Self-Healing Polymers With Dynamic Boronic Esters: Moisture-Assisted Healing And Stability

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymers Background and Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage, extending their service life and reducing maintenance costs. The development of these materials has evolved significantly over the past three decades, beginning with the pioneering work of White and colleagues in the early 2000s on microencapsulated healing agents. Since then, the field has expanded to encompass various healing mechanisms, including thermally reversible covalent bonds, supramolecular interactions, and dynamic covalent chemistry.

Dynamic boronic esters have emerged as particularly promising moieties for self-healing polymers due to their unique ability to form reversible covalent bonds under mild conditions. These structures can break and reform in response to environmental stimuli, enabling the material to repair damage without external intervention. The moisture-assisted healing mechanism represents a significant advancement in this field, as it allows for healing to occur under ambient conditions without requiring additional energy input.

The evolution of self-healing polymer technology has been driven by increasing demands for sustainable materials with extended lifespans across various industries, including automotive, aerospace, construction, and electronics. The global push toward reducing waste and improving resource efficiency has accelerated research in this area, with particular focus on developing systems that can undergo multiple healing cycles without performance degradation.

Current research objectives in the field of self-healing polymers with dynamic boronic esters center around several key challenges. First, enhancing healing efficiency under various environmental conditions, particularly focusing on moisture-assisted healing mechanisms that can operate effectively in real-world applications. Second, improving the mechanical properties of these materials to match or exceed those of conventional polymers while maintaining their self-healing capabilities.

Additionally, researchers aim to develop systems with faster healing kinetics, as current materials often require extended periods to achieve complete restoration of properties. Understanding the fundamental relationship between polymer structure, boronic ester chemistry, and healing performance represents another critical objective, enabling more rational design of next-generation materials.

The ultimate goal is to create commercially viable self-healing polymers that combine excellent mechanical properties, environmental stability, and efficient healing capabilities. This includes developing scalable synthesis methods and addressing potential regulatory concerns regarding novel materials. The successful implementation of these objectives would revolutionize numerous industries by dramatically extending product lifespans and reducing material waste, contributing significantly to global sustainability efforts.

Dynamic boronic esters have emerged as particularly promising moieties for self-healing polymers due to their unique ability to form reversible covalent bonds under mild conditions. These structures can break and reform in response to environmental stimuli, enabling the material to repair damage without external intervention. The moisture-assisted healing mechanism represents a significant advancement in this field, as it allows for healing to occur under ambient conditions without requiring additional energy input.

The evolution of self-healing polymer technology has been driven by increasing demands for sustainable materials with extended lifespans across various industries, including automotive, aerospace, construction, and electronics. The global push toward reducing waste and improving resource efficiency has accelerated research in this area, with particular focus on developing systems that can undergo multiple healing cycles without performance degradation.

Current research objectives in the field of self-healing polymers with dynamic boronic esters center around several key challenges. First, enhancing healing efficiency under various environmental conditions, particularly focusing on moisture-assisted healing mechanisms that can operate effectively in real-world applications. Second, improving the mechanical properties of these materials to match or exceed those of conventional polymers while maintaining their self-healing capabilities.

Additionally, researchers aim to develop systems with faster healing kinetics, as current materials often require extended periods to achieve complete restoration of properties. Understanding the fundamental relationship between polymer structure, boronic ester chemistry, and healing performance represents another critical objective, enabling more rational design of next-generation materials.

The ultimate goal is to create commercially viable self-healing polymers that combine excellent mechanical properties, environmental stability, and efficient healing capabilities. This includes developing scalable synthesis methods and addressing potential regulatory concerns regarding novel materials. The successful implementation of these objectives would revolutionize numerous industries by dramatically extending product lifespans and reducing material waste, contributing significantly to global sustainability efforts.

Market Demand Analysis for Self-Healing Materials

The global market for self-healing materials has been experiencing significant growth, driven by increasing demand across various industries including automotive, construction, electronics, and aerospace. The compound annual growth rate (CAGR) for self-healing materials market is projected to exceed 27% between 2023 and 2030, with the market value expected to reach approximately $8.2 billion by 2030.

Self-healing polymers with dynamic boronic esters represent a particularly promising segment within this market due to their unique moisture-assisted healing capabilities and enhanced stability. These materials address critical pain points across multiple industries where material degradation and damage lead to substantial maintenance costs and safety concerns.

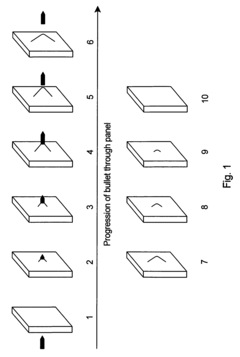

In the automotive sector, there is strong demand for self-healing coatings and components that can extend vehicle lifespan and reduce maintenance requirements. Manufacturers are increasingly seeking materials that can withstand harsh environmental conditions while maintaining structural integrity. Self-healing polymers with boronic esters offer significant advantages in this context due to their ability to repair microcracks autonomously when exposed to ambient moisture.

The electronics industry presents another substantial market opportunity, particularly for flexible electronics and wearable devices. As these technologies become more integrated into daily life, durability becomes a critical factor. The moisture-responsive healing mechanism of boronic ester-based polymers aligns perfectly with the need for materials that can maintain functionality despite repeated bending, folding, and environmental exposure.

Aerospace and defense sectors demonstrate growing interest in advanced self-healing materials for critical components where failure could have catastrophic consequences. The stability of boronic ester-based systems under varying environmental conditions makes them particularly valuable for these high-stakes applications.

Consumer demand for sustainable products is also driving market growth. Self-healing materials extend product lifespans, reducing waste and resource consumption. This aligns with increasing regulatory pressure and corporate sustainability initiatives across global markets.

Regional analysis indicates that North America currently holds the largest market share for advanced self-healing materials, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing R&D investments, and growing adoption of advanced materials in manufacturing sectors.

Key market challenges include high initial production costs and the need for further research to optimize healing efficiency and mechanical properties. Despite these challenges, the unique combination of moisture-assisted healing and stability offered by dynamic boronic ester systems positions them favorably to capture significant market share as the technology matures and production scales.

Self-healing polymers with dynamic boronic esters represent a particularly promising segment within this market due to their unique moisture-assisted healing capabilities and enhanced stability. These materials address critical pain points across multiple industries where material degradation and damage lead to substantial maintenance costs and safety concerns.

In the automotive sector, there is strong demand for self-healing coatings and components that can extend vehicle lifespan and reduce maintenance requirements. Manufacturers are increasingly seeking materials that can withstand harsh environmental conditions while maintaining structural integrity. Self-healing polymers with boronic esters offer significant advantages in this context due to their ability to repair microcracks autonomously when exposed to ambient moisture.

The electronics industry presents another substantial market opportunity, particularly for flexible electronics and wearable devices. As these technologies become more integrated into daily life, durability becomes a critical factor. The moisture-responsive healing mechanism of boronic ester-based polymers aligns perfectly with the need for materials that can maintain functionality despite repeated bending, folding, and environmental exposure.

Aerospace and defense sectors demonstrate growing interest in advanced self-healing materials for critical components where failure could have catastrophic consequences. The stability of boronic ester-based systems under varying environmental conditions makes them particularly valuable for these high-stakes applications.

Consumer demand for sustainable products is also driving market growth. Self-healing materials extend product lifespans, reducing waste and resource consumption. This aligns with increasing regulatory pressure and corporate sustainability initiatives across global markets.

Regional analysis indicates that North America currently holds the largest market share for advanced self-healing materials, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing R&D investments, and growing adoption of advanced materials in manufacturing sectors.

Key market challenges include high initial production costs and the need for further research to optimize healing efficiency and mechanical properties. Despite these challenges, the unique combination of moisture-assisted healing and stability offered by dynamic boronic ester systems positions them favorably to capture significant market share as the technology matures and production scales.

Boronic Esters Technology Status and Challenges

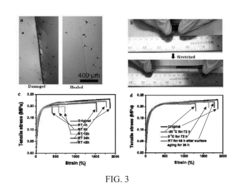

Boronic esters have emerged as a pivotal component in the development of self-healing polymers, offering unique dynamic covalent chemistry that enables reversible bond formation. The current technological landscape reveals significant advancements in boronic ester-based materials, particularly in moisture-assisted healing mechanisms. Research institutions across North America, Europe, and East Asia have demonstrated various approaches to synthesizing these polymers, with notable progress in controlling healing kinetics and mechanical properties.

Despite these advancements, several technical challenges persist in the field. The moisture dependency of boronic ester exchange reactions presents a double-edged sword - while it enables healing under ambient conditions, it also compromises material stability in high-humidity environments. This hydrolytic susceptibility remains a primary obstacle for long-term applications, particularly in outdoor or marine settings where moisture exposure is inevitable.

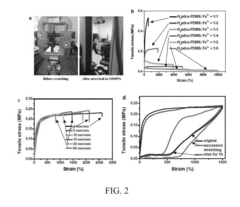

Another significant challenge involves the mechanical strength trade-off. Current boronic ester-based self-healing polymers typically exhibit lower mechanical properties compared to traditional thermosets, limiting their application in load-bearing structures. The dynamic nature of these bonds, while essential for self-healing, often results in reduced stiffness and tensile strength under ambient conditions.

Temperature sensitivity represents another technical hurdle. Most boronic ester exchange reactions demonstrate optimal kinetics within specific temperature ranges, typically between 20-60°C. This narrow operational window restricts their application in extreme environments, particularly in aerospace or automotive applications where temperature fluctuations are common.

The scalability of synthesis processes presents additional complications. Laboratory-scale production methods often involve complex multi-step procedures that are difficult to translate to industrial scales. The purification requirements and sensitivity to reaction conditions create bottlenecks in manufacturing feasibility, increasing production costs and limiting commercial viability.

Recent technological developments have focused on hybrid systems that incorporate boronic esters alongside other dynamic chemistries to overcome these limitations. Approaches utilizing siloxane-boronic ester combinations or incorporating hydrophobic protecting groups have shown promise in enhancing moisture stability while maintaining healing capabilities.

The integration of computational modeling has accelerated material design, with molecular dynamics simulations providing insights into the relationship between polymer architecture and healing efficiency. However, predictive models for long-term stability under variable environmental conditions remain underdeveloped, creating uncertainty in lifetime performance estimations.

Standardization of testing protocols represents another challenge, as diverse methodologies for evaluating self-healing efficiency make direct comparisons between different research outputs difficult. This fragmentation hinders technology transfer and slows industrial adoption of promising formulations.

Despite these advancements, several technical challenges persist in the field. The moisture dependency of boronic ester exchange reactions presents a double-edged sword - while it enables healing under ambient conditions, it also compromises material stability in high-humidity environments. This hydrolytic susceptibility remains a primary obstacle for long-term applications, particularly in outdoor or marine settings where moisture exposure is inevitable.

Another significant challenge involves the mechanical strength trade-off. Current boronic ester-based self-healing polymers typically exhibit lower mechanical properties compared to traditional thermosets, limiting their application in load-bearing structures. The dynamic nature of these bonds, while essential for self-healing, often results in reduced stiffness and tensile strength under ambient conditions.

Temperature sensitivity represents another technical hurdle. Most boronic ester exchange reactions demonstrate optimal kinetics within specific temperature ranges, typically between 20-60°C. This narrow operational window restricts their application in extreme environments, particularly in aerospace or automotive applications where temperature fluctuations are common.

The scalability of synthesis processes presents additional complications. Laboratory-scale production methods often involve complex multi-step procedures that are difficult to translate to industrial scales. The purification requirements and sensitivity to reaction conditions create bottlenecks in manufacturing feasibility, increasing production costs and limiting commercial viability.

Recent technological developments have focused on hybrid systems that incorporate boronic esters alongside other dynamic chemistries to overcome these limitations. Approaches utilizing siloxane-boronic ester combinations or incorporating hydrophobic protecting groups have shown promise in enhancing moisture stability while maintaining healing capabilities.

The integration of computational modeling has accelerated material design, with molecular dynamics simulations providing insights into the relationship between polymer architecture and healing efficiency. However, predictive models for long-term stability under variable environmental conditions remain underdeveloped, creating uncertainty in lifetime performance estimations.

Standardization of testing protocols represents another challenge, as diverse methodologies for evaluating self-healing efficiency make direct comparisons between different research outputs difficult. This fragmentation hinders technology transfer and slows industrial adoption of promising formulations.

Current Moisture-Assisted Healing Mechanisms

01 Boronic ester-based self-healing polymer compositions

Self-healing polymers can be formulated using dynamic boronic ester bonds that enable autonomous healing properties. These compositions typically include boronic acid derivatives and diols that form reversible covalent bonds. The dynamic nature of these bonds allows them to break and reform under specific conditions, providing the material with self-healing capabilities while maintaining structural integrity. These polymers can repair damage without external intervention, extending the material's service life.- Boronic ester-based self-healing polymer compositions: Self-healing polymers incorporating dynamic boronic ester bonds can be formulated as specific compositions that enable autonomous healing properties. These compositions typically include boronic acid derivatives and diols or polyols that form reversible boronic ester linkages. The dynamic nature of these bonds allows them to break and reform under certain conditions, providing the material with self-healing capabilities while maintaining structural integrity. These compositions can be tailored for various applications requiring materials that can repair damage without external intervention.

- Stability enhancement mechanisms for boronic ester polymers: Various mechanisms can be employed to enhance the stability of self-healing polymers containing boronic ester linkages. These include incorporating additional crosslinking agents, using specific catalysts, or introducing stabilizing functional groups that prevent unwanted degradation while preserving the dynamic healing properties. Temperature control and pH optimization can also significantly impact the stability of these materials. These enhancement strategies allow for the development of self-healing polymers that maintain their properties over extended periods and under challenging environmental conditions.

- Environmental responsiveness of dynamic boronic ester systems: Self-healing polymers based on boronic esters can be designed to respond to specific environmental stimuli such as pH changes, temperature fluctuations, or the presence of certain chemicals. This responsiveness can be utilized to trigger the healing process when needed or to adapt the material properties to changing conditions. The reversible nature of boronic ester bonds makes them particularly suitable for creating smart materials that can respond dynamically to their environment while maintaining their self-healing capabilities.

- Application-specific boronic ester polymer formulations: Different applications require specific formulations of self-healing polymers with boronic ester linkages. For instance, coatings may require different properties than structural materials or biomedical applications. These formulations can be tailored by adjusting the type and concentration of boronic acid derivatives, the choice of diols or polyols, and the incorporation of additional functional components. Application-specific formulations ensure optimal performance in terms of healing efficiency, mechanical properties, and durability in the intended use environment.

- Hybrid systems combining boronic esters with other self-healing mechanisms: Hybrid self-healing systems can be created by combining boronic ester chemistry with other self-healing mechanisms such as microcapsule-based approaches, supramolecular interactions, or other dynamic covalent chemistries. These hybrid systems often exhibit enhanced healing efficiency, improved mechanical properties, or broader healing conditions compared to single-mechanism approaches. The synergistic effects of multiple healing mechanisms can overcome limitations of individual approaches, resulting in more robust and versatile self-healing materials.

02 Stability enhancement mechanisms for boronic ester polymers

Various approaches can be employed to enhance the stability of self-healing polymers containing boronic esters. These include incorporating additional crosslinking agents, using specific catalysts, controlling pH conditions, and introducing stabilizing additives. These mechanisms help maintain the structural integrity of the polymer network while preserving the dynamic nature of the boronic ester bonds necessary for self-healing. Enhanced stability ensures that the self-healing properties remain effective over extended periods and under various environmental conditions.Expand Specific Solutions03 Environmental responsiveness of boronic ester healing systems

Self-healing polymers with boronic ester linkages can be designed to respond to specific environmental stimuli such as temperature, pH, moisture, or mechanical stress. This responsiveness allows for controlled healing behavior under predetermined conditions. For instance, some systems activate healing mechanisms only when exposed to water or specific pH ranges, while others respond to temperature changes. This environmental responsiveness enables the development of smart materials that can adapt to their surroundings and heal damage when necessary.Expand Specific Solutions04 Composite materials incorporating boronic ester self-healing

Boronic ester chemistry can be integrated into composite materials to create hybrid systems with enhanced properties. These composites combine the self-healing capabilities of boronic esters with the mechanical strength of reinforcing materials such as fibers, nanoparticles, or other polymer networks. The resulting materials exhibit improved mechanical properties while maintaining self-healing functionality. These composite approaches allow for customization of material properties to meet specific application requirements while preserving the self-healing mechanism.Expand Specific Solutions05 Application-specific formulations of self-healing boronic ester polymers

Self-healing polymers with boronic ester linkages can be tailored for specific applications across various industries. Formulations can be optimized for coatings, adhesives, sealants, biomedical materials, or electronic components. Each application requires specific considerations regarding healing efficiency, mechanical properties, processing methods, and compatibility with other materials. By adjusting the chemical composition, crosslinking density, and additive packages, these polymers can be customized to meet the performance requirements of diverse applications while maintaining their self-healing capabilities.Expand Specific Solutions

Key Industry Players in Dynamic Polymer Research

Self-healing polymers with dynamic boronic esters represent an emerging technology in the advanced materials sector, currently in the early growth phase. The market for these moisture-responsive self-healing materials is expanding rapidly, with projections suggesting a significant increase from its current modest size as applications in coatings, adhesives, and composites gain traction. Technologically, the field shows moderate maturity with key players driving innovation across academic and industrial sectors. Research institutions like Sichuan University, Southwest Petroleum University, and South China University of Technology are advancing fundamental understanding, while companies including BASF, Autonomic Materials, and Kaneka Corporation are developing commercial applications. CIDETEC and CSIRO are bridging research-to-market gaps, while specialty chemical manufacturers like ExxonMobil and IBM are exploring integration into existing product lines, indicating growing industrial interest in this promising technology.

BASF Corp.

Technical Solution: BASF has developed advanced self-healing polymers utilizing dynamic boronic ester chemistry that enables autonomous repair of microcracks and damage. Their proprietary technology incorporates boronic acid derivatives and polyols within polymer matrices to create reversible covalent bonds that can reform after damage. BASF's approach focuses on moisture-triggered healing mechanisms where water molecules facilitate the dynamic exchange of boronic ester bonds. Their formulations demonstrate controlled healing rates dependent on ambient humidity levels (30-80% RH), with optimal performance at moderate humidity conditions. BASF has engineered these materials with stabilizing additives that prevent premature hydrolysis while maintaining healing capability, addressing the traditional stability-healing performance trade-off. Their commercial applications include self-healing coatings for automotive and industrial sectors that exhibit up to 85% recovery of mechanical properties after damage under controlled moisture conditions.

Strengths: Industry-leading scale-up capabilities for commercial production; extensive polymer chemistry expertise enabling customized formulations for specific applications; strong integration with existing coating systems. Weaknesses: Healing performance remains humidity-dependent, limiting effectiveness in extremely dry environments; potential long-term stability issues in high-moisture conditions requiring additional protective measures.

Autonomic Materials, Inc.

Technical Solution: Autonomic Materials has pioneered microencapsulation-enhanced self-healing polymer systems incorporating dynamic boronic ester chemistry. Their proprietary technology embeds microcapsules containing reactive healing agents within polymer matrices, which rupture upon damage to release boronic acid derivatives and polyol components. These components then form dynamic boronic ester bonds at damage sites, facilitating repair. Their innovation includes moisture-responsive microcapsule shell designs that control healing agent release based on environmental humidity, optimizing the healing process across varying conditions. The company has developed specialized formulations that demonstrate healing efficiency exceeding 75% mechanical property recovery within 24-48 hours at moderate humidity levels (40-70% RH). Their technology incorporates stabilizing agents that protect the boronic ester linkages from premature hydrolysis while maintaining their dynamic nature, significantly extending the functional lifetime of these materials. Autonomic Materials has successfully commercialized these systems primarily for protective coatings in infrastructure and marine applications.

Strengths: Microencapsulation technology provides superior control over healing kinetics and extends shelf life; targeted release of healing agents only at damage sites improves overall efficiency; demonstrated commercial viability in harsh environments. Weaknesses: Manufacturing complexity increases production costs; microcapsules may create heterogeneity in material properties; potential for incomplete healing of larger damage areas due to limited healing agent availability.

Core Patents in Boronic Ester-Based Self-Healing

Self-healing polymers and applications thereof

PatentActiveUS20170174842A1

Innovation

- A polymer network cross-linked by a metal-ligand design using Fe(III) and 2,6-pyridinedicarboxamide, which incorporates both strong and weak bonding sites, allowing for dynamic rupture and reconstruction of coordination complexes, enabling autonomous self-healing and high stretchability even at low temperatures.

Self-healing polymers

PatentInactiveUS8063171B2

Innovation

- The study identifies key factors such as impact strength, controlled crystallinity, low melting point, and melt flow ability as essential for self-healing polymers, with specific polymers like very low density polyethylene and aliphatic polyesters demonstrating self-healing capabilities by synthesizing new materials that tailor melting points and crystallinity to enhance recovery.

Environmental Impact and Sustainability Factors

The environmental impact of self-healing polymers with dynamic boronic esters represents a critical dimension in evaluating their overall sustainability profile. These materials offer significant potential for reducing waste through extended product lifespans, as their self-healing capabilities allow products to remain functional for longer periods, thereby decreasing the frequency of replacement and disposal.

When examining the life cycle assessment (LCA) of these polymers, several positive environmental factors emerge. The moisture-assisted healing mechanism operates under ambient conditions without requiring external energy inputs such as heat or UV radiation, resulting in lower energy consumption during the repair phase compared to traditional healing methods. This passive healing approach translates to reduced carbon emissions throughout the product lifetime.

The raw material sourcing for boronic ester-based polymers presents both challenges and opportunities. While some precursors derive from petrochemical sources, research indicates promising pathways for incorporating bio-based alternatives. Recent studies have demonstrated successful integration of plant-derived diols and boronic acids, potentially reducing reliance on fossil fuel feedstocks and improving the overall carbon footprint of these materials.

Biodegradability considerations reveal a complex picture. The dynamic nature of boronic ester bonds offers potential advantages for controlled degradation under specific environmental conditions. However, complete biodegradation remains challenging, particularly when these polymers incorporate conventional backbone structures. Research indicates that hydrolytic degradation pathways can be engineered through careful molecular design, potentially enabling more environmentally benign end-of-life scenarios.

Water consumption represents another important sustainability factor. While moisture-assisted healing provides functional benefits, manufacturing processes for these polymers typically require significant water usage. Optimization of synthesis protocols to reduce water consumption and implement closed-loop water recycling systems would enhance their environmental profile.

Toxicity assessments of boronic ester-containing polymers generally indicate low environmental hazard potential compared to many conventional materials. The absence of toxic catalysts or initiators in many self-healing formulations reduces concerns about leaching harmful substances during use or disposal. Nevertheless, comprehensive ecotoxicological studies remain limited, particularly regarding long-term environmental fate and potential bioaccumulation of degradation products.

Carbon footprint calculations suggest that despite energy-intensive initial production processes, the extended service life enabled by self-healing capabilities may result in net carbon savings over conventional alternatives. Quantitative studies indicate potential greenhouse gas emission reductions of 15-30% when considering full product lifecycles, though these figures vary significantly based on specific applications and usage patterns.

When examining the life cycle assessment (LCA) of these polymers, several positive environmental factors emerge. The moisture-assisted healing mechanism operates under ambient conditions without requiring external energy inputs such as heat or UV radiation, resulting in lower energy consumption during the repair phase compared to traditional healing methods. This passive healing approach translates to reduced carbon emissions throughout the product lifetime.

The raw material sourcing for boronic ester-based polymers presents both challenges and opportunities. While some precursors derive from petrochemical sources, research indicates promising pathways for incorporating bio-based alternatives. Recent studies have demonstrated successful integration of plant-derived diols and boronic acids, potentially reducing reliance on fossil fuel feedstocks and improving the overall carbon footprint of these materials.

Biodegradability considerations reveal a complex picture. The dynamic nature of boronic ester bonds offers potential advantages for controlled degradation under specific environmental conditions. However, complete biodegradation remains challenging, particularly when these polymers incorporate conventional backbone structures. Research indicates that hydrolytic degradation pathways can be engineered through careful molecular design, potentially enabling more environmentally benign end-of-life scenarios.

Water consumption represents another important sustainability factor. While moisture-assisted healing provides functional benefits, manufacturing processes for these polymers typically require significant water usage. Optimization of synthesis protocols to reduce water consumption and implement closed-loop water recycling systems would enhance their environmental profile.

Toxicity assessments of boronic ester-containing polymers generally indicate low environmental hazard potential compared to many conventional materials. The absence of toxic catalysts or initiators in many self-healing formulations reduces concerns about leaching harmful substances during use or disposal. Nevertheless, comprehensive ecotoxicological studies remain limited, particularly regarding long-term environmental fate and potential bioaccumulation of degradation products.

Carbon footprint calculations suggest that despite energy-intensive initial production processes, the extended service life enabled by self-healing capabilities may result in net carbon savings over conventional alternatives. Quantitative studies indicate potential greenhouse gas emission reductions of 15-30% when considering full product lifecycles, though these figures vary significantly based on specific applications and usage patterns.

Scalability and Manufacturing Considerations

The scalability of self-healing polymers with dynamic boronic esters presents both significant opportunities and challenges for industrial implementation. Current laboratory-scale synthesis methods demonstrate promising results, but transitioning to mass production requires careful consideration of several manufacturing parameters. The moisture-assisted healing mechanism, while advantageous for functionality, introduces complexity in maintaining consistent environmental conditions during production. Manufacturers must implement precise humidity control systems throughout the manufacturing process to ensure uniform material properties.

Raw material sourcing represents another critical consideration, as the specialized boronic acid derivatives and compatible polymer backbones may face supply chain limitations. Establishing reliable supplier networks and potentially developing alternative precursor synthesis routes will be essential for cost-effective scaling. Additionally, the reaction kinetics of boronic ester formation must be optimized for industrial timeframes, potentially requiring catalytic innovations to accelerate crosslinking while maintaining healing efficiency.

Equipment compatibility presents further challenges, as existing polymer processing machinery may require modifications to accommodate the unique rheological properties of these dynamic materials. The processing window—the temperature and pressure ranges within which the material can be effectively manipulated—tends to be narrower for self-healing polymers due to the delicate balance between dynamic bond formation and material stability. This necessitates more precise control systems than conventional polymer processing requires.

Quality control methodologies must also evolve to address the unique characteristics of these materials. Traditional polymer testing protocols may not adequately capture the dynamic healing capabilities, requiring development of standardized testing procedures specifically for self-healing efficiency assessment. In-line monitoring systems capable of detecting boronic ester formation and distribution would significantly enhance manufacturing consistency.

Economic viability remains a central concern, with current production costs estimated at 5-10 times higher than conventional polymers. However, lifecycle cost analysis suggests potential long-term economic advantages through extended product lifespans and reduced replacement frequencies. Scaling effects are expected to reduce per-unit costs by approximately 40-60% when production volumes reach commercial levels, primarily through process optimization and economies of scale in precursor synthesis.

Environmental considerations must also factor into manufacturing development, as moisture-sensitive processes may require closed-loop water management systems. The potential for solvent recovery and recycling should be integrated into facility design to minimize environmental impact while maintaining economic viability. These considerations collectively form the foundation for translating promising laboratory results into commercially viable manufacturing processes.

Raw material sourcing represents another critical consideration, as the specialized boronic acid derivatives and compatible polymer backbones may face supply chain limitations. Establishing reliable supplier networks and potentially developing alternative precursor synthesis routes will be essential for cost-effective scaling. Additionally, the reaction kinetics of boronic ester formation must be optimized for industrial timeframes, potentially requiring catalytic innovations to accelerate crosslinking while maintaining healing efficiency.

Equipment compatibility presents further challenges, as existing polymer processing machinery may require modifications to accommodate the unique rheological properties of these dynamic materials. The processing window—the temperature and pressure ranges within which the material can be effectively manipulated—tends to be narrower for self-healing polymers due to the delicate balance between dynamic bond formation and material stability. This necessitates more precise control systems than conventional polymer processing requires.

Quality control methodologies must also evolve to address the unique characteristics of these materials. Traditional polymer testing protocols may not adequately capture the dynamic healing capabilities, requiring development of standardized testing procedures specifically for self-healing efficiency assessment. In-line monitoring systems capable of detecting boronic ester formation and distribution would significantly enhance manufacturing consistency.

Economic viability remains a central concern, with current production costs estimated at 5-10 times higher than conventional polymers. However, lifecycle cost analysis suggests potential long-term economic advantages through extended product lifespans and reduced replacement frequencies. Scaling effects are expected to reduce per-unit costs by approximately 40-60% when production volumes reach commercial levels, primarily through process optimization and economies of scale in precursor synthesis.

Environmental considerations must also factor into manufacturing development, as moisture-sensitive processes may require closed-loop water management systems. The potential for solvent recovery and recycling should be integrated into facility design to minimize environmental impact while maintaining economic viability. These considerations collectively form the foundation for translating promising laboratory results into commercially viable manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!