How Carbon-negative Concrete Assists in Net-zero Building Designs

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material, has traditionally been a significant contributor to global carbon emissions due to its production process, particularly cement manufacturing. The evolution of carbon-negative concrete represents a paradigm shift in construction materials science, moving from carbon-intensive processes toward solutions that actively remove carbon dioxide from the atmosphere. This technological transformation began in the early 2000s with initial research into alternative cementitious materials and has accelerated dramatically over the past decade.

The development trajectory of carbon-negative concrete has been marked by several key innovations. Early approaches focused on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the 2010s, researchers began exploring carbon sequestration directly within concrete, utilizing CO2 as a reactant in the curing process. Recent breakthroughs have introduced novel binders that can absorb and permanently mineralize CO2 during hardening, transforming concrete from a carbon source to a carbon sink.

Current carbon-negative concrete technologies employ various mechanisms, including carbonation curing, where CO2 is injected during the manufacturing process; alternative binding agents derived from industrial byproducts; and innovative aggregates capable of absorbing CO2 throughout the concrete's lifecycle. These approaches collectively aim to revolutionize the environmental profile of concrete while maintaining or enhancing its structural performance characteristics.

The primary objective of carbon-negative concrete development is to create building materials that contribute meaningfully to climate change mitigation while meeting the growing global demand for construction. Specific technical goals include achieving verifiable carbon sequestration of at least 100kg CO2 per cubic meter of concrete, maintaining comparable strength and durability to conventional concrete, and ensuring economic viability for widespread adoption in commercial construction projects.

Beyond environmental benefits, carbon-negative concrete aims to serve as an enabling technology for net-zero building designs by addressing embodied carbon—the emissions associated with building materials and construction processes. This represents a crucial complement to operational carbon reduction strategies in the built environment. The technology seeks to transform concrete from being part of the climate problem to becoming an integral component of the solution, supporting the construction industry's transition toward carbon neutrality by 2050.

The development trajectory of carbon-negative concrete has been marked by several key innovations. Early approaches focused on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the 2010s, researchers began exploring carbon sequestration directly within concrete, utilizing CO2 as a reactant in the curing process. Recent breakthroughs have introduced novel binders that can absorb and permanently mineralize CO2 during hardening, transforming concrete from a carbon source to a carbon sink.

Current carbon-negative concrete technologies employ various mechanisms, including carbonation curing, where CO2 is injected during the manufacturing process; alternative binding agents derived from industrial byproducts; and innovative aggregates capable of absorbing CO2 throughout the concrete's lifecycle. These approaches collectively aim to revolutionize the environmental profile of concrete while maintaining or enhancing its structural performance characteristics.

The primary objective of carbon-negative concrete development is to create building materials that contribute meaningfully to climate change mitigation while meeting the growing global demand for construction. Specific technical goals include achieving verifiable carbon sequestration of at least 100kg CO2 per cubic meter of concrete, maintaining comparable strength and durability to conventional concrete, and ensuring economic viability for widespread adoption in commercial construction projects.

Beyond environmental benefits, carbon-negative concrete aims to serve as an enabling technology for net-zero building designs by addressing embodied carbon—the emissions associated with building materials and construction processes. This represents a crucial complement to operational carbon reduction strategies in the built environment. The technology seeks to transform concrete from being part of the climate problem to becoming an integral component of the solution, supporting the construction industry's transition toward carbon neutrality by 2050.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental awareness and stringent regulations aimed at reducing carbon emissions in the building sector. Currently valued at approximately $300 billion globally, this market is projected to grow at a compound annual growth rate of 11.3% through 2030, with carbon-negative concrete representing one of the fastest-growing segments.

Demand for carbon-negative concrete is particularly strong in regions with ambitious climate targets, including the European Union, North America, and progressive Asian markets like Singapore and Japan. The EU's Green Deal and Renovation Wave strategy have created significant market pull, while in North America, green building certifications like LEED and the Architecture 2030 Challenge are driving adoption of carbon-negative building materials.

Commercial buildings represent the largest market segment (38%), followed by residential construction (32%) and infrastructure projects (30%). This distribution reflects the corporate sector's growing commitment to environmental, social, and governance (ESG) principles and the marketing advantages of carbon-neutral or negative buildings.

Price sensitivity remains a significant market factor, with carbon-negative concrete currently commanding a premium of 15-25% over traditional concrete. However, this premium is steadily decreasing as production scales up and technologies mature. Market research indicates that developers are increasingly willing to absorb this premium when lifecycle costs and carbon taxation benefits are factored into financial models.

Supply chain dynamics are evolving rapidly, with traditional cement manufacturers investing heavily in carbon-negative technologies while facing competition from innovative startups. The market is seeing significant venture capital investment, with over $500 million directed toward carbon-negative concrete technologies in the past two years alone.

Consumer awareness and preference for sustainable building materials have reached critical mass in developed markets. According to recent surveys, 72% of commercial tenants express preference for buildings constructed with low-carbon materials, and 68% of homebuyers indicate willingness to pay a premium for homes with smaller carbon footprints.

Regulatory tailwinds are strengthening the market position of carbon-negative concrete. Carbon pricing mechanisms, embodied carbon regulations, and government procurement policies favoring low-carbon materials are creating powerful market incentives. For instance, several jurisdictions have implemented or are considering "Buy Clean" policies that establish maximum acceptable global warming potential values for construction materials used in public projects.

The competitive landscape is characterized by rapid innovation and strategic partnerships between material scientists, concrete producers, and construction firms. This collaborative approach is accelerating market adoption and creating integrated solutions that address both technical performance and carbon reduction goals.

Demand for carbon-negative concrete is particularly strong in regions with ambitious climate targets, including the European Union, North America, and progressive Asian markets like Singapore and Japan. The EU's Green Deal and Renovation Wave strategy have created significant market pull, while in North America, green building certifications like LEED and the Architecture 2030 Challenge are driving adoption of carbon-negative building materials.

Commercial buildings represent the largest market segment (38%), followed by residential construction (32%) and infrastructure projects (30%). This distribution reflects the corporate sector's growing commitment to environmental, social, and governance (ESG) principles and the marketing advantages of carbon-neutral or negative buildings.

Price sensitivity remains a significant market factor, with carbon-negative concrete currently commanding a premium of 15-25% over traditional concrete. However, this premium is steadily decreasing as production scales up and technologies mature. Market research indicates that developers are increasingly willing to absorb this premium when lifecycle costs and carbon taxation benefits are factored into financial models.

Supply chain dynamics are evolving rapidly, with traditional cement manufacturers investing heavily in carbon-negative technologies while facing competition from innovative startups. The market is seeing significant venture capital investment, with over $500 million directed toward carbon-negative concrete technologies in the past two years alone.

Consumer awareness and preference for sustainable building materials have reached critical mass in developed markets. According to recent surveys, 72% of commercial tenants express preference for buildings constructed with low-carbon materials, and 68% of homebuyers indicate willingness to pay a premium for homes with smaller carbon footprints.

Regulatory tailwinds are strengthening the market position of carbon-negative concrete. Carbon pricing mechanisms, embodied carbon regulations, and government procurement policies favoring low-carbon materials are creating powerful market incentives. For instance, several jurisdictions have implemented or are considering "Buy Clean" policies that establish maximum acceptable global warming potential values for construction materials used in public projects.

The competitive landscape is characterized by rapid innovation and strategic partnerships between material scientists, concrete producers, and construction firms. This collaborative approach is accelerating market adoption and creating integrated solutions that address both technical performance and carbon reduction goals.

Global Status and Barriers in Carbon-negative Concrete Development

Carbon-negative concrete technology has seen significant advancements globally, though implementation remains uneven across different regions. In North America, companies like CarbonCure and Solidia Technologies have made substantial progress in commercializing carbon-capturing concrete solutions, with several pilot projects demonstrating feasibility in real-world construction scenarios. The European Union leads in regulatory frameworks supporting low-carbon building materials, with countries like Sweden and Norway implementing carbon taxes that incentivize adoption of carbon-negative alternatives.

Asia presents a mixed landscape, with Japan and Singapore emerging as innovation hubs for sustainable concrete technologies, while China, despite being the world's largest concrete producer, has only recently begun investing significantly in carbon-negative formulations. The Middle East, particularly the UAE, has initiated ambitious projects incorporating carbon-negative concrete in new urban developments, leveraging their financial resources to accelerate adoption.

Despite these advancements, several critical barriers impede widespread implementation. Technical challenges remain prominent, including scalability issues with current carbon capture mechanisms and inconsistent performance across varying climate conditions. The durability and long-term structural integrity of carbon-negative concrete formulations require further validation through extended testing periods, creating hesitancy among structural engineers and building code authorities.

Economic barriers present significant obstacles, with carbon-negative concrete typically commanding a 15-30% price premium over conventional products. This cost differential, though gradually narrowing, remains prohibitive for many construction projects, particularly in cost-sensitive markets. The absence of standardized carbon accounting methodologies further complicates value proposition assessments, making it difficult to quantify the true environmental and economic benefits.

Regulatory frameworks lag behind technological innovation in most jurisdictions. Building codes and material standards developed for traditional concrete often inadvertently create barriers for novel formulations. The certification process for new construction materials remains lengthy and expensive, deterring smaller innovators from entering the market.

Knowledge gaps and industry inertia constitute additional barriers. The construction industry's traditionally conservative approach to material innovation creates resistance to adopting novel solutions without extensive track records. Limited awareness among architects, engineers, and contractors regarding carbon-negative concrete capabilities and application methods further restricts market penetration.

Supply chain constraints also limit growth, with specialized ingredients for carbon-negative formulations facing availability challenges. The geographical distribution of production facilities remains concentrated in developed economies, creating logistical hurdles for global implementation.

Asia presents a mixed landscape, with Japan and Singapore emerging as innovation hubs for sustainable concrete technologies, while China, despite being the world's largest concrete producer, has only recently begun investing significantly in carbon-negative formulations. The Middle East, particularly the UAE, has initiated ambitious projects incorporating carbon-negative concrete in new urban developments, leveraging their financial resources to accelerate adoption.

Despite these advancements, several critical barriers impede widespread implementation. Technical challenges remain prominent, including scalability issues with current carbon capture mechanisms and inconsistent performance across varying climate conditions. The durability and long-term structural integrity of carbon-negative concrete formulations require further validation through extended testing periods, creating hesitancy among structural engineers and building code authorities.

Economic barriers present significant obstacles, with carbon-negative concrete typically commanding a 15-30% price premium over conventional products. This cost differential, though gradually narrowing, remains prohibitive for many construction projects, particularly in cost-sensitive markets. The absence of standardized carbon accounting methodologies further complicates value proposition assessments, making it difficult to quantify the true environmental and economic benefits.

Regulatory frameworks lag behind technological innovation in most jurisdictions. Building codes and material standards developed for traditional concrete often inadvertently create barriers for novel formulations. The certification process for new construction materials remains lengthy and expensive, deterring smaller innovators from entering the market.

Knowledge gaps and industry inertia constitute additional barriers. The construction industry's traditionally conservative approach to material innovation creates resistance to adopting novel solutions without extensive track records. Limited awareness among architects, engineers, and contractors regarding carbon-negative concrete capabilities and application methods further restricts market penetration.

Supply chain constraints also limit growth, with specialized ingredients for carbon-negative formulations facing availability challenges. The geographical distribution of production facilities remains concentrated in developed economies, creating logistical hurdles for global implementation.

Current Carbon-negative Concrete Formulations and Applications

01 CO2 capture and sequestration in concrete production

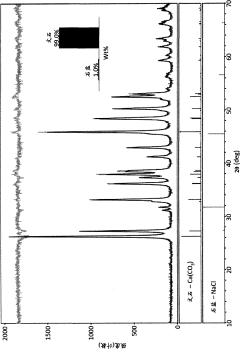

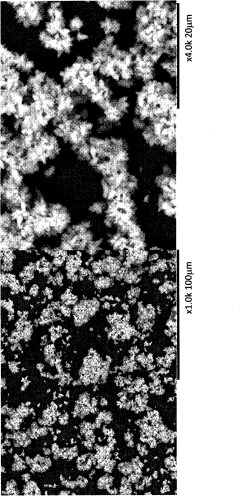

Technologies that enable the capture and permanent sequestration of carbon dioxide during concrete manufacturing processes. These methods involve incorporating CO2 directly into concrete mixtures where it undergoes mineralization reactions with calcium-containing compounds, effectively converting gaseous CO2 into stable carbonate minerals within the concrete matrix. This approach not only reduces the carbon footprint of concrete production but can also improve certain mechanical properties of the final product.- CO2 capture and sequestration in concrete: Technologies that enable concrete to actively capture and permanently sequester carbon dioxide during the curing process, transforming CO2 from a greenhouse gas into a mineral component of the concrete structure. These methods involve introducing CO2 during mixing or curing phases, where it reacts with calcium compounds to form stable carbonate minerals, effectively locking carbon into the concrete while potentially improving its strength and durability.

- Alternative low-carbon binders and cement substitutes: Development of novel binding materials that can partially or completely replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, magnesium-based cements, and other innovative formulations that require less energy to produce and generate fewer emissions during manufacturing while maintaining or enhancing concrete performance characteristics.

- Incorporation of carbon-negative additives and fillers: Integration of materials with negative carbon footprints into concrete mixtures, such as biochar, agricultural waste products, or engineered carbon-capturing minerals. These additives not only reduce the amount of cement required but also bring their own carbon sequestration benefits to the final product, effectively lowering the overall carbon footprint of the concrete while potentially improving certain performance aspects.

- Enhanced carbonation curing processes: Specialized curing techniques that accelerate and maximize the natural carbonation process in concrete. These methods involve controlled exposure to CO2-rich environments under specific temperature and humidity conditions, optimizing the conversion of calcium hydroxide to calcium carbonate throughout the concrete matrix, resulting in improved strength development while permanently sequestering carbon dioxide.

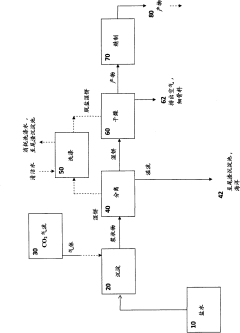

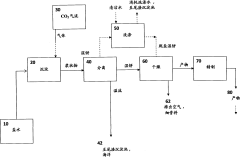

- Carbon-negative concrete production systems: Integrated manufacturing approaches and systems designed to produce concrete with a net negative carbon footprint through the combination of multiple carbon reduction strategies. These systems often incorporate renewable energy sources, carbon capture technologies, alternative raw materials, and optimized production processes to ensure that more CO2 is sequestered than emitted throughout the entire concrete lifecycle.

02 Alternative cementitious materials for carbon reduction

Development of novel binders and supplementary cementitious materials that can partially or completely replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, magnesium-based cements, and various industrial byproducts like fly ash and slag. By reducing the clinker content or eliminating Portland cement altogether, these materials can substantially lower the carbon footprint of concrete while maintaining or enhancing performance characteristics.Expand Specific Solutions03 Biomass incorporation and carbonation curing techniques

Methods for incorporating biomass-derived materials into concrete formulations and specialized curing techniques that promote accelerated carbonation. Biomass additives can include agricultural waste, wood products, or other plant-derived materials that store biogenic carbon. When combined with carbonation curing processes that expose fresh concrete to CO2-rich environments, these approaches can significantly increase carbon sequestration potential while potentially improving concrete durability and reducing curing time.Expand Specific Solutions04 Carbon-negative aggregate production and utilization

Processes for manufacturing concrete aggregates that have net-negative carbon footprints through carbon mineralization or incorporation of carbon-sequestering materials. These specialized aggregates can be produced using industrial waste streams, natural minerals with high CO2 absorption capacity, or through artificial weathering processes. When used in concrete mixtures, these aggregates contribute to overall carbon negativity while fulfilling the structural requirements of conventional aggregates.Expand Specific Solutions05 Integrated systems for carbon-negative concrete production

Comprehensive technological systems that combine multiple carbon reduction strategies throughout the concrete production lifecycle. These integrated approaches may include on-site carbon capture from cement kilns, renewable energy utilization, optimization of mix designs, and end-of-life recarbonation processes. By addressing carbon emissions at multiple stages of production and use, these systems aim to create truly carbon-negative concrete products that serve as long-term carbon sinks while maintaining necessary engineering properties.Expand Specific Solutions

Leading Organizations in Sustainable Concrete Innovation

Carbon-negative concrete technology is emerging as a critical component in net-zero building designs, currently positioned in the early growth phase of market development. The global market for carbon-negative concrete is expanding rapidly, projected to reach significant scale as construction industries worldwide face increasing pressure to reduce carbon footprints. Technologically, the field shows varying degrees of maturity, with companies like Carbon Limit Co. pioneering innovative carbon capture solutions directly in concrete, while established institutions such as Worcester Polytechnic Institute, The Hong Kong Polytechnic University, and Chongqing University contribute substantial research advancements. Traditional cement manufacturers including SUNGSHIN CEMENT and Cement Australia are adapting their processes, while construction giants like China Construction First Building Group integrate these materials into large-scale projects, demonstrating the technology's gradual mainstream adoption across the building materials value chain.

Procarbon Bio AB

Technical Solution: Procarbon Bio has developed an innovative carbon-negative concrete solution utilizing bio-based additives derived from agricultural waste. Their proprietary "BioCarb" technology incorporates specially processed plant materials that have high carbon sequestration potential when integrated into concrete mixtures. The bio-additives create microporous structures within the concrete that actively absorb CO2 throughout the material's lifetime. Additionally, their formulation includes novel binding agents that reduce the need for traditional cement by up to 40% while maintaining structural integrity. Procarbon's concrete captures approximately 120kg of CO2 per cubic meter, effectively offsetting the emissions generated during production. The company has also developed a complementary carbon accounting system that allows builders to precisely measure and verify the carbon negativity of their concrete applications, providing valuable data for net-zero building certification processes. Their technology has been successfully implemented in several Scandinavian building projects, demonstrating its effectiveness in real-world applications.

Strengths: Uses renewable bio-based materials from agricultural waste streams, creating additional environmental benefits beyond carbon reduction. Their solution provides precise carbon accounting, valuable for green building certifications and carbon credits. Weaknesses: Bio-based additives may have variable availability depending on agricultural seasons and regions. The technology may require special mixing procedures that differ from conventional concrete practices.

Cement Australia Pty Ltd.

Technical Solution: Cement Australia has pioneered a carbon-negative concrete technology called "EcoCarbon" that incorporates industrial by-products and carbon capture mechanisms. Their approach uses supplementary cementitious materials (SCMs) like fly ash and blast furnace slag to replace significant portions of traditional Portland cement, reducing the carbon footprint by up to 60% initially. The innovation extends further with their proprietary carbon mineralization process that actively absorbs CO2 during curing, transforming it into stable carbonate compounds within the concrete matrix. Cement Australia has also developed specialized admixtures that enhance CO2 absorption capacity while maintaining or improving structural performance. Their concrete formulations are engineered specifically for net-zero building designs, offering various grades that balance carbon sequestration with performance requirements for different structural applications. The company has implemented this technology in several commercial projects across Australia, demonstrating scalability and real-world effectiveness.

Strengths: Utilizes readily available industrial by-products, creating a circular economy solution while reducing carbon emissions. Their technology maintains or improves concrete performance characteristics while achieving carbon negativity. Weaknesses: May face challenges with consistent supply of specific industrial by-products needed for their formulations. The technology might require adjustments for different climate zones and building codes outside Australia.

Key Patents and Research in CO2 Sequestration Technologies

Charcoal products made with phenolic resin binder and methods for making thereof

PatentPendingUS20240209178A1

Innovation

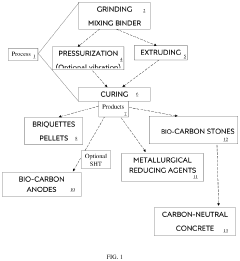

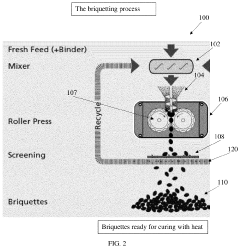

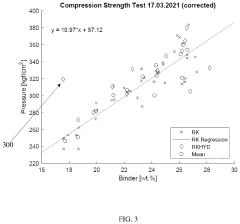

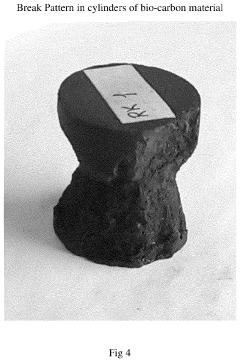

- A bio-carbon material comprising charcoal and a phenolic resin binder, with the binder comprising at least 50% phenolic resin, is developed, which can be compressed to achieve high strength and used in various forms such as briquettes, anodes, or concrete aggregates, reducing the need for fossil fuels and sequestering carbon.

Co2-sequestering formed building materials

PatentActiveCN101990523A

Innovation

- Development of carbon-negative concrete using CO2-sequestering components that can reduce CO2 by up to 2 tons or more per ton of material.

- Creation of blended cements combining CO2-sequestering supplementary cementitious materials (SCMs) with fly ash, slag and/or Portland cement to produce low, neutral, or negative carbon footprint concrete.

- Development of carbon-negative concrete that achieves high compressive strength (4000 psi at 28 days) without negatively impacting construction schedules.

Regulatory Frameworks and Carbon Credit Opportunities

The global regulatory landscape for carbon-negative concrete is rapidly evolving, creating both compliance requirements and economic opportunities for stakeholders in the construction industry. The Paris Agreement has been instrumental in establishing international frameworks that encourage the adoption of carbon-negative building materials, with many countries implementing national policies that set specific carbon reduction targets for the construction sector. These regulatory frameworks typically include building codes that mandate lower embodied carbon in construction materials, performance standards for concrete production, and procurement policies that favor low-carbon alternatives.

In the European Union, the Carbon Border Adjustment Mechanism (CBAM) and the EU Emissions Trading System (EU ETS) create economic incentives for carbon-negative concrete by putting a price on carbon emissions. Similarly, in North America, initiatives like the Buy Clean California Act and Canada's Greening Government Strategy prioritize construction materials with lower carbon footprints in public procurement. These regulations are increasingly being adopted by private sector entities as well, who recognize the business advantages of early compliance.

Carbon credit markets present significant financial opportunities for developers utilizing carbon-negative concrete. These markets allow building projects that sequester carbon to generate tradable credits, creating additional revenue streams beyond the primary construction business. The voluntary carbon market has seen substantial growth, with carbon credits from building materials achieving premium prices due to their verifiability and permanence compared to other offset types. Projects using carbon-negative concrete can potentially earn between $20-150 per ton of CO2 sequestered, depending on market conditions and verification standards.

Certification systems like LEED, BREEAM, and the Living Building Challenge have incorporated criteria that reward carbon-negative materials, further incentivizing their adoption. These systems often provide additional points or recognition for projects that demonstrate net carbon sequestration, enhancing the market value of buildings constructed with carbon-negative concrete. Some jurisdictions have begun implementing tax incentives, accelerated permitting processes, and density bonuses for projects that exceed carbon performance benchmarks.

The integration of carbon accounting into financial reporting is becoming increasingly standardized through frameworks like the Task Force on Climate-related Financial Disclosures (TCFD). This trend is driving investment toward carbon-negative building technologies as companies seek to improve their environmental performance metrics. Forward-thinking developers are leveraging these regulatory frameworks and carbon market opportunities to position their projects as premium offerings in an increasingly carbon-conscious market, demonstrating how compliance requirements can be transformed into competitive advantages.

In the European Union, the Carbon Border Adjustment Mechanism (CBAM) and the EU Emissions Trading System (EU ETS) create economic incentives for carbon-negative concrete by putting a price on carbon emissions. Similarly, in North America, initiatives like the Buy Clean California Act and Canada's Greening Government Strategy prioritize construction materials with lower carbon footprints in public procurement. These regulations are increasingly being adopted by private sector entities as well, who recognize the business advantages of early compliance.

Carbon credit markets present significant financial opportunities for developers utilizing carbon-negative concrete. These markets allow building projects that sequester carbon to generate tradable credits, creating additional revenue streams beyond the primary construction business. The voluntary carbon market has seen substantial growth, with carbon credits from building materials achieving premium prices due to their verifiability and permanence compared to other offset types. Projects using carbon-negative concrete can potentially earn between $20-150 per ton of CO2 sequestered, depending on market conditions and verification standards.

Certification systems like LEED, BREEAM, and the Living Building Challenge have incorporated criteria that reward carbon-negative materials, further incentivizing their adoption. These systems often provide additional points or recognition for projects that demonstrate net carbon sequestration, enhancing the market value of buildings constructed with carbon-negative concrete. Some jurisdictions have begun implementing tax incentives, accelerated permitting processes, and density bonuses for projects that exceed carbon performance benchmarks.

The integration of carbon accounting into financial reporting is becoming increasingly standardized through frameworks like the Task Force on Climate-related Financial Disclosures (TCFD). This trend is driving investment toward carbon-negative building technologies as companies seek to improve their environmental performance metrics. Forward-thinking developers are leveraging these regulatory frameworks and carbon market opportunities to position their projects as premium offerings in an increasingly carbon-conscious market, demonstrating how compliance requirements can be transformed into competitive advantages.

Life Cycle Assessment of Carbon-negative Concrete in Net-zero Buildings

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of carbon-negative concrete throughout its entire lifecycle in net-zero building applications. This assessment begins with raw material extraction and continues through manufacturing, transportation, installation, use phase, and end-of-life disposal or recycling. For carbon-negative concrete, the LCA reveals significant advantages compared to traditional Portland cement concrete.

The production phase analysis demonstrates that carbon-negative concrete can sequester more CO2 than it emits during manufacturing. This occurs through innovative carbonation processes that permanently bind CO2 within the concrete matrix. Companies like Carbicrete and CarbonCure have developed technologies that inject captured carbon dioxide into concrete during mixing, resulting in a stronger product while permanently sequestering carbon. Quantitative assessments indicate potential carbon sequestration of 100-150 kg CO2 per cubic meter of concrete.

Transportation impacts remain similar to conventional concrete, though some carbon-negative formulations may have different weight characteristics affecting fuel consumption. The installation phase generally mirrors traditional concrete methods, with minimal differential environmental impacts.

During the use phase, carbon-negative concrete continues to absorb atmospheric CO2 through natural carbonation processes, albeit at a slower rate than during production. This ongoing carbon sequestration represents an additional environmental benefit not present in conventional concrete. Studies suggest this passive absorption can account for an additional 5-10% carbon reduction over a 50-year building lifespan.

End-of-life considerations reveal further advantages, as crushed carbon-negative concrete can absorb additional CO2 when exposed to air, potentially creating a second carbon sequestration opportunity during recycling. This characteristic supports circular economy principles in construction waste management.

When integrated into net-zero building designs, carbon-negative concrete contributes significantly to reducing embodied carbon—the emissions associated with building materials and construction processes. This is particularly valuable as operational carbon emissions decrease through energy efficiency measures, making embodied carbon an increasingly significant portion of a building's total carbon footprint.

Comprehensive LCA studies demonstrate that incorporating carbon-negative concrete can reduce a building's total lifecycle emissions by 10-25%, depending on the application scope and specific formulation used. This reduction represents a critical contribution to achieving true net-zero performance across the entire building lifecycle, rather than focusing solely on operational energy consumption.

The production phase analysis demonstrates that carbon-negative concrete can sequester more CO2 than it emits during manufacturing. This occurs through innovative carbonation processes that permanently bind CO2 within the concrete matrix. Companies like Carbicrete and CarbonCure have developed technologies that inject captured carbon dioxide into concrete during mixing, resulting in a stronger product while permanently sequestering carbon. Quantitative assessments indicate potential carbon sequestration of 100-150 kg CO2 per cubic meter of concrete.

Transportation impacts remain similar to conventional concrete, though some carbon-negative formulations may have different weight characteristics affecting fuel consumption. The installation phase generally mirrors traditional concrete methods, with minimal differential environmental impacts.

During the use phase, carbon-negative concrete continues to absorb atmospheric CO2 through natural carbonation processes, albeit at a slower rate than during production. This ongoing carbon sequestration represents an additional environmental benefit not present in conventional concrete. Studies suggest this passive absorption can account for an additional 5-10% carbon reduction over a 50-year building lifespan.

End-of-life considerations reveal further advantages, as crushed carbon-negative concrete can absorb additional CO2 when exposed to air, potentially creating a second carbon sequestration opportunity during recycling. This characteristic supports circular economy principles in construction waste management.

When integrated into net-zero building designs, carbon-negative concrete contributes significantly to reducing embodied carbon—the emissions associated with building materials and construction processes. This is particularly valuable as operational carbon emissions decrease through energy efficiency measures, making embodied carbon an increasingly significant portion of a building's total carbon footprint.

Comprehensive LCA studies demonstrate that incorporating carbon-negative concrete can reduce a building's total lifecycle emissions by 10-25%, depending on the application scope and specific formulation used. This reduction represents a critical contribution to achieving true net-zero performance across the entire building lifecycle, rather than focusing solely on operational energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!