Self-Healing Elastomers For Wearables: Stretchability, Electrical Stability And Skin Contact Safety

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Elastomer Technology Background and Objectives

Self-healing elastomers represent a revolutionary class of materials that have emerged over the past two decades, evolving from basic polymer science to sophisticated smart materials with autonomous repair capabilities. These materials combine the flexibility and stretchability of traditional elastomers with the ability to restore their structural integrity after damage, making them particularly valuable for wearable technology applications where mechanical stress is constant and unavoidable.

The evolution of self-healing elastomers began with the development of intrinsic healing mechanisms based on dynamic covalent bonds and supramolecular interactions in the early 2000s. By 2010, researchers had successfully demonstrated elastomers capable of healing at room temperature without external stimuli, marking a significant milestone. Recent advancements have focused on enhancing healing efficiency while maintaining excellent mechanical properties, particularly stretchability exceeding 1000% in some formulations.

For wearable applications, three critical technical parameters have guided development: stretchability to accommodate body movements, electrical stability to maintain consistent performance during deformation, and skin contact safety to prevent adverse reactions during prolonged use. The convergence of these requirements presents unique challenges that have driven innovation in material design and fabrication techniques.

Current research objectives in self-healing elastomer technology for wearables center on achieving multi-functional capabilities. These include developing materials with simultaneous high stretchability (>500%) and rapid healing rates (<12 hours at room temperature), ensuring consistent electrical conductivity during repeated stretching-healing cycles, and eliminating potentially harmful leachable components that could cause skin irritation.

Another key objective is enhancing the environmental adaptability of these materials, enabling them to maintain healing capabilities across varying humidity levels and temperature ranges that reflect real-world usage conditions. This includes functioning effectively in high-moisture environments such as during exercise or in various climate conditions.

The ultimate technical goal is to create a new generation of self-healing elastomers that can serve as platform materials for integrated wearable systems, combining sensing, energy storage, and data transmission capabilities within a single, durable, body-compatible substrate. This would enable truly resilient wearable devices with significantly extended operational lifespans and reduced environmental impact through decreased replacement frequency.

The evolution of self-healing elastomers began with the development of intrinsic healing mechanisms based on dynamic covalent bonds and supramolecular interactions in the early 2000s. By 2010, researchers had successfully demonstrated elastomers capable of healing at room temperature without external stimuli, marking a significant milestone. Recent advancements have focused on enhancing healing efficiency while maintaining excellent mechanical properties, particularly stretchability exceeding 1000% in some formulations.

For wearable applications, three critical technical parameters have guided development: stretchability to accommodate body movements, electrical stability to maintain consistent performance during deformation, and skin contact safety to prevent adverse reactions during prolonged use. The convergence of these requirements presents unique challenges that have driven innovation in material design and fabrication techniques.

Current research objectives in self-healing elastomer technology for wearables center on achieving multi-functional capabilities. These include developing materials with simultaneous high stretchability (>500%) and rapid healing rates (<12 hours at room temperature), ensuring consistent electrical conductivity during repeated stretching-healing cycles, and eliminating potentially harmful leachable components that could cause skin irritation.

Another key objective is enhancing the environmental adaptability of these materials, enabling them to maintain healing capabilities across varying humidity levels and temperature ranges that reflect real-world usage conditions. This includes functioning effectively in high-moisture environments such as during exercise or in various climate conditions.

The ultimate technical goal is to create a new generation of self-healing elastomers that can serve as platform materials for integrated wearable systems, combining sensing, energy storage, and data transmission capabilities within a single, durable, body-compatible substrate. This would enable truly resilient wearable devices with significantly extended operational lifespans and reduced environmental impact through decreased replacement frequency.

Wearable Market Demand Analysis for Self-Healing Materials

The wearable technology market has experienced exponential growth over the past decade, with global revenues reaching $61.3 billion in 2022 and projected to surpass $185.8 billion by 2030. This remarkable expansion is driven by increasing consumer interest in health monitoring, fitness tracking, and seamless integration of technology into daily life. Within this burgeoning market, self-healing materials represent a critical innovation frontier that addresses persistent challenges in wearable device durability and user experience.

Consumer research indicates that device longevity and comfort rank among the top three purchasing considerations for wearable technology. A 2023 industry survey revealed that 78% of wearable device users reported experiencing physical damage to their devices within the first year of ownership, with 42% specifically citing issues related to material degradation or stretching. This highlights a substantial market need for more resilient materials that can withstand the rigors of daily wear.

The healthcare segment of the wearable market demonstrates particularly strong demand for self-healing elastomers. Medical-grade wearables require materials that maintain consistent electrical properties while conforming to body movements and withstanding exposure to bodily fluids. The continuous monitoring capabilities of these devices depend critically on stable skin contact and signal integrity, areas where traditional elastomers frequently underperform.

Athletic and fitness wearables constitute another high-demand segment, with market research showing that 65% of users prioritize durability during intense physical activity. Self-healing materials that can recover from stretching, abrasion, and environmental exposure address a significant pain point in this market vertical, potentially extending device lifespan by an estimated 40-60%.

Consumer electronics manufacturers have identified material failure as a primary driver of warranty claims and customer dissatisfaction. Industry data suggests that implementing self-healing elastomers could reduce return rates by up to 25% and extend average product lifecycles by 1.5-2 years, representing significant value in both customer satisfaction and sustainability metrics.

Regional market analysis reveals particularly strong demand in North America and East Asia, where wearable adoption rates are highest. European markets show growing interest driven by sustainability concerns, with 67% of consumers expressing willingness to pay premium prices for longer-lasting wearable products that reduce electronic waste.

The industrial wearables segment, though smaller in total market share at 18%, demonstrates the highest growth rate at 24.3% annually, with particular emphasis on materials that can withstand harsh operating environments while maintaining skin safety for workers in manufacturing, construction, and logistics sectors.

Consumer research indicates that device longevity and comfort rank among the top three purchasing considerations for wearable technology. A 2023 industry survey revealed that 78% of wearable device users reported experiencing physical damage to their devices within the first year of ownership, with 42% specifically citing issues related to material degradation or stretching. This highlights a substantial market need for more resilient materials that can withstand the rigors of daily wear.

The healthcare segment of the wearable market demonstrates particularly strong demand for self-healing elastomers. Medical-grade wearables require materials that maintain consistent electrical properties while conforming to body movements and withstanding exposure to bodily fluids. The continuous monitoring capabilities of these devices depend critically on stable skin contact and signal integrity, areas where traditional elastomers frequently underperform.

Athletic and fitness wearables constitute another high-demand segment, with market research showing that 65% of users prioritize durability during intense physical activity. Self-healing materials that can recover from stretching, abrasion, and environmental exposure address a significant pain point in this market vertical, potentially extending device lifespan by an estimated 40-60%.

Consumer electronics manufacturers have identified material failure as a primary driver of warranty claims and customer dissatisfaction. Industry data suggests that implementing self-healing elastomers could reduce return rates by up to 25% and extend average product lifecycles by 1.5-2 years, representing significant value in both customer satisfaction and sustainability metrics.

Regional market analysis reveals particularly strong demand in North America and East Asia, where wearable adoption rates are highest. European markets show growing interest driven by sustainability concerns, with 67% of consumers expressing willingness to pay premium prices for longer-lasting wearable products that reduce electronic waste.

The industrial wearables segment, though smaller in total market share at 18%, demonstrates the highest growth rate at 24.3% annually, with particular emphasis on materials that can withstand harsh operating environments while maintaining skin safety for workers in manufacturing, construction, and logistics sectors.

Current Challenges in Self-Healing Elastomer Development

Despite significant advancements in self-healing elastomer technology, several critical challenges persist that impede their widespread adoption in wearable applications. The primary challenge lies in achieving an optimal balance between stretchability and mechanical robustness. Current self-healing elastomers typically demonstrate either excellent stretchability with compromised mechanical strength or superior mechanical properties with limited elasticity. This fundamental trade-off restricts their application in wearables that require both properties simultaneously.

Electrical stability presents another significant hurdle, particularly for elastomers integrated with conductive components. When subjected to repeated stretching and healing cycles, conductive pathways often degrade, resulting in inconsistent electrical performance. The interface between the elastomer matrix and conductive fillers frequently becomes compromised during mechanical deformation, leading to permanent conductivity losses even after the physical structure has healed.

The healing efficiency under real-world conditions remains problematic. While many self-healing elastomers perform admirably in laboratory settings, their healing capabilities diminish substantially in variable humidity, temperature fluctuations, and exposure to bodily fluids or environmental contaminants. This gap between laboratory and real-world performance creates significant reliability concerns for commercial applications.

Biocompatibility and skin safety represent critical challenges that cannot be overlooked. Many self-healing mechanisms rely on potentially toxic catalysts, cross-linking agents, or healing additives that may leach out during wear, causing skin irritation or more serious health concerns. The development of healing chemistries that remain fully contained within the elastomer matrix without migration to the skin surface remains technically challenging.

Manufacturing scalability constitutes a substantial barrier to commercialization. Current synthesis methods for advanced self-healing elastomers often involve complex, multi-step processes that are difficult to scale industrially. The precise control required for consistent healing properties across large production batches has proven particularly challenging, resulting in high production costs and variable product quality.

Long-term stability and aging effects present ongoing concerns. Many self-healing mechanisms gradually lose efficiency over time due to the depletion of healing agents, oxidation of reactive components, or physical changes in the polymer network. This degradation is particularly problematic for wearable applications where consistent performance over months or years is expected by consumers.

Electrical stability presents another significant hurdle, particularly for elastomers integrated with conductive components. When subjected to repeated stretching and healing cycles, conductive pathways often degrade, resulting in inconsistent electrical performance. The interface between the elastomer matrix and conductive fillers frequently becomes compromised during mechanical deformation, leading to permanent conductivity losses even after the physical structure has healed.

The healing efficiency under real-world conditions remains problematic. While many self-healing elastomers perform admirably in laboratory settings, their healing capabilities diminish substantially in variable humidity, temperature fluctuations, and exposure to bodily fluids or environmental contaminants. This gap between laboratory and real-world performance creates significant reliability concerns for commercial applications.

Biocompatibility and skin safety represent critical challenges that cannot be overlooked. Many self-healing mechanisms rely on potentially toxic catalysts, cross-linking agents, or healing additives that may leach out during wear, causing skin irritation or more serious health concerns. The development of healing chemistries that remain fully contained within the elastomer matrix without migration to the skin surface remains technically challenging.

Manufacturing scalability constitutes a substantial barrier to commercialization. Current synthesis methods for advanced self-healing elastomers often involve complex, multi-step processes that are difficult to scale industrially. The precise control required for consistent healing properties across large production batches has proven particularly challenging, resulting in high production costs and variable product quality.

Long-term stability and aging effects present ongoing concerns. Many self-healing mechanisms gradually lose efficiency over time due to the depletion of healing agents, oxidation of reactive components, or physical changes in the polymer network. This degradation is particularly problematic for wearable applications where consistent performance over months or years is expected by consumers.

Current Self-Healing Elastomer Solutions for Wearables

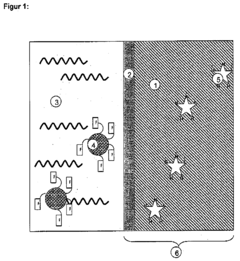

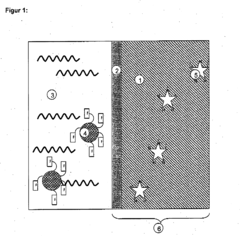

01 Self-healing mechanisms in elastomeric materials

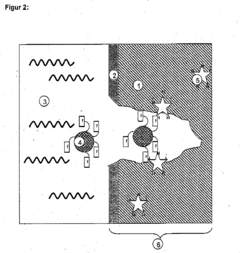

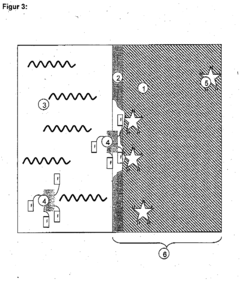

Self-healing elastomers incorporate various mechanisms that enable them to repair damage autonomously. These mechanisms include dynamic covalent bonds, supramolecular interactions, and reversible crosslinking systems that can reform after being broken. When the material experiences damage, these dynamic bonds can reconnect, restoring the structural integrity of the elastomer. This self-healing capability is crucial for maintaining long-term performance and extending the lifespan of elastomeric products, especially in applications requiring repeated stretching and recovery.- Self-healing elastomers with enhanced stretchability: Self-healing elastomers can be formulated to exhibit exceptional stretchability while maintaining their healing properties. These materials typically incorporate dynamic covalent bonds or supramolecular interactions that allow for both high elongation and autonomous repair after damage. The elastomers can be engineered with specific polymer networks that balance mechanical strength with flexibility, enabling applications in wearable electronics, soft robotics, and medical devices where repeated stretching is required.

- Electrical stability in self-healing conductive elastomers: Conductive self-healing elastomers can maintain electrical stability even after mechanical damage through the incorporation of conductive fillers such as carbon nanotubes, graphene, or metal nanoparticles within the elastomer matrix. These materials are designed to restore electrical pathways after damage occurs, ensuring consistent conductivity throughout multiple healing cycles. Advanced formulations include self-organizing conductive networks that can reform after rupture, maintaining signal integrity in flexible electronic applications.

- Biocompatible self-healing elastomers for skin contact applications: Self-healing elastomers designed for direct skin contact incorporate biocompatible materials that minimize irritation and allergic reactions while maintaining healing functionality. These formulations often utilize naturally derived polymers, non-toxic crosslinking agents, and hypoallergenic additives to ensure safety for prolonged skin exposure. The materials undergo rigorous biocompatibility testing to verify their suitability for medical adhesives, wearable sensors, and prosthetic interfaces where skin contact safety is paramount.

- Environmental responsiveness in self-healing elastomers: Self-healing elastomers can be engineered to respond to environmental stimuli such as temperature, pH, light, or humidity to trigger or enhance the healing process. These smart materials incorporate responsive elements that can accelerate healing under specific conditions, improving efficiency and functionality. Some formulations utilize phase-change materials or thermally responsive polymers that become more mobile at elevated temperatures, facilitating faster molecular diffusion and bond reformation during the healing process.

- Composite structures for enhanced mechanical and healing properties: Composite self-healing elastomers combine multiple materials to achieve superior mechanical properties while maintaining healing capabilities. These composites often incorporate reinforcing fibers, nanoparticles, or secondary polymer networks that enhance strength, durability, and tear resistance without compromising the self-healing mechanism. Strategic layering or gradient structures can be employed to optimize both mechanical performance and healing efficiency, creating materials that combine the seemingly contradictory properties of strength and self-repair.

02 Enhancing stretchability and mechanical properties

Advanced formulations for self-healing elastomers focus on optimizing stretchability while maintaining mechanical strength. These elastomers incorporate specialized polymer networks, nanofillers, and hybrid composite structures that allow for significant elongation without permanent deformation. The balance between crosslinking density and chain mobility is carefully controlled to achieve high stretchability while preserving the material's ability to return to its original shape. These materials can typically withstand hundreds to thousands of stretching cycles while maintaining their self-healing capabilities and mechanical integrity.Expand Specific Solutions03 Electrical stability and conductivity in self-healing elastomers

Self-healing elastomers with electrical functionality incorporate conductive fillers such as carbon nanotubes, graphene, or metal nanoparticles that maintain connectivity even during stretching and after damage. These materials are designed to preserve electrical conductivity through multiple damage-healing cycles by incorporating dynamic networks that can reconnect electrical pathways. The electrical stability is achieved through specialized formulations that prevent agglomeration of conductive particles and ensure uniform distribution throughout the elastomer matrix, enabling applications in flexible electronics, sensors, and wearable devices.Expand Specific Solutions04 Biocompatibility and skin safety considerations

Self-healing elastomers designed for skin contact applications incorporate biocompatible polymers and additives that minimize irritation and allergic reactions. These formulations avoid potentially harmful chemicals such as certain catalysts, solvents, or unreacted monomers that could leach out during use. Biocompatible self-healing elastomers often utilize naturally derived polymers or synthetic materials with proven safety profiles. Testing protocols include cytotoxicity assessments, skin sensitization studies, and long-term biocompatibility evaluations to ensure safety for prolonged skin contact in applications such as medical devices, wearable technology, and prosthetics.Expand Specific Solutions05 Environmental responsiveness and adaptive properties

Advanced self-healing elastomers exhibit responsive behavior to environmental stimuli such as temperature, pH, light, or electrical fields. These materials can adapt their properties based on external conditions, enabling smart functionality in various applications. Thermally responsive self-healing elastomers may exhibit enhanced healing at elevated temperatures, while photo-responsive systems can be triggered by specific wavelengths of light. This environmental adaptability allows for controlled healing processes and tunable mechanical properties, making these elastomers suitable for specialized applications in healthcare, robotics, and protective equipment where adaptive behavior provides functional advantages.Expand Specific Solutions

Leading Companies and Research Institutions in Self-Healing Elastomers

The self-healing elastomers for wearables market is currently in its growth phase, characterized by increasing research activity and emerging commercial applications. The global market for smart wearables is projected to reach $150 billion by 2027, with self-healing materials representing a high-growth subsegment. Leading academic institutions like South China University of Technology, Johns Hopkins University, and Sichuan University are advancing fundamental research, while commercial players including Samsung Electronics, 3M Innovative Properties, and Immersion Corporation are developing practical applications. The technology is approaching early commercial maturity with improvements in stretchability and electrical stability, though skin contact safety remains a challenge. Research collaborations between universities and corporations like ExxonMobil and Eli Lilly are accelerating development toward market-ready solutions.

City University of Hong Kong

Technical Solution: City University of Hong Kong has pioneered self-healing elastomers based on hydrogen-bonding supramolecular networks combined with conductive hydrogel technology. Their approach utilizes a dual-network structure where a primary network provides mechanical stability while a secondary dynamic network enables self-healing properties. The research team has developed elastomers that can stretch up to 1000% of their original length while maintaining electrical functionality, with healing efficiencies exceeding 90% after complete severing. Their materials incorporate biocompatible ionic liquids as conductive elements, which maintain stable electrical properties even under extreme deformation. A key innovation is their "island-bridge" structural design that localizes strain to designated regions, protecting critical electronic components while allowing for overall device flexibility. The university has also developed specialized surface treatments that enhance skin adhesion while minimizing irritation, addressing a critical challenge in wearable device comfort and longevity.

Strengths: Exceptional stretchability combined with high healing efficiency; innovative structural design that protects electronic components; excellent biocompatibility and skin adhesion properties. Weaknesses: Potential electrical performance degradation in low humidity environments; relatively complex manufacturing process requiring precise control of multiple components; concerns about long-term stability of ionic conductivity.

Fundación CIDETEC

Technical Solution: CIDETEC has developed advanced self-healing elastomers based on dynamic covalent chemistry, specifically utilizing Diels-Alder reactions to create reversible crosslinks in polymer networks. Their proprietary technology enables elastomers to recover up to 97% of their original mechanical properties after damage through thermal activation. The materials incorporate conductive fillers like carbon nanotubes and silver nanowires that maintain electrical conductivity even during stretching and healing cycles. CIDETEC's approach includes surface modification of these fillers to improve dispersion and interface compatibility with the elastomer matrix, resulting in stable electrical properties under mechanical deformation. Their recent innovations include multi-stimuli responsive healing mechanisms that can be triggered by heat, light, or electrical current, making them particularly suitable for wearable applications where different environmental conditions may be encountered.

Strengths: Superior healing efficiency with near-complete recovery of mechanical properties; versatile healing triggers allowing application-specific optimization; excellent biocompatibility through careful material selection. Weaknesses: Relatively slow healing times at ambient temperatures; higher production costs compared to conventional elastomers; potential durability concerns after multiple healing cycles.

Key Patents and Research on Stretchable Self-Healing Materials

Self-healing elastomer system

PatentInactiveEP2105288A1

Innovation

- A self-healing elastomer system with a surface and interior featuring covalently bonded functional groups in the elastomer matrix and a liquid phase containing specific additive functional groups, allowing for selective reaction and bonding at damaged sites without external intervention, using a catalyst to accelerate the healing process.

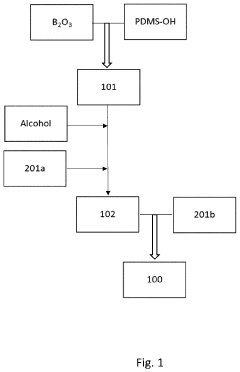

Self-healing elastomers and method of making the same

PatentPendingUS20240228781A1

Innovation

- Development of an intrinsically self-healing elastomer with an interpenetrating polymer network comprising polyborosiloxane-based and polydimethylsiloxane-based polymers, achieved through a method involving boron trioxide nanoparticles and hydroxyl-terminated polydimethylsiloxane, which provides enhanced mechanical properties, transparency, and autonomous self-healing capabilities without external stimuli.

Biocompatibility and Skin Safety Assessment Protocols

The assessment of biocompatibility and skin safety for self-healing elastomers in wearable applications requires rigorous protocols that meet international standards. ISO 10993 series, particularly ISO 10993-10 for skin irritation and sensitization, serves as the foundation for these evaluations. These protocols typically begin with in vitro cytotoxicity testing using standardized cell lines such as human dermal fibroblasts or keratinocytes to assess material toxicity before advancing to more complex assessments.

For wearable applications, protocols must specifically address prolonged skin contact scenarios. The Draize test and its modified versions remain relevant for initial irritation assessment, though ethical considerations have led to the development of reconstructed human epidermis (RHE) models like EpiDerm™ and SkinEthic™. These 3D tissue models provide valuable alternatives that reduce animal testing while maintaining predictive accuracy for human responses.

Sensitization potential evaluation typically follows the Local Lymph Node Assay (LLNA) or human patch testing protocols. For self-healing elastomers specifically, additional considerations include testing the material both in its original state and after healing cycles to ensure safety properties remain consistent throughout the material's functional lifetime.

Leachable and extractable testing represents another critical component of these protocols. Simulated sweat solutions (as defined in ISO 105-E04) and artificial sebum are employed to extract potential irritants or sensitizers under conditions mimicking real-world wear. Analytical techniques including HPLC-MS and GC-MS are then utilized to identify and quantify these compounds, with particular attention to catalysts, crosslinking agents, and degradation products specific to self-healing mechanisms.

Long-term biocompatibility assessment protocols must account for the unique properties of self-healing elastomers. This includes evaluating potential changes in material properties after repeated healing cycles and assessing whether healing mechanisms might generate new compounds with different safety profiles. Protocols typically incorporate accelerated aging studies to predict long-term performance and safety.

Regulatory frameworks governing these protocols vary globally, with the FDA requiring compliance with ISO 10993 for medical devices in the US, while the EU's Medical Device Regulation (MDR) imposes similar requirements with additional emphasis on risk management. For consumer wearables, regulations are generally less stringent but still require demonstration of safety under normal use conditions.

For wearable applications, protocols must specifically address prolonged skin contact scenarios. The Draize test and its modified versions remain relevant for initial irritation assessment, though ethical considerations have led to the development of reconstructed human epidermis (RHE) models like EpiDerm™ and SkinEthic™. These 3D tissue models provide valuable alternatives that reduce animal testing while maintaining predictive accuracy for human responses.

Sensitization potential evaluation typically follows the Local Lymph Node Assay (LLNA) or human patch testing protocols. For self-healing elastomers specifically, additional considerations include testing the material both in its original state and after healing cycles to ensure safety properties remain consistent throughout the material's functional lifetime.

Leachable and extractable testing represents another critical component of these protocols. Simulated sweat solutions (as defined in ISO 105-E04) and artificial sebum are employed to extract potential irritants or sensitizers under conditions mimicking real-world wear. Analytical techniques including HPLC-MS and GC-MS are then utilized to identify and quantify these compounds, with particular attention to catalysts, crosslinking agents, and degradation products specific to self-healing mechanisms.

Long-term biocompatibility assessment protocols must account for the unique properties of self-healing elastomers. This includes evaluating potential changes in material properties after repeated healing cycles and assessing whether healing mechanisms might generate new compounds with different safety profiles. Protocols typically incorporate accelerated aging studies to predict long-term performance and safety.

Regulatory frameworks governing these protocols vary globally, with the FDA requiring compliance with ISO 10993 for medical devices in the US, while the EU's Medical Device Regulation (MDR) imposes similar requirements with additional emphasis on risk management. For consumer wearables, regulations are generally less stringent but still require demonstration of safety under normal use conditions.

Environmental Impact and Sustainability Considerations

The development of self-healing elastomers for wearable technology necessitates careful consideration of environmental impacts throughout their lifecycle. Current elastomer production processes often rely heavily on petroleum-based feedstocks, contributing to carbon emissions and resource depletion. The manufacturing of these materials typically involves energy-intensive processes and potentially hazardous chemicals, raising concerns about their overall ecological footprint.

When examining the environmental profile of self-healing elastomers, material degradability emerges as a critical factor. Traditional elastomers can persist in the environment for hundreds of years, whereas newer bio-based and biodegradable self-healing elastomers offer promising alternatives with significantly reduced environmental persistence. Research indicates that incorporating naturally derived components such as cellulose, chitosan, or plant oils can enhance biodegradability while maintaining self-healing capabilities.

Waste generation represents another significant environmental challenge. The electronic components integrated into wearable devices containing these elastomers often contain rare earth metals and toxic substances that complicate end-of-life management. Innovative design approaches focusing on modular construction and material separation can facilitate recycling and reduce electronic waste. Some researchers have developed self-healing elastomers with reversible crosslinking mechanisms that enable material recovery and reprocessing, potentially extending product lifecycles.

Energy efficiency during the use phase presents both challenges and opportunities. While self-healing properties extend product lifespan—reducing replacement frequency and associated resource consumption—the healing mechanisms themselves may require energy inputs such as heat or light. Recent advances in ambient-temperature healing mechanisms and photocatalytic self-repair systems have shown promise in minimizing these energy requirements.

Water consumption and pollution also warrant attention in sustainability assessments. Manufacturing processes for specialized elastomers often require significant water inputs and may generate contaminated wastewater. Closed-loop production systems and water-efficient synthesis methods are being explored to address these concerns, with some manufacturers reporting up to 40% reductions in water usage through process optimization.

Carbon footprint considerations extend beyond manufacturing to include transportation and end-of-life scenarios. Life cycle assessment studies suggest that the extended durability of self-healing materials can offset initial production impacts if designed properly. Several research groups have demonstrated carbon-neutral or carbon-negative elastomer formulations by incorporating CO2 as a feedstock in polymer synthesis, potentially transforming a greenhouse gas into a valuable resource.

When examining the environmental profile of self-healing elastomers, material degradability emerges as a critical factor. Traditional elastomers can persist in the environment for hundreds of years, whereas newer bio-based and biodegradable self-healing elastomers offer promising alternatives with significantly reduced environmental persistence. Research indicates that incorporating naturally derived components such as cellulose, chitosan, or plant oils can enhance biodegradability while maintaining self-healing capabilities.

Waste generation represents another significant environmental challenge. The electronic components integrated into wearable devices containing these elastomers often contain rare earth metals and toxic substances that complicate end-of-life management. Innovative design approaches focusing on modular construction and material separation can facilitate recycling and reduce electronic waste. Some researchers have developed self-healing elastomers with reversible crosslinking mechanisms that enable material recovery and reprocessing, potentially extending product lifecycles.

Energy efficiency during the use phase presents both challenges and opportunities. While self-healing properties extend product lifespan—reducing replacement frequency and associated resource consumption—the healing mechanisms themselves may require energy inputs such as heat or light. Recent advances in ambient-temperature healing mechanisms and photocatalytic self-repair systems have shown promise in minimizing these energy requirements.

Water consumption and pollution also warrant attention in sustainability assessments. Manufacturing processes for specialized elastomers often require significant water inputs and may generate contaminated wastewater. Closed-loop production systems and water-efficient synthesis methods are being explored to address these concerns, with some manufacturers reporting up to 40% reductions in water usage through process optimization.

Carbon footprint considerations extend beyond manufacturing to include transportation and end-of-life scenarios. Life cycle assessment studies suggest that the extended durability of self-healing materials can offset initial production impacts if designed properly. Several research groups have demonstrated carbon-neutral or carbon-negative elastomer formulations by incorporating CO2 as a feedstock in polymer synthesis, potentially transforming a greenhouse gas into a valuable resource.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!