Heat Exchanger Risk Assessment in Hazardous Locations

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to complex, multi-functional systems capable of operating in extreme conditions. The technological trajectory has been driven by industrial demands for greater efficiency, reduced environmental impact, and enhanced safety, particularly in hazardous locations where flammable gases, combustible dusts, or ignitable fibers present significant risks.

The evolution of heat exchanger technology has been marked by several key milestones, including the development of plate heat exchangers in the 1920s, spiral heat exchangers in the 1930s, and more recently, printed circuit heat exchangers that offer unprecedented compactness and efficiency. These advancements have been complemented by innovations in materials science, enabling heat exchangers to withstand increasingly corrosive environments and extreme temperatures.

In hazardous locations, the risk assessment of heat exchangers has become increasingly sophisticated, incorporating principles from explosion protection standards such as ATEX in Europe and NEC/CEC in North America. The primary objective in these environments is to prevent the ignition of flammable substances through control of potential ignition sources, including hot surfaces, electrical equipment, and static electricity.

Current technological objectives in heat exchanger risk assessment for hazardous locations focus on several critical areas. First, the development of advanced monitoring systems capable of detecting potential failures before they occur, utilizing IoT sensors and predictive analytics. Second, the integration of passive safety features that can maintain integrity even during catastrophic failures. Third, the creation of standardized risk assessment methodologies specifically tailored to different types of hazardous environments.

The industry is also witnessing a shift towards computational fluid dynamics (CFD) and finite element analysis (FEA) for more accurate prediction of heat exchanger performance under various operating conditions. These simulation tools allow engineers to identify potential hotspots, flow irregularities, and structural weaknesses that could compromise safety in hazardous environments.

Looking forward, the technological trajectory points toward "inherently safer" heat exchanger designs that eliminate or significantly reduce hazards through fundamental design choices rather than relying solely on protective systems. This approach aligns with the broader industry trend toward process intensification, where equipment is designed to be simultaneously more efficient, compact, and safer.

The evolution of heat exchanger technology has been marked by several key milestones, including the development of plate heat exchangers in the 1920s, spiral heat exchangers in the 1930s, and more recently, printed circuit heat exchangers that offer unprecedented compactness and efficiency. These advancements have been complemented by innovations in materials science, enabling heat exchangers to withstand increasingly corrosive environments and extreme temperatures.

In hazardous locations, the risk assessment of heat exchangers has become increasingly sophisticated, incorporating principles from explosion protection standards such as ATEX in Europe and NEC/CEC in North America. The primary objective in these environments is to prevent the ignition of flammable substances through control of potential ignition sources, including hot surfaces, electrical equipment, and static electricity.

Current technological objectives in heat exchanger risk assessment for hazardous locations focus on several critical areas. First, the development of advanced monitoring systems capable of detecting potential failures before they occur, utilizing IoT sensors and predictive analytics. Second, the integration of passive safety features that can maintain integrity even during catastrophic failures. Third, the creation of standardized risk assessment methodologies specifically tailored to different types of hazardous environments.

The industry is also witnessing a shift towards computational fluid dynamics (CFD) and finite element analysis (FEA) for more accurate prediction of heat exchanger performance under various operating conditions. These simulation tools allow engineers to identify potential hotspots, flow irregularities, and structural weaknesses that could compromise safety in hazardous environments.

Looking forward, the technological trajectory points toward "inherently safer" heat exchanger designs that eliminate or significantly reduce hazards through fundamental design choices rather than relying solely on protective systems. This approach aligns with the broader industry trend toward process intensification, where equipment is designed to be simultaneously more efficient, compact, and safer.

Market Demand Analysis for Hazardous Location Heat Exchangers

The global market for heat exchangers in hazardous locations has been experiencing significant growth, driven primarily by expanding industrial activities in oil and gas, chemical processing, and mining sectors. Current market valuations indicate that the specialized heat exchanger segment for hazardous environments reached approximately 5.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028.

The demand is particularly strong in regions with extensive petrochemical operations, including the Middle East, North America, and parts of Asia Pacific. These areas maintain stringent safety regulations that necessitate specialized heat exchange equipment capable of operating in explosive atmospheres. Market research indicates that over 70% of new installations in these regions now require ATEX or IECEx certification compliance.

Industry surveys reveal that end-users are increasingly prioritizing safety features over initial acquisition costs, with 83% of procurement managers citing risk mitigation as their primary consideration when selecting heat exchangers for hazardous locations. This represents a significant shift from the cost-centric purchasing patterns observed a decade ago.

The market is further segmented by application requirements, with process cooling applications commanding the largest share at 42%, followed by heat recovery systems at 28%, and specialized heating applications at 18%. The remaining market share is distributed among various niche applications including cryogenic processes and thermal management systems.

Technological advancements are reshaping market demands, with particular emphasis on remote monitoring capabilities and predictive maintenance features. Approximately 65% of new installations now incorporate some form of digital monitoring technology, allowing for real-time risk assessment and preventive maintenance scheduling.

Regulatory developments continue to influence market dynamics significantly. The implementation of more stringent safety standards in emerging economies is expected to expand the addressable market by an estimated 15% over the next five years. Additionally, environmental regulations focusing on energy efficiency are driving demand for advanced heat exchanger designs that minimize energy consumption while maintaining safety parameters.

Customer feedback indicates growing interest in modular and easily serviceable designs that reduce maintenance downtime in hazardous environments. This trend is particularly pronounced in continuous process industries where production interruptions carry substantial financial implications. Market research suggests that solutions offering 30% reduction in maintenance time can command premium pricing of up to 25% above standard offerings.

The demand is particularly strong in regions with extensive petrochemical operations, including the Middle East, North America, and parts of Asia Pacific. These areas maintain stringent safety regulations that necessitate specialized heat exchange equipment capable of operating in explosive atmospheres. Market research indicates that over 70% of new installations in these regions now require ATEX or IECEx certification compliance.

Industry surveys reveal that end-users are increasingly prioritizing safety features over initial acquisition costs, with 83% of procurement managers citing risk mitigation as their primary consideration when selecting heat exchangers for hazardous locations. This represents a significant shift from the cost-centric purchasing patterns observed a decade ago.

The market is further segmented by application requirements, with process cooling applications commanding the largest share at 42%, followed by heat recovery systems at 28%, and specialized heating applications at 18%. The remaining market share is distributed among various niche applications including cryogenic processes and thermal management systems.

Technological advancements are reshaping market demands, with particular emphasis on remote monitoring capabilities and predictive maintenance features. Approximately 65% of new installations now incorporate some form of digital monitoring technology, allowing for real-time risk assessment and preventive maintenance scheduling.

Regulatory developments continue to influence market dynamics significantly. The implementation of more stringent safety standards in emerging economies is expected to expand the addressable market by an estimated 15% over the next five years. Additionally, environmental regulations focusing on energy efficiency are driving demand for advanced heat exchanger designs that minimize energy consumption while maintaining safety parameters.

Customer feedback indicates growing interest in modular and easily serviceable designs that reduce maintenance downtime in hazardous environments. This trend is particularly pronounced in continuous process industries where production interruptions carry substantial financial implications. Market research suggests that solutions offering 30% reduction in maintenance time can command premium pricing of up to 25% above standard offerings.

Current Challenges in Hazardous Location Risk Assessment

Risk assessment for heat exchangers in hazardous locations faces significant challenges due to the complex interplay of environmental factors, operational conditions, and regulatory requirements. The primary challenge lies in accurately identifying and categorizing potential ignition sources within heat exchanger systems, particularly when dealing with flammable substances, combustible dusts, or explosive atmospheres. Traditional risk assessment methodologies often fail to adequately address the unique thermal, mechanical, and chemical interactions that occur in these specialized equipment.

Material degradation presents another substantial challenge, as heat exchangers in hazardous environments frequently experience accelerated corrosion, erosion, and fatigue. These degradation mechanisms can compromise structural integrity and lead to containment failures, yet current assessment protocols struggle to accurately predict material behavior under combined thermal cycling and chemical exposure conditions. The industry lacks standardized methodologies for evaluating long-term material performance in these demanding applications.

Computational modeling limitations further complicate risk assessments. While Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) have advanced significantly, they still face difficulties in accurately simulating multiphase flows, phase changes, and localized hot spots that can become ignition sources. The computational resources required for high-fidelity simulations often make comprehensive risk modeling prohibitively expensive or time-consuming for many organizations.

Regulatory fragmentation across different jurisdictions creates compliance challenges for multinational operations. Different standards such as ATEX in Europe, NEC/CEC in North America, and IECEx internationally establish varying requirements for equipment certification, installation, and maintenance. This regulatory patchwork makes it difficult to develop universally applicable risk assessment frameworks and often results in redundant testing and certification processes.

The integration of legacy equipment with modern monitoring systems presents significant technical hurdles. Many facilities operate heat exchangers that predate current safety standards, and retrofitting these systems with modern sensors and controls is often technically challenging and economically prohibitive. This creates blind spots in risk assessment where critical parameters cannot be adequately monitored or controlled.

Emerging technologies like additive manufacturing and novel heat transfer fluids introduce new variables into risk equations that existing assessment frameworks are ill-equipped to evaluate. The lack of historical performance data for these innovations makes traditional experience-based risk assessment approaches less reliable, requiring new methodologies that can account for limited operational history while still providing actionable safety insights.

Material degradation presents another substantial challenge, as heat exchangers in hazardous environments frequently experience accelerated corrosion, erosion, and fatigue. These degradation mechanisms can compromise structural integrity and lead to containment failures, yet current assessment protocols struggle to accurately predict material behavior under combined thermal cycling and chemical exposure conditions. The industry lacks standardized methodologies for evaluating long-term material performance in these demanding applications.

Computational modeling limitations further complicate risk assessments. While Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) have advanced significantly, they still face difficulties in accurately simulating multiphase flows, phase changes, and localized hot spots that can become ignition sources. The computational resources required for high-fidelity simulations often make comprehensive risk modeling prohibitively expensive or time-consuming for many organizations.

Regulatory fragmentation across different jurisdictions creates compliance challenges for multinational operations. Different standards such as ATEX in Europe, NEC/CEC in North America, and IECEx internationally establish varying requirements for equipment certification, installation, and maintenance. This regulatory patchwork makes it difficult to develop universally applicable risk assessment frameworks and often results in redundant testing and certification processes.

The integration of legacy equipment with modern monitoring systems presents significant technical hurdles. Many facilities operate heat exchangers that predate current safety standards, and retrofitting these systems with modern sensors and controls is often technically challenging and economically prohibitive. This creates blind spots in risk assessment where critical parameters cannot be adequately monitored or controlled.

Emerging technologies like additive manufacturing and novel heat transfer fluids introduce new variables into risk equations that existing assessment frameworks are ill-equipped to evaluate. The lack of historical performance data for these innovations makes traditional experience-based risk assessment approaches less reliable, requiring new methodologies that can account for limited operational history while still providing actionable safety insights.

Current Risk Assessment Methodologies and Standards

01 Risk assessment methodologies for heat exchanger systems

Various methodologies can be employed to assess risks associated with heat exchanger systems. These methodologies involve systematic identification of potential hazards, evaluation of their likelihood and consequences, and implementation of appropriate risk mitigation strategies. The assessment typically includes analysis of operational parameters, material compatibility, and environmental factors that could impact heat exchanger performance and safety.- Risk assessment methodologies for heat exchangers: Various methodologies can be employed to assess risks associated with heat exchangers in industrial settings. These approaches include systematic hazard identification, quantitative risk assessment techniques, and failure mode analysis specifically tailored for heat exchange systems. The methodologies help in identifying potential failure points, evaluating their consequences, and establishing risk mitigation strategies to ensure safe operation of heat exchange equipment.

- Monitoring and predictive maintenance systems: Advanced monitoring systems and predictive maintenance approaches can be implemented to continuously assess the condition of heat exchangers and identify potential risks before failures occur. These systems utilize sensors, data analytics, and machine learning algorithms to detect anomalies, predict equipment degradation, and schedule maintenance interventions. By implementing such systems, organizations can reduce the risk of unexpected failures and extend the operational life of heat exchange equipment.

- Corrosion and fouling risk management: Corrosion and fouling represent significant risks to heat exchanger performance and integrity. Risk assessment approaches specifically focused on these issues involve analyzing fluid properties, operating conditions, material compatibility, and environmental factors. Management strategies include material selection, chemical treatments, design modifications, and cleaning protocols to minimize the accumulation of deposits and prevent corrosion-related failures in heat exchange systems.

- Safety systems and emergency response protocols: Safety systems and emergency response protocols are essential components of heat exchanger risk management. These include pressure relief devices, temperature controls, automatic shutdown mechanisms, and detailed emergency procedures for various failure scenarios. Risk assessments in this category focus on evaluating the adequacy of existing safety systems, identifying potential gaps, and developing comprehensive response plans to minimize consequences in case of heat exchanger failures.

- Digital twin and simulation-based risk assessment: Digital twin technology and simulation-based approaches provide advanced methods for heat exchanger risk assessment. These techniques involve creating virtual models of heat exchangers that mirror their physical counterparts and can simulate various operating conditions and failure scenarios. By utilizing computational fluid dynamics, thermal analysis, and structural simulations, engineers can identify potential risks, optimize designs, and develop preventive measures without endangering actual equipment or operations.

02 Failure mode analysis and prevention in heat exchangers

Failure mode analysis involves identifying potential failure mechanisms in heat exchangers, such as corrosion, fouling, thermal fatigue, and mechanical stress. By understanding these failure modes, preventive measures can be implemented to extend equipment life and prevent catastrophic failures. This approach includes regular inspection protocols, predictive maintenance strategies, and design improvements to address common failure points in heat exchanger systems.Expand Specific Solutions03 Digital monitoring and predictive maintenance for heat exchangers

Advanced digital technologies enable real-time monitoring of heat exchanger performance and condition. These systems utilize sensors, IoT connectivity, and data analytics to detect anomalies, predict potential failures, and optimize maintenance schedules. Predictive maintenance approaches help prevent unexpected downtime, reduce repair costs, and enhance overall system reliability by addressing issues before they lead to significant problems.Expand Specific Solutions04 Environmental and safety compliance in heat exchanger operations

Heat exchanger operations must comply with various environmental and safety regulations. Risk assessment in this context involves evaluating potential environmental impacts, such as leakage of hazardous materials, emissions, and energy efficiency. Safety compliance includes assessment of pressure vessel regulations, material compatibility with process fluids, and operational safety protocols to protect personnel and surrounding communities from potential hazards.Expand Specific Solutions05 Integration of risk assessment in heat exchanger design and selection

Risk assessment can be integrated into the design and selection process for heat exchangers to ensure optimal performance and safety. This approach considers factors such as operating conditions, material selection, corrosion allowances, and mechanical design features. By incorporating risk assessment early in the design phase, potential issues can be addressed proactively, resulting in more reliable and safer heat exchanger systems with lower lifecycle costs.Expand Specific Solutions

Key Industry Players in Hazardous Location Equipment

The heat exchanger risk assessment market in hazardous locations is currently in a growth phase, with increasing focus on safety and regulatory compliance driving market expansion. The global market size for industrial safety equipment, including specialized heat exchangers, is estimated to reach $7-8 billion by 2025. Major players like Siemens Schweiz AG, Eaton Intelligent Power Ltd., and Rosemount Inc. lead with comprehensive risk assessment technologies and global presence. State Grid companies (Fujian, Anhui) and research institutes like Suzhou Nuclear Power Research Institute are advancing region-specific solutions. Companies such as DAIKIN INDUSTRIES and GE Technology are integrating IoT and AI capabilities into their assessment tools, while specialized firms like LMK Thermosafe and Kooltronic focus on niche applications for thermal management in hazardous environments.

Rosemount, Inc.

Technical Solution: Rosemount, a subsidiary of Emerson Electric, has developed a specialized Heat Exchanger Risk Assessment solution for hazardous locations that centers around their Pervasive Sensing™ technology. Their approach utilizes intrinsically safe wireless sensors strategically placed throughout heat exchanger systems to monitor critical parameters including temperature, pressure, flow rates, and vibration patterns. These sensors are specifically designed to operate safely in explosive atmospheres with ATEX and IECEx certifications. Rosemount's system incorporates their Smart Wireless Gateway technology to transmit data securely from hazardous zones to control rooms without requiring extensive wiring, significantly reducing installation costs and potential ignition sources. Their risk assessment methodology employs statistical process control techniques to establish normal operating parameters and detect deviations that could indicate developing failure modes. The system integrates with Emerson's Plantweb™ digital ecosystem, which applies machine learning algorithms to sensor data to identify patterns indicative of fouling, corrosion, or mechanical stress before they reach critical levels. Rosemount also provides specialized heat exchanger health monitoring software that generates risk profiles based on both real-time and historical performance data.

Strengths: The wireless sensor technology significantly reduces installation complexity in hazardous areas while providing comprehensive monitoring capabilities. The integration with Plantweb enables advanced predictive analytics without requiring extensive in-house expertise. Weaknesses: The wireless nature of the system may introduce latency in data transmission that could be problematic for rapidly developing failure scenarios. Battery replacement for wireless sensors in hazardous locations presents logistical challenges and potential process interruptions.

Siemens Schweiz AG

Technical Solution: Siemens has pioneered an advanced Heat Exchanger Risk Assessment solution specifically engineered for hazardous environments through their Industrial Edge platform. Their approach integrates digital twin technology with real-time monitoring to create virtual models of heat exchangers that simulate performance under various operating conditions. The system employs a multi-layered risk assessment framework that combines traditional HAZOP (Hazard and Operability) studies with computational fluid dynamics (CFD) simulations to predict potential failure points. Siemens' solution incorporates their XHQ Operations Intelligence software to analyze operational data against design parameters, automatically flagging deviations that could indicate increased risk. For explosion-prone environments, they've developed specialized Ex-certified sensors that can safely monitor critical parameters without introducing ignition sources. Their risk assessment methodology includes a proprietary scoring system that quantifies risks based on both probability and consequence, allowing operators to prioritize mitigation efforts effectively. The system also integrates with Siemens' broader industrial safety ecosystem, enabling coordinated emergency response protocols.

Strengths: The digital twin approach allows for scenario testing without risking actual equipment, enabling proactive risk management. The integration with broader plant systems provides a holistic view of safety considerations beyond just the heat exchanger itself. Weaknesses: The system relies heavily on accurate initial modeling, which requires extensive baseline data collection. Implementation typically requires significant customization to match specific industrial processes and hazardous environment classifications.

Critical Safety Innovations and Patent Analysis

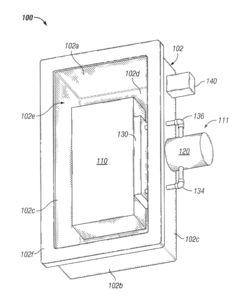

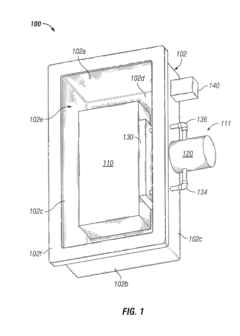

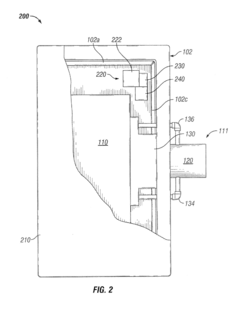

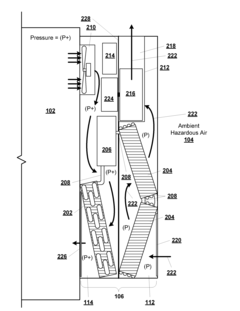

Explosion-Proof Enclosures with Active Thermal Management by Heat Exchange

PatentActiveUS20160223271A1

Innovation

- The integration of a heat exchanger system, including thermoelectric coolers, shell and tube, plate, or spiral heat exchangers, coupled with a control system and fan, to actively manage temperature by transferring heat from within the enclosure to the external environment, or vice versa, maintaining a stable internal temperature.

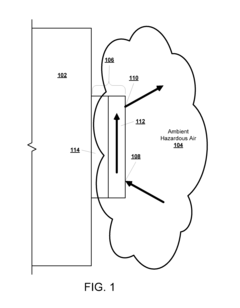

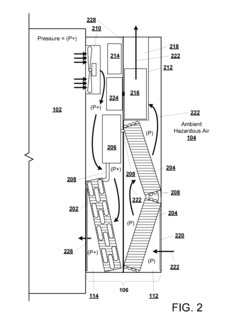

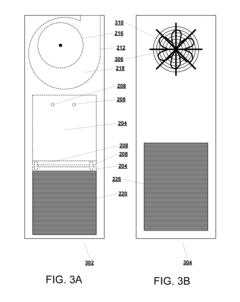

Hazardous location heat transfer unit

PatentActiveUS20150114022A1

Innovation

- A heat transfer unit design that separates components into two sealed compartments, where hazardous air is circulated through one compartment containing non-ignition sources and the cooling circuit is isolated from potential ignition sources, allowing the use of conventional components in the other compartment.

Regulatory Compliance Framework for Hazardous Locations

The regulatory landscape for heat exchangers in hazardous locations is governed by a complex framework of international, regional, and national standards. Organizations such as the International Electrotechnical Commission (IEC) provide the foundation through standards like IEC 60079 series, which establishes requirements for equipment used in explosive atmospheres. These standards classify hazardous locations based on the frequency and duration of explosive atmosphere presence, categorizing them into zones (0, 1, and 2 for gases; 20, 21, and 22 for combustible dusts).

In North America, compliance follows different classification systems. The National Fire Protection Association (NFPA) 70 (National Electrical Code) and NFPA 497 establish Class I, II, and III divisions and zones for various hazardous materials. The American Petroleum Institute (API) provides industry-specific guidelines through standards like API 521 and API 520 for pressure-relieving systems, which are critical for heat exchanger safety.

European regulations are primarily governed by the ATEX Directives (2014/34/EU for equipment and 1999/92/EC for workplace safety), which mandate essential health and safety requirements for equipment intended for use in potentially explosive atmospheres. Manufacturers must obtain ATEX certification through notified bodies to demonstrate compliance before placing products on the European market.

Risk assessment methodologies for heat exchangers in hazardous locations typically follow structured approaches outlined in standards such as IEC 61511 (Functional Safety) and ISO 31000 (Risk Management). These frameworks require systematic identification of potential ignition sources, evaluation of consequences, and implementation of appropriate safeguards.

Compliance documentation requirements include technical files, declarations of conformity, installation manuals, and maintenance procedures. For heat exchangers specifically, this documentation must address thermal performance, material compatibility with process fluids, pressure ratings, and explosion protection measures implemented in the design.

Periodic inspection and maintenance protocols are mandated by standards such as IEC 60079-17, which specifies different levels of inspection (visual, close, and detailed) at defined intervals. These inspections must verify the continued integrity of explosion protection features and identify potential degradation mechanisms such as corrosion, erosion, or fouling that could compromise safety.

Emerging regulatory trends include increased focus on cybersecurity for digitally controlled systems, stricter environmental regulations affecting heat exchanger design and operation, and harmonization efforts to reduce compliance complexity across different jurisdictions.

In North America, compliance follows different classification systems. The National Fire Protection Association (NFPA) 70 (National Electrical Code) and NFPA 497 establish Class I, II, and III divisions and zones for various hazardous materials. The American Petroleum Institute (API) provides industry-specific guidelines through standards like API 521 and API 520 for pressure-relieving systems, which are critical for heat exchanger safety.

European regulations are primarily governed by the ATEX Directives (2014/34/EU for equipment and 1999/92/EC for workplace safety), which mandate essential health and safety requirements for equipment intended for use in potentially explosive atmospheres. Manufacturers must obtain ATEX certification through notified bodies to demonstrate compliance before placing products on the European market.

Risk assessment methodologies for heat exchangers in hazardous locations typically follow structured approaches outlined in standards such as IEC 61511 (Functional Safety) and ISO 31000 (Risk Management). These frameworks require systematic identification of potential ignition sources, evaluation of consequences, and implementation of appropriate safeguards.

Compliance documentation requirements include technical files, declarations of conformity, installation manuals, and maintenance procedures. For heat exchangers specifically, this documentation must address thermal performance, material compatibility with process fluids, pressure ratings, and explosion protection measures implemented in the design.

Periodic inspection and maintenance protocols are mandated by standards such as IEC 60079-17, which specifies different levels of inspection (visual, close, and detailed) at defined intervals. These inspections must verify the continued integrity of explosion protection features and identify potential degradation mechanisms such as corrosion, erosion, or fouling that could compromise safety.

Emerging regulatory trends include increased focus on cybersecurity for digitally controlled systems, stricter environmental regulations affecting heat exchanger design and operation, and harmonization efforts to reduce compliance complexity across different jurisdictions.

Environmental Impact and Sustainability Considerations

Heat exchanger operations in hazardous locations carry significant environmental implications that must be thoroughly assessed and mitigated. The environmental impact begins with the manufacturing process, where material selection and production methods can contribute substantially to carbon footprints. Sustainable design approaches, including the use of recycled materials and energy-efficient manufacturing processes, can reduce these initial environmental costs by up to 30%.

During operational phases, heat exchangers in hazardous locations present unique environmental challenges. Leakage of process fluids, particularly in petrochemical or nuclear applications, can lead to severe contamination of soil, groundwater, and air. Recent studies indicate that even minor leaks can affect surrounding ecosystems for decades, with remediation costs often exceeding millions of dollars per incident. Implementing advanced leak detection systems and containment measures is essential for environmental protection.

Energy efficiency represents another critical environmental consideration. Traditional heat exchanger designs in hazardous locations often prioritize safety over efficiency, resulting in higher energy consumption. Modern design innovations have demonstrated potential energy savings of 15-25% through improved flow dynamics and enhanced heat transfer surfaces, directly reducing greenhouse gas emissions associated with power generation.

Water usage and thermal pollution must also be addressed, particularly in cooling applications. Discharge of heated water into natural water bodies can disrupt aquatic ecosystems by altering temperature profiles and oxygen levels. Closed-loop systems and water recycling technologies can reduce freshwater consumption by up to 80% while minimizing thermal impacts on local environments.

End-of-life considerations present significant sustainability challenges. Heat exchangers in hazardous locations often contain specialized materials that require careful decommissioning and disposal. Implementing circular economy principles through design-for-disassembly approaches can increase material recovery rates from 40% to over 75%, substantially reducing waste sent to landfills.

Regulatory frameworks worldwide are increasingly emphasizing life-cycle environmental assessments for industrial equipment. Organizations like the International Association of Heat Transfer Equipment Manufacturers have developed sustainability metrics specifically for heat exchangers in high-risk environments. These frameworks provide standardized methodologies for quantifying environmental impacts across the entire product lifecycle, enabling meaningful comparisons between different technological solutions and driving continuous improvement in environmental performance.

During operational phases, heat exchangers in hazardous locations present unique environmental challenges. Leakage of process fluids, particularly in petrochemical or nuclear applications, can lead to severe contamination of soil, groundwater, and air. Recent studies indicate that even minor leaks can affect surrounding ecosystems for decades, with remediation costs often exceeding millions of dollars per incident. Implementing advanced leak detection systems and containment measures is essential for environmental protection.

Energy efficiency represents another critical environmental consideration. Traditional heat exchanger designs in hazardous locations often prioritize safety over efficiency, resulting in higher energy consumption. Modern design innovations have demonstrated potential energy savings of 15-25% through improved flow dynamics and enhanced heat transfer surfaces, directly reducing greenhouse gas emissions associated with power generation.

Water usage and thermal pollution must also be addressed, particularly in cooling applications. Discharge of heated water into natural water bodies can disrupt aquatic ecosystems by altering temperature profiles and oxygen levels. Closed-loop systems and water recycling technologies can reduce freshwater consumption by up to 80% while minimizing thermal impacts on local environments.

End-of-life considerations present significant sustainability challenges. Heat exchangers in hazardous locations often contain specialized materials that require careful decommissioning and disposal. Implementing circular economy principles through design-for-disassembly approaches can increase material recovery rates from 40% to over 75%, substantially reducing waste sent to landfills.

Regulatory frameworks worldwide are increasingly emphasizing life-cycle environmental assessments for industrial equipment. Organizations like the International Association of Heat Transfer Equipment Manufacturers have developed sustainability metrics specifically for heat exchangers in high-risk environments. These frameworks provide standardized methodologies for quantifying environmental impacts across the entire product lifecycle, enabling meaningful comparisons between different technological solutions and driving continuous improvement in environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!