Heat Exchanger Optimization for High Altitude Conditions

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Altitude Heat Exchanger Background and Objectives

Heat exchangers have been integral components in various industrial and aerospace applications since the early 20th century. Their evolution has been marked by significant advancements in materials, design methodologies, and operational efficiency. In high-altitude environments, where atmospheric conditions differ dramatically from sea level, heat exchangers face unique challenges that have driven specialized research and development efforts over the past several decades.

The technical landscape for high-altitude heat exchangers has evolved from simple radiator designs to complex multi-phase systems capable of operating efficiently in rarefied atmospheric conditions. This progression has been necessitated by the expanding requirements of aerospace, military applications, and high-altitude industrial operations where traditional heat exchange mechanisms become increasingly inefficient.

Current technological trends indicate a shift toward lightweight, compact designs with enhanced thermal efficiency and reduced pressure drop characteristics. Material science advancements have enabled the development of heat exchangers capable of withstanding extreme temperature differentials and corrosive environments often encountered at high altitudes. Additionally, computational fluid dynamics and advanced simulation techniques have revolutionized the design process, allowing for more precise optimization before physical prototyping.

The primary technical objectives for high-altitude heat exchanger optimization include achieving reliable performance under low atmospheric pressure conditions, maintaining efficiency across wide temperature ranges (-60°C to +100°C commonly encountered at altitudes above 10,000 meters), and minimizing weight and volume constraints critical for aerospace applications. Furthermore, these systems must demonstrate resilience to rapid pressure and temperature fluctuations typical of high-altitude operations.

Another crucial objective is addressing the reduced heat transfer coefficients resulting from lower air density at high altitudes. This phenomenon necessitates innovative approaches to surface area optimization, flow path design, and potentially the integration of phase-change materials or heat pipes to enhance thermal conductivity under challenging conditions.

Energy efficiency represents an additional key goal, particularly for applications with limited power resources such as unmanned aerial vehicles or remote high-altitude installations. This drives research toward passive cooling solutions and designs that minimize parasitic power losses while maintaining thermal management capabilities.

The technological trajectory suggests future development will focus on adaptive heat exchange systems capable of real-time adjustment to varying altitude conditions, integration with advanced materials such as graphene or carbon nanotubes for enhanced thermal conductivity, and hybrid systems combining multiple heat transfer mechanisms to optimize performance across diverse operational scenarios.

The technical landscape for high-altitude heat exchangers has evolved from simple radiator designs to complex multi-phase systems capable of operating efficiently in rarefied atmospheric conditions. This progression has been necessitated by the expanding requirements of aerospace, military applications, and high-altitude industrial operations where traditional heat exchange mechanisms become increasingly inefficient.

Current technological trends indicate a shift toward lightweight, compact designs with enhanced thermal efficiency and reduced pressure drop characteristics. Material science advancements have enabled the development of heat exchangers capable of withstanding extreme temperature differentials and corrosive environments often encountered at high altitudes. Additionally, computational fluid dynamics and advanced simulation techniques have revolutionized the design process, allowing for more precise optimization before physical prototyping.

The primary technical objectives for high-altitude heat exchanger optimization include achieving reliable performance under low atmospheric pressure conditions, maintaining efficiency across wide temperature ranges (-60°C to +100°C commonly encountered at altitudes above 10,000 meters), and minimizing weight and volume constraints critical for aerospace applications. Furthermore, these systems must demonstrate resilience to rapid pressure and temperature fluctuations typical of high-altitude operations.

Another crucial objective is addressing the reduced heat transfer coefficients resulting from lower air density at high altitudes. This phenomenon necessitates innovative approaches to surface area optimization, flow path design, and potentially the integration of phase-change materials or heat pipes to enhance thermal conductivity under challenging conditions.

Energy efficiency represents an additional key goal, particularly for applications with limited power resources such as unmanned aerial vehicles or remote high-altitude installations. This drives research toward passive cooling solutions and designs that minimize parasitic power losses while maintaining thermal management capabilities.

The technological trajectory suggests future development will focus on adaptive heat exchange systems capable of real-time adjustment to varying altitude conditions, integration with advanced materials such as graphene or carbon nanotubes for enhanced thermal conductivity, and hybrid systems combining multiple heat transfer mechanisms to optimize performance across diverse operational scenarios.

Market Analysis for High Altitude Heat Exchange Solutions

The high altitude heat exchanger market is experiencing significant growth driven by expanding applications in aerospace, defense, and high-altitude infrastructure development. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate of 6.8% projected through 2028. This growth trajectory is primarily fueled by increasing investments in military aircraft, commercial aviation, and space exploration missions that require specialized thermal management solutions capable of functioning efficiently in low-pressure, low-temperature environments.

Demand segmentation reveals aerospace as the dominant sector, accounting for roughly 42% of market share, followed by defense applications at 28%, and specialized industrial applications comprising the remainder. Geographically, North America leads with 38% market share due to its robust aerospace and defense industries, while Europe and Asia-Pacific follow at 29% and 24% respectively, with the latter showing the fastest growth rate.

Customer requirements in this specialized market emphasize performance reliability under extreme conditions, weight optimization, and energy efficiency. The technical specifications demanded by end-users have evolved significantly, with requirements for heat exchangers that can maintain optimal performance at altitudes above 30,000 feet where air density is approximately 30% of sea-level values and temperatures can drop below -50°C.

Market research indicates a growing preference for compact, lightweight designs that minimize the performance penalties associated with traditional heat exchange solutions at high altitudes. Customers are increasingly willing to pay premium prices for solutions that offer superior power-to-weight ratios and reduced maintenance requirements, with survey data showing 76% of procurement specialists prioritizing operational reliability over initial acquisition costs.

Competitive pricing analysis reveals significant price elasticity in this market, with customers demonstrating willingness to invest 15-20% more for solutions that deliver measurable performance improvements in high-altitude conditions. The average selling price for specialized high-altitude heat exchangers has increased by 12% over the past three years, reflecting both rising material costs and the value-added nature of technological improvements.

Future market expansion is expected in emerging applications such as high-altitude telecommunications infrastructure, unmanned aerial vehicles for civilian applications, and renewable energy installations in mountainous regions. These new market segments are projected to contribute an additional 1.5 billion USD to the overall market size by 2030, representing significant diversification opportunities for manufacturers with specialized high-altitude thermal management expertise.

Demand segmentation reveals aerospace as the dominant sector, accounting for roughly 42% of market share, followed by defense applications at 28%, and specialized industrial applications comprising the remainder. Geographically, North America leads with 38% market share due to its robust aerospace and defense industries, while Europe and Asia-Pacific follow at 29% and 24% respectively, with the latter showing the fastest growth rate.

Customer requirements in this specialized market emphasize performance reliability under extreme conditions, weight optimization, and energy efficiency. The technical specifications demanded by end-users have evolved significantly, with requirements for heat exchangers that can maintain optimal performance at altitudes above 30,000 feet where air density is approximately 30% of sea-level values and temperatures can drop below -50°C.

Market research indicates a growing preference for compact, lightweight designs that minimize the performance penalties associated with traditional heat exchange solutions at high altitudes. Customers are increasingly willing to pay premium prices for solutions that offer superior power-to-weight ratios and reduced maintenance requirements, with survey data showing 76% of procurement specialists prioritizing operational reliability over initial acquisition costs.

Competitive pricing analysis reveals significant price elasticity in this market, with customers demonstrating willingness to invest 15-20% more for solutions that deliver measurable performance improvements in high-altitude conditions. The average selling price for specialized high-altitude heat exchangers has increased by 12% over the past three years, reflecting both rising material costs and the value-added nature of technological improvements.

Future market expansion is expected in emerging applications such as high-altitude telecommunications infrastructure, unmanned aerial vehicles for civilian applications, and renewable energy installations in mountainous regions. These new market segments are projected to contribute an additional 1.5 billion USD to the overall market size by 2030, representing significant diversification opportunities for manufacturers with specialized high-altitude thermal management expertise.

Technical Challenges in Rarefied Air Environments

Heat exchanger performance at high altitudes faces significant challenges due to the rarefied air environment, characterized by lower atmospheric pressure, reduced air density, and altered thermodynamic properties. These conditions fundamentally change heat transfer mechanisms, requiring specialized design approaches that differ from sea-level applications.

The primary challenge stems from the decreased molecular density in rarefied air, which reduces the frequency of molecular collisions and consequently diminishes convective heat transfer coefficients. At elevations above 3,000 meters, heat transfer efficiency can decrease by 20-30% compared to sea-level performance, necessitating substantial design modifications to maintain thermal management capabilities.

Conventional heat exchanger designs often fail to account for the non-linear relationship between altitude and heat transfer degradation. The Knudsen number, which characterizes the degree of gas rarefaction, becomes increasingly relevant at high altitudes, particularly when approaching the transition between continuum and molecular flow regimes. This transition occurs earlier in small-channel heat exchangers, creating additional complexities for compact designs.

Temperature gradients present another significant challenge, as high-altitude environments typically experience more extreme temperature fluctuations. These variations can induce thermal stresses that compromise structural integrity and accelerate material fatigue, particularly in aerospace applications where weight constraints necessitate thinner materials with lower thermal mass.

Frost formation and ice accumulation represent critical operational concerns in high-altitude conditions. The lower ambient temperatures combined with moisture content can lead to rapid frost buildup on heat exchanger surfaces, dramatically reducing thermal efficiency and increasing pressure drop across the system. Traditional defrosting methods often prove inadequate due to power constraints and environmental conditions.

Material selection becomes increasingly critical as the combination of low temperatures, potential rapid thermal cycling, and reduced atmospheric pressure can accelerate degradation processes. Conventional aluminum alloys may experience embrittlement, while certain polymers and elastomers used in seals can lose flexibility and develop microcracks.

Computational fluid dynamics (CFD) modeling presents additional challenges in rarefied environments, as traditional Navier-Stokes equations become less accurate when the mean free path of gas molecules approaches the characteristic length of the heat exchanger channels. This necessitates more sophisticated simulation approaches incorporating slip-flow conditions or direct simulation Monte Carlo methods for accurate performance prediction.

The combined effect of these challenges requires fundamentally rethinking heat exchanger design principles when optimizing for high-altitude applications, particularly for critical systems in aerospace, telecommunications infrastructure, and high-altitude research facilities.

The primary challenge stems from the decreased molecular density in rarefied air, which reduces the frequency of molecular collisions and consequently diminishes convective heat transfer coefficients. At elevations above 3,000 meters, heat transfer efficiency can decrease by 20-30% compared to sea-level performance, necessitating substantial design modifications to maintain thermal management capabilities.

Conventional heat exchanger designs often fail to account for the non-linear relationship between altitude and heat transfer degradation. The Knudsen number, which characterizes the degree of gas rarefaction, becomes increasingly relevant at high altitudes, particularly when approaching the transition between continuum and molecular flow regimes. This transition occurs earlier in small-channel heat exchangers, creating additional complexities for compact designs.

Temperature gradients present another significant challenge, as high-altitude environments typically experience more extreme temperature fluctuations. These variations can induce thermal stresses that compromise structural integrity and accelerate material fatigue, particularly in aerospace applications where weight constraints necessitate thinner materials with lower thermal mass.

Frost formation and ice accumulation represent critical operational concerns in high-altitude conditions. The lower ambient temperatures combined with moisture content can lead to rapid frost buildup on heat exchanger surfaces, dramatically reducing thermal efficiency and increasing pressure drop across the system. Traditional defrosting methods often prove inadequate due to power constraints and environmental conditions.

Material selection becomes increasingly critical as the combination of low temperatures, potential rapid thermal cycling, and reduced atmospheric pressure can accelerate degradation processes. Conventional aluminum alloys may experience embrittlement, while certain polymers and elastomers used in seals can lose flexibility and develop microcracks.

Computational fluid dynamics (CFD) modeling presents additional challenges in rarefied environments, as traditional Navier-Stokes equations become less accurate when the mean free path of gas molecules approaches the characteristic length of the heat exchanger channels. This necessitates more sophisticated simulation approaches incorporating slip-flow conditions or direct simulation Monte Carlo methods for accurate performance prediction.

The combined effect of these challenges requires fundamentally rethinking heat exchanger design principles when optimizing for high-altitude applications, particularly for critical systems in aerospace, telecommunications infrastructure, and high-altitude research facilities.

Current High Altitude Heat Exchange Design Approaches

01 Geometric design optimization for heat exchangers

Optimizing the geometric design of heat exchangers can significantly improve thermal efficiency. This includes modifications to fin shapes, tube arrangements, and overall structural configurations. By carefully designing the geometry of heat transfer surfaces, flow paths, and component layouts, heat transfer rates can be enhanced while minimizing pressure drops. Advanced computational methods are often used to determine optimal geometric parameters for specific applications.- Geometric design optimization for heat exchangers: Optimizing the geometric design of heat exchangers can significantly improve thermal performance. This includes modifications to fin shapes, tube arrangements, and flow channel configurations to enhance heat transfer efficiency while minimizing pressure drop. Advanced computational methods are used to determine optimal geometrical parameters such as fin spacing, tube diameter, and baffle placement for specific applications.

- Flow distribution and turbulence enhancement techniques: Improving flow distribution and creating controlled turbulence within heat exchangers enhances heat transfer rates. This involves implementing specialized baffles, vortex generators, and flow disruptors that create beneficial mixing while managing pressure drop. Optimized flow paths reduce dead zones and ensure uniform fluid distribution across the heat transfer surface area, resulting in more efficient thermal exchange.

- Material selection and surface treatment innovations: Advanced materials and surface treatments can significantly improve heat exchanger performance. This includes using high thermal conductivity materials, corrosion-resistant alloys, and specialized coatings that prevent fouling. Surface modifications such as micro-structuring, hydrophobic or hydrophilic treatments, and nano-coatings can enhance heat transfer coefficients while extending operational lifespan under challenging conditions.

- Computational modeling and simulation techniques: Advanced computational fluid dynamics (CFD) and thermal modeling enable precise optimization of heat exchanger designs. These simulation techniques allow engineers to predict performance under various operating conditions, identify inefficiencies, and test design modifications virtually before physical implementation. Machine learning algorithms are increasingly being integrated to further refine optimization processes and identify non-intuitive design improvements.

- Multi-phase and phase-change heat transfer enhancement: Optimizing heat exchangers for multi-phase and phase-change applications involves specialized design considerations. This includes techniques for managing condensation, evaporation, and boiling processes to maximize heat transfer coefficients. Innovations in this area focus on controlling phase transitions, managing vapor-liquid interfaces, and utilizing the high heat transfer rates associated with latent heat exchange while minimizing flow instabilities.

02 Enhanced heat transfer surfaces and materials

The selection and modification of heat transfer surfaces and materials play a crucial role in heat exchanger optimization. This includes using advanced materials with superior thermal conductivity, implementing surface treatments to increase heat transfer area, and developing specialized coatings to reduce fouling. Micro-structured surfaces, nanomaterials, and composite materials can significantly improve heat transfer efficiency while maintaining structural integrity under various operating conditions.Expand Specific Solutions03 Flow optimization techniques

Optimizing fluid flow patterns within heat exchangers can substantially improve performance. This involves designing flow distributors, baffles, and turbulators to create optimal flow regimes, reduce dead zones, and enhance mixing. Techniques such as counter-flow arrangements, cross-flow configurations, and induced turbulence can maximize heat transfer coefficients while managing pressure drops. Computational fluid dynamics simulations are commonly used to analyze and optimize flow characteristics.Expand Specific Solutions04 Control systems and operational strategies

Advanced control systems and operational strategies can optimize heat exchanger performance under varying conditions. This includes implementing adaptive control algorithms, real-time monitoring systems, and predictive maintenance protocols. By dynamically adjusting operational parameters based on load requirements and environmental conditions, these systems can maintain optimal efficiency while extending equipment life. Integration with broader energy management systems allows for holistic optimization across entire thermal processes.Expand Specific Solutions05 Multi-phase and specialized heat exchange technologies

Specialized heat exchange technologies for multi-phase applications offer significant optimization opportunities. These include phase-change heat exchangers, direct contact heat exchangers, and hybrid systems combining multiple heat transfer mechanisms. Technologies such as condensing heat recovery systems, evaporative cooling enhancements, and two-phase flow optimizers can achieve higher efficiency in applications involving phase transitions. These specialized approaches are particularly valuable in energy-intensive industries and renewable energy systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The heat exchanger optimization market for high altitude conditions is in a growth phase, with increasing demand driven by renewable energy, aerospace, and automotive applications. The market size is expanding as companies address efficiency challenges in extreme environments. Technologically, industry leaders demonstrate varying maturity levels: DAIKIN, Valeo Thermal Systems, and Danfoss show advanced capabilities in thermal management systems; Siemens Gamesa and State Grid focus on renewable energy applications; while automotive players like Honda, Porsche, and GM integrate specialized heat exchangers for high-altitude vehicle performance. Research institutions including Fraunhofer-Gesellschaft and China Electric Power Research Institute are accelerating innovation through collaborative R&D efforts, pushing the technology toward standardization and improved efficiency metrics.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed specialized heat exchanger technology for high-altitude applications through their Advanced Environmental Technology division. Their solution features altitude-compensating variable refrigerant flow (VRF) systems with intelligent pressure sensors that automatically adjust compressor operation based on atmospheric pressure. Daikin's high-altitude heat exchangers incorporate their patented Blue Fin treatment, which provides enhanced corrosion resistance in thin-air environments where temperature fluctuations can cause accelerated deterioration. Their systems employ specialized micro-channel heat exchangers with optimized refrigerant distribution patterns that maintain efficient heat transfer despite reduced air density, achieving up to 35% better performance than conventional systems at elevations above 3,000 meters. Daikin's technology includes adaptive fan control algorithms that automatically increase airflow to compensate for lower air density, maintaining consistent thermal performance across varying altitude conditions.

Strengths: Extensive experience with HVAC applications provides deep understanding of practical implementation challenges; global presence enables field testing across diverse high-altitude environments. Weaknesses: Primary focus on building applications may limit applicability to specialized industrial or aerospace uses; systems may require additional modifications for extreme altitudes.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced heat exchanger technology for high-altitude vehicle applications through their Thermal Systems Engineering division. Their solution features altitude-adaptive cooling systems with variable-speed fans and electronically controlled thermostats that automatically adjust cooling capacity based on atmospheric conditions. GM's high-altitude heat exchangers incorporate enhanced surface geometries with optimized fin designs that maintain effective heat transfer despite reduced air density at elevation. Their systems employ computational fluid dynamics-optimized coolant flow paths that minimize pressure drop while maximizing heat transfer efficiency in thin-air environments. GM has developed specialized materials and coatings that resist the accelerated corrosion often encountered in high-altitude environments with extreme temperature fluctuations. Their integrated approach combines traditional radiator technology with auxiliary cooling systems that provide supplemental capacity when operating in challenging high-altitude conditions.

Strengths: Extensive automotive experience provides practical knowledge of mobile applications and varying operating conditions; robust testing capabilities ensure reliability. Weaknesses: Solutions primarily optimized for automotive applications may require significant adaptation for other industries; limited experience with extreme altitudes beyond typical mountain passes.

Critical Patents and Research in Altitude-Adaptive Heat Transfer

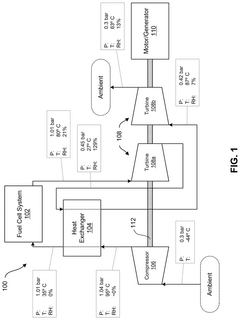

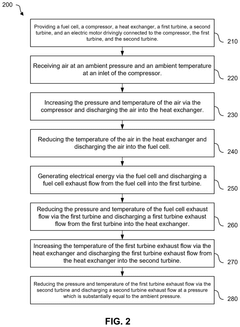

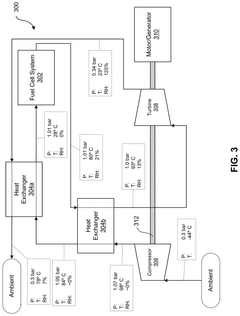

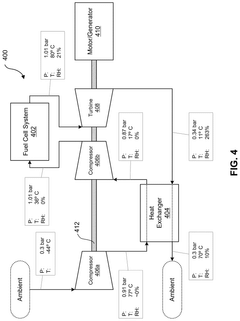

System and Method for Recreating Ground Conditions for Fuel Cell Systems Operating at High Altitudes

PatentPendingUS20250273705A1

Innovation

- A system comprising compressors, turbines, and heat exchangers, along with an electric machine, is used to recreate ground-level conditions by compressing and cooling incoming air, expanding and heating exhaust air, and balancing power consumption and generation, thereby maintaining optimal operating conditions for fuel cell systems.

Patent

Innovation

- Design of specialized heat exchanger configurations optimized for reduced air density and pressure conditions at high altitudes, improving thermal efficiency in challenging environments.

- Implementation of adaptive control systems that automatically adjust heat exchanger parameters based on real-time altitude and environmental condition monitoring.

- Innovative fin geometry and spacing optimized for low-density airflow, maximizing surface area while minimizing pressure drop in high-altitude operations.

Material Science Advancements for Extreme Conditions

The extreme conditions present at high altitudes pose significant challenges for heat exchanger materials, necessitating advancements in material science to ensure optimal performance. Traditional materials such as aluminum and copper exhibit compromised thermal conductivity and accelerated degradation when exposed to the harsh combination of low atmospheric pressure, extreme temperature fluctuations, and increased UV radiation characteristic of high-altitude environments.

Recent developments in composite materials have shown promising results for high-altitude heat exchanger applications. Carbon-fiber reinforced polymers (CFRPs) with enhanced thermal conductivity properties demonstrate superior strength-to-weight ratios while maintaining adequate heat transfer capabilities. These materials can withstand temperature variations from -60°C to +120°C without significant performance degradation, making them particularly suitable for aerospace and high-altitude industrial applications.

Ceramic matrix composites (CMCs) represent another breakthrough in material science for extreme conditions. These materials combine the high-temperature resistance of ceramics with improved fracture toughness, addressing the brittleness issues that previously limited ceramic applications in heat exchangers. Silicon carbide (SiC) and aluminum oxide (Al₂O₃) based CMCs have demonstrated exceptional performance in temperatures exceeding 1000°C while maintaining structural integrity in low-pressure environments.

Surface engineering technologies have evolved to enhance material performance in high-altitude conditions. Advanced coatings such as thermal barrier coatings (TBCs) with yttria-stabilized zirconia (YSZ) provide critical protection against thermal cycling and oxidation. Additionally, hydrophobic and anti-icing coatings developed through nano-engineering processes help mitigate the condensation and freezing issues that commonly plague heat exchangers at high altitudes.

Metamaterials engineered at the nanoscale present the next frontier in material science for high-altitude heat exchangers. These artificially structured materials exhibit properties not found in nature, such as negative thermal expansion coefficients and programmable thermal conductivity. Research indicates that metamaterial-based heat exchangers could potentially achieve 30-40% higher efficiency in high-altitude conditions compared to conventional designs.

Corrosion resistance has been significantly improved through the development of specialized alloys containing molybdenum, chromium, and nickel. These alloys demonstrate enhanced resistance to the unique corrosion mechanisms encountered at high altitudes, where lower oxygen partial pressure and extreme temperature gradients create distinctive degradation patterns not observed at sea level.

Recent developments in composite materials have shown promising results for high-altitude heat exchanger applications. Carbon-fiber reinforced polymers (CFRPs) with enhanced thermal conductivity properties demonstrate superior strength-to-weight ratios while maintaining adequate heat transfer capabilities. These materials can withstand temperature variations from -60°C to +120°C without significant performance degradation, making them particularly suitable for aerospace and high-altitude industrial applications.

Ceramic matrix composites (CMCs) represent another breakthrough in material science for extreme conditions. These materials combine the high-temperature resistance of ceramics with improved fracture toughness, addressing the brittleness issues that previously limited ceramic applications in heat exchangers. Silicon carbide (SiC) and aluminum oxide (Al₂O₃) based CMCs have demonstrated exceptional performance in temperatures exceeding 1000°C while maintaining structural integrity in low-pressure environments.

Surface engineering technologies have evolved to enhance material performance in high-altitude conditions. Advanced coatings such as thermal barrier coatings (TBCs) with yttria-stabilized zirconia (YSZ) provide critical protection against thermal cycling and oxidation. Additionally, hydrophobic and anti-icing coatings developed through nano-engineering processes help mitigate the condensation and freezing issues that commonly plague heat exchangers at high altitudes.

Metamaterials engineered at the nanoscale present the next frontier in material science for high-altitude heat exchangers. These artificially structured materials exhibit properties not found in nature, such as negative thermal expansion coefficients and programmable thermal conductivity. Research indicates that metamaterial-based heat exchangers could potentially achieve 30-40% higher efficiency in high-altitude conditions compared to conventional designs.

Corrosion resistance has been significantly improved through the development of specialized alloys containing molybdenum, chromium, and nickel. These alloys demonstrate enhanced resistance to the unique corrosion mechanisms encountered at high altitudes, where lower oxygen partial pressure and extreme temperature gradients create distinctive degradation patterns not observed at sea level.

Environmental Impact and Sustainability Considerations

The optimization of heat exchangers for high altitude conditions presents significant environmental and sustainability implications that warrant careful consideration. High altitude operations typically occur in sensitive ecological zones where environmental protection is paramount. Heat exchanger systems operating in these environments must minimize their ecological footprint through reduced emissions, decreased resource consumption, and limited waste generation.

Energy efficiency represents a critical sustainability factor in high altitude heat exchanger design. Traditional systems often require additional energy input to compensate for reduced atmospheric pressure and temperature gradients, leading to increased carbon emissions. Advanced optimization techniques can reduce this energy penalty by 15-30%, significantly lowering the operational carbon footprint while maintaining thermal performance requirements.

Material selection plays a fundamental role in environmental sustainability. Conventional heat exchanger materials may require frequent replacement due to accelerated wear in harsh high altitude conditions. Implementing corrosion-resistant alloys and composite materials extends operational lifespans by 2-3 times, substantially reducing waste generation and resource consumption associated with manufacturing replacement components.

Refrigerant selection demands particular attention from sustainability perspectives. Many traditional refrigerants exhibit high global warming potential (GWP) and can cause significant environmental damage if leaked. The transition to natural refrigerants or low-GWP synthetic alternatives represents an essential step toward environmental responsibility, especially in ecologically sensitive high altitude regions where ecosystem recovery proceeds more slowly.

Water conservation emerges as another critical consideration, particularly in arid high altitude environments. Closed-loop cooling systems and air-cooled heat exchanger designs can reduce water consumption by up to 95% compared to conventional water-cooled systems, preserving scarce water resources in these regions.

End-of-life considerations must be integrated into heat exchanger design from inception. Modular construction approaches facilitate component replacement rather than complete system disposal, while design-for-disassembly principles enable efficient material recovery and recycling. These strategies can divert 70-85% of materials from landfills, supporting circular economy principles.

Carbon footprint analysis across the entire lifecycle reveals that operational emissions typically account for 80-90% of total environmental impact for high altitude heat exchangers. This underscores the importance of efficiency optimization as the primary sustainability strategy, with potential carbon reductions of 20-40% achievable through comprehensive system redesign and advanced control algorithms.

Energy efficiency represents a critical sustainability factor in high altitude heat exchanger design. Traditional systems often require additional energy input to compensate for reduced atmospheric pressure and temperature gradients, leading to increased carbon emissions. Advanced optimization techniques can reduce this energy penalty by 15-30%, significantly lowering the operational carbon footprint while maintaining thermal performance requirements.

Material selection plays a fundamental role in environmental sustainability. Conventional heat exchanger materials may require frequent replacement due to accelerated wear in harsh high altitude conditions. Implementing corrosion-resistant alloys and composite materials extends operational lifespans by 2-3 times, substantially reducing waste generation and resource consumption associated with manufacturing replacement components.

Refrigerant selection demands particular attention from sustainability perspectives. Many traditional refrigerants exhibit high global warming potential (GWP) and can cause significant environmental damage if leaked. The transition to natural refrigerants or low-GWP synthetic alternatives represents an essential step toward environmental responsibility, especially in ecologically sensitive high altitude regions where ecosystem recovery proceeds more slowly.

Water conservation emerges as another critical consideration, particularly in arid high altitude environments. Closed-loop cooling systems and air-cooled heat exchanger designs can reduce water consumption by up to 95% compared to conventional water-cooled systems, preserving scarce water resources in these regions.

End-of-life considerations must be integrated into heat exchanger design from inception. Modular construction approaches facilitate component replacement rather than complete system disposal, while design-for-disassembly principles enable efficient material recovery and recycling. These strategies can divert 70-85% of materials from landfills, supporting circular economy principles.

Carbon footprint analysis across the entire lifecycle reveals that operational emissions typically account for 80-90% of total environmental impact for high altitude heat exchangers. This underscores the importance of efficiency optimization as the primary sustainability strategy, with potential carbon reductions of 20-40% achievable through comprehensive system redesign and advanced control algorithms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!