meet the growing demands of the medical field.

The primary objective in the evolution of EVA for medical devices is to enhance patient care through improved material properties. Researchers and manufacturers aim to develop EVA formulations that offer superior biocompatibility, durability, and functionality. This includes creating EVA variants with enhanced flexibility, transparency, and resistance to sterilization processes, all while maintaining or improving its inherent benefits.

Another key goal is to expand the range of medical applications for EVA. As healthcare needs diversify, there is a push to adapt EVA for use in more specialized medical devices, from advanced drug delivery systems to sophisticated implantable devices. This expansion requires continuous innovation in EVA composition and processing techniques.

Sustainability has also become a critical objective in recent years. The medical device industry is increasingly focused on developing eco-friendly materials, and EVA is no exception. Efforts are underway to create biodegradable or recyclable EVA formulations that maintain the material's desirable properties while reducing environmental impact.

The evolution of EVA in medical devices is also driven by regulatory requirements. As safety standards become more stringent, there is a constant need to improve the material's purity, reduce potential leachables, and enhance its overall safety profile. This has led to the development of medical-grade EVA that meets or exceeds regulatory standards across different global markets.

Looking ahead, the future trends in EVA for medical devices are likely to focus on smart materials and personalized healthcare. There is growing interest in developing EVA composites that can incorporate sensors or respond to specific biological triggers. This could lead to the creation of intelligent medical devices capable of real-time monitoring and adaptive responses to patient needs.

In conclusion, the evolution of EVA in medical devices is characterized by a continuous drive for improvement and innovation. From its initial adoption to its current advanced formulations, EVA has proven to be a versatile and valuable material in healthcare. The ongoing objectives center around enhancing its properties, expanding its applications, ensuring sustainability, meeting regulatory demands, and preparing for the next generation of smart medical devices.

The primary objective in the evolution of EVA for medical devices is to enhance patient care through improved material properties. Researchers and manufacturers aim to develop EVA formulations that offer superior biocompatibility, durability, and functionality. This includes creating EVA variants with enhanced flexibility, transparency, and resistance to sterilization processes, all while maintaining or improving its inherent benefits.

Another key goal is to expand the range of medical applications for EVA. As healthcare needs diversify, there is a push to adapt EVA for use in more specialized medical devices, from advanced drug delivery systems to sophisticated implantable devices. This expansion requires continuous innovation in EVA composition and processing techniques.

Sustainability has also become a critical objective in recent years. The medical device industry is increasingly focused on developing eco-friendly materials, and EVA is no exception. Efforts are underway to create biodegradable or recyclable EVA formulations that maintain the material's desirable properties while reducing environmental impact.

The evolution of EVA in medical devices is also driven by regulatory requirements. As safety standards become more stringent, there is a constant need to improve the material's purity, reduce potential leachables, and enhance its overall safety profile. This has led to the development of medical-grade EVA that meets or exceeds regulatory standards across different global markets.

Looking ahead, the future trends in EVA for medical devices are likely to focus on smart materials and personalized healthcare. There is growing interest in developing EVA composites that can incorporate sensors or respond to specific biological triggers. This could lead to the creation of intelligent medical devices capable of real-time monitoring and adaptive responses to patient needs.

In conclusion, the evolution of EVA in medical devices is characterized by a continuous drive for improvement and innovation. From its initial adoption to its current advanced formulations, EVA has proven to be a versatile and valuable material in healthcare. The ongoing objectives center around enhancing its properties, expanding its applications, ensuring sustainability, meeting regulatory demands, and preparing for the next generation of smart medical devices.

Market Analysis for Medical-Grade EVA

The medical-grade Ethylene Vinyl Acetate (EVA) market is experiencing significant growth, driven by the increasing demand for advanced medical devices and the material's unique properties. The global market for medical-grade EVA is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2028. This growth is primarily attributed to the rising prevalence of chronic diseases, an aging population, and the continuous development of innovative medical technologies.

In the medical device sector, EVA is widely used in various applications due to its excellent biocompatibility, flexibility, and chemical resistance. The material finds extensive use in drug delivery systems, medical tubing, catheters, and wound dressings. The pharmaceutical industry, in particular, is a major consumer of medical-grade EVA, utilizing it in controlled release drug delivery systems and transdermal patches.

Geographically, North America currently dominates the medical-grade EVA market, accounting for approximately 35% of the global market share. This dominance is due to the region's advanced healthcare infrastructure, high healthcare expenditure, and presence of major medical device manufacturers. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, with a CAGR of 7.5% during the forecast period. This growth is fueled by improving healthcare facilities, increasing medical tourism, and rising disposable incomes in countries like China and India.

The market is characterized by intense competition among key players, including DuPont, Celanese Corporation, Exxon Mobil Corporation, and LyondellBasell Industries. These companies are focusing on research and development to enhance the properties of medical-grade EVA and expand its applications in the healthcare sector. Strategic collaborations with medical device manufacturers and healthcare providers are also becoming increasingly common to drive innovation and market penetration.

One of the key trends shaping the market is the growing demand for biodegradable and sustainable medical-grade EVA. As environmental concerns gain prominence, manufacturers are investing in developing eco-friendly alternatives that maintain the desirable properties of traditional EVA. This shift towards sustainability is expected to create new opportunities in the market and potentially reshape the competitive landscape in the coming years.

In the medical device sector, EVA is widely used in various applications due to its excellent biocompatibility, flexibility, and chemical resistance. The material finds extensive use in drug delivery systems, medical tubing, catheters, and wound dressings. The pharmaceutical industry, in particular, is a major consumer of medical-grade EVA, utilizing it in controlled release drug delivery systems and transdermal patches.

Geographically, North America currently dominates the medical-grade EVA market, accounting for approximately 35% of the global market share. This dominance is due to the region's advanced healthcare infrastructure, high healthcare expenditure, and presence of major medical device manufacturers. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, with a CAGR of 7.5% during the forecast period. This growth is fueled by improving healthcare facilities, increasing medical tourism, and rising disposable incomes in countries like China and India.

The market is characterized by intense competition among key players, including DuPont, Celanese Corporation, Exxon Mobil Corporation, and LyondellBasell Industries. These companies are focusing on research and development to enhance the properties of medical-grade EVA and expand its applications in the healthcare sector. Strategic collaborations with medical device manufacturers and healthcare providers are also becoming increasingly common to drive innovation and market penetration.

One of the key trends shaping the market is the growing demand for biodegradable and sustainable medical-grade EVA. As environmental concerns gain prominence, manufacturers are investing in developing eco-friendly alternatives that maintain the desirable properties of traditional EVA. This shift towards sustainability is expected to create new opportunities in the market and potentially reshape the competitive landscape in the coming years.

Current EVA Limitations in Medical Applications

Ethylene Vinyl Acetate (EVA) has been widely used in medical devices due to its versatility and biocompatibility. However, as medical technology advances, several limitations of EVA in medical applications have become apparent, necessitating further research and development.

One of the primary limitations of EVA in medical applications is its relatively low heat resistance. While EVA performs well at room temperature, it can soften or deform at higher temperatures, which may be problematic in certain medical procedures or during sterilization processes. This thermal instability can compromise the structural integrity of medical devices, potentially leading to device failure or reduced efficacy.

Another significant limitation is EVA's limited barrier properties. Although EVA provides some resistance to moisture and gases, it is not impermeable. This can be problematic in applications where maintaining a sterile environment or preventing drug leakage is crucial. The permeability of EVA may lead to contamination or reduced shelf life of medical products, particularly in drug delivery systems or packaging for sensitive medical components.

EVA also faces challenges in terms of its mechanical properties. While it offers good flexibility and impact resistance, it may not provide sufficient strength or durability for certain high-stress medical applications. This limitation can restrict its use in load-bearing implants or devices that require long-term structural stability under physiological conditions.

The material's susceptibility to degradation under certain conditions is another concern. Exposure to UV light, certain chemicals, or prolonged contact with bodily fluids can lead to the breakdown of EVA over time. This degradation can result in the release of potentially harmful compounds or compromise the functionality of medical devices, raising safety concerns for long-term implantable devices.

Furthermore, EVA's limited compatibility with certain drugs and active pharmaceutical ingredients (APIs) poses challenges in drug delivery applications. Some drugs may interact unfavorably with EVA, leading to reduced efficacy or unwanted chemical reactions. This limitation restricts the range of pharmaceuticals that can be effectively delivered using EVA-based systems.

Lastly, the processing and manufacturing of EVA for medical applications can be complex and costly. Achieving consistent quality and meeting stringent regulatory requirements for medical-grade EVA products often requires specialized equipment and processes. This can lead to higher production costs and longer development times for EVA-based medical devices.

These limitations highlight the need for ongoing research and development in EVA technology for medical applications. Addressing these challenges through material modifications, composite formulations, or novel processing techniques will be crucial in expanding the utility of EVA in future medical devices and therapies.

One of the primary limitations of EVA in medical applications is its relatively low heat resistance. While EVA performs well at room temperature, it can soften or deform at higher temperatures, which may be problematic in certain medical procedures or during sterilization processes. This thermal instability can compromise the structural integrity of medical devices, potentially leading to device failure or reduced efficacy.

Another significant limitation is EVA's limited barrier properties. Although EVA provides some resistance to moisture and gases, it is not impermeable. This can be problematic in applications where maintaining a sterile environment or preventing drug leakage is crucial. The permeability of EVA may lead to contamination or reduced shelf life of medical products, particularly in drug delivery systems or packaging for sensitive medical components.

EVA also faces challenges in terms of its mechanical properties. While it offers good flexibility and impact resistance, it may not provide sufficient strength or durability for certain high-stress medical applications. This limitation can restrict its use in load-bearing implants or devices that require long-term structural stability under physiological conditions.

The material's susceptibility to degradation under certain conditions is another concern. Exposure to UV light, certain chemicals, or prolonged contact with bodily fluids can lead to the breakdown of EVA over time. This degradation can result in the release of potentially harmful compounds or compromise the functionality of medical devices, raising safety concerns for long-term implantable devices.

Furthermore, EVA's limited compatibility with certain drugs and active pharmaceutical ingredients (APIs) poses challenges in drug delivery applications. Some drugs may interact unfavorably with EVA, leading to reduced efficacy or unwanted chemical reactions. This limitation restricts the range of pharmaceuticals that can be effectively delivered using EVA-based systems.

Lastly, the processing and manufacturing of EVA for medical applications can be complex and costly. Achieving consistent quality and meeting stringent regulatory requirements for medical-grade EVA products often requires specialized equipment and processes. This can lead to higher production costs and longer development times for EVA-based medical devices.

These limitations highlight the need for ongoing research and development in EVA technology for medical applications. Addressing these challenges through material modifications, composite formulations, or novel processing techniques will be crucial in expanding the utility of EVA in future medical devices and therapies.

Existing EVA Formulations for Medical Use

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly employed in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and thermal properties can be tailored by adjusting the vinyl acetate content and molecular weight of the EVA copolymer.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It is commonly used in footwear, sports equipment, and building insulation. The foam can be crosslinked to enhance its physical properties and heat resistance.

- EVA in solar panel encapsulation: EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps to improve the durability and efficiency of photovoltaic modules. The EVA encapsulant is typically crosslinked to enhance its performance in outdoor conditions.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes the addition of compatibilizers, crosslinking agents, and fillers to improve mechanical strength, flame retardancy, or processability. EVA blends are used in various industries, including packaging, automotive, and construction.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used as a base polymer in hot melt adhesives, pressure-sensitive adhesives, and other bonding applications. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam density and properties can be controlled through formulation and processing techniques.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and protection for solar cells. The material helps to enhance the durability and performance of solar panels by protecting the cells from moisture, UV radiation, and mechanical stress. Specialized EVA formulations are developed to meet the specific requirements of solar panel encapsulation.Expand Specific Solutions05 EVA in packaging and film applications

EVA is utilized in various packaging and film applications due to its flexibility, clarity, and barrier properties. It can be used to produce stretch films, shrink films, and food packaging materials. The material's properties can be modified through copolymerization or blending to enhance specific characteristics such as heat-sealability, puncture resistance, or gas barrier properties.Expand Specific Solutions

Key EVA Manufacturers and Suppliers

The market for ethylene vinyl acetate (EVA) in medical devices is in a growth phase, driven by increasing demand for advanced healthcare solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, EVA applications in medical devices are evolving, with companies like China Petroleum & Chemical Corp., Celanese International Corp., and Hanwha Chemical Co., Ltd. leading innovation. These firms are developing enhanced EVA formulations for improved biocompatibility, durability, and drug delivery capabilities. Emerging players such as Borealis AG and LTS LOHMANN Therapie-Systeme AG are also contributing to technological advancements, particularly in specialized medical applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is advancing EVA technology for medical devices through innovative copolymerization techniques. They are developing EVA grades with enhanced biocompatibility and controlled release properties[1]. Their research focuses on optimizing the vinyl acetate content and molecular weight distribution to achieve specific mechanical and thermal properties suitable for various medical applications[2]. Sinopec is also exploring the incorporation of functional additives into EVA formulations to impart antimicrobial or anti-inflammatory properties, addressing the growing demand for multifunctional medical materials[3].

Strengths: Extensive petrochemical expertise, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Relatively new entrant in specialized medical-grade EVA market, potential regulatory hurdles in international markets.

Celanese International Corp.

Technical Solution: Celanese is at the forefront of EVA innovation for medical devices, focusing on developing high-performance, medical-grade EVA resins. Their VitalDose® EVA platform offers customizable drug delivery solutions with precise control over release kinetics[4]. Celanese is investing in advanced polymer processing techniques to create EVA formulations with improved barrier properties and stability, crucial for long-term implantable devices[5]. They are also exploring the integration of EVA with other polymers to create hybrid materials that combine the flexibility of EVA with enhanced mechanical strength or biodegradability[6].

Strengths: Established leader in medical-grade polymers, strong intellectual property portfolio, and global manufacturing presence. Weaknesses: High dependence on petrochemical feedstocks, potential vulnerability to raw material price fluctuations.

Innovative EVA Properties for Medical Devices

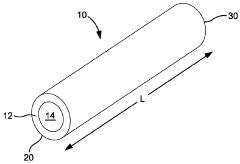

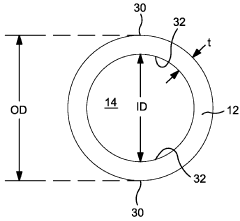

Medical Tube

PatentInactiveUS20180163033A1

Innovation

- A medical tube composed of a polymer composition comprising ethylene vinyl acetate polymer and viscoelastic additives, with controlled vinyl acetate content and melt flow index, which reduces kinking tendency and maintains transparency and biocompatibility while minimizing chlorine content.

PROCESS AND PRODUCT BIOMEMBRAN DEVICE FOR THE SLOW RELEASE OF BIOACTIVE COMPOUNDS

PatentInactiveBR102015026487A2

Innovation

- A biomembrane device made from poly[(ethylene)-co-(vinyl acetate)] (Amazônia Skin EVA) is developed, saturated with Chondroitinase ABC, allowing for a slow release of the enzyme through a complex morphology with microcompartments, ensuring a controlled diffusion pattern.

Regulatory Framework for Medical-Grade EVA

The regulatory framework for medical-grade Ethylene Vinyl Acetate (EVA) is a critical aspect of its use in medical devices. As the healthcare industry continues to evolve, regulatory bodies worldwide are adapting their guidelines to ensure the safety and efficacy of medical devices incorporating EVA materials. The U.S. Food and Drug Administration (FDA) plays a pivotal role in setting standards for medical-grade EVA, particularly through its 510(k) clearance process for medical devices. This process requires manufacturers to demonstrate that their EVA-based devices are substantially equivalent to legally marketed predicate devices in terms of safety and effectiveness.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have introduced more stringent requirements for medical devices, including those utilizing EVA. These regulations emphasize the importance of clinical evidence, post-market surveillance, and traceability throughout the supply chain. Manufacturers must now provide more comprehensive technical documentation and conduct thorough risk assessments for EVA-based medical devices.

The International Organization for Standardization (ISO) has also developed specific standards relevant to medical-grade EVA, such as ISO 10993 for biocompatibility testing and ISO 13485 for quality management systems in medical device manufacturing. These standards are continuously updated to reflect advancements in materials science and medical technology, ensuring that EVA-based devices meet the highest quality and safety benchmarks.

Emerging trends in the regulatory landscape for medical-grade EVA include a growing focus on sustainability and environmental impact. Regulatory bodies are beginning to incorporate guidelines for the lifecycle management of medical devices, including considerations for the disposal and recycling of EVA materials. This shift is likely to influence future product development and manufacturing processes in the medical device industry.

Additionally, as personalized medicine gains traction, regulators are exploring frameworks to address the use of custom-made or 3D-printed medical devices that may incorporate EVA materials. This presents new challenges in terms of quality control and standardization, requiring adaptive regulatory approaches to ensure patient safety while fostering innovation.

The global harmonization of regulatory standards for medical-grade EVA is another key trend. Initiatives like the Medical Device Single Audit Program (MDSAP) aim to streamline the audit process across multiple regulatory jurisdictions, potentially simplifying compliance for manufacturers of EVA-based medical devices operating in international markets.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have introduced more stringent requirements for medical devices, including those utilizing EVA. These regulations emphasize the importance of clinical evidence, post-market surveillance, and traceability throughout the supply chain. Manufacturers must now provide more comprehensive technical documentation and conduct thorough risk assessments for EVA-based medical devices.

The International Organization for Standardization (ISO) has also developed specific standards relevant to medical-grade EVA, such as ISO 10993 for biocompatibility testing and ISO 13485 for quality management systems in medical device manufacturing. These standards are continuously updated to reflect advancements in materials science and medical technology, ensuring that EVA-based devices meet the highest quality and safety benchmarks.

Emerging trends in the regulatory landscape for medical-grade EVA include a growing focus on sustainability and environmental impact. Regulatory bodies are beginning to incorporate guidelines for the lifecycle management of medical devices, including considerations for the disposal and recycling of EVA materials. This shift is likely to influence future product development and manufacturing processes in the medical device industry.

Additionally, as personalized medicine gains traction, regulators are exploring frameworks to address the use of custom-made or 3D-printed medical devices that may incorporate EVA materials. This presents new challenges in terms of quality control and standardization, requiring adaptive regulatory approaches to ensure patient safety while fostering innovation.

The global harmonization of regulatory standards for medical-grade EVA is another key trend. Initiatives like the Medical Device Single Audit Program (MDSAP) aim to streamline the audit process across multiple regulatory jurisdictions, potentially simplifying compliance for manufacturers of EVA-based medical devices operating in international markets.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development and application of Ethylene Vinyl Acetate (EVA) for medical devices. As the use of EVA in healthcare continues to expand, manufacturers and researchers must prioritize these aspects to ensure patient safety and regulatory compliance.

EVA's biocompatibility profile has been extensively studied, demonstrating its suitability for various medical applications. The material's low toxicity and minimal tissue reactivity make it an attractive choice for implantable devices and drug delivery systems. However, ongoing research is focused on further improving its biocompatibility, particularly for long-term implantation scenarios.

One of the key trends in EVA biocompatibility is the development of surface modification techniques. These methods aim to enhance cell adhesion, reduce protein adsorption, and minimize the risk of thrombosis. Plasma treatment, grafting of bioactive molecules, and nanostructuring of EVA surfaces are among the promising approaches being explored to optimize tissue-material interactions.

Safety considerations for EVA in medical devices extend beyond biocompatibility to include mechanical stability, degradation resistance, and leachable compounds. Researchers are investigating ways to improve EVA's long-term stability in physiological environments, ensuring that devices maintain their structural integrity and functionality over extended periods.

The potential release of additives and degradation products from EVA-based medical devices is a critical safety concern. Future trends in this area include the development of more stable EVA formulations with reduced leaching potential and the implementation of advanced analytical techniques for comprehensive characterization of extractables and leachables.

Antimicrobial properties are becoming increasingly important in EVA-based medical devices to prevent device-associated infections. Researchers are exploring various strategies to impart antimicrobial activity to EVA, such as incorporating antimicrobial agents into the polymer matrix or applying antimicrobial coatings.

Regulatory bodies are continually updating guidelines for biocompatibility and safety testing of medical devices. Future trends in EVA development will likely involve more rigorous and comprehensive testing protocols, including advanced in vitro models and long-term in vivo studies to better predict device performance and safety in clinical settings.

As personalized medicine advances, there is a growing interest in tailoring EVA formulations to specific patient needs. This may involve developing EVA variants with customized mechanical properties, drug release profiles, or biocompatibility characteristics to optimize device performance for individual patients or specific medical conditions.

EVA's biocompatibility profile has been extensively studied, demonstrating its suitability for various medical applications. The material's low toxicity and minimal tissue reactivity make it an attractive choice for implantable devices and drug delivery systems. However, ongoing research is focused on further improving its biocompatibility, particularly for long-term implantation scenarios.

One of the key trends in EVA biocompatibility is the development of surface modification techniques. These methods aim to enhance cell adhesion, reduce protein adsorption, and minimize the risk of thrombosis. Plasma treatment, grafting of bioactive molecules, and nanostructuring of EVA surfaces are among the promising approaches being explored to optimize tissue-material interactions.

Safety considerations for EVA in medical devices extend beyond biocompatibility to include mechanical stability, degradation resistance, and leachable compounds. Researchers are investigating ways to improve EVA's long-term stability in physiological environments, ensuring that devices maintain their structural integrity and functionality over extended periods.

The potential release of additives and degradation products from EVA-based medical devices is a critical safety concern. Future trends in this area include the development of more stable EVA formulations with reduced leaching potential and the implementation of advanced analytical techniques for comprehensive characterization of extractables and leachables.

Antimicrobial properties are becoming increasingly important in EVA-based medical devices to prevent device-associated infections. Researchers are exploring various strategies to impart antimicrobial activity to EVA, such as incorporating antimicrobial agents into the polymer matrix or applying antimicrobial coatings.

Regulatory bodies are continually updating guidelines for biocompatibility and safety testing of medical devices. Future trends in EVA development will likely involve more rigorous and comprehensive testing protocols, including advanced in vitro models and long-term in vivo studies to better predict device performance and safety in clinical settings.

As personalized medicine advances, there is a growing interest in tailoring EVA formulations to specific patient needs. This may involve developing EVA variants with customized mechanical properties, drug release profiles, or biocompatibility characteristics to optimize device performance for individual patients or specific medical conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!