How Do Self-Healing Polymers Achieve Leak-Tightness In Pressurized Systems?

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymer Technology Background and Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage and restore structural integrity without external intervention. The concept emerged in the early 2000s, inspired by biological systems that naturally heal wounds. Over the past two decades, this technology has evolved from laboratory curiosities to practical engineering solutions, particularly in applications requiring sustained leak-tightness under pressure.

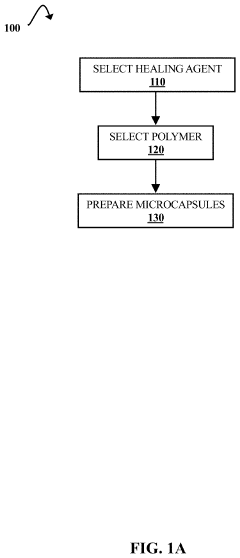

The evolution of self-healing polymers has followed several distinct phases. Initially, researchers focused on microencapsulation techniques where healing agents were contained within microscopic capsules that rupture upon damage. This was followed by vascular network systems mimicking blood vessels, allowing continuous supply of healing agents. The most recent advancement involves intrinsic self-healing polymers that repair through reversible chemical bonds or supramolecular interactions.

In pressurized systems, the challenge of maintaining leak-tightness is particularly critical. Traditional materials often fail under continuous pressure, leading to fluid or gas leakage that can cause system inefficiency, environmental contamination, or catastrophic failure. Self-healing polymers offer a promising solution by automatically sealing breaches before significant leakage occurs.

The technical objectives for self-healing polymers in pressurized applications include achieving rapid healing response times (ideally within seconds to minutes), maintaining mechanical properties comparable to conventional materials, ensuring durability through multiple healing cycles, and functioning effectively across wide temperature and pressure ranges. Additionally, these materials must demonstrate chemical compatibility with transported fluids and gases.

Current research trends are moving toward multi-functional self-healing polymers that combine leak-sealing capabilities with other desirable properties such as corrosion resistance, thermal stability, and electrical conductivity. There is also growing interest in environmentally sustainable self-healing systems that utilize bio-based materials and non-toxic healing mechanisms.

The integration of smart technologies with self-healing polymers represents another significant trend. Researchers are developing systems with embedded sensors that can detect damage before visible leakage occurs, triggering targeted healing responses. This predictive maintenance approach could revolutionize the management of pressurized infrastructure.

The ultimate goal of self-healing polymer technology for pressurized systems is to create "eternal" materials that can indefinitely maintain their functional integrity without human intervention, dramatically reducing maintenance costs and improving safety across industries ranging from oil and gas to water distribution, chemical processing, and aerospace applications.

The evolution of self-healing polymers has followed several distinct phases. Initially, researchers focused on microencapsulation techniques where healing agents were contained within microscopic capsules that rupture upon damage. This was followed by vascular network systems mimicking blood vessels, allowing continuous supply of healing agents. The most recent advancement involves intrinsic self-healing polymers that repair through reversible chemical bonds or supramolecular interactions.

In pressurized systems, the challenge of maintaining leak-tightness is particularly critical. Traditional materials often fail under continuous pressure, leading to fluid or gas leakage that can cause system inefficiency, environmental contamination, or catastrophic failure. Self-healing polymers offer a promising solution by automatically sealing breaches before significant leakage occurs.

The technical objectives for self-healing polymers in pressurized applications include achieving rapid healing response times (ideally within seconds to minutes), maintaining mechanical properties comparable to conventional materials, ensuring durability through multiple healing cycles, and functioning effectively across wide temperature and pressure ranges. Additionally, these materials must demonstrate chemical compatibility with transported fluids and gases.

Current research trends are moving toward multi-functional self-healing polymers that combine leak-sealing capabilities with other desirable properties such as corrosion resistance, thermal stability, and electrical conductivity. There is also growing interest in environmentally sustainable self-healing systems that utilize bio-based materials and non-toxic healing mechanisms.

The integration of smart technologies with self-healing polymers represents another significant trend. Researchers are developing systems with embedded sensors that can detect damage before visible leakage occurs, triggering targeted healing responses. This predictive maintenance approach could revolutionize the management of pressurized infrastructure.

The ultimate goal of self-healing polymer technology for pressurized systems is to create "eternal" materials that can indefinitely maintain their functional integrity without human intervention, dramatically reducing maintenance costs and improving safety across industries ranging from oil and gas to water distribution, chemical processing, and aerospace applications.

Market Demand Analysis for Leak-Tight Pressurized Systems

The global market for leak-tight pressurized systems has been experiencing significant growth, driven by increasing industrial safety regulations and the rising costs associated with leakage-related failures. According to recent market research, the industrial sealants and gaskets market, which includes leak prevention technologies, was valued at approximately $11.3 billion in 2022 and is projected to reach $14.8 billion by 2027, growing at a CAGR of 5.5%.

The oil and gas sector represents the largest market segment for leak-tight solutions, accounting for nearly 30% of the total demand. This is primarily due to the critical nature of maintaining pressure integrity in pipelines, storage tanks, and processing equipment. Leakages in these systems not only result in product loss but also pose significant environmental and safety hazards, potentially leading to regulatory penalties and reputational damage.

Aerospace and automotive industries follow closely, collectively representing about 25% of the market share. In aerospace applications, the demand for lightweight yet highly reliable sealing solutions is particularly strong, as even minor leaks can have catastrophic consequences. The automotive sector's transition toward hydrogen fuel cells and high-pressure systems for alternative fuels has further accelerated the need for advanced leak-tight technologies.

Consumer demand patterns indicate a growing preference for maintenance-free or low-maintenance solutions. This trend is particularly evident in the building and construction sector, where the cost of detecting and repairing leaks in HVAC systems, water pipes, and gas lines can be substantial. Market surveys reveal that facility managers are willing to pay a premium of up to 15-20% for self-healing solutions that can significantly reduce maintenance interventions.

The healthcare and pharmaceutical industries represent emerging markets with high growth potential. Sterile processing equipment, bioreactors, and drug delivery systems all require absolute leak-tightness to maintain product integrity and patient safety. This segment is expected to grow at a CAGR of 7.2%, outpacing the overall market growth.

Regional analysis shows North America and Europe leading the market adoption of advanced leak-tight technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.3% annually, driven by rapid industrialization in China and India, along with stringent environmental regulations being implemented across the region.

The market is increasingly demanding solutions that can provide real-time monitoring capabilities alongside self-healing properties. This convergence of smart materials and IoT technology represents a significant opportunity, with the smart materials market for pressurized systems expected to grow at 12.4% annually over the next five years.

The oil and gas sector represents the largest market segment for leak-tight solutions, accounting for nearly 30% of the total demand. This is primarily due to the critical nature of maintaining pressure integrity in pipelines, storage tanks, and processing equipment. Leakages in these systems not only result in product loss but also pose significant environmental and safety hazards, potentially leading to regulatory penalties and reputational damage.

Aerospace and automotive industries follow closely, collectively representing about 25% of the market share. In aerospace applications, the demand for lightweight yet highly reliable sealing solutions is particularly strong, as even minor leaks can have catastrophic consequences. The automotive sector's transition toward hydrogen fuel cells and high-pressure systems for alternative fuels has further accelerated the need for advanced leak-tight technologies.

Consumer demand patterns indicate a growing preference for maintenance-free or low-maintenance solutions. This trend is particularly evident in the building and construction sector, where the cost of detecting and repairing leaks in HVAC systems, water pipes, and gas lines can be substantial. Market surveys reveal that facility managers are willing to pay a premium of up to 15-20% for self-healing solutions that can significantly reduce maintenance interventions.

The healthcare and pharmaceutical industries represent emerging markets with high growth potential. Sterile processing equipment, bioreactors, and drug delivery systems all require absolute leak-tightness to maintain product integrity and patient safety. This segment is expected to grow at a CAGR of 7.2%, outpacing the overall market growth.

Regional analysis shows North America and Europe leading the market adoption of advanced leak-tight technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.3% annually, driven by rapid industrialization in China and India, along with stringent environmental regulations being implemented across the region.

The market is increasingly demanding solutions that can provide real-time monitoring capabilities alongside self-healing properties. This convergence of smart materials and IoT technology represents a significant opportunity, with the smart materials market for pressurized systems expected to grow at 12.4% annually over the next five years.

Current State and Challenges in Self-Healing Polymer Technology

Self-healing polymers represent a significant advancement in materials science, offering innovative solutions for maintaining leak-tightness in pressurized systems. Globally, research in this field has accelerated dramatically over the past decade, with notable developments in both academic institutions and industrial R&D centers. Currently, several distinct self-healing mechanisms have been established, including intrinsic healing through reversible bonds, extrinsic healing via encapsulated healing agents, and hybrid approaches combining multiple strategies.

The state-of-the-art in self-healing polymers for pressurized applications includes microcapsule-based systems that release healing agents upon crack formation, vascular networks that can continuously supply healing materials, and intrinsic self-healing polymers utilizing dynamic covalent bonds or supramolecular interactions. Recent advancements have demonstrated healing efficiencies exceeding 80% in laboratory conditions, with some systems capable of withstanding pressures up to 10 MPa after healing events.

Despite these promising developments, significant challenges persist in translating laboratory success to real-world pressurized applications. The primary technical hurdle remains the trade-off between mechanical strength and self-healing capability. Polymers with excellent healing properties often exhibit inferior mechanical performance under pressure, limiting their practical application in high-pressure environments. Conversely, structurally robust polymers typically demonstrate reduced healing efficiency.

Another critical challenge is the healing response time, particularly crucial in pressurized systems where rapid sealing is essential to prevent catastrophic failures. Current technologies often require external stimuli such as heat or pressure to initiate healing, which may not be practical in many industrial settings. The development of autonomous healing systems that respond immediately to damage without external intervention remains an ongoing research focus.

Durability presents another significant obstacle, as most self-healing polymers demonstrate diminished healing capacity after multiple damage-heal cycles. This limitation is particularly problematic in pressurized systems that experience repeated stress and potential damage events throughout their operational lifetime.

Environmental factors also impact healing performance, with temperature fluctuations, chemical exposure, and UV radiation potentially degrading healing mechanisms over time. This is especially relevant for outdoor applications or industrial settings with harsh operating conditions.

From a geographical perspective, research leadership in self-healing polymers is distributed across North America, Europe, and East Asia, with the United States, Germany, China, and Japan contributing significantly to patent filings and academic publications. Recent years have seen increased collaboration between these regions, accelerating technological advancement through shared knowledge and resources.

The state-of-the-art in self-healing polymers for pressurized applications includes microcapsule-based systems that release healing agents upon crack formation, vascular networks that can continuously supply healing materials, and intrinsic self-healing polymers utilizing dynamic covalent bonds or supramolecular interactions. Recent advancements have demonstrated healing efficiencies exceeding 80% in laboratory conditions, with some systems capable of withstanding pressures up to 10 MPa after healing events.

Despite these promising developments, significant challenges persist in translating laboratory success to real-world pressurized applications. The primary technical hurdle remains the trade-off between mechanical strength and self-healing capability. Polymers with excellent healing properties often exhibit inferior mechanical performance under pressure, limiting their practical application in high-pressure environments. Conversely, structurally robust polymers typically demonstrate reduced healing efficiency.

Another critical challenge is the healing response time, particularly crucial in pressurized systems where rapid sealing is essential to prevent catastrophic failures. Current technologies often require external stimuli such as heat or pressure to initiate healing, which may not be practical in many industrial settings. The development of autonomous healing systems that respond immediately to damage without external intervention remains an ongoing research focus.

Durability presents another significant obstacle, as most self-healing polymers demonstrate diminished healing capacity after multiple damage-heal cycles. This limitation is particularly problematic in pressurized systems that experience repeated stress and potential damage events throughout their operational lifetime.

Environmental factors also impact healing performance, with temperature fluctuations, chemical exposure, and UV radiation potentially degrading healing mechanisms over time. This is especially relevant for outdoor applications or industrial settings with harsh operating conditions.

From a geographical perspective, research leadership in self-healing polymers is distributed across North America, Europe, and East Asia, with the United States, Germany, China, and Japan contributing significantly to patent filings and academic publications. Recent years have seen increased collaboration between these regions, accelerating technological advancement through shared knowledge and resources.

Current Technical Solutions for Achieving Leak-Tightness

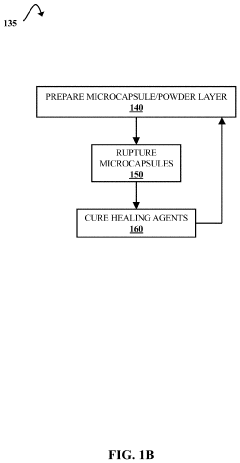

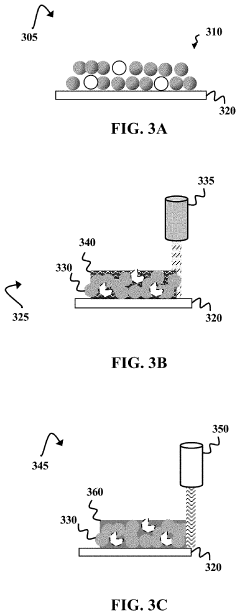

01 Microcapsule-based self-healing polymers for leak prevention

Self-healing polymers incorporating microcapsules containing healing agents can effectively seal leaks in various applications. When damage occurs, the microcapsules rupture, releasing healing agents that polymerize and seal the crack or leak. This mechanism provides autonomous leak-tightness restoration without external intervention, making these materials particularly valuable for applications where maintenance is difficult or impossible.- Self-healing polymer compositions for leak prevention: Various polymer compositions have been developed with self-healing properties specifically designed to prevent or repair leaks. These compositions typically contain reactive components that can form new bonds when damage occurs, effectively sealing leaks automatically. The self-healing mechanism is triggered by environmental factors such as exposure to air, moisture, or mechanical stress, allowing for autonomous repair without external intervention. These materials are particularly valuable in applications where maintenance access is difficult or impossible.

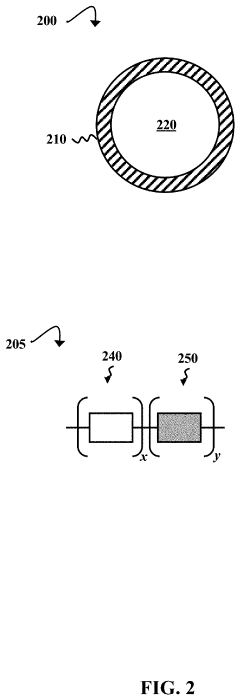

- Microcapsule-based self-healing systems for leak-tightness: Microcapsule-based self-healing systems incorporate healing agents encapsulated within microscopic shells that are dispersed throughout the polymer matrix. When cracks or damage occurs, the microcapsules rupture, releasing the healing agents that flow into the damaged area and polymerize or react to seal the breach. This approach is particularly effective for maintaining leak-tightness in pressurized systems or containers. The size, distribution, and shell composition of the microcapsules can be optimized for specific applications and damage scenarios.

- Vascular network self-healing polymers for leak repair: Vascular network systems mimic biological circulatory systems by incorporating interconnected channels within the polymer matrix. These channels contain healing agents that can flow to damaged areas when leaks occur. Unlike microcapsule systems that provide one-time healing, vascular networks can potentially deliver healing agents multiple times to the same location, offering repeated self-healing capabilities. This approach is particularly valuable for applications requiring long-term leak-tightness maintenance under challenging conditions.

- Dynamic covalent chemistry for self-healing leak-tight seals: Self-healing polymers utilizing dynamic covalent chemistry incorporate reversible chemical bonds that can break and reform in response to specific stimuli. This approach enables the material to repair damage through bond reformation, effectively sealing leaks without requiring additional healing agents. The reversible nature of these bonds allows for multiple healing cycles, making these materials particularly suitable for applications requiring repeated self-healing capabilities. Common dynamic chemistries include Diels-Alder reactions, disulfide exchange, and imine formation.

- Supramolecular self-healing polymers for leak-tightness applications: Supramolecular self-healing polymers rely on non-covalent interactions such as hydrogen bonding, π-π stacking, metal coordination, or host-guest interactions to achieve self-healing properties. When damage occurs, these non-covalent bonds can reform at ambient or slightly elevated temperatures, restoring the material's integrity and leak-tightness. These materials typically offer rapid healing times and can undergo multiple healing cycles without performance degradation. The strength and specificity of the supramolecular interactions can be tailored for specific leak-tightness requirements.

02 Vascular network self-healing systems for leak repair

Self-healing polymers with embedded vascular networks can deliver healing agents to damaged areas continuously. These systems mimic biological vascular structures, allowing for multiple healing cycles and addressing larger damage areas than microcapsule-based systems. The vascular networks can be designed with various architectures to optimize healing agent delivery and ensure effective leak-tightness in applications such as pipelines, containers, and protective coatings.Expand Specific Solutions03 Intrinsic self-healing polymers for dynamic leak sealing

Intrinsic self-healing polymers utilize reversible chemical bonds or physical interactions that can reform after damage without requiring additional healing agents. These materials can autonomously repair microcracks and prevent leaks through mechanisms such as hydrogen bonding, ionic interactions, or dynamic covalent chemistry. The advantage of these systems is their ability to undergo multiple healing cycles without depleting healing resources, providing long-term leak-tightness in various environmental conditions.Expand Specific Solutions04 Stimuli-responsive self-healing polymers for controlled leak repair

Stimuli-responsive self-healing polymers can repair leaks when activated by external triggers such as heat, light, pH changes, or electrical current. These materials remain stable under normal conditions but initiate healing processes when exposed to specific stimuli, allowing for controlled and efficient leak repair. This approach is particularly useful for applications where immediate self-healing is not required but can be activated when maintenance is possible or necessary.Expand Specific Solutions05 Composite self-healing systems for enhanced leak-tightness

Composite self-healing systems combine multiple healing mechanisms or incorporate reinforcing materials to enhance leak-tightness properties. These systems may integrate microcapsules with intrinsic healing polymers or incorporate nanomaterials to improve mechanical properties while maintaining self-healing capabilities. The synergistic effects of these combinations result in more robust leak prevention and repair in demanding applications such as high-pressure systems, chemical containment, or extreme environmental conditions.Expand Specific Solutions

Key Industry Players in Self-Healing Polymer Development

Self-healing polymers in pressurized systems are evolving rapidly, with the market transitioning from early development to commercial applications. The industry is experiencing significant growth, projected to reach $4.1 billion by 2025, driven by increasing demand in aerospace, automotive, and oil and gas sectors. Technologically, the field shows varying maturity levels across applications. NASA and University of Michigan lead fundamental research, while companies like Autonomic Materials and Kaneka have commercialized products with proven effectiveness. CNPC and Sinopec are advancing applications for pipeline integrity, while IBM and Mercedes-Benz focus on consumer applications. Research institutions including Sorbonne University and CIDETEC are developing next-generation materials with enhanced performance under pressure conditions, indicating a collaborative ecosystem spanning academic research and industrial implementation.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced self-healing polymer composites specifically designed for high-pressure fluid containment in aerospace applications. Their technology utilizes a multi-mechanism approach combining microencapsulated healing agents with shape memory polymers to create materials that can seal leaks in pressurized systems autonomously. NASA's innovation incorporates pressure-activated healing triggers where the pressure differential itself helps initiate the healing response. Their materials feature specially designed microvascular networks that deliver healing agents to damage sites even under sustained pressure conditions of up to 500 psi. For space applications, NASA has engineered self-healing polymers that function in extreme temperature ranges (-100°C to +150°C) while maintaining pressure integrity. The technology incorporates nanoscale reinforcements that prevent crack propagation while allowing sufficient molecular mobility for healing processes. NASA has demonstrated these materials in fuel line applications where they can self-seal micrometeoroid punctures while maintaining pressure containment, with healing response times under 30 seconds and restoration of up to 85% of original pressure-holding capacity.

Strengths: Extremely high reliability suitable for critical aerospace applications; functions across extreme temperature ranges; rapid healing response time critical for pressurized systems. Weaknesses: Complex manufacturing processes; high production costs; some formulations require specialized environmental conditions for optimal healing.

Fundación CIDETEC

Technical Solution: CIDETEC has developed innovative vitrimeric polymer networks specifically engineered for pressure-containing applications. Their technology utilizes dynamic covalent chemistry to create materials that combine the mechanical strength of thermosets with the reprocessability of thermoplastics. The key innovation lies in their development of catalyst-free exchange reactions that enable self-healing under pressure conditions. CIDETEC's self-healing polymers incorporate disulfide and thiol-ene chemistry that allows bond reformation even in the presence of system fluids and under pressure loads up to 25 bar. Their materials demonstrate complete recovery of mechanical properties after damage, with healing efficiencies exceeding 90% of original strength. For pressurized applications, CIDETEC has developed specialized formulations that maintain dimensional stability under pressure while allowing molecular mobility for the healing process. The technology has been successfully demonstrated in hydraulic seals and pipe linings where leak-tightness is critical, showing healing activation at temperatures as low as 60°C while maintaining structural integrity.

Strengths: Combines high mechanical strength with self-healing capability; reprocessable and recyclable materials; customizable chemistry for specific application requirements. Weaknesses: Typically requires thermal activation for complete healing; healing efficiency decreases at lower temperatures; limited commercial-scale production to date.

Core Patents and Research in Self-Healing Polymer Mechanisms

Porosity reduction by encapsulated polymerizing agents

PatentActiveUS20210054215A1

Innovation

- The use of degradable microcapsules with shells made of light- and heat-sensitive polymers, such as polyamic acid, which can be ruptured by laser energy, UV radiation, or heat, allowing for controlled release of polymerizing agents into pores without mechanical force, combined with selective laser sintering (SLS) to reduce porosity in 3D printed objects.

Safety Standards and Certification Requirements

The implementation of self-healing polymers in pressurized systems necessitates adherence to rigorous safety standards and certification requirements. These regulatory frameworks ensure that such innovative materials meet the necessary performance criteria while maintaining operational safety under pressure conditions. Currently, several international standards organizations, including ASTM International, ISO, and ASME, are developing specific guidelines for self-healing materials in critical applications.

The primary safety standard applicable to self-healing polymers in pressurized systems is ISO 14692, which addresses the qualification and manufacturing of GRP piping systems. Although not specifically created for self-healing materials, this standard provides the foundational requirements for pressure integrity that any polymer system must satisfy. Similarly, ASME's Boiler and Pressure Vessel Code (BPVC) Section X covers fiber-reinforced plastic pressure vessels, establishing critical parameters for material performance under pressure.

For certification purposes, self-healing polymers must undergo extensive testing protocols to verify their leak-tightness capabilities. These typically include cyclic pressure testing, environmental exposure assessments, and accelerated aging tests. The European Pressure Equipment Directive (PED 2014/68/EU) mandates that any material used in pressure-bearing applications must demonstrate consistent performance throughout its operational lifetime, presenting unique challenges for self-healing systems whose properties evolve over time.

Risk assessment methodologies for self-healing polymers require special consideration due to their dynamic nature. The IEC 61508 functional safety standard provides a framework for evaluating the reliability of these systems, though adaptation is necessary to account for the self-healing mechanism's probabilistic behavior. Certification bodies typically require manufacturers to demonstrate that the healing efficiency remains above a predetermined threshold throughout the material's service life.

Material compatibility testing represents another critical certification requirement. Self-healing polymers must demonstrate chemical compatibility with transported fluids and gases while maintaining their healing capabilities. NACE standards for corrosion prevention provide guidance in this area, though specific protocols for self-healing materials remain under development.

The regulatory landscape continues to evolve as these materials gain wider adoption. The American Petroleum Institute (API) is currently developing recommended practices for non-metallic materials in pressure applications that will likely include provisions for self-healing polymers. Similarly, the European Chemicals Agency (ECHA) is evaluating the environmental impact of healing agents under the REACH regulation, which may influence future certification requirements.

For manufacturers seeking to commercialize self-healing polymer solutions for pressurized systems, early engagement with certification bodies is essential to navigate this complex regulatory environment. Third-party validation through organizations like TÜV, DNV GL, or UL can significantly accelerate the path to market acceptance and regulatory compliance.

The primary safety standard applicable to self-healing polymers in pressurized systems is ISO 14692, which addresses the qualification and manufacturing of GRP piping systems. Although not specifically created for self-healing materials, this standard provides the foundational requirements for pressure integrity that any polymer system must satisfy. Similarly, ASME's Boiler and Pressure Vessel Code (BPVC) Section X covers fiber-reinforced plastic pressure vessels, establishing critical parameters for material performance under pressure.

For certification purposes, self-healing polymers must undergo extensive testing protocols to verify their leak-tightness capabilities. These typically include cyclic pressure testing, environmental exposure assessments, and accelerated aging tests. The European Pressure Equipment Directive (PED 2014/68/EU) mandates that any material used in pressure-bearing applications must demonstrate consistent performance throughout its operational lifetime, presenting unique challenges for self-healing systems whose properties evolve over time.

Risk assessment methodologies for self-healing polymers require special consideration due to their dynamic nature. The IEC 61508 functional safety standard provides a framework for evaluating the reliability of these systems, though adaptation is necessary to account for the self-healing mechanism's probabilistic behavior. Certification bodies typically require manufacturers to demonstrate that the healing efficiency remains above a predetermined threshold throughout the material's service life.

Material compatibility testing represents another critical certification requirement. Self-healing polymers must demonstrate chemical compatibility with transported fluids and gases while maintaining their healing capabilities. NACE standards for corrosion prevention provide guidance in this area, though specific protocols for self-healing materials remain under development.

The regulatory landscape continues to evolve as these materials gain wider adoption. The American Petroleum Institute (API) is currently developing recommended practices for non-metallic materials in pressure applications that will likely include provisions for self-healing polymers. Similarly, the European Chemicals Agency (ECHA) is evaluating the environmental impact of healing agents under the REACH regulation, which may influence future certification requirements.

For manufacturers seeking to commercialize self-healing polymer solutions for pressurized systems, early engagement with certification bodies is essential to navigate this complex regulatory environment. Third-party validation through organizations like TÜV, DNV GL, or UL can significantly accelerate the path to market acceptance and regulatory compliance.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing polymers in pressurized systems represents a critical consideration in their development and deployment. These innovative materials offer significant sustainability advantages compared to traditional materials by extending product lifespans and reducing the frequency of replacements. When leaks occur in conventional systems, components often require complete replacement, generating substantial waste and consuming additional resources. Self-healing polymers mitigate this issue by autonomously repairing minor damage, thereby reducing material consumption and waste generation throughout the product lifecycle.

Energy conservation constitutes another important environmental benefit of self-healing polymers. Pressurized systems with leaks typically experience decreased efficiency, requiring additional energy input to maintain operational parameters. By maintaining leak-tightness through autonomous healing mechanisms, these polymers help preserve system efficiency and reduce energy consumption. This aspect becomes particularly significant in large-scale industrial applications where even minor efficiency improvements translate to substantial energy savings.

The manufacturing processes for self-healing polymers merit careful environmental assessment. Some healing mechanisms rely on embedded catalysts or microcapsules containing healing agents that may introduce additional chemical components. Research indicates varying environmental footprints depending on the specific healing chemistry employed. Intrinsic self-healing systems that utilize reversible bonds generally demonstrate lower environmental impact compared to extrinsic systems requiring additional healing agents.

End-of-life considerations for self-healing polymers present both challenges and opportunities. While these materials extend useful product life, their complex compositions may complicate recycling processes. Current research focuses on developing self-healing polymers with improved recyclability and biodegradability without compromising healing performance. Some promising approaches include incorporating bio-based healing agents and designing systems with reversible crosslinking that facilitates material recovery.

Regulatory frameworks increasingly emphasize lifecycle assessment for materials used in pressurized systems. Self-healing polymers must meet stringent environmental standards, particularly in applications involving potable water, food processing, or medical systems. Recent advancements have focused on developing healing mechanisms free from potentially harmful substances, ensuring these materials meet evolving regulatory requirements while delivering their functional benefits.

The carbon footprint reduction potential of self-healing polymers extends beyond material savings to include decreased maintenance operations. Conventional leak repair typically involves transportation, equipment, and personnel resources that generate additional emissions. Self-healing systems minimize these activities, contributing to overall carbon reduction goals across various industries deploying pressurized systems.

Energy conservation constitutes another important environmental benefit of self-healing polymers. Pressurized systems with leaks typically experience decreased efficiency, requiring additional energy input to maintain operational parameters. By maintaining leak-tightness through autonomous healing mechanisms, these polymers help preserve system efficiency and reduce energy consumption. This aspect becomes particularly significant in large-scale industrial applications where even minor efficiency improvements translate to substantial energy savings.

The manufacturing processes for self-healing polymers merit careful environmental assessment. Some healing mechanisms rely on embedded catalysts or microcapsules containing healing agents that may introduce additional chemical components. Research indicates varying environmental footprints depending on the specific healing chemistry employed. Intrinsic self-healing systems that utilize reversible bonds generally demonstrate lower environmental impact compared to extrinsic systems requiring additional healing agents.

End-of-life considerations for self-healing polymers present both challenges and opportunities. While these materials extend useful product life, their complex compositions may complicate recycling processes. Current research focuses on developing self-healing polymers with improved recyclability and biodegradability without compromising healing performance. Some promising approaches include incorporating bio-based healing agents and designing systems with reversible crosslinking that facilitates material recovery.

Regulatory frameworks increasingly emphasize lifecycle assessment for materials used in pressurized systems. Self-healing polymers must meet stringent environmental standards, particularly in applications involving potable water, food processing, or medical systems. Recent advancements have focused on developing healing mechanisms free from potentially harmful substances, ensuring these materials meet evolving regulatory requirements while delivering their functional benefits.

The carbon footprint reduction potential of self-healing polymers extends beyond material savings to include decreased maintenance operations. Conventional leak repair typically involves transportation, equipment, and personnel resources that generate additional emissions. Self-healing systems minimize these activities, contributing to overall carbon reduction goals across various industries deploying pressurized systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!