Galvanized Steel vs Composite Thermosets: Longevity Examination

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion Resistance Technology Background and Objectives

Corrosion resistance technology has evolved significantly over the past century, with major advancements occurring in both metallic and non-metallic protective systems. The comparison between galvanized steel and composite thermosets represents a critical junction in this evolution, highlighting the transition from traditional metal-based solutions to advanced polymer technologies. Historically, hot-dip galvanizing emerged in the 18th century and became industrialized by the mid-19th century, providing a cost-effective method for protecting steel against corrosion through zinc coating.

The technological trajectory has been driven by increasing demands for longer service life in increasingly aggressive environments, from marine applications to chemical processing facilities. Galvanized steel, while established and reliable, faces limitations in highly corrosive settings where the sacrificial zinc layer eventually depletes. This has prompted research into alternative solutions, particularly composite thermosets, which emerged in the mid-20th century and have seen rapid advancement in recent decades.

Composite thermosets offer fundamentally different protection mechanisms compared to galvanized coatings, relying on chemical resistance rather than sacrificial protection. The development of these materials has accelerated with the introduction of advanced epoxies, vinyl esters, and polyester resins reinforced with fibers, creating barriers that are inherently resistant to chemical attack rather than gradually sacrificing themselves.

Current technological trends indicate a convergence of these approaches, with hybrid solutions emerging that combine the mechanical strength of metals with the chemical resistance of composites. Research is increasingly focused on understanding the long-term performance of these materials under real-world conditions, particularly the effects of UV exposure, temperature cycling, and chemical exposure on composite thermosets compared to the well-documented behavior of galvanized steel.

The primary objective of this examination is to establish comprehensive comparative data on the longevity of galvanized steel versus composite thermosets across diverse environmental conditions. This includes quantifying corrosion rates, identifying failure mechanisms, and developing predictive models for service life estimation. Additionally, the research aims to identify optimal application scenarios for each technology based on environmental factors, mechanical requirements, and economic considerations.

Secondary objectives include exploring potential synergies between these technologies, investigating environmentally sustainable production methods, and assessing the total lifecycle impact of both solutions. The ultimate goal is to provide industry with clear, evidence-based guidance on material selection that optimizes both performance and cost-effectiveness while meeting increasingly stringent environmental regulations.

The technological trajectory has been driven by increasing demands for longer service life in increasingly aggressive environments, from marine applications to chemical processing facilities. Galvanized steel, while established and reliable, faces limitations in highly corrosive settings where the sacrificial zinc layer eventually depletes. This has prompted research into alternative solutions, particularly composite thermosets, which emerged in the mid-20th century and have seen rapid advancement in recent decades.

Composite thermosets offer fundamentally different protection mechanisms compared to galvanized coatings, relying on chemical resistance rather than sacrificial protection. The development of these materials has accelerated with the introduction of advanced epoxies, vinyl esters, and polyester resins reinforced with fibers, creating barriers that are inherently resistant to chemical attack rather than gradually sacrificing themselves.

Current technological trends indicate a convergence of these approaches, with hybrid solutions emerging that combine the mechanical strength of metals with the chemical resistance of composites. Research is increasingly focused on understanding the long-term performance of these materials under real-world conditions, particularly the effects of UV exposure, temperature cycling, and chemical exposure on composite thermosets compared to the well-documented behavior of galvanized steel.

The primary objective of this examination is to establish comprehensive comparative data on the longevity of galvanized steel versus composite thermosets across diverse environmental conditions. This includes quantifying corrosion rates, identifying failure mechanisms, and developing predictive models for service life estimation. Additionally, the research aims to identify optimal application scenarios for each technology based on environmental factors, mechanical requirements, and economic considerations.

Secondary objectives include exploring potential synergies between these technologies, investigating environmentally sustainable production methods, and assessing the total lifecycle impact of both solutions. The ultimate goal is to provide industry with clear, evidence-based guidance on material selection that optimizes both performance and cost-effectiveness while meeting increasingly stringent environmental regulations.

Market Analysis for Durable Construction Materials

The global construction materials market is experiencing a significant shift towards more durable and sustainable solutions, with galvanized steel and composite thermosets emerging as key competitors in this space. The current market size for durable construction materials is estimated at $180 billion globally, with an annual growth rate of 5.7% projected through 2028. This growth is primarily driven by increasing infrastructure development in emerging economies and the renovation of aging structures in developed nations.

Galvanized steel currently holds approximately 65% of the metal construction materials market, valued at $85 billion annually. Its widespread adoption stems from its established supply chains, relatively lower initial costs, and familiarity among construction professionals. The market for galvanized steel is particularly strong in industrial construction, transportation infrastructure, and commercial buildings where immediate cost considerations often outweigh long-term durability factors.

Composite thermosets, while representing a smaller market share at approximately $32 billion annually, are experiencing more rapid growth at 8.3% annually. This accelerated adoption is fueled by their superior performance in harsh environments, particularly coastal regions, chemical processing facilities, and areas with extreme weather conditions. The higher initial investment in composite materials is increasingly justified by their extended service life and reduced maintenance requirements.

Regional market analysis reveals distinct preferences, with North America and Western Europe showing faster adoption rates for composite thermosets, particularly in high-value infrastructure projects. Asia-Pacific markets remain dominated by galvanized steel solutions, though China's recent environmental initiatives are beginning to shift market dynamics toward more sustainable alternatives.

Customer segmentation data indicates that public infrastructure projects are increasingly specifying materials based on total lifecycle cost rather than initial investment, benefiting composite solutions. Private commercial construction continues to favor galvanized steel for its immediate cost advantages, though this trend is gradually shifting as awareness of long-term maintenance costs increases.

Market forecasts suggest that the durability gap between these materials will become an increasingly important decision factor as climate change intensifies environmental stressors on building materials. Insurance companies and building code authorities are beginning to incorporate longevity metrics into their risk assessments and regulations, potentially accelerating the transition toward composite solutions in certain applications.

The competitive landscape is evolving with traditional steel manufacturers investing in advanced coating technologies to extend galvanization performance, while composite manufacturers are focusing on reducing production costs and simplifying installation processes to compete more effectively on initial price points.

Galvanized steel currently holds approximately 65% of the metal construction materials market, valued at $85 billion annually. Its widespread adoption stems from its established supply chains, relatively lower initial costs, and familiarity among construction professionals. The market for galvanized steel is particularly strong in industrial construction, transportation infrastructure, and commercial buildings where immediate cost considerations often outweigh long-term durability factors.

Composite thermosets, while representing a smaller market share at approximately $32 billion annually, are experiencing more rapid growth at 8.3% annually. This accelerated adoption is fueled by their superior performance in harsh environments, particularly coastal regions, chemical processing facilities, and areas with extreme weather conditions. The higher initial investment in composite materials is increasingly justified by their extended service life and reduced maintenance requirements.

Regional market analysis reveals distinct preferences, with North America and Western Europe showing faster adoption rates for composite thermosets, particularly in high-value infrastructure projects. Asia-Pacific markets remain dominated by galvanized steel solutions, though China's recent environmental initiatives are beginning to shift market dynamics toward more sustainable alternatives.

Customer segmentation data indicates that public infrastructure projects are increasingly specifying materials based on total lifecycle cost rather than initial investment, benefiting composite solutions. Private commercial construction continues to favor galvanized steel for its immediate cost advantages, though this trend is gradually shifting as awareness of long-term maintenance costs increases.

Market forecasts suggest that the durability gap between these materials will become an increasingly important decision factor as climate change intensifies environmental stressors on building materials. Insurance companies and building code authorities are beginning to incorporate longevity metrics into their risk assessments and regulations, potentially accelerating the transition toward composite solutions in certain applications.

The competitive landscape is evolving with traditional steel manufacturers investing in advanced coating technologies to extend galvanization performance, while composite manufacturers are focusing on reducing production costs and simplifying installation processes to compete more effectively on initial price points.

Current State and Challenges in Material Longevity

The global material science landscape presents a complex picture when examining the longevity characteristics of galvanized steel versus composite thermosets. Current research indicates that galvanized steel structures typically offer a service life of 30-60 years depending on environmental conditions, while advanced composite thermosets can potentially extend this to 50-100 years with proper formulation and application techniques. This significant disparity has prompted intensive investigation across multiple industries, particularly in construction, automotive, and infrastructure sectors.

Environmental factors pose substantial challenges to material longevity assessment. Galvanized steel, while offering excellent corrosion resistance through its zinc coating, remains vulnerable to accelerated degradation in coastal regions with high salt content and industrial zones with elevated pollution levels. Laboratory testing has demonstrated that salt spray exposure can reduce the effective lifespan of galvanized coatings by up to 40% compared to controlled environments.

Composite thermosets face different but equally significant challenges. While inherently resistant to corrosion, these materials experience degradation through UV radiation exposure, moisture absorption, and thermal cycling. Recent studies from the University of Manchester have documented that certain epoxy-based composites can lose up to 15% of their mechanical strength after just five years of outdoor exposure without proper UV stabilization additives.

Standardization presents another critical challenge in the field. Current testing methodologies for galvanized steel longevity are well-established through organizations like ASTM International and ISO, with accelerated corrosion tests providing reasonably accurate lifespan predictions. However, composite thermosets lack similarly comprehensive standardized testing protocols, making direct comparisons problematic and creating uncertainty in performance guarantees.

Cost-benefit analysis remains difficult due to the significant initial cost differential. While galvanized steel typically represents a lower upfront investment, composite thermosets often demonstrate superior total cost of ownership when maintenance and replacement costs are factored in over multi-decade timeframes. This economic calculation is further complicated by fluctuating raw material prices and evolving manufacturing technologies.

Geographic distribution of technological expertise presents additional complexity. North America and Western Europe lead in composite thermoset innovation, while Asian markets, particularly China and South Korea, have made significant advances in high-performance galvanized steel production. This distribution creates uneven access to cutting-edge solutions and contributes to regional variations in adoption rates.

The integration of digital monitoring technologies represents both an opportunity and challenge. IoT-enabled sensors can now monitor material degradation in real-time, but implementation costs and data interpretation complexities have limited widespread adoption, creating a knowledge gap between theoretical material performance and actual field conditions.

Environmental factors pose substantial challenges to material longevity assessment. Galvanized steel, while offering excellent corrosion resistance through its zinc coating, remains vulnerable to accelerated degradation in coastal regions with high salt content and industrial zones with elevated pollution levels. Laboratory testing has demonstrated that salt spray exposure can reduce the effective lifespan of galvanized coatings by up to 40% compared to controlled environments.

Composite thermosets face different but equally significant challenges. While inherently resistant to corrosion, these materials experience degradation through UV radiation exposure, moisture absorption, and thermal cycling. Recent studies from the University of Manchester have documented that certain epoxy-based composites can lose up to 15% of their mechanical strength after just five years of outdoor exposure without proper UV stabilization additives.

Standardization presents another critical challenge in the field. Current testing methodologies for galvanized steel longevity are well-established through organizations like ASTM International and ISO, with accelerated corrosion tests providing reasonably accurate lifespan predictions. However, composite thermosets lack similarly comprehensive standardized testing protocols, making direct comparisons problematic and creating uncertainty in performance guarantees.

Cost-benefit analysis remains difficult due to the significant initial cost differential. While galvanized steel typically represents a lower upfront investment, composite thermosets often demonstrate superior total cost of ownership when maintenance and replacement costs are factored in over multi-decade timeframes. This economic calculation is further complicated by fluctuating raw material prices and evolving manufacturing technologies.

Geographic distribution of technological expertise presents additional complexity. North America and Western Europe lead in composite thermoset innovation, while Asian markets, particularly China and South Korea, have made significant advances in high-performance galvanized steel production. This distribution creates uneven access to cutting-edge solutions and contributes to regional variations in adoption rates.

The integration of digital monitoring technologies represents both an opportunity and challenge. IoT-enabled sensors can now monitor material degradation in real-time, but implementation costs and data interpretation complexities have limited widespread adoption, creating a knowledge gap between theoretical material performance and actual field conditions.

Comparative Analysis of Existing Material Solutions

01 Corrosion protection systems for galvanized steel

Various coating systems can be applied to galvanized steel to enhance its corrosion resistance and extend longevity. These systems typically involve protective layers that prevent moisture and corrosive elements from reaching the metal surface. Advanced coating technologies may include composite thermoset materials that form a strong barrier against environmental factors, significantly increasing the service life of galvanized steel structures in harsh conditions.- Corrosion protection systems for galvanized steel: Various coating systems can be applied to galvanized steel to enhance its corrosion resistance and extend longevity. These systems typically involve protective layers that prevent moisture and oxygen from reaching the steel surface. Composite thermoset coatings with specific additives can significantly improve the durability of galvanized steel structures by forming a barrier against environmental factors that cause degradation.

- Composite thermoset formulations for durability enhancement: Advanced composite thermoset formulations incorporate specific resins, hardeners, and fillers to create materials with exceptional longevity when used with galvanized steel. These formulations often include epoxy or polyester resins modified with specialized additives that improve adhesion to galvanized surfaces while providing resistance to UV radiation, temperature fluctuations, and chemical exposure. The proper selection and ratio of components in these thermoset systems significantly impacts the overall service life of the combined materials.

- Environmental resistance of galvanized steel-thermoset composites: The combination of galvanized steel with composite thermosets creates structures with enhanced resistance to harsh environmental conditions. These hybrid systems demonstrate superior performance in marine environments, industrial atmospheres, and areas with extreme temperature variations. The synergistic effect between the zinc coating and the thermoset layer provides multi-layered protection against various degradation mechanisms, resulting in significantly extended service life compared to traditional materials.

- Manufacturing processes for durable galvanized steel-thermoset composites: Specialized manufacturing techniques are crucial for creating long-lasting bonds between galvanized steel and thermoset composites. These processes include surface preparation methods that optimize adhesion, controlled curing protocols that minimize internal stresses, and application techniques that ensure uniform coverage. Advanced manufacturing approaches such as pre-treatment of galvanized surfaces, multi-layer application systems, and precision-controlled curing environments significantly enhance the longevity of the resulting composite structures.

- Testing and performance evaluation methods for longevity prediction: Various accelerated testing methodologies have been developed to predict the long-term performance of galvanized steel-thermoset composite systems. These include cyclic corrosion tests, weathering chambers, mechanical stress testing, and electrochemical evaluation techniques. Data from these tests helps in quantifying expected service life and identifying potential failure mechanisms. Advanced monitoring systems can also be incorporated into structures to provide real-time data on the condition of the protective systems throughout their service life.

02 Composite thermoset formulations for durability enhancement

Specialized thermoset composite formulations can be engineered to provide superior durability when applied to galvanized steel substrates. These formulations typically contain resins, hardeners, and various additives that create a cross-linked polymer network with excellent adhesion to zinc-coated surfaces. The resulting composite materials offer enhanced resistance to UV radiation, temperature fluctuations, and chemical exposure, thereby extending the functional lifespan of galvanized steel components.Expand Specific Solutions03 Environmental resistance of galvanized steel-composite systems

The combination of galvanized steel with composite thermoset materials creates structures with exceptional environmental resistance. These hybrid systems can withstand extreme weather conditions, salt spray exposure, and industrial pollutants. The synergistic effect between the sacrificial protection provided by the zinc coating and the barrier protection from the thermoset composite results in significantly extended service life compared to either material used independently, particularly in aggressive environments.Expand Specific Solutions04 Manufacturing processes for durable galvanized steel-composite structures

Specialized manufacturing techniques are essential for creating durable bonds between galvanized steel and composite thermoset materials. These processes may include surface preparation methods, controlled curing conditions, and innovative joining technologies. Advanced manufacturing approaches ensure optimal adhesion between the dissimilar materials, minimize internal stresses, and prevent delamination over time, resulting in composite structures with extended service life even under demanding conditions.Expand Specific Solutions05 Testing and performance evaluation methods for longevity prediction

Various testing methodologies have been developed to evaluate and predict the long-term performance of galvanized steel-composite thermoset systems. These include accelerated aging tests, cyclic corrosion testing, mechanical property assessments after environmental exposure, and computational modeling approaches. Such evaluation methods help quantify the expected service life of these hybrid material systems and identify optimal formulations and designs for specific application environments.Expand Specific Solutions

Key Industry Players in Galvanized Steel and Composites

The galvanized steel versus composite thermosets market is currently in a mature growth phase, with global players competing across diverse applications. The market size is substantial, estimated at several billion dollars annually, driven by construction, automotive, and infrastructure sectors. In terms of technical maturity, galvanized steel technology is well-established, with major steel producers like JFE Steel, NIPPON STEEL, Baoshan Iron & Steel, and POSCO Holdings dominating through incremental innovations. Conversely, composite thermosets represent a growing segment with companies like Kansai Paint, NCH Corp, and Arkema France advancing material science applications. Academic institutions including Clemson University and Case Western Reserve University are contributing significant research to improve longevity performance of both materials, while companies like Vasitars and Huawei are exploring specialized applications in infrastructure and telecommunications.

JFE Steel Corp.

Technical Solution: JFE Steel has developed advanced galvanized steel products with enhanced longevity through their proprietary JFE Super ZINC coating technology. Their approach combines zinc with small amounts of magnesium and aluminum to create a triple-layer protection system that significantly improves corrosion resistance compared to conventional galvanized steel. The company's research has demonstrated that their galvanized steel products can maintain structural integrity for 50+ years in moderate environmental conditions. JFE's technical solution includes specialized hot-dip galvanizing processes that create uniform coating thickness (typically 45-100 μm) and strong metallurgical bonding between the zinc coating and steel substrate. Their ZAM® coating technology has shown up to 10 times better corrosion resistance than conventional galvanized steel in salt spray tests. Additionally, JFE has developed environmentally friendly chromium-free passivation treatments that maintain corrosion protection while eliminating hexavalent chromium. Their galvanized products undergo rigorous accelerated aging tests simulating decades of environmental exposure to validate longevity claims.

Strengths: Superior corrosion resistance in harsh environments, established manufacturing infrastructure, lower initial costs than composites, and recyclability at end-of-life. Their products maintain excellent mechanical properties while providing enhanced protection. Weaknesses: Higher weight compared to composite alternatives, potential for galvanic corrosion when in contact with certain metals, and limited design flexibility compared to molded composites.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has pioneered SuperDyma® technology, an advanced galvanized steel solution featuring a zinc-aluminum-magnesium-silicon alloy coating that provides exceptional corrosion resistance for extended service life. Their research demonstrates corrosion resistance approximately 10-20 times greater than conventional hot-dip galvanized steel. The company's technical approach involves precise control of the coating microstructure, creating a protective layer that forms stable corrosion products that seal and protect the underlying steel. Their galvanized products undergo a specialized annealing process that optimizes the zinc-iron intermetallic compounds at the interface, enhancing adhesion and preventing coating delamination during forming operations. Nippon Steel has also developed environmentally compliant chromium-free passivation treatments that maintain long-term protection while meeting global environmental regulations. Their comprehensive longevity testing protocol includes cyclic corrosion testing, outdoor exposure in various climates, and electrochemical impedance spectroscopy to quantify protection mechanisms. Recent innovations include self-healing coating technologies that can repair minor damage through sacrificial protection mechanisms, further extending service life in challenging environments.

Strengths: Exceptional corrosion resistance even at cut edges and scratches, established global manufacturing presence, consistent quality control, and compatibility with existing steel processing equipment. Their products maintain formability while providing superior protection. Weaknesses: Higher production costs than standard galvanized steel, potential for coating damage during aggressive forming operations, and limited temperature resistance compared to high-performance composites.

Technical Innovations in Material Science

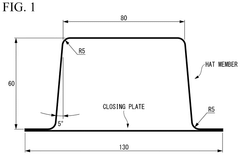

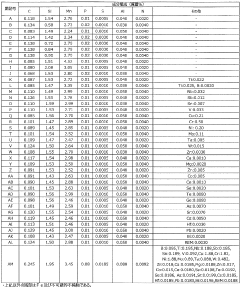

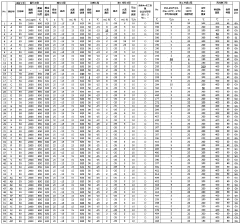

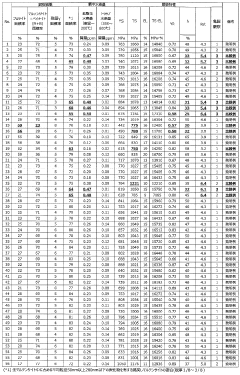

Galvanized steel sheet

PatentPendingUS20250163553A1

Innovation

- A galvanized steel sheet with a specific chemical composition and microstructure, including a chemical composition of C: 0.150 to 0.350%, Si: 0.100 to 2.500%, Mn: 1.50 to 4.50%, and a microstructure at a ¼ position of the sheet thickness with ferrite: 2.0 to 25.0%, bainite: 10.0% or less, tempered martensite: more than 60.0% and 93.0% or less, and retained austenite: 5.0% or more, along with an area ratio of retained austenite in contact with a 30° grain boundary with specific Mn concentration and grain size.

Galvanized steel sheet, member, and method for manufacturing same

PatentWO2023191020A1

Innovation

- A galvanized steel sheet with a specific steel structure and composition, including a base steel sheet with a tempered martensite microstructure and a galvanized layer, optimized to reduce diffusible hydrogen and enhance hydrogen trapping, achieving high yield ratio, tensile strength, and excellent bendability and stretch flangeability.

Environmental Impact Assessment of Material Choices

The environmental impact of material selection in construction and manufacturing has become increasingly critical as industries strive for sustainability. When comparing galvanized steel and composite thermosets, their environmental footprints differ significantly across their life cycles, from raw material extraction to end-of-life disposal.

Galvanized steel production involves energy-intensive processes, particularly during mining and smelting. The zinc coating process, while providing corrosion resistance, introduces additional environmental concerns through zinc mining and processing. However, steel's recyclability presents a significant environmental advantage, with recycling rates exceeding 85% in many developed markets, substantially reducing the need for virgin material extraction and associated environmental degradation.

Composite thermosets, conversely, typically require petroleum-based raw materials, contributing to fossil fuel depletion. Their manufacturing processes generally consume less energy than steel production but often involve volatile organic compounds (VOCs) and other potentially harmful chemicals. The most significant environmental drawback of thermosets lies in their end-of-life management; their cross-linked molecular structure makes them virtually impossible to recycle through conventional methods.

Longevity considerations substantially influence the environmental assessment. Galvanized steel's durability in various environments means fewer replacements over time, reducing cumulative resource consumption. Modern hot-dip galvanized steel can maintain structural integrity for 50-100 years in many applications. Composite thermosets offer comparable or superior longevity in specific applications, particularly in corrosive environments where even galvanized steel may deteriorate.

Carbon footprint analysis reveals that galvanized steel typically generates higher initial greenhouse gas emissions during production (approximately 1.8-2.5 kg CO2e per kg of material) compared to composite thermosets (1.2-2.0 kg CO2e per kg). However, steel's recyclability and longer service life in certain applications may offset this initial disadvantage when assessed over multiple decades of use.

Water usage and pollution present another critical dimension. Steel production consumes substantial water volumes (approximately 13-25 cubic meters per ton) and can generate contaminated wastewater containing heavy metals. Composite manufacturing generally requires less water but may introduce more persistent organic pollutants into water systems through production residues and microplastic generation during weathering.

Emerging life cycle assessment (LCA) methodologies increasingly favor materials with circular economy potential, potentially shifting environmental preference toward galvanized steel despite its higher initial environmental impact. However, innovations in biodegradable composites and thermoset recycling technologies may eventually challenge this advantage, highlighting the dynamic nature of environmental impact assessments in material selection decisions.

Galvanized steel production involves energy-intensive processes, particularly during mining and smelting. The zinc coating process, while providing corrosion resistance, introduces additional environmental concerns through zinc mining and processing. However, steel's recyclability presents a significant environmental advantage, with recycling rates exceeding 85% in many developed markets, substantially reducing the need for virgin material extraction and associated environmental degradation.

Composite thermosets, conversely, typically require petroleum-based raw materials, contributing to fossil fuel depletion. Their manufacturing processes generally consume less energy than steel production but often involve volatile organic compounds (VOCs) and other potentially harmful chemicals. The most significant environmental drawback of thermosets lies in their end-of-life management; their cross-linked molecular structure makes them virtually impossible to recycle through conventional methods.

Longevity considerations substantially influence the environmental assessment. Galvanized steel's durability in various environments means fewer replacements over time, reducing cumulative resource consumption. Modern hot-dip galvanized steel can maintain structural integrity for 50-100 years in many applications. Composite thermosets offer comparable or superior longevity in specific applications, particularly in corrosive environments where even galvanized steel may deteriorate.

Carbon footprint analysis reveals that galvanized steel typically generates higher initial greenhouse gas emissions during production (approximately 1.8-2.5 kg CO2e per kg of material) compared to composite thermosets (1.2-2.0 kg CO2e per kg). However, steel's recyclability and longer service life in certain applications may offset this initial disadvantage when assessed over multiple decades of use.

Water usage and pollution present another critical dimension. Steel production consumes substantial water volumes (approximately 13-25 cubic meters per ton) and can generate contaminated wastewater containing heavy metals. Composite manufacturing generally requires less water but may introduce more persistent organic pollutants into water systems through production residues and microplastic generation during weathering.

Emerging life cycle assessment (LCA) methodologies increasingly favor materials with circular economy potential, potentially shifting environmental preference toward galvanized steel despite its higher initial environmental impact. However, innovations in biodegradable composites and thermoset recycling technologies may eventually challenge this advantage, highlighting the dynamic nature of environmental impact assessments in material selection decisions.

Life Cycle Cost Analysis and ROI Considerations

When evaluating the economic viability of galvanized steel versus composite thermosets for structural applications, a comprehensive life cycle cost analysis (LCCA) provides critical insights beyond initial investment considerations. The LCCA for galvanized steel typically reveals lower upfront costs, with market prices approximately 30-40% less than comparable composite thermoset solutions. However, this initial advantage diminishes when examining total ownership costs over extended periods.

Maintenance expenditures represent a significant differentiator between these materials. Galvanized steel structures generally require maintenance interventions every 15-20 years, including surface treatment, rust removal, and recoating. These recurring costs, when calculated over a 50-year service life, can add 40-60% to the initial investment. Conversely, composite thermosets demonstrate minimal maintenance requirements, with potential interventions limited to surface cleaning and occasional minor repairs, adding only 10-15% to initial costs over the same period.

Replacement frequency further impacts the economic equation. Field studies indicate galvanized steel components in harsh environments may require replacement after 25-30 years, while composite thermosets consistently demonstrate 40+ year performance without structural compromise. This difference creates substantial labor and material replacement costs for steel solutions that are often overlooked in preliminary assessments.

Energy efficiency considerations also favor composite materials. The superior insulation properties of thermosets can reduce energy consumption in climate-controlled structures by 15-25% annually compared to steel alternatives. When monetized over decades of operation, these savings can offset a significant portion of the higher initial investment in composite solutions.

Return on investment calculations reveal compelling patterns. While galvanized steel offers faster initial ROI (typically 3-5 years), composite thermosets demonstrate superior long-term returns when evaluated over 25+ year horizons. The crossover point where composite solutions become more economically advantageous typically occurs between years 12-18, depending on environmental exposure conditions and specific application requirements.

Risk assessment must also factor into economic analysis. The volatility of steel prices, which have fluctuated by up to 30% in recent years, introduces financial uncertainty for long-term projects. Composite materials, while not immune to price variations, have demonstrated greater price stability, with fluctuations generally limited to 5-10% over similar periods, allowing for more reliable long-term budgeting and financial planning.

Maintenance expenditures represent a significant differentiator between these materials. Galvanized steel structures generally require maintenance interventions every 15-20 years, including surface treatment, rust removal, and recoating. These recurring costs, when calculated over a 50-year service life, can add 40-60% to the initial investment. Conversely, composite thermosets demonstrate minimal maintenance requirements, with potential interventions limited to surface cleaning and occasional minor repairs, adding only 10-15% to initial costs over the same period.

Replacement frequency further impacts the economic equation. Field studies indicate galvanized steel components in harsh environments may require replacement after 25-30 years, while composite thermosets consistently demonstrate 40+ year performance without structural compromise. This difference creates substantial labor and material replacement costs for steel solutions that are often overlooked in preliminary assessments.

Energy efficiency considerations also favor composite materials. The superior insulation properties of thermosets can reduce energy consumption in climate-controlled structures by 15-25% annually compared to steel alternatives. When monetized over decades of operation, these savings can offset a significant portion of the higher initial investment in composite solutions.

Return on investment calculations reveal compelling patterns. While galvanized steel offers faster initial ROI (typically 3-5 years), composite thermosets demonstrate superior long-term returns when evaluated over 25+ year horizons. The crossover point where composite solutions become more economically advantageous typically occurs between years 12-18, depending on environmental exposure conditions and specific application requirements.

Risk assessment must also factor into economic analysis. The volatility of steel prices, which have fluctuated by up to 30% in recent years, introduces financial uncertainty for long-term projects. Composite materials, while not immune to price variations, have demonstrated greater price stability, with fluctuations generally limited to 5-10% over similar periods, allowing for more reliable long-term budgeting and financial planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!