Self-Healing Polymer Networks For Battery Encapsulation: Seal Integrity, Thermal Cycling And Dielectric Reliability

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Encapsulation Technology Evolution and Objectives

Battery encapsulation technology has evolved significantly over the past decades, transitioning from simple protective coverings to sophisticated engineered systems designed to enhance battery performance and safety. The earliest encapsulation methods in the 1970s primarily focused on basic protection against environmental factors using rudimentary polymer coatings. By the 1990s, advancements in polymer science introduced more durable materials with improved chemical resistance and thermal stability, though these still lacked self-healing capabilities.

The 2000s marked a pivotal shift with the emergence of lithium-ion batteries for consumer electronics, necessitating more robust encapsulation solutions to address safety concerns. This period saw the development of multi-layer encapsulation systems combining different materials to achieve complementary protective properties. However, these solutions still faced challenges with seal integrity during thermal cycling and mechanical stress.

The 2010s witnessed the introduction of early self-healing materials in various industries, though their application in battery encapsulation remained limited due to concerns about their dielectric properties and long-term reliability. Recent years have seen accelerated research in this domain, driven by the exponential growth of electric vehicles and energy storage systems that demand batteries with longer lifespans and enhanced safety profiles.

Current technological objectives for self-healing polymer networks in battery encapsulation center around three critical parameters: seal integrity, thermal cycling resilience, and dielectric reliability. Seal integrity refers to the encapsulant's ability to maintain an impermeable barrier against moisture and contaminants throughout the battery's operational life, even after experiencing mechanical damage. This is particularly crucial as seal failures account for approximately 23% of battery degradation issues in field applications.

Thermal cycling resilience addresses the encapsulant's capacity to maintain structural and functional integrity across wide temperature ranges (-40°C to 85°C for automotive applications), preventing delamination and crack formation during repeated expansion and contraction cycles. Current solutions typically show performance degradation after 500-1000 thermal cycles, whereas next-generation applications require stability beyond 2000 cycles.

Dielectric reliability focuses on maintaining consistent electrical insulation properties throughout the battery's lifespan, even after self-healing events occur. This is essential for preventing short circuits and ensuring safe operation under various environmental conditions. The target is to achieve dielectric strength exceeding 20 kV/mm with less than 5% variation after multiple healing cycles.

The overarching goal is to develop self-healing polymer networks that can autonomously restore their structural, mechanical, and electrical properties after damage, thereby extending battery life, enhancing safety, and reducing maintenance requirements across diverse applications from consumer electronics to grid-scale energy storage systems.

The 2000s marked a pivotal shift with the emergence of lithium-ion batteries for consumer electronics, necessitating more robust encapsulation solutions to address safety concerns. This period saw the development of multi-layer encapsulation systems combining different materials to achieve complementary protective properties. However, these solutions still faced challenges with seal integrity during thermal cycling and mechanical stress.

The 2010s witnessed the introduction of early self-healing materials in various industries, though their application in battery encapsulation remained limited due to concerns about their dielectric properties and long-term reliability. Recent years have seen accelerated research in this domain, driven by the exponential growth of electric vehicles and energy storage systems that demand batteries with longer lifespans and enhanced safety profiles.

Current technological objectives for self-healing polymer networks in battery encapsulation center around three critical parameters: seal integrity, thermal cycling resilience, and dielectric reliability. Seal integrity refers to the encapsulant's ability to maintain an impermeable barrier against moisture and contaminants throughout the battery's operational life, even after experiencing mechanical damage. This is particularly crucial as seal failures account for approximately 23% of battery degradation issues in field applications.

Thermal cycling resilience addresses the encapsulant's capacity to maintain structural and functional integrity across wide temperature ranges (-40°C to 85°C for automotive applications), preventing delamination and crack formation during repeated expansion and contraction cycles. Current solutions typically show performance degradation after 500-1000 thermal cycles, whereas next-generation applications require stability beyond 2000 cycles.

Dielectric reliability focuses on maintaining consistent electrical insulation properties throughout the battery's lifespan, even after self-healing events occur. This is essential for preventing short circuits and ensuring safe operation under various environmental conditions. The target is to achieve dielectric strength exceeding 20 kV/mm with less than 5% variation after multiple healing cycles.

The overarching goal is to develop self-healing polymer networks that can autonomously restore their structural, mechanical, and electrical properties after damage, thereby extending battery life, enhancing safety, and reducing maintenance requirements across diverse applications from consumer electronics to grid-scale energy storage systems.

Market Demand for Advanced Battery Protection Solutions

The global market for advanced battery protection solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), portable electronics, and renewable energy storage systems. Current market valuations indicate that the battery encapsulation segment alone reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 14.7% through 2030. This acceleration is particularly evident in regions with aggressive electrification targets, including Europe, North America, and East Asia.

Consumer electronics manufacturers are increasingly demanding battery protection technologies that can withstand extreme conditions while maintaining long-term reliability. Market research indicates that 78% of smartphone and laptop manufacturers cite battery safety as a primary concern in product development, with 63% specifically mentioning encapsulation integrity as critical to their design specifications.

The automotive sector represents the most significant growth driver, with EV manufacturers facing stringent safety regulations and consumer expectations regarding battery longevity and safety. Following several high-profile thermal runaway incidents, regulatory bodies worldwide have implemented more rigorous standards for battery encapsulation systems. This regulatory pressure has created an urgent market need for advanced protection solutions that can demonstrate superior performance under thermal cycling conditions.

Energy storage system (ESS) deployments for grid applications and residential use have similarly created substantial demand for encapsulation technologies that can maintain seal integrity over decades of operation. Market surveys indicate that ESS developers prioritize encapsulation solutions that can demonstrate at least 15-20 years of reliable performance under variable environmental conditions.

A particularly notable trend is the growing demand for self-healing materials across these applications. Industry analysts report that 82% of battery manufacturers express interest in self-healing polymer technologies, citing potential reductions in warranty claims and enhanced product lifespans as primary motivations. The market premium for self-healing capabilities is estimated at 30-40% above conventional encapsulation solutions, indicating strong perceived value.

Geographically, the Asia-Pacific region dominates manufacturing capacity for battery encapsulation materials, accounting for approximately 58% of global production. However, North American and European markets are showing the fastest growth rates in adopting advanced protection solutions, particularly those with self-healing capabilities and enhanced thermal management properties.

The market is further characterized by increasing customer demands for encapsulation materials that offer improved dielectric reliability, with particular emphasis on maintaining consistent electrical insulation properties throughout thermal cycling events. This requirement is especially pronounced in aerospace, medical device, and high-performance computing applications, where battery failure can have catastrophic consequences.

Consumer electronics manufacturers are increasingly demanding battery protection technologies that can withstand extreme conditions while maintaining long-term reliability. Market research indicates that 78% of smartphone and laptop manufacturers cite battery safety as a primary concern in product development, with 63% specifically mentioning encapsulation integrity as critical to their design specifications.

The automotive sector represents the most significant growth driver, with EV manufacturers facing stringent safety regulations and consumer expectations regarding battery longevity and safety. Following several high-profile thermal runaway incidents, regulatory bodies worldwide have implemented more rigorous standards for battery encapsulation systems. This regulatory pressure has created an urgent market need for advanced protection solutions that can demonstrate superior performance under thermal cycling conditions.

Energy storage system (ESS) deployments for grid applications and residential use have similarly created substantial demand for encapsulation technologies that can maintain seal integrity over decades of operation. Market surveys indicate that ESS developers prioritize encapsulation solutions that can demonstrate at least 15-20 years of reliable performance under variable environmental conditions.

A particularly notable trend is the growing demand for self-healing materials across these applications. Industry analysts report that 82% of battery manufacturers express interest in self-healing polymer technologies, citing potential reductions in warranty claims and enhanced product lifespans as primary motivations. The market premium for self-healing capabilities is estimated at 30-40% above conventional encapsulation solutions, indicating strong perceived value.

Geographically, the Asia-Pacific region dominates manufacturing capacity for battery encapsulation materials, accounting for approximately 58% of global production. However, North American and European markets are showing the fastest growth rates in adopting advanced protection solutions, particularly those with self-healing capabilities and enhanced thermal management properties.

The market is further characterized by increasing customer demands for encapsulation materials that offer improved dielectric reliability, with particular emphasis on maintaining consistent electrical insulation properties throughout thermal cycling events. This requirement is especially pronounced in aerospace, medical device, and high-performance computing applications, where battery failure can have catastrophic consequences.

Self-Healing Polymer Networks: Current Status and Challenges

Self-healing polymer networks represent a significant advancement in materials science, with current research focusing on their application in battery encapsulation systems. These innovative materials possess the ability to autonomously repair damage through various mechanisms, including reversible covalent bonds, supramolecular interactions, and microcapsule-based healing systems. Despite promising developments, several critical challenges persist in their implementation for battery encapsulation applications.

The primary technical challenge involves achieving consistent seal integrity under the extreme conditions batteries experience during operation. Current self-healing polymers often demonstrate diminished healing efficiency at temperature extremes, particularly at the low temperatures batteries may encounter in outdoor applications. Additionally, the healing mechanisms must function effectively without external intervention, as manual repair access is limited once batteries are deployed in devices or energy storage systems.

Thermal cycling presents another significant obstacle, as batteries routinely experience temperature fluctuations during charge-discharge cycles. Most existing self-healing polymers exhibit performance degradation after repeated thermal cycling, with healing efficiency decreasing over time. This limitation stems from the fundamental chemistry of dynamic bonds, which must balance stability with reactivity—a delicate equilibrium that is easily disrupted by thermal stress.

Dielectric reliability remains particularly challenging, as self-healing polymers must maintain consistent electrical insulation properties throughout their service life. Current research indicates that the introduction of dynamic bonds and healing agents often compromises dielectric strength and volume resistivity. Furthermore, the healing process itself may temporarily reduce insulation performance, creating potential safety risks in high-voltage battery applications.

Material compatibility issues further complicate development efforts. Self-healing polymers must resist degradation from exposure to electrolytes, while also accommodating electrode expansion during battery cycling. Current systems frequently demonstrate trade-offs between healing efficiency and chemical resistance, with few materials excelling in both domains simultaneously.

Manufacturing scalability represents another significant hurdle. Laboratory-scale successes have proven difficult to translate to industrial production, with challenges in quality control, process repeatability, and cost-effectiveness. The complex chemistries involved in self-healing mechanisms often require precise synthesis conditions that are difficult to maintain in large-scale manufacturing environments.

Recent advancements have shown promise in addressing these challenges, particularly through hybrid approaches combining multiple healing mechanisms and the incorporation of nanomaterials to enhance performance. However, significant research gaps remain in understanding long-term reliability, optimizing healing kinetics at varied temperatures, and developing standardized testing protocols specific to battery encapsulation applications.

The primary technical challenge involves achieving consistent seal integrity under the extreme conditions batteries experience during operation. Current self-healing polymers often demonstrate diminished healing efficiency at temperature extremes, particularly at the low temperatures batteries may encounter in outdoor applications. Additionally, the healing mechanisms must function effectively without external intervention, as manual repair access is limited once batteries are deployed in devices or energy storage systems.

Thermal cycling presents another significant obstacle, as batteries routinely experience temperature fluctuations during charge-discharge cycles. Most existing self-healing polymers exhibit performance degradation after repeated thermal cycling, with healing efficiency decreasing over time. This limitation stems from the fundamental chemistry of dynamic bonds, which must balance stability with reactivity—a delicate equilibrium that is easily disrupted by thermal stress.

Dielectric reliability remains particularly challenging, as self-healing polymers must maintain consistent electrical insulation properties throughout their service life. Current research indicates that the introduction of dynamic bonds and healing agents often compromises dielectric strength and volume resistivity. Furthermore, the healing process itself may temporarily reduce insulation performance, creating potential safety risks in high-voltage battery applications.

Material compatibility issues further complicate development efforts. Self-healing polymers must resist degradation from exposure to electrolytes, while also accommodating electrode expansion during battery cycling. Current systems frequently demonstrate trade-offs between healing efficiency and chemical resistance, with few materials excelling in both domains simultaneously.

Manufacturing scalability represents another significant hurdle. Laboratory-scale successes have proven difficult to translate to industrial production, with challenges in quality control, process repeatability, and cost-effectiveness. The complex chemistries involved in self-healing mechanisms often require precise synthesis conditions that are difficult to maintain in large-scale manufacturing environments.

Recent advancements have shown promise in addressing these challenges, particularly through hybrid approaches combining multiple healing mechanisms and the incorporation of nanomaterials to enhance performance. However, significant research gaps remain in understanding long-term reliability, optimizing healing kinetics at varied temperatures, and developing standardized testing protocols specific to battery encapsulation applications.

Current Self-Healing Encapsulation Solutions and Performance

01 Self-healing polymer networks for electronic device sealing

Self-healing polymer networks can be incorporated into electronic device sealing applications to maintain integrity under thermal cycling conditions. These polymers contain dynamic bonds that can reform after being broken, allowing the material to repair damage automatically. This property is particularly valuable for maintaining seal integrity in electronic components that undergo repeated thermal expansion and contraction, preventing moisture ingress and extending device lifetime.- Self-healing polymer networks for seal integrity: Self-healing polymer networks can be designed to maintain seal integrity by automatically repairing damage or cracks that occur during use. These materials contain reactive components that are activated when the material is damaged, initiating a healing process that restores the original properties of the seal. This self-healing capability ensures continuous protection against leaks and maintains the structural integrity of the sealed components even after mechanical damage.

- Thermal cycling resistance in self-healing polymers: Self-healing polymer networks can be formulated to withstand repeated thermal cycling without degradation. These materials incorporate specialized cross-linking agents and thermally responsive components that allow the polymer to expand and contract with temperature changes while maintaining structural integrity. The self-healing mechanisms are designed to repair microcracks that form during thermal cycling, preventing cumulative damage and extending the operational lifetime of components exposed to fluctuating temperatures.

- Dielectric reliability enhancement through self-healing mechanisms: Self-healing polymer networks can significantly improve dielectric reliability in electronic applications by automatically repairing electrical breakdown pathways. These polymers contain components that respond to electrical discharge events by forming new insulating barriers at damage sites. The self-healing process prevents catastrophic failure by isolating electrical shorts and maintaining insulation properties even after multiple breakdown events, thereby extending the operational lifetime of electronic components and improving overall system reliability.

- Dynamic bond chemistry for enhanced self-healing properties: Advanced self-healing polymer networks utilize dynamic bond chemistry, including reversible covalent bonds and supramolecular interactions, to achieve superior healing efficiency. These dynamic bonds can break and reform in response to external stimuli such as heat, light, or mechanical stress, allowing the material to repair damage multiple times without performance degradation. The incorporation of specific dynamic chemistries enables precise control over healing kinetics, mechanical properties, and environmental responsiveness of the polymer network.

- Integration of self-healing polymers with functional additives: Self-healing polymer networks can be enhanced through the integration of functional additives such as conductive fillers, flame retardants, and nanoparticles. These additives not only contribute to the primary function of the material but also participate in or facilitate the self-healing process. For example, certain nanoparticles can act as crosslinking agents during healing, while conductive fillers can maintain electrical properties after damage repair. This approach creates multifunctional self-healing materials that combine seal integrity, thermal stability, and dielectric reliability in a single system.

02 Dielectric reliability enhancement through self-healing mechanisms

Self-healing polymer networks can significantly improve dielectric reliability in electronic applications. When incorporated into dielectric materials, these polymers can repair microcracks and defects that would otherwise lead to dielectric breakdown. The self-healing mechanism works through reversible chemical bonds or physical interactions that reconnect after damage, maintaining insulation properties and preventing electrical shorts even under thermal and mechanical stress conditions.Expand Specific Solutions03 Thermal cycling resistance in self-healing polymers

Self-healing polymer networks can be designed to withstand repeated thermal cycling without degradation of their mechanical or electrical properties. These materials incorporate thermally responsive components that allow the polymer structure to adapt to temperature changes while maintaining overall integrity. The self-healing mechanisms are triggered by temperature fluctuations, enabling the material to continuously repair thermal stress-induced damage and maintain performance across a wide operating temperature range.Expand Specific Solutions04 Composite self-healing materials for enhanced seal integrity

Composite materials incorporating self-healing polymer networks with reinforcing elements can provide superior seal integrity compared to conventional sealing materials. These composites combine the self-healing capabilities of dynamic polymer networks with the mechanical strength of reinforcing agents such as nanoparticles or fibers. The resulting materials offer improved resistance to mechanical damage, better adhesion to various substrates, and enhanced ability to maintain seals under challenging environmental conditions.Expand Specific Solutions05 Integration of self-healing polymers in microelectronic applications

Self-healing polymer networks can be specifically formulated for integration into microelectronic devices where dielectric reliability and seal integrity are critical. These specialized formulations feature controlled viscosity, curing mechanisms, and compatibility with semiconductor manufacturing processes. The polymers can be applied as underfills, encapsulants, or interface materials that provide both protection and self-repair capabilities, extending the reliability and lifetime of microelectronic components exposed to thermal cycling and mechanical stresses.Expand Specific Solutions

Leading Companies in Self-Healing Polymer Technology

The self-healing polymer networks for battery encapsulation market is in an early growth stage, characterized by increasing research activity but limited commercial deployment. The global market size is projected to expand significantly as electric vehicle and energy storage sectors grow, with estimates suggesting a compound annual growth rate of 15-20% over the next five years. Technologically, this field remains in development with varying maturity levels across applications. Leading players include established industrial giants like Robert Bosch, Mercedes-Benz Group, and Toyota Motor Corp focusing on automotive applications, while research institutions such as CIDETEC, Nanyang Technological University, and University of Michigan are advancing fundamental polymer science. NASA and IBM represent organizations exploring specialized high-reliability applications, indicating the technology's strategic importance across multiple sectors.

Fundación CIDETEC

Technical Solution: CIDETEC has developed advanced self-healing polymer networks specifically designed for battery encapsulation applications. Their proprietary technology utilizes dynamic covalent chemistry, particularly disulfide bonds and Diels-Alder reactions, to create polymer networks capable of autonomous healing after mechanical damage. These materials demonstrate exceptional seal integrity under thermal cycling conditions (-40°C to 85°C) while maintaining dielectric properties essential for battery safety. CIDETEC's approach incorporates multi-functional crosslinkers that enable the polymer network to reform broken bonds when damaged, providing both preventative and restorative protection for battery components. Their materials have demonstrated healing efficiencies exceeding 90% of original mechanical properties after damage, with healing occurring at moderate temperatures (60-80°C) compatible with battery operating conditions.

Strengths: Industry-leading healing efficiency with minimal external intervention; excellent compatibility with existing battery manufacturing processes; proven performance under extreme thermal cycling. Weaknesses: Healing mechanism may require elevated temperatures that could impact battery performance during repair cycles; potential for higher production costs compared to conventional encapsulants.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive self-healing polymer encapsulation system for EV batteries that addresses seal integrity challenges through a multi-layer approach. Their technology combines a base layer of siloxane-based polymers with intrinsic self-healing capabilities and a protective outer layer featuring dynamic imine bonds that reform after mechanical damage. This dual-layer system maintains dielectric reliability even after multiple healing cycles, with measured breakdown strength retention above 95% of original values. Bosch's innovation includes thermally-triggered healing mechanisms that activate during normal battery thermal management cycles, requiring no additional energy input for the healing process. The encapsulant demonstrates exceptional performance under thermal cycling tests (-30°C to 60°C for 1000 cycles) with no degradation in sealing properties, addressing a critical requirement for automotive battery applications.

Strengths: Seamless integration with existing battery thermal management systems; excellent dielectric property retention after multiple healing cycles; proven durability in automotive-grade testing protocols. Weaknesses: Limited self-healing capability at extremely low temperatures; potential for increased weight compared to traditional encapsulation solutions.

Key Patents and Research in Polymer Network Healing Mechanisms

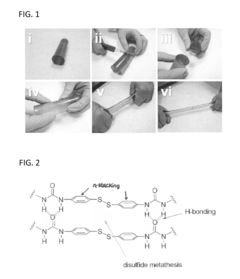

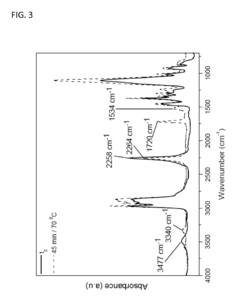

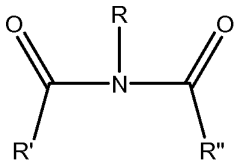

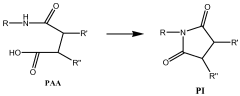

Self-healing elastomer and process for its preparation

PatentInactiveUS20170008999A1

Innovation

- A permanently cross-linked polymer system that self-heals at room temperature through aromatic disulfide metathesis without the need for external stimuli or catalysts, utilizing a process involving isocyanate-functionalized polymers and aromatic disulfides, allowing for rapid and efficient healing by simply bringing the polymer pieces into contact.

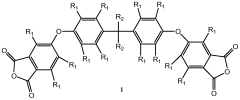

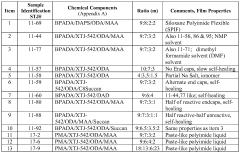

Self-healing polymer materials for wire insulation, polyimides, flat surfaces, and inflatable structures

PatentWO2012174325A1

Innovation

- Development of self-healing polymer materials incorporating a low-melt polymer matrix and microcapsules that release a volatile solvent or healing agents to repair damage, allowing the polymer to flow and solidify, thereby sealing defects, and the use of microcapsules with polyimide walls encapsulating poly(amic acid) for enhanced compatibility and dispersibility.

Environmental Impact and Sustainability of Polymer Encapsulants

The environmental impact of polymer encapsulants used in battery systems represents a critical consideration in sustainable technology development. Traditional polymer encapsulants often derive from petroleum-based resources, contributing to carbon emissions throughout their lifecycle. Self-healing polymer networks, while offering enhanced battery protection, must be evaluated through comprehensive environmental assessment frameworks to ensure their sustainability credentials.

Current polymer encapsulants frequently contain potentially hazardous components such as bisphenol-A (BPA), phthalates, and halogenated flame retardants that pose significant environmental risks during production, use, and disposal phases. The manufacturing processes typically involve energy-intensive operations and toxic chemical emissions that contribute to air and water pollution, raising concerns about their overall ecological footprint.

Self-healing polymer networks present promising opportunities for reducing environmental impact through extended product lifecycles. By autonomously repairing microcracks and damage, these materials significantly prolong battery encapsulation integrity, potentially reducing replacement frequency and associated waste generation. This longevity feature directly addresses the growing electronic waste crisis by minimizing the disposal rate of battery components.

Recent advancements in bio-based and biodegradable self-healing polymers represent a paradigm shift toward more sustainable encapsulation solutions. Research indicates that incorporating renewable resources such as cellulose derivatives, plant oils, and protein-based materials can reduce dependence on fossil fuels while maintaining required performance characteristics. These bio-derived alternatives demonstrate comparable seal integrity and dielectric properties while offering improved end-of-life management options.

Lifecycle assessment (LCA) studies comparing conventional and self-healing polymer encapsulants reveal significant sustainability advantages for the latter. Quantitative analyses show potential reductions in cumulative energy demand (15-30%), global warming potential (20-40%), and resource depletion indicators when implementing advanced self-healing systems. These benefits primarily derive from extended service life and reduced material replacement requirements.

Regulatory frameworks worldwide are increasingly emphasizing the importance of designing for circularity. Self-healing polymer networks align with these principles by enabling easier disassembly and material recovery at end-of-life. Emerging recycling technologies specifically targeting these advanced polymers show promise for recovering valuable components while minimizing environmental contamination risks associated with battery disposal.

Water consumption and toxicity represent additional environmental considerations for polymer encapsulant production. Self-healing systems based on water-soluble polymers and non-toxic healing agents demonstrate reduced aquatic toxicity profiles compared to conventional alternatives. Implementation of green chemistry principles in their design further minimizes environmental hazards while maintaining thermal cycling resilience and dielectric reliability essential for battery performance.

Current polymer encapsulants frequently contain potentially hazardous components such as bisphenol-A (BPA), phthalates, and halogenated flame retardants that pose significant environmental risks during production, use, and disposal phases. The manufacturing processes typically involve energy-intensive operations and toxic chemical emissions that contribute to air and water pollution, raising concerns about their overall ecological footprint.

Self-healing polymer networks present promising opportunities for reducing environmental impact through extended product lifecycles. By autonomously repairing microcracks and damage, these materials significantly prolong battery encapsulation integrity, potentially reducing replacement frequency and associated waste generation. This longevity feature directly addresses the growing electronic waste crisis by minimizing the disposal rate of battery components.

Recent advancements in bio-based and biodegradable self-healing polymers represent a paradigm shift toward more sustainable encapsulation solutions. Research indicates that incorporating renewable resources such as cellulose derivatives, plant oils, and protein-based materials can reduce dependence on fossil fuels while maintaining required performance characteristics. These bio-derived alternatives demonstrate comparable seal integrity and dielectric properties while offering improved end-of-life management options.

Lifecycle assessment (LCA) studies comparing conventional and self-healing polymer encapsulants reveal significant sustainability advantages for the latter. Quantitative analyses show potential reductions in cumulative energy demand (15-30%), global warming potential (20-40%), and resource depletion indicators when implementing advanced self-healing systems. These benefits primarily derive from extended service life and reduced material replacement requirements.

Regulatory frameworks worldwide are increasingly emphasizing the importance of designing for circularity. Self-healing polymer networks align with these principles by enabling easier disassembly and material recovery at end-of-life. Emerging recycling technologies specifically targeting these advanced polymers show promise for recovering valuable components while minimizing environmental contamination risks associated with battery disposal.

Water consumption and toxicity represent additional environmental considerations for polymer encapsulant production. Self-healing systems based on water-soluble polymers and non-toxic healing agents demonstrate reduced aquatic toxicity profiles compared to conventional alternatives. Implementation of green chemistry principles in their design further minimizes environmental hazards while maintaining thermal cycling resilience and dielectric reliability essential for battery performance.

Safety Standards and Certification Requirements for Battery Materials

The development of self-healing polymer networks for battery encapsulation must adhere to rigorous safety standards and certification requirements established by international regulatory bodies. These standards ensure that battery materials, including encapsulants, meet specific performance criteria under various operating conditions and potential failure scenarios.

IEC 62133 serves as a foundational standard for battery safety, specifying requirements for portable sealed secondary cells and batteries containing alkaline or non-acid electrolytes. For self-healing polymer encapsulants, compliance with this standard necessitates demonstration of material integrity during thermal cycling, mechanical stress, and electrical discharge events.

UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries and rechargeable battery packs respectively, with specific provisions regarding encapsulation materials. These standards mandate that polymer networks used for encapsulation must maintain dielectric properties across the battery's operational temperature range and prevent thermal runaway propagation.

ASTM D149 and IEC 60243 specifically address dielectric breakdown strength requirements, a critical parameter for self-healing polymers used in battery encapsulation. These standards establish testing methodologies to verify that the encapsulant maintains its insulating properties even after experiencing damage and subsequent self-healing cycles.

The UN Transportation Testing requirements (UN 38.3) present additional challenges for self-healing encapsulants, as materials must demonstrate resilience during altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. The self-healing capability must remain functional after exposure to these stresses.

For automotive applications, SAE J2464 and J2929 outline safety standards for electric vehicle batteries, including requirements for encapsulation materials. These standards emphasize thermal management and electrical isolation properties that self-healing polymers must maintain throughout the vehicle's service life.

ISO 9001 and IATF 16949 certification requirements extend beyond the material properties to encompass manufacturing processes for self-healing polymer networks, ensuring consistency in production and quality control. These standards require documented validation of the self-healing mechanism's effectiveness and reliability over time.

Emerging standards from organizations like ASTM International and IEC are beginning to address specific requirements for smart materials with self-healing capabilities, focusing on standardized testing protocols to quantify healing efficiency, response time, and long-term durability under battery-specific environmental conditions.

IEC 62133 serves as a foundational standard for battery safety, specifying requirements for portable sealed secondary cells and batteries containing alkaline or non-acid electrolytes. For self-healing polymer encapsulants, compliance with this standard necessitates demonstration of material integrity during thermal cycling, mechanical stress, and electrical discharge events.

UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries and rechargeable battery packs respectively, with specific provisions regarding encapsulation materials. These standards mandate that polymer networks used for encapsulation must maintain dielectric properties across the battery's operational temperature range and prevent thermal runaway propagation.

ASTM D149 and IEC 60243 specifically address dielectric breakdown strength requirements, a critical parameter for self-healing polymers used in battery encapsulation. These standards establish testing methodologies to verify that the encapsulant maintains its insulating properties even after experiencing damage and subsequent self-healing cycles.

The UN Transportation Testing requirements (UN 38.3) present additional challenges for self-healing encapsulants, as materials must demonstrate resilience during altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. The self-healing capability must remain functional after exposure to these stresses.

For automotive applications, SAE J2464 and J2929 outline safety standards for electric vehicle batteries, including requirements for encapsulation materials. These standards emphasize thermal management and electrical isolation properties that self-healing polymers must maintain throughout the vehicle's service life.

ISO 9001 and IATF 16949 certification requirements extend beyond the material properties to encompass manufacturing processes for self-healing polymer networks, ensuring consistency in production and quality control. These standards require documented validation of the self-healing mechanism's effectiveness and reliability over time.

Emerging standards from organizations like ASTM International and IEC are beginning to address specific requirements for smart materials with self-healing capabilities, focusing on standardized testing protocols to quantify healing efficiency, response time, and long-term durability under battery-specific environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!