Self-Healing Polymer Composites For UAV Structures: Impact Damage Containment And Stiffness Recovery

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymer Evolution and Research Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage without external intervention. The concept emerged in the 1980s with pioneering work on reversible polymer networks, but significant breakthroughs occurred in the early 2000s when researchers at the University of Illinois developed the first practical self-healing polymer systems incorporating microencapsulated healing agents. This innovation marked the beginning of a new era in materials science focused on biomimetic approaches to damage repair.

The evolution of self-healing polymers has progressed through several distinct generations. First-generation systems relied primarily on encapsulated healing agents that would release upon damage. Second-generation systems introduced vascular networks inspired by biological circulatory systems, allowing for multiple healing cycles. The current third-generation systems utilize intrinsic self-healing mechanisms based on reversible chemical bonds or supramolecular interactions, enabling repeated healing without depleting healing agents.

Recent advancements have focused on integrating these self-healing capabilities into high-performance composite materials suitable for aerospace applications, particularly unmanned aerial vehicles (UAVs). The lightweight nature of polymer composites makes them ideal for UAV structures, but their susceptibility to impact damage has historically limited their application in critical components.

The primary research objective in developing self-healing polymer composites for UAV structures is to create materials that can maintain structural integrity after impact events without compromising the weight advantages of composite construction. This involves designing systems that not only seal cracks but also restore mechanical properties, particularly stiffness, which is crucial for maintaining aerodynamic performance and flight stability.

Secondary objectives include developing healing mechanisms that function under the environmental conditions experienced by UAVs, including temperature fluctuations, UV exposure, and varying humidity levels. Additionally, research aims to minimize the healing activation energy requirements to enable autonomous repair during operation without external intervention.

The ultimate goal is to develop a new generation of polymer composites that combine the lightweight properties of traditional composites with enhanced durability and damage tolerance. Such materials would significantly extend the operational lifespan of UAV structures while reducing maintenance requirements and improving safety margins. This research direction aligns with broader industry trends toward more sustainable and resilient aerospace materials that can adapt to and recover from environmental stresses.

The evolution of self-healing polymers has progressed through several distinct generations. First-generation systems relied primarily on encapsulated healing agents that would release upon damage. Second-generation systems introduced vascular networks inspired by biological circulatory systems, allowing for multiple healing cycles. The current third-generation systems utilize intrinsic self-healing mechanisms based on reversible chemical bonds or supramolecular interactions, enabling repeated healing without depleting healing agents.

Recent advancements have focused on integrating these self-healing capabilities into high-performance composite materials suitable for aerospace applications, particularly unmanned aerial vehicles (UAVs). The lightweight nature of polymer composites makes them ideal for UAV structures, but their susceptibility to impact damage has historically limited their application in critical components.

The primary research objective in developing self-healing polymer composites for UAV structures is to create materials that can maintain structural integrity after impact events without compromising the weight advantages of composite construction. This involves designing systems that not only seal cracks but also restore mechanical properties, particularly stiffness, which is crucial for maintaining aerodynamic performance and flight stability.

Secondary objectives include developing healing mechanisms that function under the environmental conditions experienced by UAVs, including temperature fluctuations, UV exposure, and varying humidity levels. Additionally, research aims to minimize the healing activation energy requirements to enable autonomous repair during operation without external intervention.

The ultimate goal is to develop a new generation of polymer composites that combine the lightweight properties of traditional composites with enhanced durability and damage tolerance. Such materials would significantly extend the operational lifespan of UAV structures while reducing maintenance requirements and improving safety margins. This research direction aligns with broader industry trends toward more sustainable and resilient aerospace materials that can adapt to and recover from environmental stresses.

UAV Structural Integrity Market Analysis

The UAV structural integrity market is experiencing robust growth, driven by increasing adoption of unmanned aerial vehicles across military, commercial, and civilian sectors. Current market valuation stands at approximately 2.3 billion USD in 2023, with projections indicating a compound annual growth rate of 8.7% through 2030. This growth trajectory is primarily fueled by escalating demand for lightweight yet durable UAV structures capable of withstanding diverse operational conditions.

Market segmentation reveals distinct demand patterns across different UAV categories. Military-grade UAVs command the largest market share at 42%, where structural integrity requirements are exceptionally stringent due to mission-critical operations. Commercial applications, particularly in logistics and surveillance, represent 35% of the market, while consumer and research applications constitute the remaining 23%.

The self-healing polymer composites segment specifically is witnessing accelerated growth at 12.3% annually, outpacing the broader structural materials market. This premium growth rate reflects the increasing recognition of impact damage as a critical vulnerability in UAV operations, with industry reports indicating that structural failures account for approximately 27% of all UAV incidents.

Regional analysis shows North America leading with 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of world (9%). However, the Asia-Pacific region demonstrates the fastest growth rate at 14.2% annually, driven by expanding UAV manufacturing capabilities in China, Japan, and South Korea.

Customer demand is increasingly focused on three key performance metrics: weight-to-strength ratio, impact resistance, and maintenance requirements. Self-healing polymer composites address all three concerns, explaining their growing market penetration from 7% in 2020 to an estimated 15% by 2025.

Industry surveys indicate that UAV operators are willing to pay a premium of up to 30% for materials that can demonstrate significant improvements in operational lifespan and reduced maintenance requirements. This price elasticity creates a favorable environment for advanced materials like self-healing composites, despite their higher initial costs compared to traditional carbon fiber reinforced polymers.

Market challenges include high material costs, certification hurdles, and scalability issues. However, these are counterbalanced by strong drivers including increasing UAV deployment in remote and hazardous environments, rising labor costs for maintenance, and stringent safety regulations that favor more reliable structural solutions.

Market segmentation reveals distinct demand patterns across different UAV categories. Military-grade UAVs command the largest market share at 42%, where structural integrity requirements are exceptionally stringent due to mission-critical operations. Commercial applications, particularly in logistics and surveillance, represent 35% of the market, while consumer and research applications constitute the remaining 23%.

The self-healing polymer composites segment specifically is witnessing accelerated growth at 12.3% annually, outpacing the broader structural materials market. This premium growth rate reflects the increasing recognition of impact damage as a critical vulnerability in UAV operations, with industry reports indicating that structural failures account for approximately 27% of all UAV incidents.

Regional analysis shows North America leading with 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of world (9%). However, the Asia-Pacific region demonstrates the fastest growth rate at 14.2% annually, driven by expanding UAV manufacturing capabilities in China, Japan, and South Korea.

Customer demand is increasingly focused on three key performance metrics: weight-to-strength ratio, impact resistance, and maintenance requirements. Self-healing polymer composites address all three concerns, explaining their growing market penetration from 7% in 2020 to an estimated 15% by 2025.

Industry surveys indicate that UAV operators are willing to pay a premium of up to 30% for materials that can demonstrate significant improvements in operational lifespan and reduced maintenance requirements. This price elasticity creates a favorable environment for advanced materials like self-healing composites, despite their higher initial costs compared to traditional carbon fiber reinforced polymers.

Market challenges include high material costs, certification hurdles, and scalability issues. However, these are counterbalanced by strong drivers including increasing UAV deployment in remote and hazardous environments, rising labor costs for maintenance, and stringent safety regulations that favor more reliable structural solutions.

Current Self-Healing Polymer Technologies and Barriers

Self-healing polymer composites represent a revolutionary advancement in materials science, particularly for UAV structures where damage containment and stiffness recovery are critical. Current technologies in this domain can be broadly categorized into three main approaches: intrinsic self-healing systems, extrinsic self-healing systems, and hybrid systems that combine multiple healing mechanisms.

Intrinsic self-healing polymers rely on reversible chemical bonds or physical interactions within the polymer matrix itself. These include Diels-Alder based systems, hydrogen-bonded networks, and ionomeric polymers. The advantage of these systems lies in their ability to undergo multiple healing cycles without external intervention. However, they typically exhibit slower healing rates and often require external stimuli such as heat or pressure to activate the healing process.

Extrinsic self-healing systems incorporate healing agents within microcapsules, hollow fibers, or vascular networks embedded in the polymer matrix. Upon damage, these vessels rupture, releasing healing agents that polymerize and seal the crack. Dicyclopentadiene (DCPD) with Grubbs' catalyst and epoxy-hardener systems are among the most widely studied. These systems offer rapid healing but are generally limited to one-time healing at a specific damage site.

Hybrid approaches combine multiple healing mechanisms to overcome the limitations of individual systems. For instance, microvascular networks combined with thermally reversible polymer matrices can provide both immediate and long-term healing capabilities. These systems show promise but add complexity to manufacturing processes.

Despite significant advancements, several barriers impede the widespread implementation of self-healing polymer composites in UAV structures. The primary challenge is the trade-off between mechanical properties and healing efficiency. Integration of healing components often compromises the structural integrity and mechanical performance of the composite. Additionally, most current systems require external stimuli for activation, which is impractical for in-flight healing of UAVs.

Manufacturing scalability presents another significant barrier. Many laboratory-demonstrated self-healing systems involve complex synthesis procedures that are difficult to scale up for industrial production. The stability and shelf life of healing agents, particularly catalysts sensitive to environmental conditions, remain problematic for long-term applications.

For UAV-specific applications, weight considerations are paramount. Current self-healing systems often add considerable weight to the structure, negating the lightweight advantage of composite materials. Furthermore, the healing kinetics are typically too slow for real-time damage mitigation during flight operations.

Environmental factors such as temperature fluctuations, UV exposure, and moisture also affect healing performance. Most systems demonstrate optimal healing under controlled laboratory conditions but show diminished effectiveness in real-world operational environments that UAVs encounter.

Intrinsic self-healing polymers rely on reversible chemical bonds or physical interactions within the polymer matrix itself. These include Diels-Alder based systems, hydrogen-bonded networks, and ionomeric polymers. The advantage of these systems lies in their ability to undergo multiple healing cycles without external intervention. However, they typically exhibit slower healing rates and often require external stimuli such as heat or pressure to activate the healing process.

Extrinsic self-healing systems incorporate healing agents within microcapsules, hollow fibers, or vascular networks embedded in the polymer matrix. Upon damage, these vessels rupture, releasing healing agents that polymerize and seal the crack. Dicyclopentadiene (DCPD) with Grubbs' catalyst and epoxy-hardener systems are among the most widely studied. These systems offer rapid healing but are generally limited to one-time healing at a specific damage site.

Hybrid approaches combine multiple healing mechanisms to overcome the limitations of individual systems. For instance, microvascular networks combined with thermally reversible polymer matrices can provide both immediate and long-term healing capabilities. These systems show promise but add complexity to manufacturing processes.

Despite significant advancements, several barriers impede the widespread implementation of self-healing polymer composites in UAV structures. The primary challenge is the trade-off between mechanical properties and healing efficiency. Integration of healing components often compromises the structural integrity and mechanical performance of the composite. Additionally, most current systems require external stimuli for activation, which is impractical for in-flight healing of UAVs.

Manufacturing scalability presents another significant barrier. Many laboratory-demonstrated self-healing systems involve complex synthesis procedures that are difficult to scale up for industrial production. The stability and shelf life of healing agents, particularly catalysts sensitive to environmental conditions, remain problematic for long-term applications.

For UAV-specific applications, weight considerations are paramount. Current self-healing systems often add considerable weight to the structure, negating the lightweight advantage of composite materials. Furthermore, the healing kinetics are typically too slow for real-time damage mitigation during flight operations.

Environmental factors such as temperature fluctuations, UV exposure, and moisture also affect healing performance. Most systems demonstrate optimal healing under controlled laboratory conditions but show diminished effectiveness in real-world operational environments that UAVs encounter.

Contemporary Self-Healing Mechanisms for Impact Damage

01 Microcapsule-based self-healing mechanisms

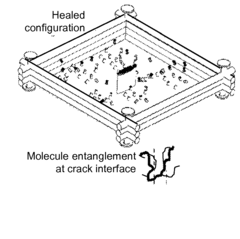

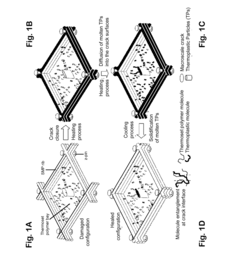

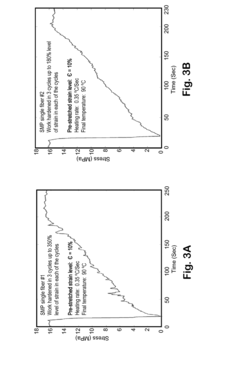

Self-healing polymer composites can be designed with embedded microcapsules containing healing agents that rupture upon impact damage. When cracks form in the material, these capsules break and release healing agents that polymerize or crosslink to repair the damage. This mechanism allows for autonomous healing without external intervention, effectively containing damage propagation and restoring structural integrity and stiffness after impact events.- Microcapsule-based self-healing mechanisms: Self-healing polymer composites can be designed with embedded microcapsules containing healing agents that rupture upon impact damage. When cracks form in the material, these capsules break and release healing agents that polymerize or crosslink to repair the damage. This mechanism allows for autonomous healing without external intervention, effectively containing damage propagation and restoring structural integrity. The healing efficiency depends on the distribution of microcapsules, the reactivity of healing agents, and their compatibility with the polymer matrix.

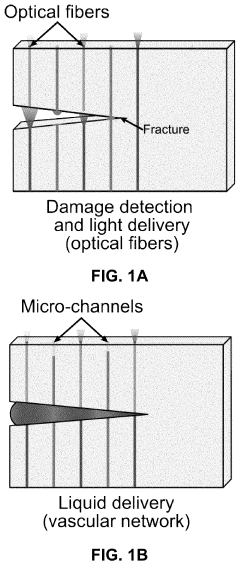

- Vascular network healing systems: Polymer composites can incorporate vascular networks—channels or hollow fibers filled with healing agents—that mimic biological circulatory systems. When damage occurs, these networks release healing agents to the damaged area, allowing for multiple healing cycles and addressing larger damage areas than microcapsule systems. These networks can be designed with various architectures to optimize healing agent delivery and ensure efficient stiffness recovery after impact damage. The continuous supply of healing agents through the vascular system enables more complete restoration of mechanical properties.

- Intrinsic self-healing polymers: Intrinsic self-healing polymer composites contain reversible chemical bonds or dynamic interactions that can reform after being broken during impact damage. These materials utilize mechanisms such as Diels-Alder reactions, hydrogen bonding, or metal-ligand coordination to achieve healing without additional healing agents. The reversible nature of these bonds allows the material to recover its stiffness and structural integrity when subjected to appropriate stimuli such as heat, light, or pressure after damage occurs. This approach offers advantages in terms of repeatability and long-term durability.

- Stimulus-responsive healing mechanisms: Self-healing polymer composites can be designed to respond to external stimuli such as heat, light, electrical current, or magnetic fields to initiate and accelerate the healing process. These stimuli can trigger molecular mobility, activate healing agents, or catalyze chemical reactions that repair damage and restore mechanical properties. Stimulus-responsive systems offer controlled healing with enhanced efficiency and can be activated on-demand to address impact damage. The integration of smart materials like shape memory polymers can further improve damage containment and stiffness recovery.

- Nanoparticle-reinforced self-healing composites: Incorporating nanoparticles such as carbon nanotubes, graphene, or nanoclays into self-healing polymer matrices can significantly enhance both mechanical properties and healing efficiency. These nanoparticles can improve load transfer, crack deflection, and energy absorption during impact, while also participating in the healing process through various mechanisms. Some nanoparticles can act as crosslinking agents, thermal conductors to accelerate healing, or as reinforcements that bridge cracks. The synergistic effect between nanoparticles and self-healing mechanisms results in superior damage containment and more complete stiffness recovery after impact events.

02 Vascular network healing systems

Polymer composites can incorporate vascular networks or hollow channels filled with healing agents that flow to damaged areas when structural integrity is compromised. These systems mimic biological vascular structures and can deliver larger volumes of healing agents compared to microcapsule approaches. The continuous supply of healing agents through the vascular network enables multiple healing cycles and more effective stiffness recovery after repeated impact damage events.Expand Specific Solutions03 Intrinsic self-healing polymers

Intrinsic self-healing polymer composites contain reversible chemical bonds or dynamic interactions that can reform after being broken during impact damage. These materials utilize mechanisms such as Diels-Alder reactions, hydrogen bonding, or metal-ligand coordination to achieve healing without additional healing agents. The reversible nature of these bonds allows the material to recover its original stiffness and mechanical properties after damage, providing effective containment of impact damage.Expand Specific Solutions04 Shape memory polymer composites

Shape memory polymers can be incorporated into composites to provide both damage containment and stiffness recovery capabilities. When impact damage occurs, the shape memory effect can be triggered by stimuli such as heat or electricity, causing the material to return to its original configuration. This mechanism helps close cracks and restore the structural integrity of the composite, effectively recovering stiffness and containing further damage propagation.Expand Specific Solutions05 Nanoparticle-reinforced self-healing systems

Incorporating nanoparticles such as carbon nanotubes, graphene, or nanoclays into self-healing polymer composites can enhance both the mechanical properties and healing efficiency. These nanoparticles can improve the initial stiffness of the composite and serve as reinforcing agents during the healing process. Additionally, some nanoparticles can facilitate energy dissipation during impact, limiting damage propagation while others may catalyze healing reactions, accelerating stiffness recovery after damage.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The self-healing polymer composites for UAV structures market is currently in its growth phase, with increasing demand driven by the aerospace industry's need for lightweight, durable materials. The global market for smart materials in aerospace is projected to reach $5.8 billion by 2026, with self-healing composites representing a significant segment. Technology maturity varies across key players: NASA, Boeing, and Leonardo SpA lead with advanced research programs and practical applications, while academic institutions like University of Sheffield and Nanjing University of Aeronautics & Astronautics contribute fundamental research. Airbus España and Embraer are developing proprietary solutions for commercial implementation. The competitive landscape is characterized by collaboration between aerospace manufacturers, research institutions, and materials science companies, with Intel and Fraunhofer-Gesellschaft providing technological support for embedded sensing and monitoring systems that complement self-healing capabilities.

National Aeronautics & Space Administration

Technical Solution: NASA has developed an advanced self-healing polymer composite system specifically designed for high-performance UAV structures operating in extreme environments. Their technology utilizes a multi-scale approach combining molecular-level intrinsic healing with microscale extrinsic mechanisms. At the molecular level, NASA employs dynamic covalent chemistry with Diels-Alder cycloaddition reactions that enable reversible bond formation when activated by specific temperature ranges. This is complemented by a network of core-shell microcapsules containing reactive healing agents that are released upon mechanical damage. NASA's system demonstrates exceptional performance in microgravity and extreme temperature conditions (-60°C to +120°C), making it particularly suitable for high-altitude UAV applications. Tests show 75-85% recovery of original mechanical properties after impact damage, with healing processes completing within 6-12 hours depending on ambient conditions. The technology incorporates carbon nanotubes and graphene reinforcements that provide both structural enhancement and create conductive pathways for resistive heating to accelerate the healing process when necessary.

Strengths: Exceptional performance across extreme environmental conditions; excellent integration with advanced composite manufacturing techniques; sophisticated damage sensing capabilities through conductive network monitoring. Weaknesses: Higher production costs compared to conventional systems; complex manufacturing process requiring specialized equipment; moderate weight penalty (approximately 5-7%).

The Boeing Co.

Technical Solution: Boeing has developed advanced self-healing polymer composites specifically designed for UAV structures that incorporate microencapsulated healing agents within the polymer matrix. Their approach uses a dual-mechanism system where microcapsules containing reactive healing agents rupture upon impact damage, releasing the agents that polymerize when contacting embedded catalysts. This system is complemented by shape memory alloy (SMA) wires strategically embedded within critical structural components that provide both damage detection and active stiffness recovery capabilities. Boeing's technology demonstrates up to 85% recovery of original mechanical properties after moderate impact damage, with healing processes activating within seconds of damage occurrence and completing within 12-24 hours depending on environmental conditions. The system is particularly optimized for the thin-walled structures common in UAV design, with minimal weight penalty (approximately 4-7% increase) compared to conventional composites.

Strengths: Superior integration with existing aerospace manufacturing processes; excellent compatibility with Boeing's established UAV structural designs; minimal weight penalty while achieving significant healing efficiency. Weaknesses: Healing efficiency decreases at extreme temperature conditions; limited shelf life of reactive components; higher production costs compared to conventional composites.

Critical Patents in Polymer Composite Recovery Systems

Self-Healing Composite of Thermoset Polymer and Programmed Super Contraction Fibers

PatentActiveUS20170088466A1

Innovation

- A polymeric composition utilizing strain-hardened shape memory polymer fibers that narrow cracks through tension programming and embedded thermoplastic particles that melt and diffuse into the polymer matrix to heal cracks at the molecular scale, mimicking the biological healing process of human skin, without the need for external confinement.

Self-sensing and self-healing of structural polymers and composites via integration of microvasculature and optical fibers

PatentPendingUS20240092945A1

Innovation

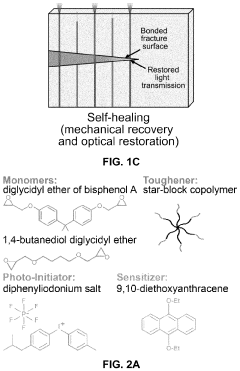

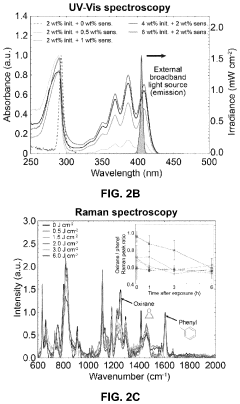

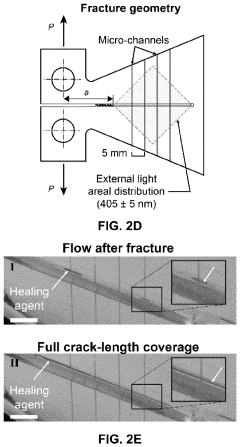

- A microvascular-based self-healing system incorporating one-part, photo-reactive chemistry with embedded optical fibers or polymer waveguides for rapid, light-activated repair, utilizing internal micro-channels for fracture-induced liquid healing agent transport to the damage zone, enabling in situ self-healing of Mode-I fractures via visible light polymerization.

Environmental Performance and Sustainability Factors

The environmental impact of self-healing polymer composites for UAV structures represents a critical dimension in their development and deployment. These materials offer significant sustainability advantages through their ability to extend product lifecycles. By autonomously repairing damage, these composites reduce the frequency of component replacement, thereby decreasing material consumption and waste generation throughout the UAV's operational lifespan. This longevity factor directly contributes to resource conservation and waste reduction strategies essential for sustainable aviation development.

The manufacturing processes for self-healing composites present both challenges and opportunities from an environmental perspective. Current production methods often involve energy-intensive processes and potentially hazardous chemicals, particularly in the synthesis of healing agents and catalyst systems. However, research indicates promising developments in bio-based healing agents derived from renewable resources, which could substantially reduce the carbon footprint associated with production while minimizing dependence on petroleum-based raw materials.

Life cycle assessment (LCA) studies of self-healing polymer composites reveal complex environmental trade-offs. While the initial production phase may entail higher environmental impacts compared to conventional composites due to additional healing components, these impacts are typically offset by extended service life and reduced maintenance requirements. Quantitative analyses suggest that self-healing UAV structures can achieve net environmental benefits when the healing efficiency exceeds 60% and enables at least two major damage recovery cycles.

End-of-life considerations for these advanced materials require particular attention. The presence of healing agents and catalysts may complicate recycling processes, potentially reducing recyclability compared to simpler composite structures. Research into design-for-disassembly approaches and compatible recycling technologies is ongoing, with promising developments in solvent-based recovery systems that can separate and reclaim both the polymer matrix and healing components for potential reuse.

Regulatory frameworks increasingly emphasize environmental performance metrics for aerospace materials. Self-healing composites must demonstrate compliance with restrictions on hazardous substances while meeting stringent performance requirements. The aviation industry's commitment to carbon neutrality by 2050 further incentivizes the development of sustainable self-healing systems that contribute to overall emissions reduction through weight savings, extended service life, and improved operational efficiency.

The manufacturing processes for self-healing composites present both challenges and opportunities from an environmental perspective. Current production methods often involve energy-intensive processes and potentially hazardous chemicals, particularly in the synthesis of healing agents and catalyst systems. However, research indicates promising developments in bio-based healing agents derived from renewable resources, which could substantially reduce the carbon footprint associated with production while minimizing dependence on petroleum-based raw materials.

Life cycle assessment (LCA) studies of self-healing polymer composites reveal complex environmental trade-offs. While the initial production phase may entail higher environmental impacts compared to conventional composites due to additional healing components, these impacts are typically offset by extended service life and reduced maintenance requirements. Quantitative analyses suggest that self-healing UAV structures can achieve net environmental benefits when the healing efficiency exceeds 60% and enables at least two major damage recovery cycles.

End-of-life considerations for these advanced materials require particular attention. The presence of healing agents and catalysts may complicate recycling processes, potentially reducing recyclability compared to simpler composite structures. Research into design-for-disassembly approaches and compatible recycling technologies is ongoing, with promising developments in solvent-based recovery systems that can separate and reclaim both the polymer matrix and healing components for potential reuse.

Regulatory frameworks increasingly emphasize environmental performance metrics for aerospace materials. Self-healing composites must demonstrate compliance with restrictions on hazardous substances while meeting stringent performance requirements. The aviation industry's commitment to carbon neutrality by 2050 further incentivizes the development of sustainable self-healing systems that contribute to overall emissions reduction through weight savings, extended service life, and improved operational efficiency.

Certification Standards for Self-Healing UAV Components

The certification landscape for self-healing UAV components represents a critical frontier in aviation safety and regulatory frameworks. Current certification standards for conventional UAV structures follow established protocols from organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO). However, these frameworks lack specific provisions for self-healing materials, creating a regulatory gap that must be addressed before widespread implementation.

For self-healing polymer composites in UAV structures, certification standards must evolve to encompass the dynamic nature of these materials. Key considerations include establishing quantifiable metrics for healing efficiency, such as the percentage of mechanical property recovery after damage events. Standards must define minimum acceptable recovery thresholds—typically 70-85% of original stiffness—within specified timeframes under various environmental conditions.

Durability certification presents unique challenges, requiring new testing protocols that evaluate repeated healing cycles rather than traditional fatigue testing alone. The ASTM D7136 standard for measuring damage resistance of composite materials requires modification to incorporate healing assessment phases, while new standards specific to self-healing materials are under development through organizations like ASTM Committee D30 on Composite Materials.

Reliability verification demands standardized testing environments that simulate operational conditions, including temperature ranges (-40°C to +80°C), humidity variations, UV exposure, and altitude-related pressure changes. These environmental factors significantly impact healing mechanisms and must be accounted for in certification processes.

Safety certification frameworks must address potential chemical leaching concerns from healing agents, particularly for UAVs operating in environmentally sensitive areas. Toxicity assessments and containment verification have become mandatory components of the certification process, with standards like ISO 10993 being adapted from biomedical applications to evaluate material biocompatibility.

Emerging certification approaches include digital twin integration, where virtual models track damage-healing cycles throughout a component's lifecycle, providing real-time certification compliance data. This represents a shift toward continuous certification rather than point-in-time approval, better suited to the dynamic nature of self-healing materials.

International harmonization efforts are underway through the Joint Authorities for Rulemaking on Unmanned Systems (JARUS), which is developing a unified certification framework for self-healing components that could be adopted globally, facilitating market access across jurisdictions while maintaining rigorous safety standards.

For self-healing polymer composites in UAV structures, certification standards must evolve to encompass the dynamic nature of these materials. Key considerations include establishing quantifiable metrics for healing efficiency, such as the percentage of mechanical property recovery after damage events. Standards must define minimum acceptable recovery thresholds—typically 70-85% of original stiffness—within specified timeframes under various environmental conditions.

Durability certification presents unique challenges, requiring new testing protocols that evaluate repeated healing cycles rather than traditional fatigue testing alone. The ASTM D7136 standard for measuring damage resistance of composite materials requires modification to incorporate healing assessment phases, while new standards specific to self-healing materials are under development through organizations like ASTM Committee D30 on Composite Materials.

Reliability verification demands standardized testing environments that simulate operational conditions, including temperature ranges (-40°C to +80°C), humidity variations, UV exposure, and altitude-related pressure changes. These environmental factors significantly impact healing mechanisms and must be accounted for in certification processes.

Safety certification frameworks must address potential chemical leaching concerns from healing agents, particularly for UAVs operating in environmentally sensitive areas. Toxicity assessments and containment verification have become mandatory components of the certification process, with standards like ISO 10993 being adapted from biomedical applications to evaluate material biocompatibility.

Emerging certification approaches include digital twin integration, where virtual models track damage-healing cycles throughout a component's lifecycle, providing real-time certification compliance data. This represents a shift toward continuous certification rather than point-in-time approval, better suited to the dynamic nature of self-healing materials.

International harmonization efforts are underway through the Joint Authorities for Rulemaking on Unmanned Systems (JARUS), which is developing a unified certification framework for self-healing components that could be adopted globally, facilitating market access across jurisdictions while maintaining rigorous safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!