Self-Healing Coatings For Marine Hardware: Underwater Healing, Biofouling Resistance And Corrosion Control

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Self-Healing Coatings Background and Objectives

Marine self-healing coatings represent a revolutionary advancement in protective surface technologies, emerging from decades of research in materials science and marine engineering. The evolution of these coatings began with conventional anti-corrosive paints in the mid-20th century, progressing through various generations of increasingly sophisticated formulations designed to withstand the harsh marine environment.

The marine industry has long struggled with three interconnected challenges: corrosion, biofouling, and mechanical damage. These factors collectively cost the global maritime sector an estimated $200 billion annually through increased fuel consumption, maintenance requirements, and reduced operational lifespans of vessels and infrastructure.

Recent technological breakthroughs in polymer chemistry, nanotechnology, and biomimetic design have converged to enable the development of coatings with autonomous healing capabilities. These advanced materials can detect damage at the molecular level and initiate repair processes without external intervention, even in underwater conditions where traditional maintenance is difficult and costly.

The self-healing mechanism typically relies on one of several approaches: microencapsulation systems that release healing agents when damaged, reversible chemical bonds that reconnect after breakage, or shape-memory materials that return to their original configuration when triggered. Each approach offers distinct advantages depending on the specific application requirements and environmental conditions.

Biofouling resistance has evolved from toxic copper and tin-based formulations toward environmentally sustainable alternatives that mimic natural defense mechanisms found in marine organisms. These biomimetic approaches create surfaces that prevent organism attachment without releasing harmful compounds into the ecosystem.

The technical objectives for next-generation marine self-healing coatings focus on several key parameters: extending operational lifespans to 10+ years without dry-dock maintenance, achieving healing efficiency above 85% in underwater conditions, maintaining biofouling resistance throughout the coating lifecycle, and ensuring environmental compliance with increasingly stringent international regulations.

Current research aims to develop integrated systems that simultaneously address all three challenges—corrosion, biofouling, and mechanical damage—within a single coating system. This holistic approach represents a paradigm shift from traditional solutions that typically addressed each problem separately, often with competing or contradictory mechanisms.

The ultimate goal is to create smart, responsive coating systems that can adapt to changing environmental conditions, detect potential failures before they occur, and maintain structural integrity throughout the service life of marine hardware, thereby revolutionizing maintenance practices across the maritime industry.

The marine industry has long struggled with three interconnected challenges: corrosion, biofouling, and mechanical damage. These factors collectively cost the global maritime sector an estimated $200 billion annually through increased fuel consumption, maintenance requirements, and reduced operational lifespans of vessels and infrastructure.

Recent technological breakthroughs in polymer chemistry, nanotechnology, and biomimetic design have converged to enable the development of coatings with autonomous healing capabilities. These advanced materials can detect damage at the molecular level and initiate repair processes without external intervention, even in underwater conditions where traditional maintenance is difficult and costly.

The self-healing mechanism typically relies on one of several approaches: microencapsulation systems that release healing agents when damaged, reversible chemical bonds that reconnect after breakage, or shape-memory materials that return to their original configuration when triggered. Each approach offers distinct advantages depending on the specific application requirements and environmental conditions.

Biofouling resistance has evolved from toxic copper and tin-based formulations toward environmentally sustainable alternatives that mimic natural defense mechanisms found in marine organisms. These biomimetic approaches create surfaces that prevent organism attachment without releasing harmful compounds into the ecosystem.

The technical objectives for next-generation marine self-healing coatings focus on several key parameters: extending operational lifespans to 10+ years without dry-dock maintenance, achieving healing efficiency above 85% in underwater conditions, maintaining biofouling resistance throughout the coating lifecycle, and ensuring environmental compliance with increasingly stringent international regulations.

Current research aims to develop integrated systems that simultaneously address all three challenges—corrosion, biofouling, and mechanical damage—within a single coating system. This holistic approach represents a paradigm shift from traditional solutions that typically addressed each problem separately, often with competing or contradictory mechanisms.

The ultimate goal is to create smart, responsive coating systems that can adapt to changing environmental conditions, detect potential failures before they occur, and maintain structural integrity throughout the service life of marine hardware, thereby revolutionizing maintenance practices across the maritime industry.

Market Analysis for Advanced Marine Protective Coatings

The global market for advanced marine protective coatings is experiencing robust growth, driven by increasing maritime activities and the critical need for sustainable solutions to combat harsh marine environments. Currently valued at approximately $6.5 billion, this market is projected to reach $8.9 billion by 2027, representing a compound annual growth rate of 6.4%. Self-healing coatings with multi-functional properties are emerging as a premium segment within this broader market.

Asia-Pacific dominates the marine coatings market with nearly 40% market share, attributed to extensive shipbuilding activities in China, South Korea, and Japan. Europe follows with 30% market share, while North America accounts for 20%. The remaining 10% is distributed across other regions including the Middle East and Latin America.

Commercial shipping represents the largest application segment (45%), followed by offshore structures (25%), naval vessels (15%), and recreational marine (15%). The demand for advanced protective coatings is particularly strong in regions with high maritime traffic and severe marine conditions, such as the South China Sea, North Sea, and Gulf of Mexico.

End-users are increasingly prioritizing total lifecycle costs over initial investment, creating opportunities for premium-priced self-healing solutions that offer extended service life and reduced maintenance requirements. Market research indicates that coatings that can reduce maintenance frequency by 30% or more command significant price premiums, with customers willing to pay up to 2.5 times the cost of conventional alternatives.

The regulatory landscape is significantly influencing market dynamics. Stringent environmental regulations, particularly IMO 2020 and regional restrictions on biocides, are accelerating the shift toward environmentally friendly coating solutions. The EU's recent ban on certain biocides has created immediate market opportunities for alternative anti-fouling technologies.

Customer pain points driving market demand include high maintenance costs (estimated at $30 billion annually for the global fleet), operational downtime during recoating (averaging 5-7 days per vessel), and increasing environmental compliance requirements. Self-healing coatings addressing these challenges are positioned to capture significant market share.

Market adoption barriers include conservative industry practices, high initial costs, and limited long-term performance data. However, early adopters in premium maritime segments, including luxury yachts, naval vessels, and critical offshore infrastructure, are creating reference cases that demonstrate value proposition and accelerate broader market acceptance.

Asia-Pacific dominates the marine coatings market with nearly 40% market share, attributed to extensive shipbuilding activities in China, South Korea, and Japan. Europe follows with 30% market share, while North America accounts for 20%. The remaining 10% is distributed across other regions including the Middle East and Latin America.

Commercial shipping represents the largest application segment (45%), followed by offshore structures (25%), naval vessels (15%), and recreational marine (15%). The demand for advanced protective coatings is particularly strong in regions with high maritime traffic and severe marine conditions, such as the South China Sea, North Sea, and Gulf of Mexico.

End-users are increasingly prioritizing total lifecycle costs over initial investment, creating opportunities for premium-priced self-healing solutions that offer extended service life and reduced maintenance requirements. Market research indicates that coatings that can reduce maintenance frequency by 30% or more command significant price premiums, with customers willing to pay up to 2.5 times the cost of conventional alternatives.

The regulatory landscape is significantly influencing market dynamics. Stringent environmental regulations, particularly IMO 2020 and regional restrictions on biocides, are accelerating the shift toward environmentally friendly coating solutions. The EU's recent ban on certain biocides has created immediate market opportunities for alternative anti-fouling technologies.

Customer pain points driving market demand include high maintenance costs (estimated at $30 billion annually for the global fleet), operational downtime during recoating (averaging 5-7 days per vessel), and increasing environmental compliance requirements. Self-healing coatings addressing these challenges are positioned to capture significant market share.

Market adoption barriers include conservative industry practices, high initial costs, and limited long-term performance data. However, early adopters in premium maritime segments, including luxury yachts, naval vessels, and critical offshore infrastructure, are creating reference cases that demonstrate value proposition and accelerate broader market acceptance.

Current Challenges in Underwater Coating Technologies

The marine environment presents one of the most challenging conditions for protective coatings due to constant exposure to corrosive saltwater, varying hydrostatic pressures, and aggressive biological colonization. Current underwater coating technologies face significant limitations that hinder their effectiveness in providing long-term protection for marine hardware.

Conventional anti-corrosion coatings typically rely on barrier mechanisms that physically separate the substrate from the corrosive environment. However, these barriers inevitably develop defects during service due to mechanical damage, temperature fluctuations, and UV radiation. Once compromised, the protective function rapidly deteriorates, leading to localized corrosion that can spread beneath the coating.

Biofouling presents another major challenge, with marine organisms rapidly colonizing submerged surfaces. Current antifouling technologies predominantly utilize biocide-releasing mechanisms, which face increasing regulatory restrictions due to environmental concerns. Non-toxic alternatives such as fouling-release coatings show limited effectiveness in low-flow or stationary applications, which constitute a significant portion of marine infrastructure.

The underwater application and repair of coatings represent particularly difficult technical challenges. Conventional coating systems require dry surfaces for proper adhesion and curing, necessitating costly dry-docking procedures for maintenance. In-situ underwater repair technologies remain limited in their effectiveness and durability compared to dry-applied counterparts.

Existing self-healing mechanisms in coatings predominantly function through encapsulated healing agents that are released upon damage. However, these systems typically require specific environmental conditions, such as appropriate temperature ranges or dry periods, to effectively polymerize and restore protective properties. The underwater environment severely restricts the efficacy of these healing mechanisms.

The durability of marine coatings is further compromised by the synergistic effects of multiple degradation factors. Mechanical stress from water currents, abrasion from suspended particles, and biodegradation from microbial activity collectively accelerate coating failure beyond what would be expected from individual factors alone.

Additionally, current coating technologies often require trade-offs between different protective functions. For instance, harder coatings that resist abrasion typically have lower flexibility and impact resistance, while softer, more flexible coatings may be more susceptible to biofouling and mechanical damage. This necessitates complex multi-layer systems that increase application costs and potential points of failure.

The development of truly multifunctional coatings that simultaneously address corrosion, biofouling, and mechanical damage while maintaining self-healing capabilities underwater remains an elusive goal, representing the frontier of research in this field.

Conventional anti-corrosion coatings typically rely on barrier mechanisms that physically separate the substrate from the corrosive environment. However, these barriers inevitably develop defects during service due to mechanical damage, temperature fluctuations, and UV radiation. Once compromised, the protective function rapidly deteriorates, leading to localized corrosion that can spread beneath the coating.

Biofouling presents another major challenge, with marine organisms rapidly colonizing submerged surfaces. Current antifouling technologies predominantly utilize biocide-releasing mechanisms, which face increasing regulatory restrictions due to environmental concerns. Non-toxic alternatives such as fouling-release coatings show limited effectiveness in low-flow or stationary applications, which constitute a significant portion of marine infrastructure.

The underwater application and repair of coatings represent particularly difficult technical challenges. Conventional coating systems require dry surfaces for proper adhesion and curing, necessitating costly dry-docking procedures for maintenance. In-situ underwater repair technologies remain limited in their effectiveness and durability compared to dry-applied counterparts.

Existing self-healing mechanisms in coatings predominantly function through encapsulated healing agents that are released upon damage. However, these systems typically require specific environmental conditions, such as appropriate temperature ranges or dry periods, to effectively polymerize and restore protective properties. The underwater environment severely restricts the efficacy of these healing mechanisms.

The durability of marine coatings is further compromised by the synergistic effects of multiple degradation factors. Mechanical stress from water currents, abrasion from suspended particles, and biodegradation from microbial activity collectively accelerate coating failure beyond what would be expected from individual factors alone.

Additionally, current coating technologies often require trade-offs between different protective functions. For instance, harder coatings that resist abrasion typically have lower flexibility and impact resistance, while softer, more flexible coatings may be more susceptible to biofouling and mechanical damage. This necessitates complex multi-layer systems that increase application costs and potential points of failure.

The development of truly multifunctional coatings that simultaneously address corrosion, biofouling, and mechanical damage while maintaining self-healing capabilities underwater remains an elusive goal, representing the frontier of research in this field.

Existing Self-Healing Coating Solutions for Marine Hardware

01 Self-healing mechanisms for underwater coatings

Various self-healing mechanisms can be incorporated into coatings to repair damage when submerged underwater. These include encapsulated healing agents that release upon damage, shape memory polymers that return to their original form, and dynamic chemical bonds that reform after breaking. These mechanisms enable coatings to autonomously repair scratches, cracks, and other damage while maintaining their protective properties in underwater environments.- Self-healing mechanisms for underwater coatings: Various self-healing mechanisms can be incorporated into coatings for underwater applications. These include microcapsule-based systems that release healing agents when damaged, intrinsic self-healing polymers that can reform bonds when broken, and stimuli-responsive materials that activate healing processes in response to environmental triggers. These mechanisms enable coatings to autonomously repair damage while submerged, extending their service life and maintaining protective properties in marine environments.

- Anti-biofouling coating compositions: Specialized coating compositions can prevent biofouling in underwater applications. These formulations incorporate biocides, antifouling polymers, or surface-modifying additives that create unfavorable conditions for marine organism attachment. Some compositions utilize silicone-based materials with low surface energy, copper-containing compounds, or natural biocide alternatives derived from marine organisms. These coatings maintain clean surfaces underwater, reducing maintenance costs and improving operational efficiency of marine structures.

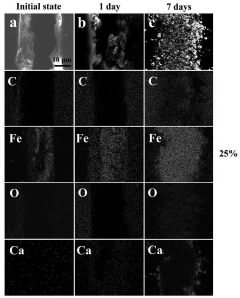

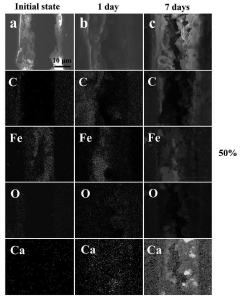

- Corrosion inhibition systems for underwater applications: Advanced corrosion inhibition systems for underwater applications utilize multiple protection mechanisms. These include barrier coatings that physically separate metal from corrosive environments, sacrificial protection through zinc-rich primers or galvanic anodes, and active corrosion inhibitors that can be released on demand. Some systems incorporate nanoparticles or layered materials that enhance barrier properties while providing additional functionality like self-healing or biofouling resistance.

- Smart responsive coating technologies: Smart responsive coatings adapt to changing underwater conditions through engineered responsiveness to environmental stimuli. These coatings can change properties in response to pH shifts, temperature variations, mechanical damage, or the presence of specific chemicals. Some utilize shape-memory polymers that return to original configurations after deformation, while others incorporate phase-changing materials or dynamic chemical networks. These technologies enable coatings to actively respond to underwater challenges rather than serving as passive barriers.

- Nanocomposite coatings for enhanced underwater performance: Nanocomposite coatings incorporate nanoscale materials to enhance underwater performance. These formulations may include nanoparticles like silica, graphene, carbon nanotubes, or metal oxides dispersed within polymer matrices. The nanomaterials significantly improve mechanical strength, adhesion, barrier properties, and durability while enabling additional functionalities like self-healing or antimicrobial properties. Some nanocomposites also feature hierarchical structures that mimic natural underwater organisms with exceptional protective capabilities.

02 Anti-biofouling coating compositions

Specialized coating compositions can prevent biofouling in underwater applications. These formulations incorporate biocides, surface-modifying agents, or biomimetic structures that prevent the attachment and growth of marine organisms. Some compositions utilize copper compounds, silicone-based materials, or hydrophobic/hydrophilic patterns to create surfaces that resist biological colonization while maintaining environmental compatibility and durability in marine environments.Expand Specific Solutions03 Corrosion-resistant self-healing coatings

Advanced coating systems combine corrosion inhibitors with self-healing capabilities to provide long-term protection for metal substrates underwater. These coatings often incorporate sacrificial materials, ion-exchange compounds, or pH-responsive components that activate upon exposure to corrosive environments. The self-healing mechanism can trap and neutralize corrosive species while simultaneously repairing physical damage to maintain the coating's protective barrier properties.Expand Specific Solutions04 Smart responsive coating systems

Smart coating systems respond to environmental stimuli such as pH changes, temperature fluctuations, or mechanical damage to trigger healing processes underwater. These coatings may incorporate conductive polymers, shape-memory materials, or stimulus-responsive microcapsules that release healing agents when needed. The responsive nature allows for targeted and efficient healing only when and where damage occurs, extending the coating's service life in challenging underwater conditions.Expand Specific Solutions05 Environmentally friendly underwater coating technologies

Eco-friendly underwater coating technologies utilize biodegradable polymers, natural compounds, and non-toxic additives to provide self-healing and anti-fouling properties without harming marine ecosystems. These formulations may incorporate plant-derived compounds, enzyme-based systems, or biocompatible polymers that offer protection while minimizing environmental impact. The sustainable approach addresses growing concerns about traditional marine coatings' ecological effects while maintaining effective performance in underwater applications.Expand Specific Solutions

Leading Companies in Marine Coating Industry

The self-healing coatings for marine hardware market is currently in a growth phase, with increasing demand driven by maritime industries seeking sustainable solutions for underwater asset protection. The market size is expanding rapidly as marine infrastructure development accelerates globally. Technologically, the field shows varying maturity levels, with academic institutions like Jilin University, Ocean University of China, and MIT leading fundamental research, while companies such as Autonomic Materials and Ocean Shield are commercializing practical applications. Established industrial players including Tata Steel, Indian Oil, and Toyota Motor Europe are investing in implementation, indicating the technology's transition from laboratory to commercial viability. The competitive landscape features collaboration between research institutions and industry partners, with Naval Research Laboratory and Technical University of Denmark contributing significant innovations in biofouling resistance and corrosion control mechanisms.

Autonomic Materials, Inc.

Technical Solution: Autonomic Materials has developed proprietary microencapsulation technology for self-healing coatings specifically designed for marine applications. Their system incorporates microcapsules containing reactive healing agents that rupture upon mechanical damage, releasing compounds that polymerize when exposed to the marine environment. The technology features a dual-action mechanism where the primary healing components address physical damage while secondary components provide active corrosion inhibition. Their formulations include specialized siloxane-based healing agents that maintain effectiveness in saltwater environments and can operate effectively at various underwater depths and temperatures. The company has demonstrated healing efficiency exceeding 85% in standardized scratch tests under simulated marine conditions, with healing activation occurring within 24-48 hours of damage. Their coatings also incorporate biocide-releasing mechanisms triggered by biofilm formation, providing on-demand protection against biofouling without continuous biocide release.

Strengths: Highly specialized in microencapsulation technology with proven effectiveness in marine environments; dual-action healing and corrosion protection; environmentally responsive triggering mechanisms. Weaknesses: Healing efficiency decreases at greater depths and extreme temperatures; limited shelf life of reactive components; higher production costs compared to conventional marine coatings.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed advanced self-healing coating technologies for marine applications through their network of laboratories. Their approach utilizes a hybrid organic-inorganic matrix incorporating encapsulated healing agents and corrosion inhibitors that are released upon mechanical damage or environmental triggers. The technology features a multi-stage healing process where initial damage triggers the release of primary healing agents, followed by secondary reactions that strengthen the repaired area and provide enhanced corrosion protection. CSIR's formulations incorporate naturally derived components including modified chitosan and alginate derivatives that provide both healing capabilities and resistance to marine biofouling. Their coatings demonstrate particularly strong performance in tropical marine environments, where accelerated corrosion and biofouling are significant challenges. Testing has shown these coatings can reduce maintenance requirements by up to 60% compared to conventional marine protective systems. The technology also incorporates specialized surface texturing that works synergistically with the chemical components to reduce initial biofouling attachment while maintaining self-healing capabilities.

Strengths: Comprehensive research approach addressing multiple aspects of marine protection; incorporation of sustainable, bio-derived components; excellent performance in tropical marine environments. Weaknesses: Variable performance across different marine conditions; healing efficiency decreases over time; requires specialized application techniques for optimal performance.

Key Innovations in Underwater Healing Mechanisms

A coating with antifouling, anticorrosion and bionic self-healing functions and preparation method thereof

PatentActiveCN116355514B

Innovation

- Polyurethane is used as the film-forming material, modified boron nitride is added to simulate the fiber structure of animal cartilage tissue, and disulfide bonds are introduced through bis(2-hydroxyethyl) disulfide, combined with 2-octyl-4,5-disulfide. Chloroisothiazolone is used as an antifouling agent to prepare coatings with antifouling, anticorrosive and bionic self-healing functions.

Method for simulating biological self-repairing of marine anticorrosive coating and application of shewanella putrefaciens

PatentPendingCN115558380A

Innovation

- The biological self-healing method of simulated marine anti-corrosion coating is used to mix the putrefactive Shewanella bacterial suspension with simulated seawater and immerse it into the metal damaged by the anti-corrosion coating. The self-repair of the coating is achieved through the biomineralization of microorganisms. The extracellular electron transfer (EET) process is used to regulate the content of organic carbon sources in the environment to form a dense and uniform biomineralized film to shield and repair damaged areas of the coating.

Environmental Impact and Sustainability Considerations

The environmental impact of marine coatings has become a critical consideration as maritime industries face increasing regulatory scrutiny and sustainability demands. Traditional anti-fouling and anti-corrosion coatings often contain heavy metals and biocides that leach into marine ecosystems, causing significant ecological damage. Self-healing coatings represent a paradigm shift in this domain, potentially reducing the environmental footprint of marine hardware protection systems.

Self-healing coating technologies can substantially extend the service life of marine structures, thereby reducing the frequency of reapplication and associated environmental disruptions. This longevity factor translates directly into decreased raw material consumption, lower energy requirements for manufacturing replacement coatings, and reduced waste generation throughout the product lifecycle.

The biofouling resistance mechanisms in advanced self-healing coatings increasingly rely on physical deterrence rather than toxic release, marking a significant advancement in eco-friendly design. These mechanisms include surface topography manipulation, hydrophobic properties, and controlled surface degradation that minimize the need for environmentally harmful biocides while maintaining effective fouling prevention.

Regulatory frameworks worldwide are evolving to restrict environmentally detrimental substances in marine coatings. The International Maritime Organization's (IMO) ban on tributyltin (TBT) compounds and increasing restrictions on copper-based formulations have accelerated research into sustainable alternatives. Self-healing coatings align with these regulatory trends, positioning them favorably in the evolving compliance landscape.

Life cycle assessment (LCA) studies indicate that self-healing marine coatings can reduce environmental impact by 30-45% compared to conventional systems when considering factors such as resource depletion, aquatic toxicity, and carbon footprint. This improvement stems primarily from extended service intervals and reduced maintenance requirements for protected hardware.

Biodegradability and biocompatibility represent frontier considerations in self-healing coating development. Research is advancing toward formulations that, at end-of-life, break down into environmentally benign compounds rather than persistent pollutants. This approach addresses growing concerns about microplastic pollution and long-term marine ecosystem health.

The carbon footprint reduction potential of self-healing coatings extends beyond manufacturing considerations. By maintaining optimal hull surface conditions for longer periods, these coatings contribute to vessel fuel efficiency, potentially reducing greenhouse gas emissions from global shipping operations by an estimated 5-8% according to preliminary studies.

Circular economy principles are increasingly informing the design of next-generation marine coatings. Researchers are exploring bio-based precursors, renewable resources, and recovery systems that allow for the recapture and reuse of coating components, further enhancing the sustainability profile of self-healing marine protection systems.

Self-healing coating technologies can substantially extend the service life of marine structures, thereby reducing the frequency of reapplication and associated environmental disruptions. This longevity factor translates directly into decreased raw material consumption, lower energy requirements for manufacturing replacement coatings, and reduced waste generation throughout the product lifecycle.

The biofouling resistance mechanisms in advanced self-healing coatings increasingly rely on physical deterrence rather than toxic release, marking a significant advancement in eco-friendly design. These mechanisms include surface topography manipulation, hydrophobic properties, and controlled surface degradation that minimize the need for environmentally harmful biocides while maintaining effective fouling prevention.

Regulatory frameworks worldwide are evolving to restrict environmentally detrimental substances in marine coatings. The International Maritime Organization's (IMO) ban on tributyltin (TBT) compounds and increasing restrictions on copper-based formulations have accelerated research into sustainable alternatives. Self-healing coatings align with these regulatory trends, positioning them favorably in the evolving compliance landscape.

Life cycle assessment (LCA) studies indicate that self-healing marine coatings can reduce environmental impact by 30-45% compared to conventional systems when considering factors such as resource depletion, aquatic toxicity, and carbon footprint. This improvement stems primarily from extended service intervals and reduced maintenance requirements for protected hardware.

Biodegradability and biocompatibility represent frontier considerations in self-healing coating development. Research is advancing toward formulations that, at end-of-life, break down into environmentally benign compounds rather than persistent pollutants. This approach addresses growing concerns about microplastic pollution and long-term marine ecosystem health.

The carbon footprint reduction potential of self-healing coatings extends beyond manufacturing considerations. By maintaining optimal hull surface conditions for longer periods, these coatings contribute to vessel fuel efficiency, potentially reducing greenhouse gas emissions from global shipping operations by an estimated 5-8% according to preliminary studies.

Circular economy principles are increasingly informing the design of next-generation marine coatings. Researchers are exploring bio-based precursors, renewable resources, and recovery systems that allow for the recapture and reuse of coating components, further enhancing the sustainability profile of self-healing marine protection systems.

Standardization and Testing Protocols for Marine Coatings

The standardization and testing of marine self-healing coatings represents a critical challenge in the industry due to the complex underwater environment and multiple performance requirements. Currently, there exists significant fragmentation in testing methodologies across different regions and organizations, making direct performance comparisons difficult.

The International Maritime Organization (IMO) and ASTM International have established baseline protocols for marine coating evaluation, but specific standards for self-healing properties remain underdeveloped. Key testing parameters include healing efficiency measurement, healing activation mechanisms, and long-term performance under cyclic damage conditions.

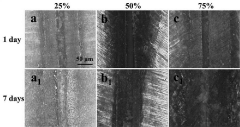

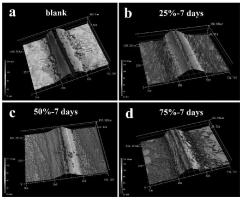

Accelerated testing protocols are essential for this technology, as real-world marine exposure typically requires 3-5 years for conclusive results. Current accelerated methods include salt spray chambers (ASTM B117), cyclic corrosion testing (ISO 20340), and artificial seawater immersion with programmed damage cycles. However, these methods often fail to accurately simulate the complex interplay of mechanical forces, biological activity, and chemical stressors present in actual marine environments.

Biofouling resistance testing presents particular challenges, with the ASTM D6990 and ISO 15105 standards providing frameworks for antifouling performance assessment. These must be adapted to evaluate how self-healing mechanisms interact with antifouling properties after damage events. Standardized biological test panels with representative marine organisms are being developed to ensure consistent evaluation across different coating systems.

Corrosion protection metrics require specialized electrochemical impedance spectroscopy (EIS) protocols to quantify a coating's ability to restore barrier properties after damage. The industry is moving toward standardized scratch-heal-test cycles with defined damage parameters, healing conditions, and performance thresholds.

Emerging testing approaches include digital imaging analysis for quantitative healing assessment and underwater robotics for in-situ monitoring of coating performance. These technologies promise more accurate evaluation of healing kinetics and efficiency under realistic conditions.

International collaboration between NACE International, European Federation of Corrosion, and Asian-Pacific Corrosion associations is currently underway to develop harmonized global standards specifically for self-healing marine coatings, with draft protocols expected within the next two years.

The International Maritime Organization (IMO) and ASTM International have established baseline protocols for marine coating evaluation, but specific standards for self-healing properties remain underdeveloped. Key testing parameters include healing efficiency measurement, healing activation mechanisms, and long-term performance under cyclic damage conditions.

Accelerated testing protocols are essential for this technology, as real-world marine exposure typically requires 3-5 years for conclusive results. Current accelerated methods include salt spray chambers (ASTM B117), cyclic corrosion testing (ISO 20340), and artificial seawater immersion with programmed damage cycles. However, these methods often fail to accurately simulate the complex interplay of mechanical forces, biological activity, and chemical stressors present in actual marine environments.

Biofouling resistance testing presents particular challenges, with the ASTM D6990 and ISO 15105 standards providing frameworks for antifouling performance assessment. These must be adapted to evaluate how self-healing mechanisms interact with antifouling properties after damage events. Standardized biological test panels with representative marine organisms are being developed to ensure consistent evaluation across different coating systems.

Corrosion protection metrics require specialized electrochemical impedance spectroscopy (EIS) protocols to quantify a coating's ability to restore barrier properties after damage. The industry is moving toward standardized scratch-heal-test cycles with defined damage parameters, healing conditions, and performance thresholds.

Emerging testing approaches include digital imaging analysis for quantitative healing assessment and underwater robotics for in-situ monitoring of coating performance. These technologies promise more accurate evaluation of healing kinetics and efficiency under realistic conditions.

International collaboration between NACE International, European Federation of Corrosion, and Asian-Pacific Corrosion associations is currently underway to develop harmonized global standards specifically for self-healing marine coatings, with draft protocols expected within the next two years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!