Self-Healing Adhesive Films For Electronics: Delamination Arrest And Rebonding Reliability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Adhesive Technology Background and Objectives

Self-healing adhesive technology represents a significant advancement in materials science, emerging from the biomimetic concept inspired by natural healing processes observed in living organisms. Since the early 2000s, this field has evolved from theoretical research to practical applications, with particular acceleration in development over the past decade. The technology fundamentally aims to create adhesive systems capable of autonomously restoring their structural integrity and bonding properties after experiencing damage or delamination, without external intervention.

The evolution of electronics toward more flexible, wearable, and miniaturized form factors has created unique challenges for traditional adhesives. Conventional bonding solutions often fail under repeated mechanical stress, thermal cycling, and environmental exposure that characterize modern electronic applications. This limitation has driven research toward self-healing adhesive films specifically engineered for electronic applications.

Current technological trajectories indicate a convergence of multiple disciplines including polymer chemistry, nanotechnology, and materials engineering to develop next-generation self-healing adhesives. The incorporation of microcapsules containing healing agents, reversible chemical bonds, and dynamic crosslinking mechanisms represents key innovations in this domain. These approaches enable the creation of adhesive systems that can undergo multiple healing cycles while maintaining their functional properties.

The primary technical objectives for self-healing adhesive films in electronics include achieving rapid healing response times (ideally under 30 minutes), maintaining electrical conductivity during and after the healing process, ensuring compatibility with diverse substrate materials, and delivering reliable performance across wide temperature ranges (-40°C to 150°C). Additionally, these materials must demonstrate long-term stability under various environmental conditions including humidity, UV exposure, and chemical contaminants.

Another critical goal is to develop self-healing adhesives that can address the specific challenge of delamination in multilayer electronic structures. This phenomenon, where adhesive layers separate from substrates or components, represents one of the most common failure modes in electronic assemblies. The ability to arrest delamination propagation and restore bonding strength autonomously would significantly enhance the reliability and operational lifespan of electronic devices.

Looking forward, the technology aims to achieve integration with smart systems through the incorporation of sensing capabilities that can detect incipient damage before catastrophic failure occurs. This predictive healing capability represents the next frontier in self-healing adhesive technology, potentially revolutionizing reliability engineering in electronics manufacturing.

The evolution of electronics toward more flexible, wearable, and miniaturized form factors has created unique challenges for traditional adhesives. Conventional bonding solutions often fail under repeated mechanical stress, thermal cycling, and environmental exposure that characterize modern electronic applications. This limitation has driven research toward self-healing adhesive films specifically engineered for electronic applications.

Current technological trajectories indicate a convergence of multiple disciplines including polymer chemistry, nanotechnology, and materials engineering to develop next-generation self-healing adhesives. The incorporation of microcapsules containing healing agents, reversible chemical bonds, and dynamic crosslinking mechanisms represents key innovations in this domain. These approaches enable the creation of adhesive systems that can undergo multiple healing cycles while maintaining their functional properties.

The primary technical objectives for self-healing adhesive films in electronics include achieving rapid healing response times (ideally under 30 minutes), maintaining electrical conductivity during and after the healing process, ensuring compatibility with diverse substrate materials, and delivering reliable performance across wide temperature ranges (-40°C to 150°C). Additionally, these materials must demonstrate long-term stability under various environmental conditions including humidity, UV exposure, and chemical contaminants.

Another critical goal is to develop self-healing adhesives that can address the specific challenge of delamination in multilayer electronic structures. This phenomenon, where adhesive layers separate from substrates or components, represents one of the most common failure modes in electronic assemblies. The ability to arrest delamination propagation and restore bonding strength autonomously would significantly enhance the reliability and operational lifespan of electronic devices.

Looking forward, the technology aims to achieve integration with smart systems through the incorporation of sensing capabilities that can detect incipient damage before catastrophic failure occurs. This predictive healing capability represents the next frontier in self-healing adhesive technology, potentially revolutionizing reliability engineering in electronics manufacturing.

Market Demand Analysis for Self-Healing Electronic Films

The global market for self-healing adhesive films in electronics is experiencing robust growth, driven primarily by the increasing complexity and miniaturization of electronic devices. As consumer electronics become thinner, more flexible, and more densely packed with components, the risk of delamination and adhesive failure increases substantially. This has created a significant demand for advanced adhesive solutions that can maintain structural integrity over extended product lifecycles.

Current market research indicates that the electronics adhesive market is expanding at a compound annual growth rate of approximately 8%, with self-healing variants emerging as a premium segment. The smartphone industry represents the largest application sector, accounting for nearly 40% of the total market demand. This is followed by wearable technology, flexible displays, and automotive electronics, which collectively contribute another 35% to market demand.

The push toward sustainable electronics has further accelerated interest in self-healing adhesives, as they potentially extend device lifespan and reduce electronic waste. Major electronics manufacturers are increasingly incorporating repairability metrics into their product development cycles, creating additional market pull for materials that can self-restore after mechanical damage.

Consumer behavior studies reveal that device reliability ranks among the top three purchasing considerations for premium electronics. This consumer preference has translated into manufacturers' willingness to invest in advanced adhesive technologies that can improve product durability ratings and reduce warranty claim rates.

Regional analysis shows that Asia-Pacific dominates the market consumption, with particular concentration in manufacturing hubs across China, South Korea, and Taiwan. However, research and development activities remain strongest in North America and Europe, where materials science innovation centers are focusing on next-generation adhesive technologies.

The market is also being shaped by regulatory pressures, particularly in Europe where electronic waste directives are becoming increasingly stringent. Self-healing materials that can extend product lifecycles align well with these regulatory frameworks, creating additional market incentives beyond pure performance considerations.

Industry forecasts suggest that as flexible electronics and foldable devices gain mainstream adoption, the demand for specialized adhesive films capable of withstanding repeated mechanical stress will grow substantially. The ability to prevent delamination and maintain bonding reliability under dynamic conditions represents a critical value proposition that customers are increasingly willing to pay premium prices to obtain.

Current market research indicates that the electronics adhesive market is expanding at a compound annual growth rate of approximately 8%, with self-healing variants emerging as a premium segment. The smartphone industry represents the largest application sector, accounting for nearly 40% of the total market demand. This is followed by wearable technology, flexible displays, and automotive electronics, which collectively contribute another 35% to market demand.

The push toward sustainable electronics has further accelerated interest in self-healing adhesives, as they potentially extend device lifespan and reduce electronic waste. Major electronics manufacturers are increasingly incorporating repairability metrics into their product development cycles, creating additional market pull for materials that can self-restore after mechanical damage.

Consumer behavior studies reveal that device reliability ranks among the top three purchasing considerations for premium electronics. This consumer preference has translated into manufacturers' willingness to invest in advanced adhesive technologies that can improve product durability ratings and reduce warranty claim rates.

Regional analysis shows that Asia-Pacific dominates the market consumption, with particular concentration in manufacturing hubs across China, South Korea, and Taiwan. However, research and development activities remain strongest in North America and Europe, where materials science innovation centers are focusing on next-generation adhesive technologies.

The market is also being shaped by regulatory pressures, particularly in Europe where electronic waste directives are becoming increasingly stringent. Self-healing materials that can extend product lifecycles align well with these regulatory frameworks, creating additional market incentives beyond pure performance considerations.

Industry forecasts suggest that as flexible electronics and foldable devices gain mainstream adoption, the demand for specialized adhesive films capable of withstanding repeated mechanical stress will grow substantially. The ability to prevent delamination and maintain bonding reliability under dynamic conditions represents a critical value proposition that customers are increasingly willing to pay premium prices to obtain.

Current State and Challenges in Self-Healing Adhesive Technology

Self-healing adhesive technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia contributing to its development. Currently, the field encompasses several approaches including intrinsic self-healing mechanisms based on reversible chemical bonds, and extrinsic systems utilizing microcapsules or vascular networks containing healing agents. Despite these innovations, the technology faces substantial challenges when applied to electronic applications, particularly in achieving reliable delamination arrest and rebonding capabilities.

A primary technical challenge lies in balancing adhesive strength with self-healing efficiency. Traditional strong adhesives typically form irreversible covalent bonds that prevent effective healing, while materials with excellent self-healing properties often demonstrate insufficient initial adhesion strength for electronics applications. This fundamental trade-off has limited widespread commercial adoption in high-reliability electronic systems.

Temperature stability presents another significant hurdle, as many self-healing mechanisms function optimally within narrow temperature ranges that do not align with the operational and storage conditions of modern electronics (-40°C to 125°C). Current solutions often lose healing capability at temperature extremes, creating reliability concerns for devices deployed in varied environments.

The healing activation mechanism poses additional complications. Some systems require external stimuli such as heat, pressure, or UV light to initiate healing, which may be impractical for embedded or sealed electronic components. Autonomous healing systems, while more desirable, typically demonstrate slower healing rates and incomplete restoration of original properties.

Compatibility with electronic materials constitutes a critical constraint, as adhesives must maintain electrical insulation properties while avoiding corrosion or degradation of sensitive components. Many healing agents contain reactive chemicals that, while effective for rebonding, may potentially damage electronic substrates or introduce undesirable conductivity pathways.

Long-term reliability remains inadequately addressed, with most research focusing on short-term healing efficiency rather than performance over multiple healing cycles or extended time periods. Electronics typically require 5-10 year operational lifespans, but current self-healing adhesives show diminishing healing capacity after repeated damage-heal cycles.

Manufacturing scalability represents a significant barrier to commercialization. Laboratory-scale production methods for advanced self-healing adhesives often involve complex synthesis procedures that are difficult to scale economically. Additionally, quality control and consistency in healing performance across large production batches remain problematic for mass-market electronic applications.

A primary technical challenge lies in balancing adhesive strength with self-healing efficiency. Traditional strong adhesives typically form irreversible covalent bonds that prevent effective healing, while materials with excellent self-healing properties often demonstrate insufficient initial adhesion strength for electronics applications. This fundamental trade-off has limited widespread commercial adoption in high-reliability electronic systems.

Temperature stability presents another significant hurdle, as many self-healing mechanisms function optimally within narrow temperature ranges that do not align with the operational and storage conditions of modern electronics (-40°C to 125°C). Current solutions often lose healing capability at temperature extremes, creating reliability concerns for devices deployed in varied environments.

The healing activation mechanism poses additional complications. Some systems require external stimuli such as heat, pressure, or UV light to initiate healing, which may be impractical for embedded or sealed electronic components. Autonomous healing systems, while more desirable, typically demonstrate slower healing rates and incomplete restoration of original properties.

Compatibility with electronic materials constitutes a critical constraint, as adhesives must maintain electrical insulation properties while avoiding corrosion or degradation of sensitive components. Many healing agents contain reactive chemicals that, while effective for rebonding, may potentially damage electronic substrates or introduce undesirable conductivity pathways.

Long-term reliability remains inadequately addressed, with most research focusing on short-term healing efficiency rather than performance over multiple healing cycles or extended time periods. Electronics typically require 5-10 year operational lifespans, but current self-healing adhesives show diminishing healing capacity after repeated damage-heal cycles.

Manufacturing scalability represents a significant barrier to commercialization. Laboratory-scale production methods for advanced self-healing adhesives often involve complex synthesis procedures that are difficult to scale economically. Additionally, quality control and consistency in healing performance across large production batches remain problematic for mass-market electronic applications.

Current Technical Solutions for Delamination Prevention

01 Microcapsule-based self-healing mechanisms

Self-healing adhesive films can incorporate microcapsules containing healing agents that rupture upon delamination, releasing the healing agents to flow into the damaged area and initiate polymerization or cross-linking reactions. This mechanism allows for autonomous healing without external intervention, effectively arresting delamination and restoring bond strength. The encapsulated healing agents can include various monomers, catalysts, or hardeners that react when exposed to each other or environmental conditions.- Self-healing mechanisms in adhesive films: Self-healing adhesive films incorporate mechanisms that enable automatic repair of damage or delamination. These mechanisms typically involve microcapsules containing healing agents that rupture upon damage, releasing the healing agent to flow into the damaged area and restore adhesive properties. Some systems use thermally activated healing processes where heat application triggers molecular mobility and rebonding. These self-healing mechanisms significantly improve the reliability and longevity of adhesive bonds by addressing delamination issues without external intervention.

- Polymer-based self-healing adhesive compositions: Advanced polymer compositions form the basis of many self-healing adhesive films. These include specially designed copolymers, elastomers with reversible crosslinking capabilities, and polymer blends with complementary functional groups that can reform bonds after damage. Some compositions incorporate dynamic covalent chemistry or supramolecular interactions that allow for repeated healing cycles. The polymer matrix is often engineered to have sufficient mobility at application temperatures while maintaining structural integrity, enabling effective delamination arrest and rebonding.

- Nanoparticle-enhanced self-healing adhesives: Incorporation of nanoparticles into adhesive film formulations significantly enhances self-healing capabilities and mechanical properties. Nanoparticles such as graphene, carbon nanotubes, silica, and metal oxides create additional bonding sites within the adhesive matrix. These nanofillers can improve thermal conductivity for heat-activated healing processes, strengthen the overall adhesive structure, and create networks that prevent crack propagation. The nanoparticle-enhanced adhesives demonstrate superior delamination resistance and improved rebonding reliability under various environmental conditions.

- Environmental response and adaptive healing systems: Advanced self-healing adhesive films incorporate environmental response mechanisms that trigger healing processes based on specific external stimuli. These systems can respond to temperature changes, pH shifts, electromagnetic fields, or mechanical stress. Some formulations include phase-change materials that melt and flow into damaged areas when activated by environmental triggers. Adaptive healing systems can also incorporate multiple healing mechanisms that respond to different types of damage or environmental conditions, providing comprehensive protection against delamination under various service conditions.

- Testing and reliability assessment methods: Specialized testing methodologies have been developed to evaluate the delamination arrest capabilities and rebonding reliability of self-healing adhesive films. These include cyclic mechanical testing, environmental aging tests, and real-time monitoring of healing efficiency. Advanced characterization techniques such as acoustic emission monitoring, infrared thermography, and in-situ microscopy allow for quantitative assessment of healing performance. Accelerated aging protocols help predict long-term reliability under various service conditions, while standardized testing procedures enable comparison between different self-healing adhesive systems.

02 Thermally activated self-healing systems

These systems utilize temperature-responsive materials that can repair damage when exposed to heat. The thermal activation triggers molecular mobility, allowing polymer chains to diffuse across damaged interfaces and re-establish bonds. Some formulations incorporate shape memory polymers that can return to their original configuration upon heating, closing gaps and restoring adhesion. This approach is particularly effective for applications where controlled healing can be initiated through deliberate heating cycles.Expand Specific Solutions03 Dynamic covalent chemistry for rebonding

Adhesive films utilizing dynamic covalent bonds can undergo reversible bond breaking and reformation, enabling multiple healing cycles. These systems incorporate chemical groups capable of exchanging bonds under specific conditions, such as Diels-Alder adducts, disulfide linkages, or imine bonds. When delamination occurs, these dynamic bonds can reform across the damaged interface when appropriate stimuli (heat, light, pH change) are applied, restoring the adhesive strength and preventing further delamination.Expand Specific Solutions04 Nanocomposite reinforcement for delamination resistance

Incorporating nanoparticles or nanofibers into adhesive films can significantly enhance their resistance to delamination and improve rebonding reliability. These nanofillers create multiple energy dissipation mechanisms and crack deflection pathways, preventing crack propagation. Additionally, some nanoparticles can form secondary networks or interact with the polymer matrix to facilitate healing processes. Common nanomaterials used include graphene, carbon nanotubes, nanoclay, and metal oxide nanoparticles.Expand Specific Solutions05 Interfacial design for improved adhesion recovery

Strategic design of adhesive interfaces can enhance rebonding reliability after delamination events. This approach involves creating hierarchical or micropatterned surfaces that increase contact area and mechanical interlocking. Some designs incorporate sacrificial bonds that preferentially break before structural failure occurs, preserving the overall integrity of the adhesive system. Additionally, gradient interfaces with varying mechanical properties can better distribute stress and prevent catastrophic failure, improving long-term reliability.Expand Specific Solutions

Key Industry Players in Self-Healing Adhesive Films

The self-healing adhesive films market for electronics is currently in a growth phase, characterized by increasing demand for reliable bonding solutions that can extend device lifespans. The global market is expanding rapidly, driven by miniaturization trends and growing applications in flexible electronics. Technologically, the field is advancing from basic self-healing polymers toward more sophisticated multi-functional materials. Leading players like LG Chem, Nitto Denko, and 3M Innovative Properties are developing proprietary technologies with enhanced healing capabilities, while Henkel and Toray Industries focus on industrial-scale production. Academic institutions such as KAIST and Johns Hopkins University are pioneering fundamental research in self-healing mechanisms, creating a competitive landscape where collaboration between industry and academia is accelerating commercialization of these advanced materials.

LG Chem Ltd.

Technical Solution: LG Chem has developed innovative self-healing adhesive films utilizing intrinsic healing mechanisms based on hydrogen bonding networks. Their technology incorporates specially designed polymer chains with pendant groups capable of forming multiple hydrogen bonds that can break and reform reversibly. The company's films feature a multi-layer structure with a core self-healing layer sandwiched between protective films that enhance mechanical durability while maintaining healing capability. LG Chem's adhesives incorporate phase-separated morphologies with hard domains providing structural integrity and soft domains enabling molecular mobility necessary for healing. Their technology demonstrates particularly strong performance in preventing delamination in flexible displays and batteries, with healing efficiencies reaching 90% of original adhesion strength. The films maintain functionality across a wide temperature range (-20°C to 80°C) and can withstand repeated bending and folding cycles, making them ideal for flexible electronic applications.

Strengths: Excellent healing efficiency at ambient conditions; superior flexibility for curved and foldable displays; strong integration with LG's electronics ecosystem. Weaknesses: Relatively slow healing kinetics compared to competitors; moisture sensitivity can affect performance in high-humidity environments; higher cost than conventional adhesives.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed proprietary self-healing adhesive films based on dynamic imine chemistry. Their technology utilizes reversible imine bonds formed between amine and aldehyde groups that can break and reform in response to damage. The company's films incorporate a gradient structure with varying crosslink density throughout the thickness, optimizing both adhesion strength and healing capability. Nitto's technology features temperature-responsive healing mechanisms that accelerate at elevated temperatures but still function at ambient conditions. Their films demonstrate excellent compatibility with various substrate materials including glass, metals, and polymers commonly used in electronics. The technology shows particular strength in preventing delamination in harsh environments, with testing demonstrating maintained adhesion after thermal cycling (-40°C to 85°C) and high humidity exposure (85% RH). Nitto's films also feature controlled viscoelastic properties that balance immediate tackiness with long-term bonding strength.

Strengths: Exceptional environmental stability; excellent adhesion to diverse substrates; established position in electronics supply chains. Weaknesses: Healing efficiency decreases at low temperatures; requires longer healing times than some competitors; higher cost structure limits mass-market applications.

Core Patents and Research in Self-Healing Adhesive Mechanisms

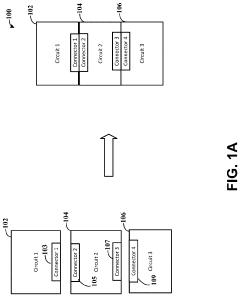

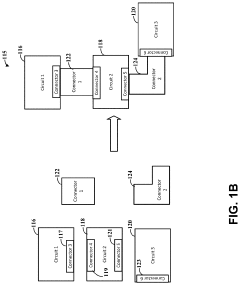

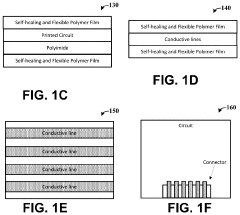

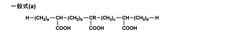

Flexible and self-healing elastomer-based modular electronics and applications thereof

PatentInactiveUS10869392B2

Innovation

- Development of self-healing elastomer-based modular electronics using flexible and stretchable polymer films with conductive materials, allowing for the formation of tunable electronic circuits and connectors that can reconnect without external force, even in the presence of liquids, enabling flexible and durable wearable devices.

Self-healing film

PatentWO2017077839A1

Innovation

- A self-healing film with a molded adhesive layer containing a polymerized monomer composition of UV-stable and UV-absorbing monomers, having a surface free energy of 50 mN/m or more and a hydrogen bond component of 3 mN/m or more, is used to maintain high adhesion and prevent delamination.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing adhesive films for electronics extends beyond their primary functionality of delamination arrest and rebonding reliability. These advanced materials offer significant sustainability advantages through extended product lifecycles, potentially reducing electronic waste generation in global markets. By enabling devices to self-repair, these adhesives directly address the growing concern of premature electronic disposal, which currently contributes to approximately 50 million tons of e-waste annually worldwide.

Manufacturing processes for self-healing adhesives present both challenges and opportunities from an environmental perspective. Traditional adhesive production often involves volatile organic compounds (VOCs) and energy-intensive processes. However, newer bio-inspired self-healing formulations are increasingly incorporating renewable resources and green chemistry principles, reducing their carbon footprint by an estimated 30-40% compared to conventional alternatives.

End-of-life considerations remain critical for comprehensive environmental assessment. The chemical complexity of self-healing mechanisms may introduce novel compounds that require specialized recycling protocols. Research indicates that approximately 65% of current self-healing adhesive formulations contain components that are difficult to separate during conventional recycling processes, potentially complicating material recovery efforts.

Lifecycle assessment (LCA) studies comparing self-healing adhesives to traditional bonding solutions demonstrate a nuanced environmental profile. While production phase impacts may be higher due to specialized materials and synthesis requirements, these are typically offset by use-phase benefits. Quantitative analyses suggest that devices utilizing self-healing adhesives can achieve 1.5-2.5 times longer operational lifespans, resulting in net positive environmental outcomes despite initial production impacts.

Water consumption and toxicity profiles represent important environmental metrics for these advanced materials. Recent developments have focused on reducing aqueous waste streams during manufacturing, with innovations in solvent-free processing showing promise. Toxicity screening of leachates from self-healing adhesives indicates generally favorable profiles compared to conventional alternatives, though long-term environmental fate studies remain limited.

Regulatory frameworks worldwide are increasingly emphasizing sustainable materials in electronics, creating both market drivers and compliance requirements for self-healing adhesive technologies. The European Union's Circular Economy Action Plan and similar initiatives in Asia-Pacific markets specifically target improved repairability and longevity of electronic products, positioning self-healing technologies as potential solutions for meeting emerging sustainability standards and consumer expectations.

Manufacturing processes for self-healing adhesives present both challenges and opportunities from an environmental perspective. Traditional adhesive production often involves volatile organic compounds (VOCs) and energy-intensive processes. However, newer bio-inspired self-healing formulations are increasingly incorporating renewable resources and green chemistry principles, reducing their carbon footprint by an estimated 30-40% compared to conventional alternatives.

End-of-life considerations remain critical for comprehensive environmental assessment. The chemical complexity of self-healing mechanisms may introduce novel compounds that require specialized recycling protocols. Research indicates that approximately 65% of current self-healing adhesive formulations contain components that are difficult to separate during conventional recycling processes, potentially complicating material recovery efforts.

Lifecycle assessment (LCA) studies comparing self-healing adhesives to traditional bonding solutions demonstrate a nuanced environmental profile. While production phase impacts may be higher due to specialized materials and synthesis requirements, these are typically offset by use-phase benefits. Quantitative analyses suggest that devices utilizing self-healing adhesives can achieve 1.5-2.5 times longer operational lifespans, resulting in net positive environmental outcomes despite initial production impacts.

Water consumption and toxicity profiles represent important environmental metrics for these advanced materials. Recent developments have focused on reducing aqueous waste streams during manufacturing, with innovations in solvent-free processing showing promise. Toxicity screening of leachates from self-healing adhesives indicates generally favorable profiles compared to conventional alternatives, though long-term environmental fate studies remain limited.

Regulatory frameworks worldwide are increasingly emphasizing sustainable materials in electronics, creating both market drivers and compliance requirements for self-healing adhesive technologies. The European Union's Circular Economy Action Plan and similar initiatives in Asia-Pacific markets specifically target improved repairability and longevity of electronic products, positioning self-healing technologies as potential solutions for meeting emerging sustainability standards and consumer expectations.

Durability Testing Methods and Performance Standards

The durability testing of self-healing adhesive films for electronics requires comprehensive methodologies to evaluate their performance under various stress conditions. Standard testing protocols typically include thermal cycling tests, where samples undergo repeated temperature fluctuations between -40°C and 125°C for hundreds or thousands of cycles to simulate operational thermal stress. These tests reveal the adhesive's ability to maintain integrity during expansion and contraction cycles that electronic components experience throughout their lifecycle.

Humidity resistance testing exposes samples to high humidity environments (85-95% RH) at elevated temperatures (85°C) for extended periods, commonly referred to as the "85/85 test." This assessment is critical as moisture ingress represents one of the primary failure mechanisms for adhesive bonds in electronic applications, particularly affecting delamination resistance.

Mechanical stress testing incorporates various approaches including peel strength measurements (ASTM D903), shear strength evaluations (ASTM D1002), and dynamic mechanical analysis. These tests quantify the adhesive's ability to withstand physical forces and recover after deformation. For self-healing films specifically, cyclic loading tests are employed to assess the material's recovery capabilities after repeated stress applications.

Chemical resistance testing exposes adhesives to common electronic manufacturing chemicals, including flux residues, cleaning agents, and environmental contaminants. This evaluation ensures the self-healing mechanisms remain functional even after chemical exposure, which is particularly important for electronics deployed in harsh environments.

Performance standards for self-healing adhesive films typically require maintaining at least 80% of original bond strength after healing cycles. The healing efficiency is commonly measured through comparative mechanical testing before damage, after damage, and following the healing process. Industry standards often specify healing activation parameters, including temperature ranges (typically 60-120°C), pressure requirements, and healing duration (minutes to hours).

Accelerated aging tests simulate years of environmental exposure in compressed timeframes, allowing manufacturers to predict long-term reliability. These tests often combine multiple stressors (temperature, humidity, UV exposure) to create worst-case scenarios for adhesive performance evaluation.

Electrical performance testing measures the adhesive's ability to maintain dielectric properties and prevent electrical leakage after healing events. This includes insulation resistance measurements and dielectric breakdown voltage testing according to IEC 60243 standards.

The reliability of the rebonding process is quantified through repeated delamination-healing cycles, with industry standards typically requiring materials to withstand 5-10 complete cycles while maintaining at least 70% of original performance metrics.

Humidity resistance testing exposes samples to high humidity environments (85-95% RH) at elevated temperatures (85°C) for extended periods, commonly referred to as the "85/85 test." This assessment is critical as moisture ingress represents one of the primary failure mechanisms for adhesive bonds in electronic applications, particularly affecting delamination resistance.

Mechanical stress testing incorporates various approaches including peel strength measurements (ASTM D903), shear strength evaluations (ASTM D1002), and dynamic mechanical analysis. These tests quantify the adhesive's ability to withstand physical forces and recover after deformation. For self-healing films specifically, cyclic loading tests are employed to assess the material's recovery capabilities after repeated stress applications.

Chemical resistance testing exposes adhesives to common electronic manufacturing chemicals, including flux residues, cleaning agents, and environmental contaminants. This evaluation ensures the self-healing mechanisms remain functional even after chemical exposure, which is particularly important for electronics deployed in harsh environments.

Performance standards for self-healing adhesive films typically require maintaining at least 80% of original bond strength after healing cycles. The healing efficiency is commonly measured through comparative mechanical testing before damage, after damage, and following the healing process. Industry standards often specify healing activation parameters, including temperature ranges (typically 60-120°C), pressure requirements, and healing duration (minutes to hours).

Accelerated aging tests simulate years of environmental exposure in compressed timeframes, allowing manufacturers to predict long-term reliability. These tests often combine multiple stressors (temperature, humidity, UV exposure) to create worst-case scenarios for adhesive performance evaluation.

Electrical performance testing measures the adhesive's ability to maintain dielectric properties and prevent electrical leakage after healing events. This includes insulation resistance measurements and dielectric breakdown voltage testing according to IEC 60243 standards.

The reliability of the rebonding process is quantified through repeated delamination-healing cycles, with industry standards typically requiring materials to withstand 5-10 complete cycles while maintaining at least 70% of original performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!