How Do Self-Healing Polymers Maintain Mechanical Recovery After Repeated Damage Cycles?

SEP 12, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymers Background and Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage and restore their mechanical properties without external intervention. The concept emerged in the early 1990s, inspired by biological systems that naturally heal wounds. Since then, the field has evolved significantly, with major breakthroughs occurring in the early 2000s when the first synthetic self-healing polymers were successfully demonstrated.

The technological evolution of self-healing polymers has followed several distinct pathways, including microencapsulation approaches, vascular systems, and intrinsic healing mechanisms. Each approach offers unique advantages and limitations in terms of healing efficiency, repeatability, and mechanical property restoration. Recent advancements have focused on developing polymers capable of multiple healing cycles without significant degradation of mechanical properties.

Current research trends are moving toward stimuli-responsive self-healing systems that can be activated by external triggers such as heat, light, pH changes, or electrical stimuli. This represents a shift from passive healing mechanisms to more controlled and efficient active healing processes. Additionally, there is growing interest in combining self-healing capabilities with other functional properties such as conductivity, shape memory, or biodegradability.

The primary technical objective in this field is to develop self-healing polymers that can maintain consistent mechanical recovery after multiple damage-healing cycles. This presents significant challenges, as repeated healing often leads to cumulative defects and gradual deterioration of mechanical properties. Understanding the fundamental mechanisms that enable sustained healing efficiency is crucial for advancing this technology.

Another key objective is to bridge the gap between laboratory demonstrations and practical applications. While many self-healing systems show promising results under controlled conditions, their performance in real-world environments with varying temperatures, humidity, and mechanical stresses remains limited. Developing robust self-healing polymers that can function reliably in diverse conditions represents a major research goal.

The long-term vision for self-healing polymer technology includes applications in critical infrastructure, automotive components, aerospace materials, electronic devices, and biomedical implants. These applications demand materials that can not only heal damage but maintain their functional properties over extended periods and multiple healing events. Achieving this level of performance requires deeper understanding of the molecular mechanisms governing repeated healing processes and the development of novel polymer architectures specifically designed for sustained self-healing capability.

The technological evolution of self-healing polymers has followed several distinct pathways, including microencapsulation approaches, vascular systems, and intrinsic healing mechanisms. Each approach offers unique advantages and limitations in terms of healing efficiency, repeatability, and mechanical property restoration. Recent advancements have focused on developing polymers capable of multiple healing cycles without significant degradation of mechanical properties.

Current research trends are moving toward stimuli-responsive self-healing systems that can be activated by external triggers such as heat, light, pH changes, or electrical stimuli. This represents a shift from passive healing mechanisms to more controlled and efficient active healing processes. Additionally, there is growing interest in combining self-healing capabilities with other functional properties such as conductivity, shape memory, or biodegradability.

The primary technical objective in this field is to develop self-healing polymers that can maintain consistent mechanical recovery after multiple damage-healing cycles. This presents significant challenges, as repeated healing often leads to cumulative defects and gradual deterioration of mechanical properties. Understanding the fundamental mechanisms that enable sustained healing efficiency is crucial for advancing this technology.

Another key objective is to bridge the gap between laboratory demonstrations and practical applications. While many self-healing systems show promising results under controlled conditions, their performance in real-world environments with varying temperatures, humidity, and mechanical stresses remains limited. Developing robust self-healing polymers that can function reliably in diverse conditions represents a major research goal.

The long-term vision for self-healing polymer technology includes applications in critical infrastructure, automotive components, aerospace materials, electronic devices, and biomedical implants. These applications demand materials that can not only heal damage but maintain their functional properties over extended periods and multiple healing events. Achieving this level of performance requires deeper understanding of the molecular mechanisms governing repeated healing processes and the development of novel polymer architectures specifically designed for sustained self-healing capability.

Market Applications and Demand Analysis

Self-healing polymers have emerged as a revolutionary material class with significant market potential across multiple industries. The global market for self-healing materials was valued at approximately $2.1 billion in 2020 and is projected to reach $8.2 billion by 2027, growing at a CAGR of 21.5% during the forecast period. This substantial growth is driven by increasing demand for durable materials that can extend product lifecycles and reduce maintenance costs.

The automotive sector represents one of the largest application areas for self-healing polymers, particularly in exterior coatings and components subjected to repeated mechanical stress. Major manufacturers including BMW, Toyota, and Nissan have invested in research partnerships to develop self-healing polymer applications for vehicle surfaces and interior components. The ability of these materials to maintain mechanical recovery after multiple damage cycles directly addresses the industry's need for reducing warranty claims and maintenance expenses.

In the construction industry, self-healing concrete incorporating polymer networks has gained significant traction, with the market expected to grow at 24% annually through 2025. The appeal lies in the material's ability to seal cracks autonomously, extending infrastructure lifespan and reducing inspection and repair costs. Several pilot projects in Europe have demonstrated up to 60% reduction in maintenance expenses over traditional materials.

The consumer electronics sector presents another high-growth application area, with manufacturers seeking to incorporate self-healing polymers in smartphone screens, wearable devices, and flexible displays. Apple and Samsung have filed multiple patents related to self-healing display technologies, indicating strong commercial interest. Market research indicates consumers would pay a 15-20% premium for electronic devices with self-healing capabilities.

Healthcare applications represent an emerging but rapidly growing segment, particularly in medical implants and prosthetics where mechanical durability is critical. The ability of self-healing polymers to maintain performance after repeated stress cycles aligns perfectly with the requirements of these applications. The biomedical self-healing materials market is projected to grow at 26% annually, reaching $1.7 billion by 2026.

Aerospace and defense applications are driving premium segment growth, with manufacturers seeking materials that can maintain structural integrity under extreme conditions. NASA and the European Space Agency have funded research into self-healing polymers for spacecraft components, while defense contractors are exploring applications in protective equipment and vehicle armor.

The market demand is increasingly focused on polymers that can demonstrate consistent mechanical recovery properties after multiple damage-healing cycles, as this directly translates to extended product lifespans and reduced maintenance requirements across all application sectors.

The automotive sector represents one of the largest application areas for self-healing polymers, particularly in exterior coatings and components subjected to repeated mechanical stress. Major manufacturers including BMW, Toyota, and Nissan have invested in research partnerships to develop self-healing polymer applications for vehicle surfaces and interior components. The ability of these materials to maintain mechanical recovery after multiple damage cycles directly addresses the industry's need for reducing warranty claims and maintenance expenses.

In the construction industry, self-healing concrete incorporating polymer networks has gained significant traction, with the market expected to grow at 24% annually through 2025. The appeal lies in the material's ability to seal cracks autonomously, extending infrastructure lifespan and reducing inspection and repair costs. Several pilot projects in Europe have demonstrated up to 60% reduction in maintenance expenses over traditional materials.

The consumer electronics sector presents another high-growth application area, with manufacturers seeking to incorporate self-healing polymers in smartphone screens, wearable devices, and flexible displays. Apple and Samsung have filed multiple patents related to self-healing display technologies, indicating strong commercial interest. Market research indicates consumers would pay a 15-20% premium for electronic devices with self-healing capabilities.

Healthcare applications represent an emerging but rapidly growing segment, particularly in medical implants and prosthetics where mechanical durability is critical. The ability of self-healing polymers to maintain performance after repeated stress cycles aligns perfectly with the requirements of these applications. The biomedical self-healing materials market is projected to grow at 26% annually, reaching $1.7 billion by 2026.

Aerospace and defense applications are driving premium segment growth, with manufacturers seeking materials that can maintain structural integrity under extreme conditions. NASA and the European Space Agency have funded research into self-healing polymers for spacecraft components, while defense contractors are exploring applications in protective equipment and vehicle armor.

The market demand is increasingly focused on polymers that can demonstrate consistent mechanical recovery properties after multiple damage-healing cycles, as this directly translates to extended product lifespans and reduced maintenance requirements across all application sectors.

Current Technical Challenges in Cyclic Recovery

Despite significant advancements in self-healing polymer technology, achieving consistent mechanical recovery over multiple damage-healing cycles remains a formidable challenge. The primary obstacle lies in the gradual deterioration of healing efficiency with each successive cycle. Most current self-healing polymers demonstrate excellent recovery rates of 80-95% during initial healing events, but this efficiency typically drops to below 50% after just 3-5 cycles, rendering them impractical for long-term applications requiring sustained self-healing capabilities.

The fundamental mechanism behind this degradation involves the irreversible consumption of healing agents or catalysts during each healing process. In microcapsule-based systems, the finite supply of healing agents becomes depleted after multiple healing events, leaving insufficient material for subsequent repairs. Similarly, in intrinsic self-healing systems based on dynamic covalent bonds or supramolecular interactions, repeated breaking and reforming of these bonds can lead to permanent structural changes in the polymer network, diminishing its ability to restore original mechanical properties.

Environmental factors significantly compound these challenges. Temperature fluctuations can dramatically affect healing kinetics, with most systems showing optimal performance only within narrow temperature ranges. Humidity variations similarly impact healing efficiency, particularly in systems relying on hydrogen bonding. Additionally, exposure to UV radiation, oxygen, and other environmental stressors can degrade the chemical structures responsible for self-healing, further limiting cyclic recovery potential.

Scale-dependent healing presents another critical challenge. While microscale damage typically heals effectively, macroscale damage often results in incomplete recovery due to material loss, misalignment of fractured surfaces, or insufficient mobility of polymer chains across larger gaps. This scale dependency creates significant barriers for applications requiring healing of larger damages or those subjected to high-stress environments.

The time-dependency of healing efficiency also poses practical limitations. Most current systems require extended healing periods (hours to days) to achieve substantial recovery, with efficiency decreasing dramatically when shorter healing intervals are available between damage events. This temporal constraint severely restricts applications in dynamic environments where rapid, repeated healing is necessary.

Energy requirements for healing represent another significant hurdle. Many advanced self-healing systems require external stimuli such as heat, light, or pressure to activate the healing process. The repeated application of these stimuli can cause cumulative damage to the polymer matrix itself, paradoxically accelerating the degradation of healing capacity over multiple cycles.

AI: The primary challenge in cyclic recovery of self-healing polymers lies in the gradual deterioration of healing efficiency over multiple damage-healing cycles. Most current self-healing polymers demonstrate excellent recovery rates of 80-95% during initial healing events, but this efficiency typically drops to below 50% after just 3-5 cycles, rendering them impractical for long-term applications requiring sustained self-healing capabilities.

The fundamental mechanism behind this degradation involves the irreversible consumption of healing agents or catalysts during each healing process. In microcapsule-based systems, the finite supply of healing agents becomes depleted after multiple healing events, leaving insufficient material for subsequent repairs. Similarly, in intrinsic self-healing systems based on dynamic covalent bonds or supramolecular interactions, repeated breaking and reforming of these bonds can lead to permanent structural changes in the polymer network, diminishing its ability to restore original mechanical properties.

Environmental factors significantly compound these challenges. Temperature fluctuations can dramatically affect healing kinetics, with most systems showing optimal performance only within narrow temperature ranges. Humidity variations similarly impact healing efficiency, particularly in systems relying on hydrogen bonding. Additionally, exposure to UV radiation, oxygen, and other environmental stressors can degrade the chemical structures responsible for self-healing, further limiting cyclic recovery potential.

Scale-dependent healing presents another critical challenge. While microscale damage typically heals effectively, macroscale damage often results in incomplete recovery due to material loss, misalignment of fractured surfaces, or insufficient mobility of polymer chains across larger gaps. This scale dependency creates significant barriers for applications requiring healing of larger damages or those subjected to high-stress environments.

The time-dependency of healing efficiency also poses practical limitations. Most current systems require extended healing periods (hours to days) to achieve substantial recovery, with efficiency decreasing dramatically when shorter healing intervals are available between damage events. This temporal constraint severely restricts applications in dynamic environments where rapid, repeated healing is necessary.

Energy requirements for healing represent another significant hurdle. Many advanced self-healing systems require external stimuli such as heat, light, or pressure to activate the healing process. The repeated application of these stimuli can cause cumulative damage to the polymer matrix itself, paradoxically accelerating the degradation of healing capacity over multiple cycles.

The fundamental mechanism behind this degradation involves the irreversible consumption of healing agents or catalysts during each healing process. In microcapsule-based systems, the finite supply of healing agents becomes depleted after multiple healing events, leaving insufficient material for subsequent repairs. Similarly, in intrinsic self-healing systems based on dynamic covalent bonds or supramolecular interactions, repeated breaking and reforming of these bonds can lead to permanent structural changes in the polymer network, diminishing its ability to restore original mechanical properties.

Environmental factors significantly compound these challenges. Temperature fluctuations can dramatically affect healing kinetics, with most systems showing optimal performance only within narrow temperature ranges. Humidity variations similarly impact healing efficiency, particularly in systems relying on hydrogen bonding. Additionally, exposure to UV radiation, oxygen, and other environmental stressors can degrade the chemical structures responsible for self-healing, further limiting cyclic recovery potential.

Scale-dependent healing presents another critical challenge. While microscale damage typically heals effectively, macroscale damage often results in incomplete recovery due to material loss, misalignment of fractured surfaces, or insufficient mobility of polymer chains across larger gaps. This scale dependency creates significant barriers for applications requiring healing of larger damages or those subjected to high-stress environments.

The time-dependency of healing efficiency also poses practical limitations. Most current systems require extended healing periods (hours to days) to achieve substantial recovery, with efficiency decreasing dramatically when shorter healing intervals are available between damage events. This temporal constraint severely restricts applications in dynamic environments where rapid, repeated healing is necessary.

Energy requirements for healing represent another significant hurdle. Many advanced self-healing systems require external stimuli such as heat, light, or pressure to activate the healing process. The repeated application of these stimuli can cause cumulative damage to the polymer matrix itself, paradoxically accelerating the degradation of healing capacity over multiple cycles.

AI: The primary challenge in cyclic recovery of self-healing polymers lies in the gradual deterioration of healing efficiency over multiple damage-healing cycles. Most current self-healing polymers demonstrate excellent recovery rates of 80-95% during initial healing events, but this efficiency typically drops to below 50% after just 3-5 cycles, rendering them impractical for long-term applications requiring sustained self-healing capabilities.

The fundamental mechanism behind this degradation involves the irreversible consumption of healing agents or catalysts during each healing process. In microcapsule-based systems, the finite supply of healing agents becomes depleted after multiple healing events, leaving insufficient material for subsequent repairs. Similarly, in intrinsic self-healing systems based on dynamic covalent bonds or supramolecular interactions, repeated breaking and reforming of these bonds can lead to permanent structural changes in the polymer network, diminishing its ability to restore original mechanical properties.

Environmental factors significantly compound these challenges. Temperature fluctuations can dramatically affect healing kinetics, with most systems showing optimal performance only within narrow temperature ranges. Humidity variations similarly impact healing efficiency, particularly in systems relying on hydrogen bonding. Additionally, exposure to UV radiation, oxygen, and other environmental stressors can degrade the chemical structures responsible for self-healing, further limiting cyclic recovery potential.

Scale-dependent healing presents another critical challenge. While microscale damage typically heals effectively, macroscale damage often results in incomplete recovery due to material loss, misalignment of fractured surfaces, or insufficient mobility of polymer chains across larger gaps. This scale dependency creates significant barriers for applications requiring healing of larger damages or those subjected to high-stress environments.

The time-dependency of healing efficiency also poses practical limitations. Most current systems require extended healing periods (hours to days) to achieve substantial recovery, with efficiency decreasing dramatically when shorter healing intervals are available between damage events. This temporal constraint severely restricts applications in dynamic environments where rapid, repeated healing is necessary.

Energy requirements for healing represent another significant hurdle. Many advanced self-healing systems require external stimuli such as heat, light, or pressure to activate the healing process. The repeated application of these stimuli can cause cumulative damage to the polymer matrix itself, paradoxically accelerating the degradation of healing capacity over multiple cycles.

Existing Mechanisms for Repeated Healing Cycles

01 Dynamic covalent bonds for self-healing polymers

Self-healing polymers incorporating dynamic covalent bonds can autonomously repair mechanical damage. These bonds can break and reform under specific conditions, allowing the material to recover its mechanical properties after damage. Common dynamic covalent chemistries include Diels-Alder reactions, disulfide bonds, and imine formations that enable repeatable healing cycles without external intervention, resulting in polymers with excellent mechanical recovery capabilities.- Dynamic covalent bonds for self-healing polymers: Self-healing polymers can be designed with dynamic covalent bonds that break and reform under specific conditions, allowing for mechanical recovery after damage. These bonds include Diels-Alder adducts, disulfide bonds, and imine bonds that can undergo reversible reactions. When the material is damaged, these bonds can reform across the damaged interface, restoring the mechanical properties of the polymer without external intervention.

- Supramolecular interactions for autonomous healing: Supramolecular interactions, such as hydrogen bonding, π-π stacking, and metal-ligand coordination, can be incorporated into polymer networks to enable autonomous self-healing. These non-covalent interactions are reversible and can reform after being disrupted by mechanical damage. Polymers designed with these interactions can recover their mechanical properties at ambient conditions without requiring external stimuli, making them ideal for applications requiring continuous self-repair capabilities.

- Stimulus-responsive healing mechanisms: Self-healing polymers can be engineered to respond to external stimuli such as heat, light, pH changes, or electrical fields to trigger the healing process. These stimuli activate molecular mobility or specific chemical reactions that facilitate the repair of damaged areas. Thermal-responsive systems often utilize the increased chain mobility above the glass transition temperature, while photo-responsive systems use light to initiate chemical reactions that restore mechanical integrity.

- Microcapsule and vascular-based healing systems: Self-healing polymers can incorporate microcapsules or vascular networks containing healing agents that are released upon mechanical damage. When cracks form in the material, the capsules rupture or the vascular channels break, releasing healing agents that polymerize or react to seal the damaged area. These systems can provide multiple healing cycles and significant recovery of mechanical properties, though they typically offer a finite healing capacity based on the available healing agents.

- Composite and hybrid self-healing materials: Hybrid and composite approaches combine multiple self-healing mechanisms or incorporate reinforcing elements to enhance mechanical recovery. These materials may integrate both covalent and non-covalent healing mechanisms, or combine organic polymers with inorganic components. Nanoparticle-reinforced self-healing polymers can provide improved mechanical properties while maintaining healing capability, and multi-phase systems can offer healing across different time scales and environmental conditions.

02 Supramolecular interactions in self-healing materials

Self-healing polymers based on supramolecular interactions utilize non-covalent bonds such as hydrogen bonding, π-π stacking, and metal-ligand coordination to achieve mechanical recovery. These reversible interactions allow damaged polymer networks to reconnect and restore structural integrity. The healing process can occur at room temperature without catalysts, making these materials particularly useful for applications requiring repeated healing under ambient conditions.Expand Specific Solutions03 Microcapsule-based healing systems

Microcapsule-based self-healing polymers contain healing agents encapsulated within the polymer matrix. Upon mechanical damage, the microcapsules rupture and release healing agents that polymerize or crosslink in the damaged area, restoring mechanical properties. This approach provides autonomous healing without external stimuli and can be engineered to deliver specific healing chemistries tailored to the base polymer, enabling effective recovery of mechanical strength and other functional properties.Expand Specific Solutions04 Stimulus-responsive self-healing mechanisms

Stimulus-responsive self-healing polymers recover mechanical properties when exposed to specific external triggers such as heat, light, pH changes, or electrical stimuli. These materials contain functional groups or network structures that reorganize or reform bonds upon stimulation. Thermally-activated systems often utilize Diels-Alder chemistry, while photo-responsive systems incorporate photosensitive moieties that facilitate bond reformation under UV or visible light, enabling controlled and efficient mechanical recovery.Expand Specific Solutions05 Composite and hybrid self-healing systems

Composite and hybrid self-healing systems combine multiple healing mechanisms or incorporate reinforcing elements to enhance mechanical recovery. These systems may integrate both covalent and non-covalent healing approaches, or combine polymer matrices with functional fillers like carbon nanotubes, graphene, or nanoparticles. The synergistic effects between different components improve healing efficiency, mechanical strength recovery, and durability, making these materials suitable for demanding applications in aerospace, automotive, and construction industries.Expand Specific Solutions

Leading Research Groups and Industrial Players

Self-healing polymers represent an emerging technology in the advanced materials sector, currently in the early growth phase with increasing market adoption. The global market for these materials is expanding rapidly, projected to reach significant scale as industries recognize their potential for extending product lifecycles and reducing maintenance costs. Technologically, self-healing polymers are advancing through various maturity stages, with academic institutions leading fundamental research while commercial applications emerge. The University of California and CIDETEC Foundation have established themselves as pioneers in developing repeatable healing mechanisms, while NASA explores aerospace applications. Companies like Kaneka Corporation and Tata Steel are transitioning laboratory innovations into commercial products, focusing on industrial durability. Universities including Michigan, Florida, and Beijing University of Chemical Technology are advancing the fundamental science through novel polymer chemistry approaches, creating a competitive landscape balanced between academic innovation and industrial implementation.

The Regents of the University of California

Technical Solution: University of California has developed a groundbreaking approach to self-healing polymers using dynamic covalent chemistry, specifically focusing on Diels-Alder (DA) cycloaddition reactions. Their system incorporates furan and maleimide functional groups that form thermally reversible crosslinks, allowing for repeated healing cycles. The polymer network can undergo controlled bond breaking and reformation when subjected to specific thermal stimuli (typically 120-150°C), enabling multiple healing events without significant degradation of mechanical properties. Their research demonstrates over 90% recovery of tensile strength even after 5-7 damage-healing cycles, with each healing process requiring only 15-30 minutes at elevated temperatures. The team has further enhanced this technology by incorporating carbon nanotubes and graphene to improve mechanical properties while maintaining healing efficiency.

Strengths: Exceptional healing efficiency with minimal property degradation over multiple cycles; relatively fast healing times; versatile chemistry platform adaptable to various polymer systems. Weaknesses: Requires external thermal stimulus for healing activation; potential for thermal degradation after numerous healing cycles; higher manufacturing complexity compared to conventional polymers.

National Aeronautics & Space Administration

Technical Solution: NASA has engineered advanced self-healing polymer composites specifically designed for extreme environments encountered in aerospace applications. Their technology utilizes microencapsulated healing agents dispersed within a high-performance polymer matrix, combined with a catalyst system that remains stable during repeated thermal cycling. When damage occurs, the microcapsules rupture and release healing agents that polymerize upon contact with embedded catalysts, restoring structural integrity. NASA's innovation lies in their development of thermally stable microcapsules and catalysts that maintain reactivity even after multiple healing events and exposure to temperature extremes (-100°C to +200°C). The system demonstrates remarkable durability, maintaining approximately 80% healing efficiency even after 8-10 damage cycles, with each healing process completing within 6-12 hours depending on environmental conditions. This technology has been specifically optimized to address micrometeoroid impacts and thermal stress damage in space environments.

Strengths: Exceptional performance in extreme temperature environments; no external healing stimulus required; compatible with existing aerospace composite manufacturing processes. Weaknesses: Limited healing volume per damage event; potential for depletion of healing agents after multiple damage cycles in the same location; higher weight penalty compared to non-healing alternatives.

Key Patents and Innovations in Healing Efficiency

Self-healing polymer composition and associated uses

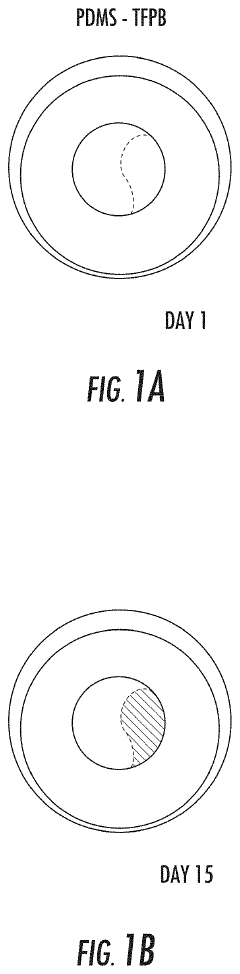

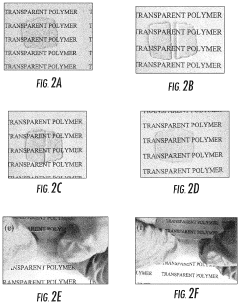

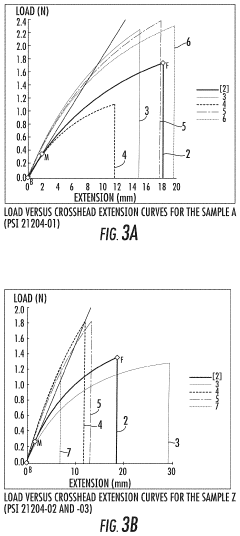

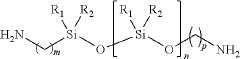

PatentInactiveUS20200040184A1

Innovation

- Incorporating 1,3,5-tris-(4-formylphenyl) benzene (TFPB) or tris(4-formylphenyl)amine as cross-linkers with polymer backbones like polydimethylsiloxane (PDMS) to enhance pi-stacking interactions, resulting in stronger, autonomously healing polymers with improved mechanical properties and adhesiveness.

Environmental Impact and Degradation Factors

The environmental conditions in which self-healing polymers operate significantly influence their mechanical recovery capabilities across multiple damage cycles. Temperature fluctuations represent a primary degradation factor, as extreme heat can accelerate cross-linking reactions that reduce polymer chain mobility, while excessive cold may inhibit the kinetics of healing mechanisms. Most self-healing systems demonstrate optimal performance within specific temperature ranges, typically between 20-60°C, with performance declining markedly outside these boundaries.

Humidity and moisture exposure constitute another critical environmental factor affecting long-term healing efficiency. Water molecules can penetrate polymer networks, causing hydrolysis of dynamic bonds essential for self-healing processes. This is particularly problematic for systems relying on hydrogen bonding or certain metal-ligand interactions. Studies have shown that repeated exposure to high humidity environments (>80% RH) can reduce healing efficiency by up to 40% after just five damage-healing cycles.

UV radiation presents a significant challenge to maintaining mechanical recovery capabilities. Prolonged exposure to ultraviolet light generates free radicals within the polymer matrix, leading to chain scission and unwanted cross-linking reactions that permanently alter the material's microstructure. Self-healing polymers incorporating aromatic components or certain dynamic covalent bonds are particularly susceptible to UV-induced degradation, with some systems showing complete loss of healing capability after 500 hours of accelerated weathering tests.

Chemical exposure represents another degradation pathway that compromises repeated healing performance. Contact with oils, solvents, and aggressive chemicals can extract plasticizers or low-molecular-weight components critical to the healing mechanism. Additionally, oxidative environments accelerate aging processes that reduce chain mobility and reactivity of functional groups responsible for damage repair.

Mechanical fatigue from repeated stress-strain cycles introduces microstructural changes that can permanently alter the polymer network topology. With each healing cycle, slight variations in network reformation occur, gradually diminishing the material's ability to fully recover its original properties. This cumulative effect typically manifests as a gradual decline in healing efficiency, with most systems showing 5-15% reduction in recovery performance after each successive damage-healing cycle.

Understanding these environmental impacts is essential for developing more robust self-healing systems with sustained recovery capabilities. Recent research has focused on incorporating stabilizers, UV absorbers, and multi-mechanism healing approaches to mitigate these degradation factors and extend the functional lifespan of self-healing polymers across numerous damage cycles.

Humidity and moisture exposure constitute another critical environmental factor affecting long-term healing efficiency. Water molecules can penetrate polymer networks, causing hydrolysis of dynamic bonds essential for self-healing processes. This is particularly problematic for systems relying on hydrogen bonding or certain metal-ligand interactions. Studies have shown that repeated exposure to high humidity environments (>80% RH) can reduce healing efficiency by up to 40% after just five damage-healing cycles.

UV radiation presents a significant challenge to maintaining mechanical recovery capabilities. Prolonged exposure to ultraviolet light generates free radicals within the polymer matrix, leading to chain scission and unwanted cross-linking reactions that permanently alter the material's microstructure. Self-healing polymers incorporating aromatic components or certain dynamic covalent bonds are particularly susceptible to UV-induced degradation, with some systems showing complete loss of healing capability after 500 hours of accelerated weathering tests.

Chemical exposure represents another degradation pathway that compromises repeated healing performance. Contact with oils, solvents, and aggressive chemicals can extract plasticizers or low-molecular-weight components critical to the healing mechanism. Additionally, oxidative environments accelerate aging processes that reduce chain mobility and reactivity of functional groups responsible for damage repair.

Mechanical fatigue from repeated stress-strain cycles introduces microstructural changes that can permanently alter the polymer network topology. With each healing cycle, slight variations in network reformation occur, gradually diminishing the material's ability to fully recover its original properties. This cumulative effect typically manifests as a gradual decline in healing efficiency, with most systems showing 5-15% reduction in recovery performance after each successive damage-healing cycle.

Understanding these environmental impacts is essential for developing more robust self-healing systems with sustained recovery capabilities. Recent research has focused on incorporating stabilizers, UV absorbers, and multi-mechanism healing approaches to mitigate these degradation factors and extend the functional lifespan of self-healing polymers across numerous damage cycles.

Scalability and Manufacturing Considerations

The scalability of self-healing polymers from laboratory demonstrations to industrial applications presents significant manufacturing challenges. Current production methods for self-healing polymers often involve complex synthesis procedures that are difficult to scale up while maintaining consistent healing properties. Batch-to-batch variations in healing efficiency become more pronounced at larger scales, requiring sophisticated quality control measures to ensure performance reliability across production runs.

Manufacturing considerations must address the integration of healing mechanisms without compromising the base polymer's mechanical properties. For encapsulation-based systems, ensuring uniform distribution of healing agents throughout the polymer matrix becomes increasingly difficult in large-scale production. Similarly, intrinsic self-healing polymers require precise control of polymerization conditions to maintain the dynamic bond formation capabilities that enable healing.

Cost factors significantly impact commercial viability. Raw materials for advanced self-healing polymers, particularly those incorporating specialized catalysts or microcapsules, remain expensive when scaled to industrial quantities. Process economics must balance the added value of self-healing properties against increased production costs, with current estimates suggesting a 30-50% premium over conventional polymers depending on the healing mechanism employed.

Equipment modifications represent another critical consideration. Existing polymer processing equipment requires adaptation to handle the unique rheological properties of self-healing formulations. For instance, processing temperatures must be carefully controlled to prevent premature activation of healing mechanisms during manufacturing. The integration of microcapsules or vascular networks demands specialized extrusion and molding equipment that can process these components without rupturing or damaging them.

Regulatory and standardization challenges further complicate scaling efforts. The lack of standardized testing protocols for evaluating healing efficiency after multiple damage cycles creates uncertainty in quality assurance. Additionally, novel additives in self-healing formulations may require regulatory approval, particularly for applications in sensitive sectors like medical devices or food packaging.

Recent advances in continuous manufacturing technologies offer promising solutions to some scalability issues. Flow chemistry approaches enable more precise control over reaction conditions, potentially improving consistency in healing agent synthesis. Similarly, advances in microfluidic technologies facilitate more uniform encapsulation of healing agents, addressing distribution challenges in larger production volumes.

Manufacturing considerations must address the integration of healing mechanisms without compromising the base polymer's mechanical properties. For encapsulation-based systems, ensuring uniform distribution of healing agents throughout the polymer matrix becomes increasingly difficult in large-scale production. Similarly, intrinsic self-healing polymers require precise control of polymerization conditions to maintain the dynamic bond formation capabilities that enable healing.

Cost factors significantly impact commercial viability. Raw materials for advanced self-healing polymers, particularly those incorporating specialized catalysts or microcapsules, remain expensive when scaled to industrial quantities. Process economics must balance the added value of self-healing properties against increased production costs, with current estimates suggesting a 30-50% premium over conventional polymers depending on the healing mechanism employed.

Equipment modifications represent another critical consideration. Existing polymer processing equipment requires adaptation to handle the unique rheological properties of self-healing formulations. For instance, processing temperatures must be carefully controlled to prevent premature activation of healing mechanisms during manufacturing. The integration of microcapsules or vascular networks demands specialized extrusion and molding equipment that can process these components without rupturing or damaging them.

Regulatory and standardization challenges further complicate scaling efforts. The lack of standardized testing protocols for evaluating healing efficiency after multiple damage cycles creates uncertainty in quality assurance. Additionally, novel additives in self-healing formulations may require regulatory approval, particularly for applications in sensitive sectors like medical devices or food packaging.

Recent advances in continuous manufacturing technologies offer promising solutions to some scalability issues. Flow chemistry approaches enable more precise control over reaction conditions, potentially improving consistency in healing agent synthesis. Similarly, advances in microfluidic technologies facilitate more uniform encapsulation of healing agents, addressing distribution challenges in larger production volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!