GaN Power Devices In Data Center Power Supplies: 48V Direct Conversion

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN Technology Evolution and Objectives

Gallium Nitride (GaN) power devices have emerged as a revolutionary technology in power electronics, offering significant advantages over traditional silicon-based solutions. The evolution of GaN technology began in the early 1990s with fundamental research into wide bandgap semiconductors, but commercial viability for power applications only materialized in the 2010s. This technological progression has been driven by increasing demands for higher efficiency, power density, and switching speeds in power conversion systems.

The development trajectory of GaN power devices has accelerated dramatically over the past decade, with substantial improvements in device performance, reliability, and cost-effectiveness. Early GaN devices faced challenges related to substrate quality, defect density, and manufacturing consistency. However, innovations in epitaxial growth techniques, device structures, and packaging technologies have progressively addressed these limitations, enabling GaN to transition from laboratory curiosity to commercial reality.

In data center applications specifically, the evolution of GaN technology aligns with the industry's shift toward more efficient power architectures. Traditional multi-stage conversion systems are increasingly being replaced by direct conversion approaches, where 48V DC is converted directly to the point-of-load voltages required by processors and other components. This architectural shift demands power devices capable of operating at higher frequencies while maintaining exceptional efficiency.

The primary technical objectives for GaN power devices in 48V direct conversion applications center around several key parameters. First is the continuous improvement of specific on-resistance (RDS(on)) to minimize conduction losses, particularly at higher operating temperatures typical in data center environments. Second is enhancing switching performance to enable operation at frequencies exceeding 1MHz, which allows for smaller passive components and higher power density.

Reliability enhancement represents another critical objective, as data centers require power supplies with exceptional mean time between failures (MTBF). This includes addressing dynamic RDS(on) degradation, gate reliability, and thermal management challenges specific to GaN technology. Additionally, cost reduction through improved manufacturing yields and economies of scale remains essential for broader adoption.

Integration capabilities also feature prominently in GaN technology objectives, with efforts focused on developing monolithic or co-packaged gate drivers, protection circuits, and control functions. These integration approaches aim to minimize parasitic inductances and capacitances that can limit the performance benefits of GaN's intrinsic high-speed switching capabilities.

The ultimate goal for GaN power devices in data center applications is to enable a paradigm shift in power supply architecture that delivers substantial improvements in energy efficiency, power density, and total cost of ownership. Industry projections suggest that fully optimized GaN-based 48V direct conversion solutions could achieve efficiency improvements of 2-3% over silicon-based alternatives, potentially saving millions in energy costs across large-scale data center deployments.

The development trajectory of GaN power devices has accelerated dramatically over the past decade, with substantial improvements in device performance, reliability, and cost-effectiveness. Early GaN devices faced challenges related to substrate quality, defect density, and manufacturing consistency. However, innovations in epitaxial growth techniques, device structures, and packaging technologies have progressively addressed these limitations, enabling GaN to transition from laboratory curiosity to commercial reality.

In data center applications specifically, the evolution of GaN technology aligns with the industry's shift toward more efficient power architectures. Traditional multi-stage conversion systems are increasingly being replaced by direct conversion approaches, where 48V DC is converted directly to the point-of-load voltages required by processors and other components. This architectural shift demands power devices capable of operating at higher frequencies while maintaining exceptional efficiency.

The primary technical objectives for GaN power devices in 48V direct conversion applications center around several key parameters. First is the continuous improvement of specific on-resistance (RDS(on)) to minimize conduction losses, particularly at higher operating temperatures typical in data center environments. Second is enhancing switching performance to enable operation at frequencies exceeding 1MHz, which allows for smaller passive components and higher power density.

Reliability enhancement represents another critical objective, as data centers require power supplies with exceptional mean time between failures (MTBF). This includes addressing dynamic RDS(on) degradation, gate reliability, and thermal management challenges specific to GaN technology. Additionally, cost reduction through improved manufacturing yields and economies of scale remains essential for broader adoption.

Integration capabilities also feature prominently in GaN technology objectives, with efforts focused on developing monolithic or co-packaged gate drivers, protection circuits, and control functions. These integration approaches aim to minimize parasitic inductances and capacitances that can limit the performance benefits of GaN's intrinsic high-speed switching capabilities.

The ultimate goal for GaN power devices in data center applications is to enable a paradigm shift in power supply architecture that delivers substantial improvements in energy efficiency, power density, and total cost of ownership. Industry projections suggest that fully optimized GaN-based 48V direct conversion solutions could achieve efficiency improvements of 2-3% over silicon-based alternatives, potentially saving millions in energy costs across large-scale data center deployments.

Market Demand for Efficient Data Center Power Solutions

The data center industry is experiencing unprecedented growth, driven by cloud computing, artificial intelligence, and the exponential increase in data processing requirements. This expansion has intensified the demand for more efficient power solutions, particularly as energy costs and environmental concerns become increasingly significant factors in data center operations. Traditional power conversion architectures in data centers typically involve multiple conversion stages, resulting in cumulative efficiency losses that translate to higher operational costs and increased carbon footprints.

Market research indicates that power consumption in data centers globally accounts for approximately 1-2% of worldwide electricity usage, with projections showing this figure could rise to 8% by 2030. This escalating energy demand creates a compelling business case for more efficient power conversion technologies. The traditional multi-stage conversion approach (AC to high-voltage DC, then to 12V, and finally to point-of-load voltages) results in efficiency losses at each conversion stage, with overall system efficiency typically ranging between 70-85%.

The shift toward 48V direct conversion using GaN power devices represents a response to these market pressures. Data center operators are increasingly prioritizing power usage effectiveness (PUE) metrics, with industry leaders pushing for PUE values approaching 1.1, compared to the industry average of 1.67. This drive for efficiency has created a market pull for innovative power solutions that can deliver tangible improvements in energy consumption.

Financial analyses demonstrate that even a 1% improvement in power conversion efficiency can translate to millions of dollars in annual savings for large-scale data centers. With global data center infrastructure spending exceeding $200 billion annually, the market for advanced power solutions represents a significant opportunity. Industry reports suggest that the market for data center power equipment is growing at a CAGR of 6.7%, with the high-efficiency segment growing even faster.

Beyond pure efficiency considerations, data center operators are also facing space constraints, particularly in urban environments where real estate costs are premium. The higher power density offered by GaN-based 48V direct conversion solutions addresses this need by reducing the physical footprint of power delivery systems, allowing for more computing resources within the same facility.

Environmental regulations and corporate sustainability commitments are further accelerating market demand for efficient power solutions. Many major technology companies have announced carbon-neutral or carbon-negative goals, creating additional market pull for technologies that can reduce energy consumption and associated emissions. This regulatory and corporate policy landscape is expected to continue favoring more efficient power conversion technologies in the foreseeable future.

Market research indicates that power consumption in data centers globally accounts for approximately 1-2% of worldwide electricity usage, with projections showing this figure could rise to 8% by 2030. This escalating energy demand creates a compelling business case for more efficient power conversion technologies. The traditional multi-stage conversion approach (AC to high-voltage DC, then to 12V, and finally to point-of-load voltages) results in efficiency losses at each conversion stage, with overall system efficiency typically ranging between 70-85%.

The shift toward 48V direct conversion using GaN power devices represents a response to these market pressures. Data center operators are increasingly prioritizing power usage effectiveness (PUE) metrics, with industry leaders pushing for PUE values approaching 1.1, compared to the industry average of 1.67. This drive for efficiency has created a market pull for innovative power solutions that can deliver tangible improvements in energy consumption.

Financial analyses demonstrate that even a 1% improvement in power conversion efficiency can translate to millions of dollars in annual savings for large-scale data centers. With global data center infrastructure spending exceeding $200 billion annually, the market for advanced power solutions represents a significant opportunity. Industry reports suggest that the market for data center power equipment is growing at a CAGR of 6.7%, with the high-efficiency segment growing even faster.

Beyond pure efficiency considerations, data center operators are also facing space constraints, particularly in urban environments where real estate costs are premium. The higher power density offered by GaN-based 48V direct conversion solutions addresses this need by reducing the physical footprint of power delivery systems, allowing for more computing resources within the same facility.

Environmental regulations and corporate sustainability commitments are further accelerating market demand for efficient power solutions. Many major technology companies have announced carbon-neutral or carbon-negative goals, creating additional market pull for technologies that can reduce energy consumption and associated emissions. This regulatory and corporate policy landscape is expected to continue favoring more efficient power conversion technologies in the foreseeable future.

GaN Power Devices: Current Status and Barriers

Gallium Nitride (GaN) power devices represent a significant advancement in power electronics, offering superior performance compared to traditional silicon-based solutions. Currently, GaN technology has reached commercial maturity for voltage ratings up to 650V, with several manufacturers producing reliable devices. These components demonstrate switching speeds 3-5 times faster than silicon counterparts, with significantly reduced switching losses and higher power density capabilities.

Despite these advantages, GaN power devices face several barriers to widespread adoption in data center power supplies for 48V direct conversion applications. The primary challenge remains cost competitiveness, with GaN devices typically commanding a 2-3x price premium over silicon alternatives. This cost differential, while narrowing annually, continues to limit adoption in price-sensitive market segments.

Manufacturing scalability presents another significant barrier. Current GaN production capacity remains limited compared to silicon, with fewer fabrication facilities capable of producing these specialized devices. This constraint affects both availability and contributes to higher costs. Additionally, the yield rates for GaN devices, while improving, have not yet reached the exceptional levels achieved in mature silicon manufacturing processes.

Reliability concerns persist among conservative data center operators. Although laboratory testing demonstrates excellent performance, long-term field reliability data spanning 5-10 years remains limited compared to silicon's extensive deployment history. This creates hesitation among mission-critical infrastructure planners who prioritize proven reliability over performance gains.

Technical integration challenges also impede adoption. GaN's faster switching speeds require careful circuit design to manage electromagnetic interference (EMI) and prevent voltage overshoots. Engineers must redesign control systems and implement sophisticated gate drivers specifically optimized for GaN characteristics, increasing development complexity and time-to-market.

The thermal management requirements differ significantly from silicon solutions. While GaN devices generate less heat overall, they concentrate this heat in smaller areas, necessitating redesigned cooling strategies. This often requires specialized packaging solutions and thermal interface materials to effectively dissipate heat from these high-power-density components.

Standardization remains fragmented across the industry, with various manufacturers employing different packaging approaches, driving requirements, and performance specifications. This lack of uniformity complicates design processes and increases engineering overhead when implementing GaN solutions in data center power architectures targeting 48V direct conversion.

Despite these advantages, GaN power devices face several barriers to widespread adoption in data center power supplies for 48V direct conversion applications. The primary challenge remains cost competitiveness, with GaN devices typically commanding a 2-3x price premium over silicon alternatives. This cost differential, while narrowing annually, continues to limit adoption in price-sensitive market segments.

Manufacturing scalability presents another significant barrier. Current GaN production capacity remains limited compared to silicon, with fewer fabrication facilities capable of producing these specialized devices. This constraint affects both availability and contributes to higher costs. Additionally, the yield rates for GaN devices, while improving, have not yet reached the exceptional levels achieved in mature silicon manufacturing processes.

Reliability concerns persist among conservative data center operators. Although laboratory testing demonstrates excellent performance, long-term field reliability data spanning 5-10 years remains limited compared to silicon's extensive deployment history. This creates hesitation among mission-critical infrastructure planners who prioritize proven reliability over performance gains.

Technical integration challenges also impede adoption. GaN's faster switching speeds require careful circuit design to manage electromagnetic interference (EMI) and prevent voltage overshoots. Engineers must redesign control systems and implement sophisticated gate drivers specifically optimized for GaN characteristics, increasing development complexity and time-to-market.

The thermal management requirements differ significantly from silicon solutions. While GaN devices generate less heat overall, they concentrate this heat in smaller areas, necessitating redesigned cooling strategies. This often requires specialized packaging solutions and thermal interface materials to effectively dissipate heat from these high-power-density components.

Standardization remains fragmented across the industry, with various manufacturers employing different packaging approaches, driving requirements, and performance specifications. This lack of uniformity complicates design processes and increases engineering overhead when implementing GaN solutions in data center power architectures targeting 48V direct conversion.

48V Direct Conversion Technical Solutions

01 GaN-based power conversion architectures

Gallium Nitride (GaN) power devices enable efficient direct conversion architectures for power systems. These architectures leverage GaN's high switching speed and low on-resistance to achieve higher power density and efficiency compared to traditional silicon-based solutions. Direct conversion topologies using GaN devices can eliminate intermediate conversion stages, reducing system complexity and improving overall performance in applications such as AC-DC and DC-DC conversion.- GaN-based power conversion architectures: Gallium Nitride (GaN) power devices enable direct conversion architectures that improve efficiency and power density in power electronics systems. These architectures leverage GaN's high switching speed and low on-resistance to reduce conversion stages, minimize losses, and enable more compact designs. Direct conversion topologies using GaN devices can operate at higher frequencies than traditional silicon-based solutions, allowing for smaller passive components and improved thermal management.

- GaN device integration for power modules: Integration techniques for GaN power devices focus on packaging multiple components into compact power modules for direct conversion applications. These approaches include embedding GaN transistors with drivers, controllers, and passive components on shared substrates to minimize parasitic effects and improve switching performance. Advanced packaging technologies enable better thermal management and electrical interconnections, resulting in higher power density and reliability for direct conversion systems.

- Thermal management solutions for GaN direct converters: Specialized thermal management techniques are essential for GaN-based direct conversion systems due to their high power density and concentrated heat generation. These solutions include advanced substrate materials with superior thermal conductivity, innovative cooling structures, and optimized layout designs that facilitate efficient heat dissipation. Effective thermal management enables GaN power devices to operate reliably at higher power levels and switching frequencies in direct conversion applications.

- Control strategies for GaN direct conversion: Specialized control algorithms and driver circuits are developed to maximize the performance of GaN devices in direct conversion applications. These control strategies address the unique characteristics of GaN transistors, including faster switching speeds and different gate drive requirements compared to silicon devices. Advanced control techniques enable precise timing, reduce switching losses, and mitigate electromagnetic interference, thereby enhancing the efficiency and reliability of GaN-based direct conversion systems.

- GaN-based wireless power transfer systems: GaN power devices enable efficient direct conversion for wireless power transfer applications. The high-frequency operation capability of GaN transistors allows for more compact resonant circuits and improved power transfer efficiency across air gaps. These systems utilize GaN's superior switching characteristics to implement direct AC-AC or DC-AC conversion with minimal components, resulting in lighter and more efficient wireless charging solutions for various applications including consumer electronics and electric vehicles.

02 GaN device integration and packaging techniques

Advanced packaging and integration techniques for GaN power devices enhance their direct conversion capabilities. These include novel substrate technologies, chip-scale packaging, and multi-chip module approaches that optimize thermal management and reduce parasitic elements. Such integration methods enable higher operating frequencies and improved power handling capabilities, which are critical for efficient direct power conversion applications.Expand Specific Solutions03 GaN-based resonant power conversion systems

Resonant power conversion systems utilizing GaN devices achieve higher efficiency through soft-switching techniques. These systems operate at frequencies significantly higher than silicon-based alternatives, enabling smaller passive components and increased power density. The implementation of resonant topologies with GaN devices allows for direct conversion with reduced switching losses and electromagnetic interference, making them suitable for applications requiring high efficiency and compact size.Expand Specific Solutions04 GaN power devices for wireless power transfer

GaN power devices enable efficient direct wireless power transfer systems through their ability to operate at high frequencies with minimal losses. These systems utilize GaN-based inverters and rectifiers to directly convert power for wireless transmission and reception. The superior switching characteristics of GaN devices allow for compact, lightweight designs with improved efficiency compared to conventional technologies, making them ideal for wireless charging applications.Expand Specific Solutions05 Thermal management solutions for GaN direct conversion

Effective thermal management is crucial for GaN-based direct conversion systems to maintain reliability and performance. Innovative cooling techniques, including advanced heat sink designs, phase-change materials, and integrated cooling channels, help dissipate the concentrated heat generated in high-power-density GaN applications. These thermal solutions enable GaN devices to operate at their full potential for direct power conversion while ensuring long-term reliability and stability under various operating conditions.Expand Specific Solutions

Key Industry Players in GaN Power Device Market

The GaN power devices market for 48V direct conversion in data centers is experiencing rapid growth, currently in an early expansion phase with increasing adoption. The market size is projected to grow significantly due to data centers' escalating power efficiency demands. Technologically, GaN solutions are maturing quickly, with companies like Navitas Semiconductor, Infineon Technologies, and GaN Systems leading innovation. InnoScience, Texas Instruments, and Delta Electronics are advancing commercial applications, while Huawei Digital Power and Silergy are expanding their presence. Research institutions like Zhejiang University and IMECAS are contributing to fundamental breakthroughs. The competitive landscape shows established semiconductor players competing with GaN-focused startups, driving both performance improvements and cost reductions essential for widespread adoption.

InnoScience (Suzhou) Technology Holding Co., Ltd.

Technical Solution: InnoScience has developed an advanced 650V GaN HEMT platform specifically optimized for data center 48V direct conversion applications. Their technology utilizes an 8-inch GaN-on-Si process with proprietary AlGaN/GaN heteroepitaxial growth techniques that achieve low defect density and high uniformity. The company's GaN power devices feature a unique lateral device structure with optimized field plates that deliver superior switching performance with reduced dynamic RDS(on) effects. For 48V direct conversion, InnoScience offers integrated GaN power solutions with gate drivers specifically designed to handle the high switching frequencies (up to 3MHz) required for efficient single-stage conversion from 48V to point-of-load voltages. Their devices demonstrate efficiency improvements of up to 3% compared to traditional silicon-based solutions, with power densities exceeding 1000W/in³ in practical implementations.

Strengths: Industry-leading 8-inch GaN-on-Si manufacturing capability providing cost advantages; superior switching performance at high frequencies; integrated solutions specifically optimized for 48V direct conversion. Weaknesses: Relatively newer entrant compared to established power semiconductor companies; limited deployment history in mission-critical data center applications.

Navitas Semiconductor Ltd.

Technical Solution: Navitas has pioneered GaNFast power ICs that integrate GaN power FETs with drive, control, and protection circuits in a single package, specifically addressing 48V direct conversion challenges in data centers. Their third-generation technology features monolithic integration that eliminates parasitic inductances between the driver and GaN switch, enabling switching frequencies above 2MHz with minimal losses. For data center applications, Navitas has developed specialized GaNFast ICs with optimized dead-time control and robust short-circuit protection mechanisms essential for mission-critical environments. Their solutions demonstrate up to 40% reduction in power losses compared to traditional multi-stage conversion architectures, while achieving power densities of 75W/in³ in 48V direct-to-point-of-load converters. The company's GaN technology enables single-stage conversion topologies like LLC resonant converters and active clamp flyback designs that maintain efficiency above 96% across wide load ranges typical in server applications.

Strengths: Industry-leading integration of GaN power and control in single package; extensive deployment experience with major server manufacturers; proven reliability with over 50 million units shipped. Weaknesses: Higher cost compared to discrete solutions; thermal management challenges in high-density applications due to concentrated heat generation in integrated packages.

Critical Patents and Innovations in GaN Power Devices

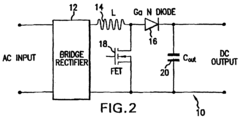

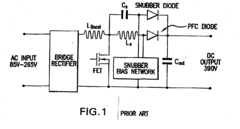

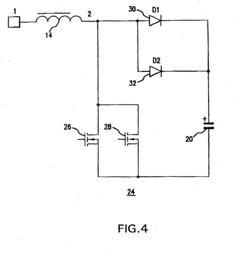

High-efficiency power conversion circuit using gallium nitride (GAN) transistors

PatentPendingIN202341090070A

Innovation

- The use of Gallium Nitride (GaN) transistors, which offer high electron mobility and fast switching speeds, enabling high-efficiency power conversion with reduced heat generation and power losses, leading to smaller form factors and increased power densities.

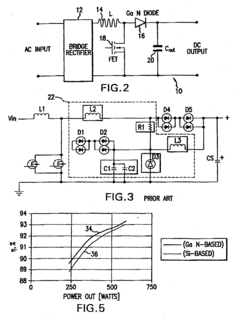

GaN semiconductor based voltage conversion device

PatentInactiveEP1679782A2

Innovation

- A voltage converter utilizing a gallium nitride (GaN) diode with a rectifier, inductor, and output charge storage device, eliminating the need for transient voltage suppression circuits and achieving high efficiency and reduced noise.

Thermal Management Challenges and Solutions

The thermal management of GaN power devices in 48V direct conversion applications for data centers presents significant challenges due to the high power density and switching frequencies involved. GaN devices, while offering superior performance over silicon counterparts, generate concentrated heat that must be effectively dissipated to maintain reliability and efficiency. The thermal conductivity of GaN substrates (typically 130-150 W/mK) is lower than that of silicon carbide, creating inherent thermal bottlenecks.

In data center power supplies utilizing 48V direct conversion, the compact design requirements exacerbate thermal challenges. These systems often operate in confined spaces with limited airflow, while simultaneously handling high current densities. Thermal simulations indicate that junction temperatures can rapidly approach critical thresholds (150-175°C) during peak load conditions, potentially compromising long-term reliability and performance.

Advanced cooling solutions have emerged to address these thermal management challenges. Direct substrate cooling techniques, where the thermal interface material directly contacts the GaN die, have demonstrated up to 30% improvement in heat dissipation compared to traditional methods. Double-sided cooling architectures, which extract heat from both the top and bottom surfaces of the device, are particularly effective for high-density applications, reducing thermal resistance by approximately 40%.

Innovative thermal interface materials (TIMs) with enhanced thermal conductivity (>5 W/mK) are being deployed to minimize the thermal resistance between GaN devices and heat sinks. Phase-change materials that optimize contact during temperature fluctuations show particular promise, maintaining consistent thermal performance across varying load conditions.

Liquid cooling solutions are gaining traction for high-power data center applications. Direct liquid cooling of GaN power stages has demonstrated the ability to handle power densities exceeding 500 W/in³ while maintaining junction temperatures below 100°C. Two-phase cooling systems utilizing dielectric fluids offer even greater cooling capacity through the latent heat of vaporization, though they require more complex implementation.

Thermal management must also address transient thermal behavior, as GaN devices can experience significant temperature spikes during rapid load changes. Advanced thermal sensors with response times under 1ms are being integrated with dynamic thermal management algorithms to adjust operating parameters in real-time, preventing thermal runaway conditions.

The industry is moving toward holistic thermal design approaches that consider the entire power conversion system rather than individual components. Computational fluid dynamics (CFD) modeling combined with electro-thermal co-simulation enables designers to optimize component placement, airflow patterns, and thermal interfaces simultaneously, resulting in more efficient and reliable 48V direct conversion power supplies for data center applications.

In data center power supplies utilizing 48V direct conversion, the compact design requirements exacerbate thermal challenges. These systems often operate in confined spaces with limited airflow, while simultaneously handling high current densities. Thermal simulations indicate that junction temperatures can rapidly approach critical thresholds (150-175°C) during peak load conditions, potentially compromising long-term reliability and performance.

Advanced cooling solutions have emerged to address these thermal management challenges. Direct substrate cooling techniques, where the thermal interface material directly contacts the GaN die, have demonstrated up to 30% improvement in heat dissipation compared to traditional methods. Double-sided cooling architectures, which extract heat from both the top and bottom surfaces of the device, are particularly effective for high-density applications, reducing thermal resistance by approximately 40%.

Innovative thermal interface materials (TIMs) with enhanced thermal conductivity (>5 W/mK) are being deployed to minimize the thermal resistance between GaN devices and heat sinks. Phase-change materials that optimize contact during temperature fluctuations show particular promise, maintaining consistent thermal performance across varying load conditions.

Liquid cooling solutions are gaining traction for high-power data center applications. Direct liquid cooling of GaN power stages has demonstrated the ability to handle power densities exceeding 500 W/in³ while maintaining junction temperatures below 100°C. Two-phase cooling systems utilizing dielectric fluids offer even greater cooling capacity through the latent heat of vaporization, though they require more complex implementation.

Thermal management must also address transient thermal behavior, as GaN devices can experience significant temperature spikes during rapid load changes. Advanced thermal sensors with response times under 1ms are being integrated with dynamic thermal management algorithms to adjust operating parameters in real-time, preventing thermal runaway conditions.

The industry is moving toward holistic thermal design approaches that consider the entire power conversion system rather than individual components. Computational fluid dynamics (CFD) modeling combined with electro-thermal co-simulation enables designers to optimize component placement, airflow patterns, and thermal interfaces simultaneously, resulting in more efficient and reliable 48V direct conversion power supplies for data center applications.

Total Cost of Ownership Analysis

The Total Cost of Ownership (TCO) analysis for GaN power devices in data center power supplies with 48V direct conversion reveals significant economic advantages over traditional silicon-based solutions. Initial acquisition costs for GaN devices typically exceed those of silicon counterparts by 15-30%, presenting a higher capital expenditure barrier. However, this premium is offset by substantial operational savings over the device lifecycle.

Energy efficiency improvements of 2-3% translate to considerable cost reductions in data center operations. For a 10MW data center, this efficiency gain can yield annual electricity savings of approximately $175,000-$260,000 at average industrial electricity rates. These savings accumulate substantially over the typical 5-7 year operational lifespan of power supply units.

The reduced cooling requirements associated with GaN's higher efficiency further enhance TCO benefits. Thermal management costs decrease by approximately 10-15% compared to silicon-based systems, reducing both energy consumption for cooling and associated infrastructure costs. This aspect is particularly valuable in high-density computing environments where thermal management represents a significant operational expense.

Space utilization improvements represent another economic advantage. The higher power density of GaN-based solutions enables more compact power supply designs, reducing the physical footprint by up to 40% compared to silicon alternatives. In data centers where space commands premium costs, this translates to substantial real estate savings or increased computing capacity within the same physical infrastructure.

Reliability metrics indicate lower failure rates for GaN-based power supplies, with Mean Time Between Failures (MTBF) improvements of 15-25%. This enhanced reliability reduces maintenance costs and minimizes costly downtime events. Conservative estimates suggest a 20% reduction in maintenance-related expenses over the product lifecycle.

Comprehensive TCO modeling across a five-year operational period demonstrates that despite higher initial investment, GaN-based 48V direct conversion solutions typically achieve break-even within 18-24 months. The cumulative five-year TCO advantage ranges from 22-30% compared to traditional silicon-based architectures, with the most significant savings derived from reduced energy consumption, cooling requirements, and space utilization.

As manufacturing scales increase and GaN technology matures, acquisition cost differentials are projected to narrow, further enhancing the TCO proposition. This economic trajectory suggests that GaN power devices will become increasingly compelling for data center operators seeking to optimize long-term operational economics while meeting escalating power efficiency demands.

Energy efficiency improvements of 2-3% translate to considerable cost reductions in data center operations. For a 10MW data center, this efficiency gain can yield annual electricity savings of approximately $175,000-$260,000 at average industrial electricity rates. These savings accumulate substantially over the typical 5-7 year operational lifespan of power supply units.

The reduced cooling requirements associated with GaN's higher efficiency further enhance TCO benefits. Thermal management costs decrease by approximately 10-15% compared to silicon-based systems, reducing both energy consumption for cooling and associated infrastructure costs. This aspect is particularly valuable in high-density computing environments where thermal management represents a significant operational expense.

Space utilization improvements represent another economic advantage. The higher power density of GaN-based solutions enables more compact power supply designs, reducing the physical footprint by up to 40% compared to silicon alternatives. In data centers where space commands premium costs, this translates to substantial real estate savings or increased computing capacity within the same physical infrastructure.

Reliability metrics indicate lower failure rates for GaN-based power supplies, with Mean Time Between Failures (MTBF) improvements of 15-25%. This enhanced reliability reduces maintenance costs and minimizes costly downtime events. Conservative estimates suggest a 20% reduction in maintenance-related expenses over the product lifecycle.

Comprehensive TCO modeling across a five-year operational period demonstrates that despite higher initial investment, GaN-based 48V direct conversion solutions typically achieve break-even within 18-24 months. The cumulative five-year TCO advantage ranges from 22-30% compared to traditional silicon-based architectures, with the most significant savings derived from reduced energy consumption, cooling requirements, and space utilization.

As manufacturing scales increase and GaN technology matures, acquisition cost differentials are projected to narrow, further enhancing the TCO proposition. This economic trajectory suggests that GaN power devices will become increasingly compelling for data center operators seeking to optimize long-term operational economics while meeting escalating power efficiency demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!