Heat Exchanger vs Cooling Tower: Efficiency Comparison

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Transfer Technology Background and Objectives

Heat transfer technology has evolved significantly over the past century, with heat exchangers and cooling towers representing two fundamental approaches to thermal management in industrial applications. Heat exchangers emerged in the early 20th century as compact solutions for transferring heat between fluids without mixing them, while cooling towers developed as evaporative cooling systems capable of rejecting large heat loads to the atmosphere. Both technologies have undergone substantial refinement through advances in materials science, computational fluid dynamics, and manufacturing techniques.

The evolution of heat transfer technology has been driven by increasing demands for energy efficiency, space optimization, and environmental sustainability. Early heat exchangers were primarily simple shell-and-tube designs, but have since diversified into plate, spiral, and microchannel configurations to address specific application requirements. Similarly, cooling towers have progressed from rudimentary wooden structures to sophisticated systems with optimized fill media, drift eliminators, and water distribution systems.

Current technological trends in heat transfer focus on maximizing efficiency while minimizing resource consumption. This includes the development of enhanced heat transfer surfaces, advanced materials with superior thermal conductivity, and hybrid systems that combine the advantages of different heat rejection methods. Additionally, there is growing interest in passive cooling technologies and systems that can operate effectively with reduced pumping power or fan energy.

The global push toward sustainability has accelerated innovation in heat transfer technology, with particular emphasis on reducing water consumption, minimizing chemical treatments, and lowering the carbon footprint of cooling systems. This has led to increased research into dry and hybrid cooling solutions, as well as systems designed for operation with alternative water sources.

The primary objective of comparing heat exchangers and cooling towers is to establish a comprehensive efficiency framework that accounts for thermal performance, energy consumption, water usage, space requirements, and lifecycle costs. This comparison must consider various operating conditions, including ambient temperature fluctuations, humidity levels, and heat load variations, as these factors significantly impact the relative performance of each technology.

Additional objectives include identifying optimal application scenarios for each technology, understanding the trade-offs between initial capital investment and operational expenses, and exploring potential synergies through integrated systems. The analysis also aims to evaluate emerging technologies that may bridge the performance gap between traditional heat exchangers and cooling towers, potentially offering superior efficiency across a broader range of operating conditions.

The evolution of heat transfer technology has been driven by increasing demands for energy efficiency, space optimization, and environmental sustainability. Early heat exchangers were primarily simple shell-and-tube designs, but have since diversified into plate, spiral, and microchannel configurations to address specific application requirements. Similarly, cooling towers have progressed from rudimentary wooden structures to sophisticated systems with optimized fill media, drift eliminators, and water distribution systems.

Current technological trends in heat transfer focus on maximizing efficiency while minimizing resource consumption. This includes the development of enhanced heat transfer surfaces, advanced materials with superior thermal conductivity, and hybrid systems that combine the advantages of different heat rejection methods. Additionally, there is growing interest in passive cooling technologies and systems that can operate effectively with reduced pumping power or fan energy.

The global push toward sustainability has accelerated innovation in heat transfer technology, with particular emphasis on reducing water consumption, minimizing chemical treatments, and lowering the carbon footprint of cooling systems. This has led to increased research into dry and hybrid cooling solutions, as well as systems designed for operation with alternative water sources.

The primary objective of comparing heat exchangers and cooling towers is to establish a comprehensive efficiency framework that accounts for thermal performance, energy consumption, water usage, space requirements, and lifecycle costs. This comparison must consider various operating conditions, including ambient temperature fluctuations, humidity levels, and heat load variations, as these factors significantly impact the relative performance of each technology.

Additional objectives include identifying optimal application scenarios for each technology, understanding the trade-offs between initial capital investment and operational expenses, and exploring potential synergies through integrated systems. The analysis also aims to evaluate emerging technologies that may bridge the performance gap between traditional heat exchangers and cooling towers, potentially offering superior efficiency across a broader range of operating conditions.

Market Demand Analysis for Cooling Systems

The global cooling systems market has been experiencing significant growth, driven by increasing industrialization, urbanization, and rising global temperatures. As of 2023, the industrial cooling systems market is valued at approximately 17.2 billion USD, with projections indicating a compound annual growth rate of 5.3% through 2030. This growth trajectory underscores the critical importance of efficient cooling technologies in various sectors.

Heat exchangers and cooling towers represent two fundamental approaches to thermal management, each addressing distinct market segments with varying requirements. The demand for heat exchangers is particularly robust in industries requiring precise temperature control, such as chemical processing, oil and gas, and food and beverage production. These sectors prioritize closed-loop systems that minimize water consumption and contamination risks.

Cooling towers, conversely, dominate markets where large-scale heat rejection is necessary, including power generation, HVAC systems for commercial buildings, and heavy manufacturing. The market demand for cooling towers has been influenced by increasing regulatory pressure regarding water conservation and treatment of discharge water, driving innovation toward more efficient designs with reduced environmental impact.

Energy efficiency has emerged as a primary market driver for both technologies. With industrial energy costs rising globally by an average of 3.7% annually over the past decade, businesses are increasingly prioritizing cooling systems that minimize operational expenses. This trend has accelerated the adoption of advanced heat exchanger technologies, including plate and frame designs that offer superior thermal efficiency compared to traditional shell and tube configurations.

Water scarcity concerns are reshaping market preferences, particularly in regions experiencing chronic water stress. According to recent environmental impact assessments, cooling systems account for approximately 15% of industrial water withdrawal globally. This has created a growing market segment for air-cooled heat exchangers and dry cooling technologies that significantly reduce or eliminate water consumption.

The market for hybrid cooling solutions, combining elements of both heat exchangers and cooling towers, has expanded at twice the rate of traditional systems over the past five years. These integrated approaches offer flexibility in operation, allowing facilities to optimize for either water or energy efficiency depending on local conditions and seasonal variations.

Geographical market distribution reveals distinct regional preferences. Asian markets, particularly China and India, show strong demand growth for both technologies, driven by rapid industrial expansion and infrastructure development. North American and European markets demonstrate greater emphasis on replacement and efficiency upgrades of existing systems, with particular focus on technologies offering reduced environmental footprint and compliance with increasingly stringent regulations.

Heat exchangers and cooling towers represent two fundamental approaches to thermal management, each addressing distinct market segments with varying requirements. The demand for heat exchangers is particularly robust in industries requiring precise temperature control, such as chemical processing, oil and gas, and food and beverage production. These sectors prioritize closed-loop systems that minimize water consumption and contamination risks.

Cooling towers, conversely, dominate markets where large-scale heat rejection is necessary, including power generation, HVAC systems for commercial buildings, and heavy manufacturing. The market demand for cooling towers has been influenced by increasing regulatory pressure regarding water conservation and treatment of discharge water, driving innovation toward more efficient designs with reduced environmental impact.

Energy efficiency has emerged as a primary market driver for both technologies. With industrial energy costs rising globally by an average of 3.7% annually over the past decade, businesses are increasingly prioritizing cooling systems that minimize operational expenses. This trend has accelerated the adoption of advanced heat exchanger technologies, including plate and frame designs that offer superior thermal efficiency compared to traditional shell and tube configurations.

Water scarcity concerns are reshaping market preferences, particularly in regions experiencing chronic water stress. According to recent environmental impact assessments, cooling systems account for approximately 15% of industrial water withdrawal globally. This has created a growing market segment for air-cooled heat exchangers and dry cooling technologies that significantly reduce or eliminate water consumption.

The market for hybrid cooling solutions, combining elements of both heat exchangers and cooling towers, has expanded at twice the rate of traditional systems over the past five years. These integrated approaches offer flexibility in operation, allowing facilities to optimize for either water or energy efficiency depending on local conditions and seasonal variations.

Geographical market distribution reveals distinct regional preferences. Asian markets, particularly China and India, show strong demand growth for both technologies, driven by rapid industrial expansion and infrastructure development. North American and European markets demonstrate greater emphasis on replacement and efficiency upgrades of existing systems, with particular focus on technologies offering reduced environmental footprint and compliance with increasingly stringent regulations.

Current Status and Challenges in Cooling Technologies

The cooling technology landscape has evolved significantly over the past decades, with heat exchangers and cooling towers representing two fundamental approaches to thermal management across various industries. Currently, heat exchangers dominate in applications requiring closed-loop cooling systems, particularly in HVAC, automotive, and process industries, while cooling towers remain prevalent in power generation, large commercial buildings, and industrial processes requiring substantial heat rejection.

Recent advancements in heat exchanger technology have focused on enhancing thermal efficiency through improved materials and designs. Plate heat exchangers have seen significant improvements in compactness and thermal performance, while microchannel heat exchangers offer exceptional heat transfer rates in smaller footprints. However, these technologies face challenges related to fouling, corrosion, and pressure drop limitations that impact long-term performance.

Cooling towers, meanwhile, have evolved toward more water-efficient designs, addressing growing concerns about water conservation. Hybrid cooling towers that combine wet and dry cooling processes have gained traction, offering flexibility in operation depending on ambient conditions and water availability. Despite these improvements, cooling towers continue to face challenges related to water consumption, treatment requirements, and biological growth management.

Energy efficiency remains a critical challenge for both technologies. Heat exchangers typically require pumping power to overcome pressure drops, while cooling towers need fan power and pumping energy. The trade-off between thermal performance and energy consumption represents a significant optimization challenge that varies considerably based on application requirements and operating conditions.

Material limitations present another substantial hurdle. Advanced heat exchanger designs often require specialized materials that can withstand high pressures, temperatures, and corrosive environments while maintaining excellent thermal conductivity. Similarly, cooling tower components must resist degradation from constant water exposure, chemical treatments, and biological activity.

Geographical and climate considerations significantly impact technology selection and performance. In water-scarce regions, dry cooling technologies are gaining prominence despite their typically lower efficiency compared to wet cooling systems. Conversely, in humid climates, the effectiveness of evaporative cooling in towers diminishes, shifting advantage toward certain types of heat exchangers.

Regulatory pressures are increasingly shaping technology development, with stricter water usage regulations, energy efficiency standards, and refrigerant restrictions driving innovation. The phase-out of certain refrigerants has accelerated research into alternative working fluids for heat exchangers, while water conservation mandates have spurred advancements in cooling tower water recovery systems.

Recent advancements in heat exchanger technology have focused on enhancing thermal efficiency through improved materials and designs. Plate heat exchangers have seen significant improvements in compactness and thermal performance, while microchannel heat exchangers offer exceptional heat transfer rates in smaller footprints. However, these technologies face challenges related to fouling, corrosion, and pressure drop limitations that impact long-term performance.

Cooling towers, meanwhile, have evolved toward more water-efficient designs, addressing growing concerns about water conservation. Hybrid cooling towers that combine wet and dry cooling processes have gained traction, offering flexibility in operation depending on ambient conditions and water availability. Despite these improvements, cooling towers continue to face challenges related to water consumption, treatment requirements, and biological growth management.

Energy efficiency remains a critical challenge for both technologies. Heat exchangers typically require pumping power to overcome pressure drops, while cooling towers need fan power and pumping energy. The trade-off between thermal performance and energy consumption represents a significant optimization challenge that varies considerably based on application requirements and operating conditions.

Material limitations present another substantial hurdle. Advanced heat exchanger designs often require specialized materials that can withstand high pressures, temperatures, and corrosive environments while maintaining excellent thermal conductivity. Similarly, cooling tower components must resist degradation from constant water exposure, chemical treatments, and biological activity.

Geographical and climate considerations significantly impact technology selection and performance. In water-scarce regions, dry cooling technologies are gaining prominence despite their typically lower efficiency compared to wet cooling systems. Conversely, in humid climates, the effectiveness of evaporative cooling in towers diminishes, shifting advantage toward certain types of heat exchangers.

Regulatory pressures are increasingly shaping technology development, with stricter water usage regulations, energy efficiency standards, and refrigerant restrictions driving innovation. The phase-out of certain refrigerants has accelerated research into alternative working fluids for heat exchangers, while water conservation mandates have spurred advancements in cooling tower water recovery systems.

Current Technical Solutions Comparison

01 Design improvements for heat exchangers

Various design improvements can enhance heat exchanger efficiency. These include optimized tube arrangements, improved fin designs, and innovative heat transfer surfaces. Such design modifications can reduce thermal resistance, improve heat transfer coefficients, and minimize pressure drops across the exchanger. Advanced materials and manufacturing techniques also contribute to creating more efficient heat exchange systems with better thermal conductivity and durability.- Design improvements for heat exchangers: Various design improvements can enhance heat exchanger efficiency. These include optimized tube arrangements, improved fin designs, and innovative surface geometries that maximize heat transfer area while minimizing pressure drop. Advanced materials with superior thermal conductivity can also be incorporated to improve overall heat transfer rates. These design enhancements result in more compact heat exchangers with higher thermal performance.

- Water distribution systems for cooling towers: Efficient water distribution systems are crucial for cooling tower performance. Innovations include spray nozzles that provide uniform water distribution over fill material, reducing dry spots and ensuring maximum contact between air and water. Advanced distribution systems can adapt to varying operational conditions and incorporate self-cleaning mechanisms to prevent clogging. These improvements enhance the evaporative cooling process and overall thermal efficiency of cooling towers.

- Integration of heat recovery systems: Heat recovery systems can significantly improve overall efficiency by capturing and reusing waste heat from cooling processes. These systems incorporate secondary heat exchangers to transfer waste heat to other processes or applications such as preheating, space heating, or domestic hot water production. Advanced control systems optimize heat recovery based on demand and available heat sources, reducing energy consumption and operational costs while improving sustainability.

- Advanced monitoring and control systems: Intelligent monitoring and control systems enhance efficiency through real-time performance optimization. These systems utilize sensors to monitor key parameters such as temperature, flow rates, and pressure differentials. Advanced algorithms analyze this data to adjust operating conditions automatically, maintaining optimal performance under varying loads and ambient conditions. Predictive maintenance capabilities identify potential issues before they affect performance, reducing downtime and extending equipment life.

- Hybrid cooling systems: Hybrid cooling systems combine different cooling technologies to optimize efficiency across varying operational and environmental conditions. These systems may integrate wet cooling, dry cooling, and mechanical refrigeration components that work together or independently based on ambient conditions and cooling demands. Sophisticated control systems determine the most efficient operating mode, reducing water consumption during cooler periods while maintaining cooling capacity during peak demand. This approach offers flexibility and improved year-round efficiency.

02 Cooling tower water distribution systems

Efficient water distribution systems are crucial for cooling tower performance. Innovations in nozzle design, spray patterns, and water flow control mechanisms can significantly improve cooling efficiency. Even water distribution ensures maximum contact between water and air, enhancing evaporative cooling. Advanced distribution systems also minimize water loss through drift and evaporation while maintaining optimal thermal performance across varying operational conditions.Expand Specific Solutions03 Energy recovery and system integration

Integrating heat exchangers and cooling towers with energy recovery systems can significantly improve overall efficiency. Waste heat recovery mechanisms, combined cycle approaches, and thermal energy storage solutions allow for better utilization of energy resources. System integration techniques that optimize the interaction between cooling towers and heat exchangers can reduce energy consumption, minimize operational costs, and improve sustainability of cooling operations.Expand Specific Solutions04 Advanced monitoring and control systems

Implementation of sophisticated monitoring and control systems can optimize the performance of heat exchangers and cooling towers. Sensors, automated controls, and predictive algorithms allow for real-time adjustments based on changing operational conditions. These systems can regulate water flow rates, fan speeds, and other parameters to maintain peak efficiency. Advanced diagnostics can also identify maintenance needs before efficiency degradation occurs, ensuring consistent performance.Expand Specific Solutions05 Novel materials and coatings for efficiency enhancement

The application of innovative materials and specialized coatings can significantly improve heat exchanger and cooling tower efficiency. Corrosion-resistant materials extend equipment lifespan, while hydrophilic or hydrophobic coatings can enhance water distribution and prevent scaling. Advanced composite materials with superior thermal properties improve heat transfer rates. Anti-fouling surfaces reduce maintenance requirements and maintain optimal thermal performance over extended operational periods.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The heat exchanger versus cooling tower efficiency comparison market is currently in a growth phase, with increasing demand driven by energy efficiency requirements across industries. The global market size is estimated to exceed $15 billion, expanding at approximately 6% CAGR. Leading players like Johnson Controls, SPX Cooling Technologies, and Baltimore Aircoil are advancing technological innovations in both systems. Companies such as DAIKIN, LG Electronics, and Hisense are focusing on energy-efficient heat exchanger technologies, while Baltimore Aircoil, SPX Cooling, and Marmon Industrial Water dominate the cooling tower segment. The technology is reaching maturity with emphasis on sustainability and smart controls, as evidenced by recent innovations from Caterpillar and NEC Corporation integrating IoT capabilities for improved performance monitoring.

Baltimore Aircoil Co., Inc.

Technical Solution: Baltimore Aircoil Company (BAC) has developed advanced hybrid cooling systems that combine the benefits of both cooling towers and heat exchangers. Their patented Smart Spray™ technology optimizes water distribution in cooling towers, improving thermal performance by up to 20% compared to conventional designs. BAC's Series 3000 Cooling Tower incorporates innovative fill media with enhanced surface area that increases heat transfer efficiency while reducing water consumption by approximately 30%. Their HXV Hybrid Cooler combines evaporative and dry cooling modes, automatically switching between them based on ambient conditions to maximize energy efficiency. The system utilizes proprietary ENDURADRIVE™ Fan System that reduces fan energy consumption by up to 45% compared to standard motors.

Strengths: Industry-leading water efficiency with systems that can operate in water-saving mode during 98% of the year in most climates. Exceptional energy performance with up to 40% lower annual energy costs compared to traditional systems. Weaknesses: Higher initial capital investment compared to conventional cooling towers, with premium pricing that may extend ROI timeframes. Requires more sophisticated control systems and maintenance protocols.

SPX Cooling Technologies, Inc.

Technical Solution: SPX Cooling Technologies has pioneered the Marley® NC® Everest® Cooling Tower, which represents a significant advancement in cooling tower efficiency. This counterflow cooling tower design achieves 50% more cooling capacity per cell and uses up to 35% less fan power than traditional factory-assembled cooling towers. Their patented MX Fill technology enhances thermal performance while minimizing drift emissions to less than 0.0005% of circulating water flow. SPX has also developed the Marley DT Fluid Cooler, a closed-circuit cooling tower that combines dry cooling technology with evaporative cooling in a single unit. This hybrid approach allows for water savings of up to 70% compared to conventional cooling towers while maintaining thermal efficiency. The company's Advanced Control Systems optimize cooling tower operation based on real-time conditions, reducing energy consumption by 10-30% depending on application and climate.

Strengths: Market-leading thermal efficiency with proven performance across diverse industrial applications. Modular designs that allow for easy capacity expansion and reduced installation costs. Weaknesses: Higher maintenance requirements for hybrid systems compared to simple heat exchangers. Performance advantages diminish in extremely humid environments where evaporative cooling efficiency is naturally limited.

Key Technical Innovations in Heat Exchange

heat exchangers and cooling towers

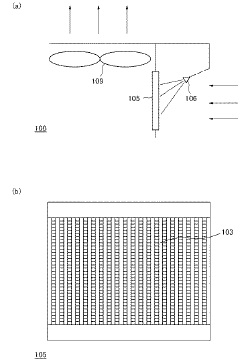

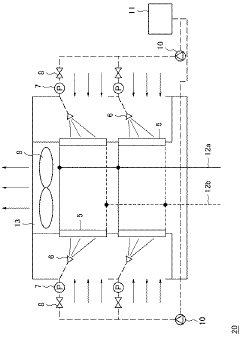

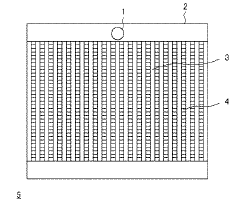

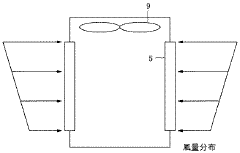

PatentActiveJPWO2017110677A1

Innovation

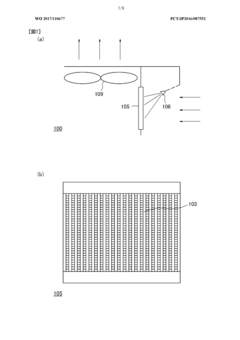

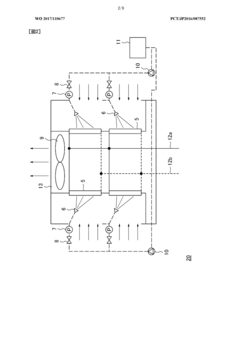

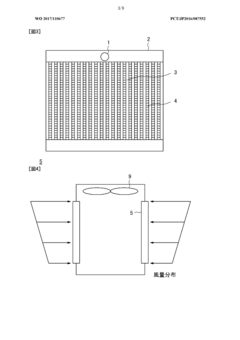

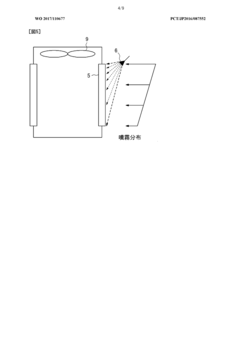

- The cooling tower employs a heat exchanger with multiple parallel flow paths inclined to facilitate gravity-driven fluid circulation, using fine droplets sprayed obliquely to enhance vaporization and reduce water consumption, while optimizing air volume distribution for efficient heat exchange.

Heat exchanger and cooling tower

PatentWO2017110677A1

Innovation

- A closed cooling tower design featuring a heat exchanger with parallel flow channels installed at an incline, utilizing a spray nozzle to direct fine water droplets onto the heat exchanger, allowing efficient vaporization and condensation while reducing water consumption and minimizing scale formation.

Environmental Impact and Sustainability Factors

The environmental impact of cooling systems represents a critical consideration in modern industrial and commercial applications. Heat exchangers and cooling towers differ significantly in their environmental footprints, with implications for sustainability initiatives and regulatory compliance. When comparing these technologies, water consumption emerges as a primary environmental concern.

Cooling towers typically consume substantial quantities of water through evaporation, drift, and blowdown processes. A medium-sized cooling tower can evaporate 2-3 gallons of water per minute per 100 tons of cooling capacity, translating to millions of gallons annually. This water consumption becomes particularly problematic in water-stressed regions where conservation is imperative.

Heat exchangers, by contrast, operate as closed systems that recirculate water or other heat transfer fluids, significantly reducing water consumption. This closed-loop design minimizes evaporative losses and eliminates the need for continuous water makeup, potentially reducing water usage by 95-98% compared to equivalent cooling towers.

Air pollution considerations also differentiate these technologies. Cooling towers can release drift—tiny water droplets containing chemicals, minerals, and potentially harmful microorganisms like Legionella—into the surrounding environment. These emissions may contribute to air quality degradation and present public health concerns in densely populated areas.

Energy efficiency translates directly to carbon footprint implications. While cooling towers leverage natural evaporative cooling principles requiring less pumping energy, heat exchangers often demand higher electrical inputs for fluid circulation. This energy differential must be evaluated against regional electricity generation profiles to determine overall greenhouse gas impacts.

Chemical treatment requirements present another environmental dimension. Cooling towers typically require extensive chemical treatment regimens including biocides, scale inhibitors, and corrosion inhibitors. These chemicals eventually enter the environment through blowdown water or drift emissions. Heat exchangers generally require fewer chemical treatments due to their closed systems, reducing potential ecological impacts from chemical discharge.

Land use efficiency also favors heat exchangers, which typically occupy smaller footprints than cooling towers of equivalent capacity. This spatial efficiency becomes particularly valuable in urban environments where space constraints are significant and land costs are premium.

Lifecycle assessment reveals that heat exchangers typically demonstrate longer operational lifespans with lower maintenance requirements, reducing resource consumption associated with replacement and repair activities. This durability factor contributes significantly to the overall sustainability profile when evaluating total environmental impact across the complete system lifecycle.

Cooling towers typically consume substantial quantities of water through evaporation, drift, and blowdown processes. A medium-sized cooling tower can evaporate 2-3 gallons of water per minute per 100 tons of cooling capacity, translating to millions of gallons annually. This water consumption becomes particularly problematic in water-stressed regions where conservation is imperative.

Heat exchangers, by contrast, operate as closed systems that recirculate water or other heat transfer fluids, significantly reducing water consumption. This closed-loop design minimizes evaporative losses and eliminates the need for continuous water makeup, potentially reducing water usage by 95-98% compared to equivalent cooling towers.

Air pollution considerations also differentiate these technologies. Cooling towers can release drift—tiny water droplets containing chemicals, minerals, and potentially harmful microorganisms like Legionella—into the surrounding environment. These emissions may contribute to air quality degradation and present public health concerns in densely populated areas.

Energy efficiency translates directly to carbon footprint implications. While cooling towers leverage natural evaporative cooling principles requiring less pumping energy, heat exchangers often demand higher electrical inputs for fluid circulation. This energy differential must be evaluated against regional electricity generation profiles to determine overall greenhouse gas impacts.

Chemical treatment requirements present another environmental dimension. Cooling towers typically require extensive chemical treatment regimens including biocides, scale inhibitors, and corrosion inhibitors. These chemicals eventually enter the environment through blowdown water or drift emissions. Heat exchangers generally require fewer chemical treatments due to their closed systems, reducing potential ecological impacts from chemical discharge.

Land use efficiency also favors heat exchangers, which typically occupy smaller footprints than cooling towers of equivalent capacity. This spatial efficiency becomes particularly valuable in urban environments where space constraints are significant and land costs are premium.

Lifecycle assessment reveals that heat exchangers typically demonstrate longer operational lifespans with lower maintenance requirements, reducing resource consumption associated with replacement and repair activities. This durability factor contributes significantly to the overall sustainability profile when evaluating total environmental impact across the complete system lifecycle.

Total Cost of Ownership Analysis

When evaluating heat exchangers versus cooling towers, the Total Cost of Ownership (TCO) analysis provides a comprehensive financial perspective beyond initial purchase costs. The capital expenditure for heat exchangers typically ranges from $50,000 to $500,000 depending on capacity and materials, while cooling towers generally cost between $75,000 and $600,000 for comparable cooling capacity. However, these initial investments represent only a fraction of lifetime costs.

Installation expenses differ significantly between the two systems. Heat exchangers require less space and simpler installation infrastructure, with installation costs typically accounting for 15-25% of equipment cost. Cooling towers demand more extensive site preparation, water supply systems, and often structural reinforcements, pushing installation costs to 30-45% of equipment value.

Operational costs heavily favor heat exchangers in most scenarios. Energy consumption analysis reveals that heat exchangers typically consume 0.3-0.5 kW per ton of cooling, while cooling towers with associated pumps and fans require 0.5-0.8 kW per ton. Over a 15-year operational period, this difference translates to approximately $150,000-$300,000 in energy savings for medium-sized industrial applications.

Water consumption represents another significant cost differential. Cooling towers lose 2-3% of circulating water through evaporation, drift, and blowdown, requiring continuous makeup water. A 500-ton cooling tower can consume 14,000-20,000 gallons daily, translating to annual costs of $15,000-$30,000 depending on regional water rates. Heat exchangers operate as closed systems with negligible water consumption, providing substantial savings in water-scarce regions.

Maintenance requirements further differentiate these technologies. Cooling towers demand regular cleaning, water treatment, and component replacement due to scale formation, biological growth, and corrosion. Annual maintenance costs typically range from 5-10% of initial investment. Heat exchangers require less frequent maintenance, with annual costs averaging 2-4% of initial investment, primarily for periodic cleaning and inspection.

Lifespan considerations favor heat exchangers, which typically operate effectively for 20-25 years with proper maintenance. Cooling towers generally require major overhauls or replacement after 15-20 years due to structural deterioration from constant water exposure. This difference in service life significantly impacts long-term ownership costs and replacement planning.

When factoring all these elements into a 20-year TCO model, heat exchangers demonstrate 15-30% lower lifetime costs than cooling towers for most industrial applications, despite potentially higher initial investment. However, specific application requirements, local climate conditions, and utility rates can significantly alter this calculation.

Installation expenses differ significantly between the two systems. Heat exchangers require less space and simpler installation infrastructure, with installation costs typically accounting for 15-25% of equipment cost. Cooling towers demand more extensive site preparation, water supply systems, and often structural reinforcements, pushing installation costs to 30-45% of equipment value.

Operational costs heavily favor heat exchangers in most scenarios. Energy consumption analysis reveals that heat exchangers typically consume 0.3-0.5 kW per ton of cooling, while cooling towers with associated pumps and fans require 0.5-0.8 kW per ton. Over a 15-year operational period, this difference translates to approximately $150,000-$300,000 in energy savings for medium-sized industrial applications.

Water consumption represents another significant cost differential. Cooling towers lose 2-3% of circulating water through evaporation, drift, and blowdown, requiring continuous makeup water. A 500-ton cooling tower can consume 14,000-20,000 gallons daily, translating to annual costs of $15,000-$30,000 depending on regional water rates. Heat exchangers operate as closed systems with negligible water consumption, providing substantial savings in water-scarce regions.

Maintenance requirements further differentiate these technologies. Cooling towers demand regular cleaning, water treatment, and component replacement due to scale formation, biological growth, and corrosion. Annual maintenance costs typically range from 5-10% of initial investment. Heat exchangers require less frequent maintenance, with annual costs averaging 2-4% of initial investment, primarily for periodic cleaning and inspection.

Lifespan considerations favor heat exchangers, which typically operate effectively for 20-25 years with proper maintenance. Cooling towers generally require major overhauls or replacement after 15-20 years due to structural deterioration from constant water exposure. This difference in service life significantly impacts long-term ownership costs and replacement planning.

When factoring all these elements into a 20-year TCO model, heat exchangers demonstrate 15-30% lower lifetime costs than cooling towers for most industrial applications, despite potentially higher initial investment. However, specific application requirements, local climate conditions, and utility rates can significantly alter this calculation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!