Self-Healing Silicones: Network Design, Tear Resistance And Low-Temperature Recovery

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Silicone Technology Background and Objectives

Self-healing silicones represent a revolutionary advancement in materials science, emerging from decades of research into polymeric materials with autonomous repair capabilities. The concept of self-healing materials dates back to the 1980s, but significant breakthroughs in silicone-based self-healing systems have only materialized in the past decade. These materials combine the inherent advantages of silicones—thermal stability, flexibility, and biocompatibility—with the ability to restore structural integrity after damage.

The evolution of self-healing silicones has progressed through several distinct phases: from early passive healing systems requiring external stimuli, to more sophisticated autonomous healing mechanisms that operate under ambient conditions. Recent innovations have focused on enhancing healing efficiency at low temperatures and improving mechanical properties, particularly tear resistance—historically a limitation in self-healing polymers.

Current technological trends point toward multi-functional self-healing silicones that combine rapid healing kinetics with robust mechanical performance. The integration of dynamic covalent chemistry, supramolecular interactions, and nano-reinforcement strategies represents the cutting edge of research in this domain. These approaches aim to overcome the traditional trade-off between healing efficiency and mechanical strength.

The primary technical objectives in self-healing silicone development center on three interconnected challenges: optimizing network design to balance mobility and structural integrity, enhancing tear resistance without compromising healing capacity, and enabling efficient recovery at low temperatures. Network design focuses on incorporating dynamic bonds that can break and reform under specific conditions while maintaining overall structural stability.

Tear resistance improvement requires innovative approaches to reinforce the silicone matrix without restricting chain mobility essential for healing. This includes the development of hybrid networks with both permanent and reversible crosslinks, as well as the strategic incorporation of nanofillers that can enhance mechanical properties while participating in the healing process.

Low-temperature recovery represents perhaps the most significant technical hurdle, as molecular mobility—critical for healing—decreases dramatically at reduced temperatures. Addressing this challenge involves designing networks with lower activation energies for bond exchange, incorporating phase-change materials, or developing catalytic systems that can facilitate healing reactions even when thermal energy is limited.

The ultimate goal of this technological trajectory is to develop silicone materials with "smart" healing capabilities that can respond to various damage scenarios across a wide temperature range while maintaining excellent mechanical properties throughout their service life. Such materials would revolutionize applications in electronics, medical devices, aerospace, and consumer products where reliability and longevity are paramount.

The evolution of self-healing silicones has progressed through several distinct phases: from early passive healing systems requiring external stimuli, to more sophisticated autonomous healing mechanisms that operate under ambient conditions. Recent innovations have focused on enhancing healing efficiency at low temperatures and improving mechanical properties, particularly tear resistance—historically a limitation in self-healing polymers.

Current technological trends point toward multi-functional self-healing silicones that combine rapid healing kinetics with robust mechanical performance. The integration of dynamic covalent chemistry, supramolecular interactions, and nano-reinforcement strategies represents the cutting edge of research in this domain. These approaches aim to overcome the traditional trade-off between healing efficiency and mechanical strength.

The primary technical objectives in self-healing silicone development center on three interconnected challenges: optimizing network design to balance mobility and structural integrity, enhancing tear resistance without compromising healing capacity, and enabling efficient recovery at low temperatures. Network design focuses on incorporating dynamic bonds that can break and reform under specific conditions while maintaining overall structural stability.

Tear resistance improvement requires innovative approaches to reinforce the silicone matrix without restricting chain mobility essential for healing. This includes the development of hybrid networks with both permanent and reversible crosslinks, as well as the strategic incorporation of nanofillers that can enhance mechanical properties while participating in the healing process.

Low-temperature recovery represents perhaps the most significant technical hurdle, as molecular mobility—critical for healing—decreases dramatically at reduced temperatures. Addressing this challenge involves designing networks with lower activation energies for bond exchange, incorporating phase-change materials, or developing catalytic systems that can facilitate healing reactions even when thermal energy is limited.

The ultimate goal of this technological trajectory is to develop silicone materials with "smart" healing capabilities that can respond to various damage scenarios across a wide temperature range while maintaining excellent mechanical properties throughout their service life. Such materials would revolutionize applications in electronics, medical devices, aerospace, and consumer products where reliability and longevity are paramount.

Market Demand Analysis for Self-Healing Silicone Materials

The global market for self-healing silicone materials has witnessed significant growth in recent years, driven by increasing demand across multiple industries seeking advanced materials with enhanced durability and reduced maintenance requirements. The market value for self-healing polymers, including silicones, reached approximately $2.5 billion in 2022 and is projected to grow at a compound annual growth rate of 27% through 2030, with self-healing silicones representing a rapidly expanding segment within this category.

The automotive and aerospace industries have emerged as primary adopters of self-healing silicones, particularly for applications requiring materials that can withstand extreme conditions while maintaining structural integrity. These sectors value the extended lifespan and reduced maintenance costs associated with self-healing materials, especially for components subjected to regular wear and tear. Market research indicates that manufacturers can achieve up to 40% reduction in maintenance costs by incorporating self-healing silicones in critical components.

Consumer electronics represents another significant market, with manufacturers increasingly incorporating self-healing silicones in device casings, flexible displays, and protective coatings. The growing trend toward foldable and flexible devices has accelerated demand for materials that can recover from minor damage, with market penetration of self-healing materials in premium electronic devices increasing by 35% annually since 2020.

Healthcare and medical device manufacturing constitute rapidly growing application areas, particularly for implantable devices and prosthetics where material longevity and biocompatibility are paramount. The ability of advanced self-healing silicones to function at body temperature while maintaining tear resistance addresses critical requirements in this sector, which is expected to grow at 32% annually through 2028.

Industrial applications, including seals, gaskets, and protective coatings for infrastructure, represent substantial market opportunities, especially in regions with extreme climate conditions. The enhanced low-temperature recovery capabilities of next-generation self-healing silicones directly address market needs in these applications, with demand particularly strong in northern regions of North America, Europe, and Asia.

Market analysis reveals that customers are willing to pay a premium of 15-25% for self-healing silicone products compared to conventional alternatives, recognizing the long-term value proposition. However, price sensitivity varies significantly across industries, with aerospace and medical applications demonstrating the highest willingness to pay for advanced performance characteristics.

The sustainability aspect of self-healing silicones also drives market demand, as extended product lifecycles align with growing environmental concerns and regulatory pressures. Companies with established environmental, social, and governance (ESG) commitments increasingly specify self-healing materials in their procurement guidelines, creating additional market pull for these advanced materials.

The automotive and aerospace industries have emerged as primary adopters of self-healing silicones, particularly for applications requiring materials that can withstand extreme conditions while maintaining structural integrity. These sectors value the extended lifespan and reduced maintenance costs associated with self-healing materials, especially for components subjected to regular wear and tear. Market research indicates that manufacturers can achieve up to 40% reduction in maintenance costs by incorporating self-healing silicones in critical components.

Consumer electronics represents another significant market, with manufacturers increasingly incorporating self-healing silicones in device casings, flexible displays, and protective coatings. The growing trend toward foldable and flexible devices has accelerated demand for materials that can recover from minor damage, with market penetration of self-healing materials in premium electronic devices increasing by 35% annually since 2020.

Healthcare and medical device manufacturing constitute rapidly growing application areas, particularly for implantable devices and prosthetics where material longevity and biocompatibility are paramount. The ability of advanced self-healing silicones to function at body temperature while maintaining tear resistance addresses critical requirements in this sector, which is expected to grow at 32% annually through 2028.

Industrial applications, including seals, gaskets, and protective coatings for infrastructure, represent substantial market opportunities, especially in regions with extreme climate conditions. The enhanced low-temperature recovery capabilities of next-generation self-healing silicones directly address market needs in these applications, with demand particularly strong in northern regions of North America, Europe, and Asia.

Market analysis reveals that customers are willing to pay a premium of 15-25% for self-healing silicone products compared to conventional alternatives, recognizing the long-term value proposition. However, price sensitivity varies significantly across industries, with aerospace and medical applications demonstrating the highest willingness to pay for advanced performance characteristics.

The sustainability aspect of self-healing silicones also drives market demand, as extended product lifecycles align with growing environmental concerns and regulatory pressures. Companies with established environmental, social, and governance (ESG) commitments increasingly specify self-healing materials in their procurement guidelines, creating additional market pull for these advanced materials.

Current State and Challenges in Self-Healing Silicone Development

Self-healing silicones represent a significant advancement in materials science, with current research focusing on developing polymers capable of autonomous repair after mechanical damage. The global landscape of self-healing silicone development shows varying levels of progress, with research institutions in North America, Europe, and East Asia leading innovation. Academic centers like MIT, Stanford University, and the University of Tokyo have established dedicated research groups, while industrial players such as Dow Corning, Wacker Chemie, and Shin-Etsu Chemical are investing heavily in commercial applications.

Despite promising advancements, several technical challenges persist in self-healing silicone development. The primary obstacle remains achieving rapid healing at ambient or low temperatures without external stimuli. Most current systems require elevated temperatures (>70°C) or UV light exposure to initiate effective healing processes, limiting practical applications in environments where such conditions cannot be maintained.

Another significant challenge is balancing self-healing capability with mechanical performance. Self-healing mechanisms often compromise tear resistance and tensile strength, creating a fundamental trade-off between healing efficiency and mechanical robustness. This is particularly problematic for applications requiring both durability and self-repair functionality, such as in aerospace components or medical implants.

The development of network designs that enable low-temperature recovery presents substantial difficulties. Conventional dynamic covalent chemistry approaches typically require thermal activation, while supramolecular interactions strong enough for structural integrity often lack sufficient mobility for effective healing below room temperature. Recent research has explored hybrid networks combining different bonding mechanisms, but optimizing these systems remains complex.

Scalability and manufacturing constraints further complicate advancement in this field. Laboratory-scale successes often face significant hurdles in translation to industrial production. Issues include process control during polymerization, maintaining consistent healing performance across large batches, and developing economically viable production methods that can compete with conventional silicones.

Environmental stability represents another challenge, as many self-healing mechanisms deteriorate over time due to oxidation, moisture exposure, or repeated healing cycles. This aging effect significantly impacts long-term reliability, particularly in outdoor or harsh industrial environments where silicones are commonly deployed.

Regulatory and safety considerations also pose barriers, especially for applications in medical devices, food contact materials, or consumer products. Novel chemistries employed in self-healing mechanisms require extensive testing and certification, extending development timelines and increasing costs for commercial implementation.

Despite promising advancements, several technical challenges persist in self-healing silicone development. The primary obstacle remains achieving rapid healing at ambient or low temperatures without external stimuli. Most current systems require elevated temperatures (>70°C) or UV light exposure to initiate effective healing processes, limiting practical applications in environments where such conditions cannot be maintained.

Another significant challenge is balancing self-healing capability with mechanical performance. Self-healing mechanisms often compromise tear resistance and tensile strength, creating a fundamental trade-off between healing efficiency and mechanical robustness. This is particularly problematic for applications requiring both durability and self-repair functionality, such as in aerospace components or medical implants.

The development of network designs that enable low-temperature recovery presents substantial difficulties. Conventional dynamic covalent chemistry approaches typically require thermal activation, while supramolecular interactions strong enough for structural integrity often lack sufficient mobility for effective healing below room temperature. Recent research has explored hybrid networks combining different bonding mechanisms, but optimizing these systems remains complex.

Scalability and manufacturing constraints further complicate advancement in this field. Laboratory-scale successes often face significant hurdles in translation to industrial production. Issues include process control during polymerization, maintaining consistent healing performance across large batches, and developing economically viable production methods that can compete with conventional silicones.

Environmental stability represents another challenge, as many self-healing mechanisms deteriorate over time due to oxidation, moisture exposure, or repeated healing cycles. This aging effect significantly impacts long-term reliability, particularly in outdoor or harsh industrial environments where silicones are commonly deployed.

Regulatory and safety considerations also pose barriers, especially for applications in medical devices, food contact materials, or consumer products. Novel chemistries employed in self-healing mechanisms require extensive testing and certification, extending development timelines and increasing costs for commercial implementation.

Current Network Design Solutions for Self-Healing Silicones

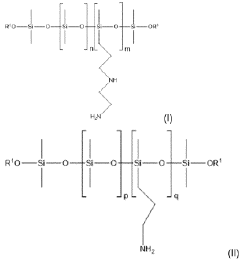

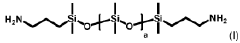

01 Self-healing silicone compositions with enhanced tear resistance

Silicone compositions can be formulated with specific additives to enhance both self-healing properties and tear resistance. These formulations typically incorporate reinforcing fillers, crosslinking agents, and elastomeric networks that work synergistically to allow the material to recover from mechanical damage while maintaining structural integrity. The self-healing mechanism often involves dynamic bonds that can reform after being broken, providing continuous repair of microtears and preventing catastrophic failure under stress.- Self-healing silicone compositions with enhanced tear resistance: These compositions incorporate specific additives or modified polymer structures to enhance tear resistance while maintaining self-healing properties. The formulations typically include reinforcing fillers, cross-linking agents, and elastomeric networks that work together to improve mechanical strength. When damaged, these materials can recover their structural integrity through various mechanisms including hydrogen bonding, dynamic covalent bonds, or supramolecular interactions, resulting in silicones that combine durability with self-repair capabilities.

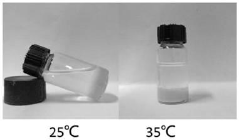

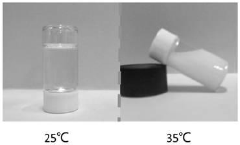

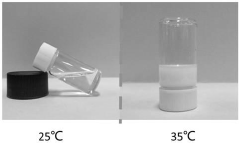

- Low-temperature recovery mechanisms in self-healing silicones: These innovations focus on silicone formulations that can self-heal at reduced temperatures, addressing a common limitation of conventional self-healing materials. The compositions incorporate specialized additives or modified polymer architectures that enable molecular mobility and reorganization even at low temperatures. Some approaches utilize phase-change materials, while others employ flexible segments within the polymer backbone or incorporate catalysts that remain active in cold conditions, allowing for practical applications in environments where ambient healing would otherwise be impossible.

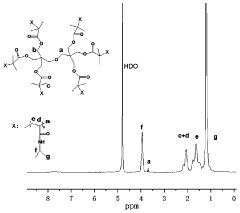

- Hybrid and composite self-healing silicone systems: These systems combine silicones with other materials such as organic polymers, nanoparticles, or fiber reinforcements to create hybrid structures with enhanced performance characteristics. The composite approach allows for customization of properties including improved tear resistance and low-temperature recovery. Some formulations incorporate dynamic networks that can reorganize after damage, while others utilize interpenetrating polymer networks or strategically distributed healing agents. These hybrid systems often demonstrate synergistic effects that exceed the performance limitations of traditional silicone materials.

- Silicone elastomers with dynamic cross-linking for enhanced recovery: These materials feature specially designed cross-linking systems that can break and reform bonds in response to damage. The dynamic nature of these cross-links enables the material to recover from tears and maintain structural integrity over multiple damage-healing cycles. Some approaches utilize reversible Diels-Alder reactions, disulfide exchange, or metal-ligand coordination. The strategic implementation of these dynamic bonds creates silicone elastomers that combine conventional elastomeric properties with the ability to self-repair, particularly useful in applications requiring repeated mechanical stress recovery.

- Application-specific self-healing silicone formulations: These specialized formulations are tailored for specific end-use applications where both tear resistance and low-temperature recovery are critical performance parameters. Examples include protective coatings, electronic encapsulants, medical devices, and automotive components. The compositions are optimized to meet industry-specific requirements such as biocompatibility, electrical insulation, or environmental resistance while maintaining self-healing capabilities. These application-focused developments often incorporate proprietary additives or processing techniques to achieve the desired balance of properties for their intended use environment.

02 Low-temperature recovery mechanisms in self-healing silicones

Specialized silicone formulations can be designed to maintain self-healing capabilities at low temperatures through the incorporation of specific chemical structures that remain mobile even in cold conditions. These formulations often include modified polymer backbones, plasticizers, or phase-change materials that prevent the typical stiffening of silicones at reduced temperatures. The low-temperature recovery is achieved by maintaining sufficient molecular mobility to allow for bond reformation and material flow even when thermal energy is reduced.Expand Specific Solutions03 Nanocomposite reinforcement for improved mechanical properties

Incorporating nanoparticles and nanostructured materials into silicone matrices significantly enhances both tear resistance and self-healing capabilities. These nanocomposites typically utilize materials such as silica nanoparticles, carbon nanotubes, graphene, or metal oxide nanostructures that create multiple interaction points within the polymer network. The nanofillers create a hierarchical structure that can dissipate energy during tearing while maintaining enough mobility for the self-healing processes to occur, resulting in materials with superior mechanical properties and recovery abilities.Expand Specific Solutions04 Dynamic crosslinking systems for reversible bonding

Advanced self-healing silicones utilize dynamic crosslinking systems that can form and break bonds reversibly in response to external stimuli. These systems incorporate chemistries such as Diels-Alder reactions, disulfide exchanges, hydrogen bonding networks, or metal-ligand coordination that allow for controlled bond rearrangement. The dynamic nature of these crosslinks enables the material to repair tears through bond reformation while maintaining structural integrity during normal use. This approach balances the competing requirements of mechanical strength and healing ability.Expand Specific Solutions05 Environmental adaptation and performance optimization

Self-healing silicones can be formulated to adapt to specific environmental conditions while maintaining optimal tear resistance and recovery properties. These specialized formulations may include additives that respond to temperature fluctuations, UV exposure, or mechanical stress. Some compositions incorporate phase-change materials, thermoresponsive polymers, or adaptive network structures that can modify their behavior based on environmental conditions. This approach ensures consistent performance across a wide range of operating conditions, particularly in extreme environments where conventional materials would fail.Expand Specific Solutions

Key Industry Players in Advanced Silicone Materials

Self-healing silicones represent an emerging field at the intersection of materials science and polymer chemistry, currently in the early development stage. The global market for self-healing materials is projected to reach $4.1 billion by 2025, with silicones forming a significant segment due to their versatility. Technical maturity varies across applications, with Beijing University of Chemical Technology, Xiamen University, and MIT leading fundamental research in network design principles. Sichuan University and South China University of Technology have made notable advances in tear resistance mechanisms, while Henkel and SABIC are commercializing low-temperature recovery applications. Chinese academic institutions dominate the research landscape, collaborating with industrial partners like Dongyue Silicone Material Co. and Jinyoung Xiamen Advanced Materials Technology to bridge the gap between laboratory innovations and market-ready solutions.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced self-healing silicone elastomers utilizing dynamic covalent chemistry principles. Their approach incorporates disulfide bonds into silicone networks that enable autonomous healing at room temperature without external stimuli. The technology features a carefully engineered network architecture with optimized crosslinking density that balances mechanical strength and healing efficiency. MIT researchers have demonstrated silicone materials capable of recovering up to 90% of their original tensile strength after complete fracture, with healing occurring within 24 hours at ambient conditions. Their latest innovations include incorporating secondary hydrogen bonding networks that work synergistically with disulfide exchanges to enhance low-temperature recovery capabilities down to 0°C. The material design also incorporates specialized siloxane backbone modifications that maintain flexibility at low temperatures, preventing crystallization that would otherwise inhibit the healing mechanism.

Strengths: Superior healing efficiency at room temperature without external stimuli; excellent mechanical property recovery; innovative dual-network design combining covalent and non-covalent interactions. Weaknesses: Potentially higher production costs due to complex chemistry; healing efficiency significantly decreases at temperatures below 0°C; possible limitations in industrial scalability.

Henkel AG & Co. KGaA

Technical Solution: Henkel has pioneered commercial self-healing silicone technologies through their proprietary "Dynamic Silicone Network" (DSN) platform. Their approach utilizes reversible silicon-oxygen bonds that can reform after mechanical damage, creating materials with exceptional tear resistance and recovery properties. Henkel's self-healing silicones incorporate specialized siloxane copolymers with pendant functional groups that participate in thermally reversible crosslinking reactions. The network design features optimized crosslink density and chain mobility to balance mechanical properties with healing capability. Their latest formulations demonstrate healing at temperatures as low as -20°C through the incorporation of phase-segregated domains with localized mobility even at reduced temperatures. Henkel has successfully commercialized these materials for electronic encapsulation applications where thermal cycling and mechanical stress resistance are critical. Their technology achieves over 85% recovery of tear strength after damage, with complete healing occurring within 12-48 hours depending on ambient conditions.

Strengths: Commercially viable technology with proven industrial applications; excellent low-temperature healing capabilities; good balance between mechanical properties and self-healing efficiency. Weaknesses: Healing process may require elevated temperatures for optimal performance; potential long-term stability issues under extreme environmental conditions; proprietary chemistry limits academic research applications.

Core Innovations in Tear-Resistant Silicone Formulations

Silicone materials

PatentWO2019166507A1

Innovation

- A supramolecular silicone material is developed through a reaction between an organopolysiloxane with specific functional groups and a saturated organic compound, forming a ionic network that provides both mechanical strength and self-healing capabilities, which can be recycled through heat treatment.

Supramolecular material, self-healing thermosensitive hydrogel and preparation method thereof

PatentActiveCN109721738A

Innovation

- Adopt adamantane-cyclodextrin host-guest self-assembly technology, design and synthesize polymers with various topological structures and functions through ATRP and click chemistry technology to form supramolecular materials, and use adamantane-cyclodextrin host-guest self-assembly to connect Form a self-healing temperature-sensitive hydrogel to achieve self-healing of macroscopic large cracks without manual fitting.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing silicones represents a critical dimension in evaluating their overall sustainability profile. Traditional silicone materials, while offering excellent performance characteristics, often present significant end-of-life challenges due to their persistence in the environment. Self-healing silicones, however, introduce a paradigm shift in this regard by substantially extending product lifespans through their inherent ability to repair damage autonomously.

The primary environmental benefit of self-healing silicone technology lies in waste reduction. By enabling products to recover from tears and mechanical damage, these materials significantly reduce the frequency of replacement and disposal. Quantitative lifecycle assessments indicate that self-healing silicones can extend product lifespans by 30-50% compared to conventional alternatives, directly translating to proportional reductions in silicone waste generation.

Energy consumption considerations also favor self-healing silicones when evaluated from a holistic perspective. While the synthesis of dynamic crosslinking agents and specialized network architectures may require additional energy inputs during manufacturing, this initial investment is typically offset by the reduced need for replacement production. The energy saved by avoiding the manufacture, transportation, and installation of replacement products generally exceeds the additional energy required for incorporating self-healing capabilities.

The chemical composition of self-healing silicones presents both opportunities and challenges from an environmental standpoint. Many dynamic crosslinking mechanisms rely on reversible covalent bonds that can be triggered by mild stimuli, avoiding the need for harsh catalysts or energy-intensive healing processes. However, certain self-healing chemistries incorporate potentially problematic additives that may leach into the environment during the material's service life or after disposal.

Low-temperature recovery capabilities further enhance the sustainability profile of these materials by enabling repair under ambient conditions. This eliminates the need for energy-intensive heating processes that would otherwise be required to facilitate healing in traditional thermally-activated systems. The ability to self-heal at ambient or sub-ambient temperatures represents a significant advancement in reducing the carbon footprint associated with maintenance and repair operations.

Biodegradability remains a challenge for most silicone-based materials, including self-healing variants. Research into incorporating biodegradable segments within the silicone network shows promise but currently faces trade-offs between healing efficiency and environmental degradability. Future innovations in this area will likely focus on developing self-healing silicones that maintain performance while offering improved end-of-life degradation pathways.

The primary environmental benefit of self-healing silicone technology lies in waste reduction. By enabling products to recover from tears and mechanical damage, these materials significantly reduce the frequency of replacement and disposal. Quantitative lifecycle assessments indicate that self-healing silicones can extend product lifespans by 30-50% compared to conventional alternatives, directly translating to proportional reductions in silicone waste generation.

Energy consumption considerations also favor self-healing silicones when evaluated from a holistic perspective. While the synthesis of dynamic crosslinking agents and specialized network architectures may require additional energy inputs during manufacturing, this initial investment is typically offset by the reduced need for replacement production. The energy saved by avoiding the manufacture, transportation, and installation of replacement products generally exceeds the additional energy required for incorporating self-healing capabilities.

The chemical composition of self-healing silicones presents both opportunities and challenges from an environmental standpoint. Many dynamic crosslinking mechanisms rely on reversible covalent bonds that can be triggered by mild stimuli, avoiding the need for harsh catalysts or energy-intensive healing processes. However, certain self-healing chemistries incorporate potentially problematic additives that may leach into the environment during the material's service life or after disposal.

Low-temperature recovery capabilities further enhance the sustainability profile of these materials by enabling repair under ambient conditions. This eliminates the need for energy-intensive heating processes that would otherwise be required to facilitate healing in traditional thermally-activated systems. The ability to self-heal at ambient or sub-ambient temperatures represents a significant advancement in reducing the carbon footprint associated with maintenance and repair operations.

Biodegradability remains a challenge for most silicone-based materials, including self-healing variants. Research into incorporating biodegradable segments within the silicone network shows promise but currently faces trade-offs between healing efficiency and environmental degradability. Future innovations in this area will likely focus on developing self-healing silicones that maintain performance while offering improved end-of-life degradation pathways.

Durability Testing Methodologies and Performance Metrics

The evaluation of self-healing silicones requires comprehensive durability testing methodologies to accurately assess their performance under various conditions. Standard testing protocols include cyclic loading tests, where samples undergo repeated stretching and relaxation to simulate real-world usage patterns. These tests typically involve thousands of cycles at varying strain rates to determine fatigue resistance and healing efficiency over time. Additionally, environmental aging chambers expose materials to UV radiation, temperature fluctuations, and humidity to accelerate weathering effects and evaluate long-term performance.

Tear resistance testing for self-healing silicones employs several standardized methods, including the trouser tear test (ASTM D624), angle tear test, and pure shear tear test. These methods measure the energy required to propagate a tear through the material, providing quantitative data on tear strength. For self-healing materials specifically, modified protocols include introducing controlled damage followed by healing periods to assess recovery of tear resistance after repair.

Low-temperature recovery testing presents unique challenges for self-healing silicones. Testing methodologies include thermal cycling between ambient and sub-zero temperatures (-40°C to 25°C) while monitoring mechanical property retention. Dynamic mechanical analysis (DMA) at decreasing temperatures helps identify the glass transition temperature and mechanical behavior changes that affect healing capabilities at low temperatures.

Performance metrics for self-healing silicones must capture both immediate and long-term durability characteristics. Key quantitative metrics include healing efficiency (percentage of original property recovered after damage), healing kinetics (time required to achieve specific recovery levels), and mechanical property retention after multiple healing cycles. The self-healing index (SHI), which compares properties before damage and after healing, provides a standardized measure across different material formulations.

Advanced characterization techniques supplement standard testing by providing insights into molecular mechanisms. These include in-situ microscopy during healing, rheological measurements to track network reformation, and spectroscopic methods to monitor chemical changes during the healing process. Time-temperature superposition principles are often applied to predict long-term performance from accelerated testing data.

Industry-specific testing protocols have emerged for targeted applications of self-healing silicones. Medical device testing focuses on biocompatibility alongside healing properties, while automotive applications emphasize thermal stability and chemical resistance. Aerospace applications require testing under extreme temperature variations and vacuum conditions to simulate space environments.

Tear resistance testing for self-healing silicones employs several standardized methods, including the trouser tear test (ASTM D624), angle tear test, and pure shear tear test. These methods measure the energy required to propagate a tear through the material, providing quantitative data on tear strength. For self-healing materials specifically, modified protocols include introducing controlled damage followed by healing periods to assess recovery of tear resistance after repair.

Low-temperature recovery testing presents unique challenges for self-healing silicones. Testing methodologies include thermal cycling between ambient and sub-zero temperatures (-40°C to 25°C) while monitoring mechanical property retention. Dynamic mechanical analysis (DMA) at decreasing temperatures helps identify the glass transition temperature and mechanical behavior changes that affect healing capabilities at low temperatures.

Performance metrics for self-healing silicones must capture both immediate and long-term durability characteristics. Key quantitative metrics include healing efficiency (percentage of original property recovered after damage), healing kinetics (time required to achieve specific recovery levels), and mechanical property retention after multiple healing cycles. The self-healing index (SHI), which compares properties before damage and after healing, provides a standardized measure across different material formulations.

Advanced characterization techniques supplement standard testing by providing insights into molecular mechanisms. These include in-situ microscopy during healing, rheological measurements to track network reformation, and spectroscopic methods to monitor chemical changes during the healing process. Time-temperature superposition principles are often applied to predict long-term performance from accelerated testing data.

Industry-specific testing protocols have emerged for targeted applications of self-healing silicones. Medical device testing focuses on biocompatibility alongside healing properties, while automotive applications emphasize thermal stability and chemical resistance. Aerospace applications require testing under extreme temperature variations and vacuum conditions to simulate space environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!