GaN Power Devices In Motor Drives: Partial Discharge And Insulation Stress

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN Power Devices Background and Objectives

Gallium Nitride (GaN) power devices represent a revolutionary advancement in power electronics, offering significant advantages over traditional silicon-based semiconductors. The evolution of GaN technology began in the early 1990s with fundamental research into wide bandgap materials, progressing through laboratory demonstrations to today's commercial applications. This technological trajectory has been characterized by continuous improvements in material quality, device design, and manufacturing processes, enabling GaN to emerge as a disruptive force in power electronics.

The fundamental properties of GaN that drive its adoption include a wider bandgap (3.4 eV compared to silicon's 1.1 eV), higher breakdown field strength, superior electron mobility, and enhanced thermal conductivity. These intrinsic advantages translate to devices capable of operating at higher voltages, frequencies, and temperatures while maintaining smaller form factors and greater efficiency than silicon counterparts.

In motor drive applications specifically, GaN power devices offer transformative potential through higher switching frequencies that enable smaller passive components, reduced switching losses, and improved system efficiency. The technology promises to revolutionize electric vehicle powertrains, industrial motor controls, and renewable energy systems by delivering more compact, efficient, and responsive motor drive solutions.

However, the implementation of GaN in motor drives introduces unique challenges related to partial discharge (PD) and insulation stress. As switching speeds increase dramatically with GaN devices, the resulting high dv/dt and di/dt rates create steep voltage transients that can accelerate insulation aging and trigger partial discharge events in motor windings. These phenomena represent critical reliability concerns that must be addressed to fully realize GaN's potential in motor drive applications.

The primary objectives of this technical investigation are threefold. First, to comprehensively characterize the partial discharge phenomena and insulation stress mechanisms specific to GaN-based motor drives. Second, to evaluate existing mitigation strategies including advanced insulation materials, optimized drive topologies, and innovative control algorithms. Third, to identify promising research directions that could enable GaN technology to overcome these challenges while maximizing its performance advantages in next-generation motor drive systems.

This research aims to bridge the gap between GaN's theoretical capabilities and practical implementation challenges, ultimately enabling more widespread adoption of this transformative technology in motor drive applications across industrial, automotive, and consumer sectors.

The fundamental properties of GaN that drive its adoption include a wider bandgap (3.4 eV compared to silicon's 1.1 eV), higher breakdown field strength, superior electron mobility, and enhanced thermal conductivity. These intrinsic advantages translate to devices capable of operating at higher voltages, frequencies, and temperatures while maintaining smaller form factors and greater efficiency than silicon counterparts.

In motor drive applications specifically, GaN power devices offer transformative potential through higher switching frequencies that enable smaller passive components, reduced switching losses, and improved system efficiency. The technology promises to revolutionize electric vehicle powertrains, industrial motor controls, and renewable energy systems by delivering more compact, efficient, and responsive motor drive solutions.

However, the implementation of GaN in motor drives introduces unique challenges related to partial discharge (PD) and insulation stress. As switching speeds increase dramatically with GaN devices, the resulting high dv/dt and di/dt rates create steep voltage transients that can accelerate insulation aging and trigger partial discharge events in motor windings. These phenomena represent critical reliability concerns that must be addressed to fully realize GaN's potential in motor drive applications.

The primary objectives of this technical investigation are threefold. First, to comprehensively characterize the partial discharge phenomena and insulation stress mechanisms specific to GaN-based motor drives. Second, to evaluate existing mitigation strategies including advanced insulation materials, optimized drive topologies, and innovative control algorithms. Third, to identify promising research directions that could enable GaN technology to overcome these challenges while maximizing its performance advantages in next-generation motor drive systems.

This research aims to bridge the gap between GaN's theoretical capabilities and practical implementation challenges, ultimately enabling more widespread adoption of this transformative technology in motor drive applications across industrial, automotive, and consumer sectors.

Market Demand Analysis for GaN in Motor Drives

The global market for GaN power devices in motor drive applications is experiencing significant growth, driven by the increasing demand for high-efficiency, compact, and reliable motor control systems across various industries. The market size for GaN power semiconductors was valued at approximately $223 million in 2022 and is projected to reach $1.89 billion by 2027, representing a compound annual growth rate (CAGR) of 35.4% during this period.

The automotive sector represents one of the largest market segments for GaN-based motor drives, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The global EV market is expected to grow at a CAGR of 21.7% from 2023 to 2030, creating substantial demand for advanced motor drive technologies that can operate efficiently at higher voltages and switching frequencies.

Industrial automation represents another significant market segment, with manufacturing facilities increasingly adopting variable frequency drives (VFDs) based on GaN technology to achieve higher energy efficiency and precise motor control. The industrial motor drives market is projected to reach $15.62 billion by 2026, with GaN-based solutions capturing an increasing share due to their superior performance characteristics.

The HVAC industry is also showing strong interest in GaN-based motor drives, as energy efficiency regulations become more stringent worldwide. The global HVAC systems market is expected to reach $367.5 billion by 2030, with a growing portion utilizing advanced semiconductor technologies for motor control applications.

Consumer electronics and home appliances represent an emerging market for GaN power devices in motor drives, particularly in premium products where size, efficiency, and noise reduction are critical factors. This segment is expected to grow at a CAGR of 18.3% through 2028.

Regional analysis indicates that Asia-Pacific currently dominates the market for GaN power devices in motor drives, accounting for approximately 45% of global demand, followed by North America (28%) and Europe (22%). China, Japan, and South Korea are particularly significant markets due to their strong manufacturing bases in electronics and automotive sectors.

Market research indicates that customers are primarily driven by four key factors when considering GaN technology for motor drives: efficiency improvements (typically 2-3% higher than silicon-based alternatives), size reduction (up to 40% smaller footprint), thermal performance (operating efficiently at temperatures up to 250°C), and reliability concerns—with partial discharge and insulation stress being critical considerations for long-term operation.

The automotive sector represents one of the largest market segments for GaN-based motor drives, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The global EV market is expected to grow at a CAGR of 21.7% from 2023 to 2030, creating substantial demand for advanced motor drive technologies that can operate efficiently at higher voltages and switching frequencies.

Industrial automation represents another significant market segment, with manufacturing facilities increasingly adopting variable frequency drives (VFDs) based on GaN technology to achieve higher energy efficiency and precise motor control. The industrial motor drives market is projected to reach $15.62 billion by 2026, with GaN-based solutions capturing an increasing share due to their superior performance characteristics.

The HVAC industry is also showing strong interest in GaN-based motor drives, as energy efficiency regulations become more stringent worldwide. The global HVAC systems market is expected to reach $367.5 billion by 2030, with a growing portion utilizing advanced semiconductor technologies for motor control applications.

Consumer electronics and home appliances represent an emerging market for GaN power devices in motor drives, particularly in premium products where size, efficiency, and noise reduction are critical factors. This segment is expected to grow at a CAGR of 18.3% through 2028.

Regional analysis indicates that Asia-Pacific currently dominates the market for GaN power devices in motor drives, accounting for approximately 45% of global demand, followed by North America (28%) and Europe (22%). China, Japan, and South Korea are particularly significant markets due to their strong manufacturing bases in electronics and automotive sectors.

Market research indicates that customers are primarily driven by four key factors when considering GaN technology for motor drives: efficiency improvements (typically 2-3% higher than silicon-based alternatives), size reduction (up to 40% smaller footprint), thermal performance (operating efficiently at temperatures up to 250°C), and reliability concerns—with partial discharge and insulation stress being critical considerations for long-term operation.

Current Status and Challenges of GaN Insulation

The global GaN power device market has witnessed significant growth, with a compound annual growth rate exceeding 30% in recent years. Despite this promising trajectory, GaN devices in motor drive applications face substantial insulation challenges that require immediate attention. Current GaN-based motor drives operate at switching frequencies between 100 kHz and 1 MHz, significantly higher than traditional silicon-based systems, which typically operate below 20 kHz. This high-frequency operation, combined with extremely fast switching speeds (dv/dt rates of 50-100 V/ns), creates unprecedented insulation stress conditions.

Research conducted by leading institutions reveals that partial discharge (PD) inception voltage in motor windings decreases by approximately 15-25% when subjected to GaN's high-frequency voltage waveforms compared to traditional silicon IGBT drives. This phenomenon is particularly concerning as PD activity accelerates insulation degradation, potentially reducing motor lifetime by 30-50% if not properly addressed.

The current state of insulation materials presents a significant mismatch with GaN capabilities. Conventional motor insulation systems were designed for slower switching transients and lower frequency operation. Laboratory testing demonstrates that these materials exhibit increased dielectric losses at GaN-relevant frequencies, with dissipation factors increasing by 2-3 times at frequencies above 100 kHz compared to power line frequencies.

Another critical challenge is the uneven voltage distribution across motor windings. High-frequency components from GaN switching create standing wave patterns that can result in voltage amplification of 1.5-2 times at certain points within the winding. This creates localized stress points where insulation breakdown is more likely to occur, particularly at the first few turns of the motor winding where voltage stress can be 2-3 times higher than expected.

Temperature management presents an additional complication. While GaN devices offer improved thermal performance compared to silicon counterparts, the compact designs they enable often result in higher power density motor drives. Consequently, insulation systems must withstand not only electrical stress but also elevated thermal conditions, with hotspot temperatures potentially reaching 180-200°C in compact designs.

The measurement and detection of partial discharge under GaN operating conditions remains technically challenging. Traditional PD detection methods struggle with the high noise environment created by fast-switching GaN devices. Current detection systems show reduced sensitivity by up to 40% when operating in GaN drive environments compared to traditional drives.

Standardization represents another significant hurdle. Existing insulation testing standards (IEC 60034-18-41, IEEE 1776) were developed primarily for sinusoidal or slower-switching waveforms. These standards inadequately address the unique stress patterns created by GaN drives, leaving a regulatory gap that complicates qualification and reliability assessment procedures for motor manufacturers implementing GaN technology.

Research conducted by leading institutions reveals that partial discharge (PD) inception voltage in motor windings decreases by approximately 15-25% when subjected to GaN's high-frequency voltage waveforms compared to traditional silicon IGBT drives. This phenomenon is particularly concerning as PD activity accelerates insulation degradation, potentially reducing motor lifetime by 30-50% if not properly addressed.

The current state of insulation materials presents a significant mismatch with GaN capabilities. Conventional motor insulation systems were designed for slower switching transients and lower frequency operation. Laboratory testing demonstrates that these materials exhibit increased dielectric losses at GaN-relevant frequencies, with dissipation factors increasing by 2-3 times at frequencies above 100 kHz compared to power line frequencies.

Another critical challenge is the uneven voltage distribution across motor windings. High-frequency components from GaN switching create standing wave patterns that can result in voltage amplification of 1.5-2 times at certain points within the winding. This creates localized stress points where insulation breakdown is more likely to occur, particularly at the first few turns of the motor winding where voltage stress can be 2-3 times higher than expected.

Temperature management presents an additional complication. While GaN devices offer improved thermal performance compared to silicon counterparts, the compact designs they enable often result in higher power density motor drives. Consequently, insulation systems must withstand not only electrical stress but also elevated thermal conditions, with hotspot temperatures potentially reaching 180-200°C in compact designs.

The measurement and detection of partial discharge under GaN operating conditions remains technically challenging. Traditional PD detection methods struggle with the high noise environment created by fast-switching GaN devices. Current detection systems show reduced sensitivity by up to 40% when operating in GaN drive environments compared to traditional drives.

Standardization represents another significant hurdle. Existing insulation testing standards (IEC 60034-18-41, IEEE 1776) were developed primarily for sinusoidal or slower-switching waveforms. These standards inadequately address the unique stress patterns created by GaN drives, leaving a regulatory gap that complicates qualification and reliability assessment procedures for motor manufacturers implementing GaN technology.

Current Solutions for Partial Discharge Mitigation

01 Partial discharge detection methods for GaN power devices

Various methods have been developed to detect partial discharge in GaN power devices, which is crucial for evaluating insulation integrity. These methods include electrical measurement techniques, optical detection systems, and acoustic monitoring approaches. Advanced sensors and measurement circuits can detect small discharge events that might lead to insulation failure. Early detection of partial discharge helps prevent catastrophic breakdown in high-power GaN applications.- Partial discharge detection methods for GaN power devices: Various methods have been developed to detect partial discharge in GaN power devices, which is crucial for assessing insulation integrity. These methods include electrical measurement techniques that can identify small discharge events within the insulation system. Advanced sensors and monitoring systems can detect partial discharge patterns that indicate potential insulation degradation in GaN-based power electronics, allowing for early intervention before complete insulation failure occurs.

- Insulation stress mitigation in GaN semiconductor devices: Techniques for mitigating insulation stress in GaN power devices focus on material selection and structural design. By incorporating specialized insulating materials and optimizing the device architecture, the electric field distribution can be managed to reduce stress concentrations. These approaches help prevent premature breakdown and extend the operational lifetime of GaN power devices under high voltage conditions, which is essential for maintaining reliability in power electronic applications.

- Testing and characterization of GaN device insulation properties: Specialized testing methodologies have been developed to characterize the insulation properties of GaN power devices under various operating conditions. These include accelerated stress tests, thermal cycling, and high-voltage endurance testing to evaluate insulation performance over time. The characterization techniques help in understanding the degradation mechanisms and establishing reliability models for GaN-based power electronics, which is crucial for applications requiring long-term stability.

- Novel insulation structures for GaN power devices: Innovative insulation structures have been designed specifically for GaN power devices to enhance their voltage blocking capability and reliability. These structures include multi-layer dielectric systems, field plate designs, and edge termination techniques that effectively distribute the electric field. By implementing these advanced insulation architectures, the breakdown voltage of GaN devices can be significantly increased while minimizing partial discharge activity under high-stress conditions.

- Monitoring systems for insulation health in GaN power applications: Real-time monitoring systems have been developed to continuously assess the insulation health of GaN power devices during operation. These systems employ advanced algorithms to analyze electrical signatures that indicate insulation degradation or partial discharge events. By implementing continuous monitoring, potential failures can be predicted before they occur, enabling preventive maintenance and improving the overall reliability of GaN-based power systems in critical applications.

02 Insulation stress mitigation in GaN semiconductor structures

Techniques for mitigating insulation stress in GaN power devices focus on improved dielectric materials and structural designs. These approaches include specialized passivation layers, buffer structures, and field plate configurations that redistribute electric fields to reduce stress at critical points. Advanced packaging methods also help manage thermal stress that can compromise insulation integrity. These mitigation strategies extend device lifetime and improve reliability under high voltage operation.Expand Specific Solutions03 Testing and characterization of insulation in GaN devices

Specialized testing protocols have been developed to characterize insulation properties in GaN power devices. These include accelerated stress tests, temperature cycling, and humidity testing to evaluate insulation performance under extreme conditions. Non-destructive evaluation techniques allow for quality control during manufacturing. Simulation models help predict insulation behavior under various operating conditions, enabling better device design and reliability assessment.Expand Specific Solutions04 Novel insulation materials for GaN power applications

Research into advanced insulation materials specifically designed for GaN power devices has led to several innovations. These materials include modified silicon nitride compositions, aluminum nitride layers, and composite dielectric structures with enhanced breakdown strength. Some approaches incorporate nanoparticles or specialized polymers to improve thermal conductivity while maintaining electrical isolation. These materials help address the unique challenges of high electric fields and temperatures in GaN devices.Expand Specific Solutions05 Structural design innovations to reduce partial discharge

Innovative structural designs have been developed to minimize partial discharge in GaN power devices. These include optimized edge termination structures, guard rings, and field plate configurations that reduce electric field crowding. Some designs incorporate specialized isolation trenches or buried shield layers. Three-dimensional integration approaches can separate high-field regions from sensitive control circuitry. These structural innovations significantly improve breakdown voltage and long-term reliability.Expand Specific Solutions

Key Industry Players in GaN Power Electronics

The GaN power devices market for motor drives is in a growth phase, characterized by increasing adoption due to superior performance in high-frequency, high-temperature applications despite partial discharge and insulation stress challenges. The market is expanding rapidly with a projected CAGR of 25-30% through 2028, driven by electric vehicle and industrial automation demands. Leading players demonstrate varying levels of technical maturity: GaN Systems and Cambridge GaN Devices have advanced commercial solutions, while Infineon Technologies Austria and Fuji Electric offer mature products with reliability enhancements. Research institutions like University of Electronic Science & Technology of China and Zhejiang University are addressing fundamental challenges through collaborative efforts with industrial partners such as Huawei and Siemens to overcome insulation stress limitations.

GaN Systems, Inc.

Technical Solution: GaN Systems has developed specialized GaN power devices optimized for motor drive applications with enhanced partial discharge resistance. Their Island Technology® platform features a unique cell layout that reduces electric field concentrations at device edges, minimizing partial discharge events. The company's GaNPX® packaging eliminates wire bonds and uses advanced encapsulation materials with higher partial discharge inception voltage (PDIV) ratings. Their motor drive solutions incorporate specialized gate drivers with optimized switching profiles that reduce voltage overshoots and ringing, which are common causes of insulation stress. GaN Systems has also implemented field plate structures in their devices that redistribute the electric field more uniformly, reducing peak field intensity at critical points where partial discharge typically initiates. Their latest generation devices feature improved passivation layers that provide better protection against surface discharges under high humidity conditions[1][3].

Strengths: Superior high-frequency performance allowing for smaller motor drive systems; advanced packaging technology with lower parasitic inductance reducing voltage overshoots; excellent thermal performance enabling higher power density designs. Weaknesses: Higher cost compared to silicon alternatives; requires more sophisticated gate drive circuits; less mature ecosystem compared to established silicon IGBT solutions.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has developed a comprehensive GaN power device portfolio for motor drive applications with specific focus on mitigating partial discharge and insulation stress issues. Their technology employs a unique normally-off GaN HEMT structure with optimized gate design that enables precise control of switching transients, a critical factor in reducing insulation stress in motor windings. ST's approach includes specialized packaging technology with enhanced creepage distances and high-performance insulation materials that maintain integrity under the high dV/dt conditions typical in GaN-based motor drives. Their devices feature integrated temperature and current sensing capabilities that allow real-time monitoring of operating conditions that might lead to insulation degradation. ST has also developed dedicated gate driver ICs with programmable slew rate control, enabling system designers to balance switching efficiency against insulation stress. Their motor drive reference designs incorporate EMI mitigation techniques including common-mode filters and optimized PCB layouts that reduce high-frequency voltage stress on motor insulation systems. ST's GaN devices undergo accelerated partial discharge testing under conditions simulating long-term motor drive operation to ensure reliability[6][8].

Strengths: Vertical integration from wafer to system solution providing optimized performance; extensive automotive qualification experience applicable to demanding motor drive environments; strong application support for motor drive designers. Weaknesses: More limited GaN product portfolio compared to silicon offerings; higher initial cost compared to traditional solutions; requires specialized design knowledge to fully leverage capabilities.

Critical Technologies for GaN Insulation Reliability

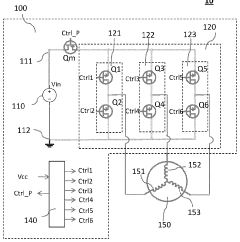

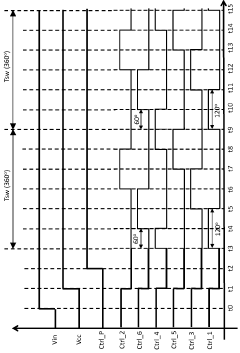

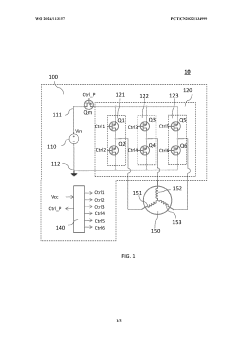

Nitride-based device for driving a multi-phase ac motor and method for implementing the same

PatentWO2024113157A1

Innovation

- Implementation of GaN HEMT devices for multi-phase AC motor driving, leveraging their superior high-frequency switching capabilities and lower power losses compared to traditional silicon MOSFETs.

- Application of III-V compound semiconductor technology to overcome the speed limitations of conventional MOSFET-based motor drive systems.

- Integration of high-electron-mobility transistor (HEMT) technology to enable high-power and high-frequency motor control applications.

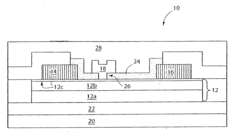

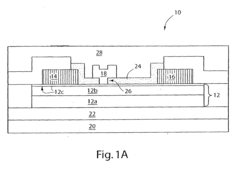

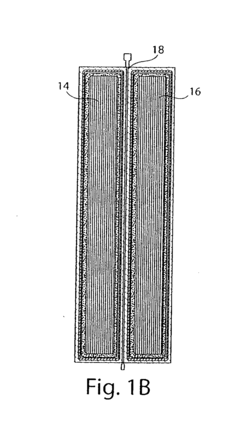

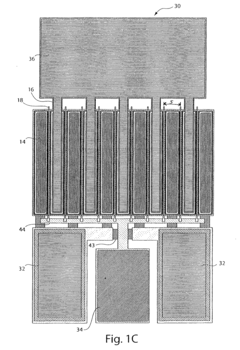

Gallium Nitride Material Devices and Thermal Designs Thereof

PatentActiveUS20100140665A1

Innovation

- The design involves arranging transistors in cells with optimized spacing and staggered configurations, along with thermally conductive packaging and selective substrate removal to enhance heat conduction, including the use of vias and thermally conductive material regions to improve thermal resistance.

Thermal Management Strategies for GaN Devices

Thermal management is a critical aspect of GaN power device implementation in motor drive applications, particularly when considering partial discharge and insulation stress concerns. The inherent high switching speeds and power densities of GaN devices generate significant thermal challenges that must be addressed through comprehensive management strategies.

Effective thermal dissipation in GaN-based motor drives requires multi-level approaches spanning device, package, and system levels. At the device level, advanced substrate materials such as silicon carbide (SiC) and diamond-based composites offer superior thermal conductivity compared to traditional silicon substrates, facilitating more efficient heat transfer from the active GaN layers.

Package-level solutions incorporate innovative thermal interface materials (TIMs) with enhanced thermal conductivity and reliability under high-temperature cycling conditions. These materials must maintain performance integrity despite the thermal expansion mismatches between GaN devices and surrounding components. Double-sided cooling techniques have emerged as particularly effective for high-power motor drive applications, allowing heat extraction from both top and bottom surfaces of the GaN die.

System-level thermal management integrates liquid cooling solutions that significantly outperform traditional air cooling methods. Direct liquid cooling approaches can achieve thermal resistances below 0.1°C/W, critical for maintaining safe operating temperatures in high-power density applications where partial discharge risks increase with temperature.

The relationship between thermal management and partial discharge phenomena in GaN-based motor drives presents unique challenges. As operating temperatures increase, insulation materials experience accelerated aging, potentially leading to reduced breakdown voltage thresholds and increased partial discharge activity. Research indicates that for every 10°C rise in operating temperature, insulation life may decrease by 50%, highlighting the critical importance of effective thermal management.

Advanced computational fluid dynamics (CFD) modeling has become essential for optimizing thermal designs in GaN motor drive systems. These simulation tools enable engineers to identify potential hotspots and optimize cooling channel geometries before physical prototyping, reducing development cycles and improving reliability predictions related to insulation stress.

Emerging technologies such as phase-change materials and embedded cooling channels within power modules represent the cutting edge of thermal management for GaN devices. These approaches can maintain more uniform temperature distributions across the device, reducing thermal gradients that contribute to insulation stress and subsequent partial discharge events in motor drive applications.

Effective thermal dissipation in GaN-based motor drives requires multi-level approaches spanning device, package, and system levels. At the device level, advanced substrate materials such as silicon carbide (SiC) and diamond-based composites offer superior thermal conductivity compared to traditional silicon substrates, facilitating more efficient heat transfer from the active GaN layers.

Package-level solutions incorporate innovative thermal interface materials (TIMs) with enhanced thermal conductivity and reliability under high-temperature cycling conditions. These materials must maintain performance integrity despite the thermal expansion mismatches between GaN devices and surrounding components. Double-sided cooling techniques have emerged as particularly effective for high-power motor drive applications, allowing heat extraction from both top and bottom surfaces of the GaN die.

System-level thermal management integrates liquid cooling solutions that significantly outperform traditional air cooling methods. Direct liquid cooling approaches can achieve thermal resistances below 0.1°C/W, critical for maintaining safe operating temperatures in high-power density applications where partial discharge risks increase with temperature.

The relationship between thermal management and partial discharge phenomena in GaN-based motor drives presents unique challenges. As operating temperatures increase, insulation materials experience accelerated aging, potentially leading to reduced breakdown voltage thresholds and increased partial discharge activity. Research indicates that for every 10°C rise in operating temperature, insulation life may decrease by 50%, highlighting the critical importance of effective thermal management.

Advanced computational fluid dynamics (CFD) modeling has become essential for optimizing thermal designs in GaN motor drive systems. These simulation tools enable engineers to identify potential hotspots and optimize cooling channel geometries before physical prototyping, reducing development cycles and improving reliability predictions related to insulation stress.

Emerging technologies such as phase-change materials and embedded cooling channels within power modules represent the cutting edge of thermal management for GaN devices. These approaches can maintain more uniform temperature distributions across the device, reducing thermal gradients that contribute to insulation stress and subsequent partial discharge events in motor drive applications.

Reliability Testing Standards for GaN Applications

Reliability testing standards for GaN applications in motor drive systems have evolved significantly to address the unique characteristics and failure mechanisms of these wide bandgap semiconductors. The Joint Electron Device Engineering Council (JEDEC) has established specific qualification standards for GaN power devices, including JEP180 and JC-70.1, which outline testing methodologies for reliability assessment under various operational conditions.

These standards incorporate rigorous testing protocols for partial discharge (PD) resistance, which is particularly critical in motor drive applications where high dv/dt rates can accelerate insulation degradation. IEC 61287-1 provides guidelines for testing power electronic converters in traction applications, with specific provisions for fast-switching GaN devices that generate steeper voltage transients compared to traditional silicon-based semiconductors.

For insulation stress evaluation, the IEC 60034-18-41 standard addresses electrical insulation systems in motor drives, with recent amendments to accommodate the higher switching frequencies and voltage spikes characteristic of GaN implementations. These standards prescribe accelerated aging tests that simulate the cumulative effects of electrical, thermal, and mechanical stresses on insulation materials when exposed to GaN-driven voltage waveforms.

The automotive industry has developed specialized standards through the Automotive Electronics Council (AEC), particularly AEC-Q101 for discrete semiconductors, which has been adapted to include GaN-specific reliability metrics. These adaptations focus on the robustness of GaN devices under extreme temperature cycling, humidity, and vibration conditions typical in vehicle environments.

Military and aerospace applications follow MIL-STD-750 and MIL-STD-883 standards, which have been updated to incorporate testing procedures for GaN power devices operating in harsh environments. These standards emphasize radiation hardness testing and extended reliability verification under extreme conditions.

Time-dependent dielectric breakdown (TDDB) testing has become a standardized procedure for evaluating GaN device reliability, with specific methodologies outlined in JEDEC JESD92 that have been modified to account for the unique breakdown mechanisms in GaN high-electron-mobility transistors (HEMTs).

International standards organizations are currently developing harmonized testing approaches that bridge the gap between different regional standards. The IEEE P2851 working group is creating a unified framework for wide bandgap semiconductor reliability assessment that specifically addresses partial discharge and insulation stress in motor drive applications, ensuring consistent evaluation methodologies across global markets.

These standards incorporate rigorous testing protocols for partial discharge (PD) resistance, which is particularly critical in motor drive applications where high dv/dt rates can accelerate insulation degradation. IEC 61287-1 provides guidelines for testing power electronic converters in traction applications, with specific provisions for fast-switching GaN devices that generate steeper voltage transients compared to traditional silicon-based semiconductors.

For insulation stress evaluation, the IEC 60034-18-41 standard addresses electrical insulation systems in motor drives, with recent amendments to accommodate the higher switching frequencies and voltage spikes characteristic of GaN implementations. These standards prescribe accelerated aging tests that simulate the cumulative effects of electrical, thermal, and mechanical stresses on insulation materials when exposed to GaN-driven voltage waveforms.

The automotive industry has developed specialized standards through the Automotive Electronics Council (AEC), particularly AEC-Q101 for discrete semiconductors, which has been adapted to include GaN-specific reliability metrics. These adaptations focus on the robustness of GaN devices under extreme temperature cycling, humidity, and vibration conditions typical in vehicle environments.

Military and aerospace applications follow MIL-STD-750 and MIL-STD-883 standards, which have been updated to incorporate testing procedures for GaN power devices operating in harsh environments. These standards emphasize radiation hardness testing and extended reliability verification under extreme conditions.

Time-dependent dielectric breakdown (TDDB) testing has become a standardized procedure for evaluating GaN device reliability, with specific methodologies outlined in JEDEC JESD92 that have been modified to account for the unique breakdown mechanisms in GaN high-electron-mobility transistors (HEMTs).

International standards organizations are currently developing harmonized testing approaches that bridge the gap between different regional standards. The IEEE P2851 working group is creating a unified framework for wide bandgap semiconductor reliability assessment that specifically addresses partial discharge and insulation stress in motor drive applications, ensuring consistent evaluation methodologies across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!