Self-Healing Polymers For Pressure-Tight Housings: Crack Closure, Seal Integrity And Proof Testing

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymer Technology Evolution and Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage, extending their service life and maintaining functionality under adverse conditions. The concept emerged in the early 2000s when researchers first demonstrated synthetic materials with self-healing capabilities inspired by biological systems. Since then, the field has evolved from simple proof-of-concept demonstrations to sophisticated engineered materials with practical applications in various industries.

The evolution of self-healing polymer technology has followed several distinct phases. Initially, researchers focused on encapsulation-based systems where healing agents were stored in microcapsules that would rupture upon damage, releasing the agents to repair cracks. This approach, pioneered by White and colleagues in 2001, provided the foundation for subsequent developments. The second generation introduced vascular networks, mimicking biological circulatory systems, which could continuously supply healing agents to damaged areas.

More recent advancements have shifted toward intrinsic self-healing mechanisms, where the polymer itself possesses reversible bonds that can reform after being broken. These include materials based on hydrogen bonding, metal-ligand coordination, dynamic covalent chemistry, and supramolecular interactions. Each approach offers specific advantages in terms of healing efficiency, mechanical properties, and environmental responsiveness.

For pressure-tight housing applications, the technology has evolved to address specific challenges related to maintaining seal integrity under varying pressure conditions. Early self-healing polymers lacked the mechanical strength and pressure resistance required for such applications. However, recent developments have yielded materials that combine self-healing properties with enhanced mechanical performance, making them suitable for pressure-containing structures.

The primary objectives of current research in self-healing polymers for pressure-tight housings include achieving rapid healing response times, maintaining structural integrity during the healing process, and ensuring consistent performance across multiple damage-healing cycles. Researchers aim to develop materials that can autonomously detect and repair microcracks before they propagate into catastrophic failures, thereby preventing pressure loss in critical systems.

Additional technical goals include improving the healing efficiency at lower temperatures, enhancing the compatibility with existing manufacturing processes, and developing standardized testing protocols to validate seal integrity after healing events. The ultimate objective is to create self-healing polymer systems that can maintain pressure-tight seals throughout their operational lifetime, significantly reducing maintenance requirements and enhancing safety in applications ranging from underwater equipment to aerospace components.

The evolution of self-healing polymer technology has followed several distinct phases. Initially, researchers focused on encapsulation-based systems where healing agents were stored in microcapsules that would rupture upon damage, releasing the agents to repair cracks. This approach, pioneered by White and colleagues in 2001, provided the foundation for subsequent developments. The second generation introduced vascular networks, mimicking biological circulatory systems, which could continuously supply healing agents to damaged areas.

More recent advancements have shifted toward intrinsic self-healing mechanisms, where the polymer itself possesses reversible bonds that can reform after being broken. These include materials based on hydrogen bonding, metal-ligand coordination, dynamic covalent chemistry, and supramolecular interactions. Each approach offers specific advantages in terms of healing efficiency, mechanical properties, and environmental responsiveness.

For pressure-tight housing applications, the technology has evolved to address specific challenges related to maintaining seal integrity under varying pressure conditions. Early self-healing polymers lacked the mechanical strength and pressure resistance required for such applications. However, recent developments have yielded materials that combine self-healing properties with enhanced mechanical performance, making them suitable for pressure-containing structures.

The primary objectives of current research in self-healing polymers for pressure-tight housings include achieving rapid healing response times, maintaining structural integrity during the healing process, and ensuring consistent performance across multiple damage-healing cycles. Researchers aim to develop materials that can autonomously detect and repair microcracks before they propagate into catastrophic failures, thereby preventing pressure loss in critical systems.

Additional technical goals include improving the healing efficiency at lower temperatures, enhancing the compatibility with existing manufacturing processes, and developing standardized testing protocols to validate seal integrity after healing events. The ultimate objective is to create self-healing polymer systems that can maintain pressure-tight seals throughout their operational lifetime, significantly reducing maintenance requirements and enhancing safety in applications ranging from underwater equipment to aerospace components.

Market Demand for Pressure-Tight Housing Solutions

The global market for pressure-tight housing solutions has been experiencing significant growth, driven by increasing demands across multiple industries including automotive, aerospace, electronics, and marine applications. These sectors require robust enclosures that maintain integrity under varying pressure conditions while ensuring longevity and reliability of internal components.

The automotive industry represents one of the largest market segments, with a growing need for pressure-tight housings in electric vehicle battery enclosures, fuel systems, and various powertrain components. As electric vehicles continue to gain market share, the demand for lightweight yet durable pressure-tight housings has intensified, creating new opportunities for advanced materials like self-healing polymers.

Aerospace applications constitute another critical market segment, where pressure-tight housings must perform under extreme conditions. The need for materials that can withstand rapid pressure changes, temperature fluctuations, and potential impact damage while maintaining seal integrity has become increasingly important as aircraft designs evolve toward more efficient and lightweight structures.

Marine and offshore industries face unique challenges related to corrosive environments and high-pressure conditions. Current solutions often require frequent maintenance and replacement, creating substantial operational costs. The market has shown strong interest in housing materials that can self-repair minor damage and maintain pressure integrity in harsh underwater environments.

Consumer electronics manufacturers are seeking more durable waterproof and pressure-resistant housings for portable devices, creating another growing market segment. As consumers demand more robust products for outdoor and extreme environment usage, the need for housings that can withstand pressure variations while maintaining perfect seals has increased dramatically.

Current market solutions predominantly rely on traditional materials such as metals, rigid polymers, and composite materials, which lack self-healing capabilities. This limitation creates significant maintenance requirements and reliability concerns, particularly in applications where continuous operation is critical or where access for repairs is difficult or costly.

The market gap for self-healing polymer solutions is substantial, with industry stakeholders actively seeking materials that can automatically respond to damage, maintain pressure integrity, and reduce maintenance costs. Early adopters are likely to be in high-value applications where failure costs are substantial, such as deep-sea equipment, aerospace components, and critical infrastructure.

Market research indicates that solutions offering verifiable seal integrity and reliable proof testing methodologies would command premium pricing, as they address fundamental pain points across multiple industries. The ability to demonstrate crack closure capabilities under actual operating conditions represents a key market differentiator for any new technology entering this space.

The automotive industry represents one of the largest market segments, with a growing need for pressure-tight housings in electric vehicle battery enclosures, fuel systems, and various powertrain components. As electric vehicles continue to gain market share, the demand for lightweight yet durable pressure-tight housings has intensified, creating new opportunities for advanced materials like self-healing polymers.

Aerospace applications constitute another critical market segment, where pressure-tight housings must perform under extreme conditions. The need for materials that can withstand rapid pressure changes, temperature fluctuations, and potential impact damage while maintaining seal integrity has become increasingly important as aircraft designs evolve toward more efficient and lightweight structures.

Marine and offshore industries face unique challenges related to corrosive environments and high-pressure conditions. Current solutions often require frequent maintenance and replacement, creating substantial operational costs. The market has shown strong interest in housing materials that can self-repair minor damage and maintain pressure integrity in harsh underwater environments.

Consumer electronics manufacturers are seeking more durable waterproof and pressure-resistant housings for portable devices, creating another growing market segment. As consumers demand more robust products for outdoor and extreme environment usage, the need for housings that can withstand pressure variations while maintaining perfect seals has increased dramatically.

Current market solutions predominantly rely on traditional materials such as metals, rigid polymers, and composite materials, which lack self-healing capabilities. This limitation creates significant maintenance requirements and reliability concerns, particularly in applications where continuous operation is critical or where access for repairs is difficult or costly.

The market gap for self-healing polymer solutions is substantial, with industry stakeholders actively seeking materials that can automatically respond to damage, maintain pressure integrity, and reduce maintenance costs. Early adopters are likely to be in high-value applications where failure costs are substantial, such as deep-sea equipment, aerospace components, and critical infrastructure.

Market research indicates that solutions offering verifiable seal integrity and reliable proof testing methodologies would command premium pricing, as they address fundamental pain points across multiple industries. The ability to demonstrate crack closure capabilities under actual operating conditions represents a key market differentiator for any new technology entering this space.

Technical Challenges in Crack Closure and Seal Integrity

The development of self-healing polymers for pressure-tight housings faces significant technical challenges, particularly in achieving effective crack closure and maintaining seal integrity. Current self-healing mechanisms often struggle with the high-pressure environments required for industrial applications. Microcapsule-based systems, while effective for small cracks, frequently fail when subjected to sustained pressure differentials exceeding 2-3 MPa, as the healing agents cannot withstand the mechanical forces during polymerization.

Vascular network healing systems offer improved healing capacity but present complex manufacturing challenges when integrated into pressure housings. Research by Toohey et al. (2018) demonstrated that these networks can collapse under external pressure exceeding 5 MPa, compromising the delivery of healing agents precisely when needed most. This fundamental limitation requires innovative structural reinforcement solutions that don't impede the healing functionality.

Another critical challenge lies in the kinetics of the healing process. Most current self-healing polymers require 24-72 hours to achieve full mechanical recovery, creating a vulnerable period during which pressure integrity cannot be guaranteed. This timing gap represents a significant barrier to implementation in safety-critical applications where immediate seal restoration is essential. Recent work by Chen and colleagues (2021) has reduced this window to 6-8 hours, but this remains insufficient for many industrial applications.

The interface between healed material and original substrate presents another persistent challenge. Spectroscopic analysis reveals that the molecular bonding at these interfaces typically achieves only 60-85% of the original material's strength. This reduction in mechanical properties is particularly problematic for pressure containment, where even small weaknesses can lead to catastrophic failure under cyclic loading conditions.

Environmental factors further complicate healing performance. Temperature fluctuations significantly impact healing efficiency, with most systems optimized for narrow operating ranges (typically 20-35°C). Performance degradation of 40-60% has been documented when operating outside these parameters. Similarly, moisture presence can interfere with polymerization reactions, particularly in intrinsic self-healing systems relying on hydrogen bonding or ionic interactions.

Validation methodologies present additional challenges. Traditional pressure testing protocols are designed for static materials and may not accurately characterize the dynamic properties of self-healing systems. The industry lacks standardized testing procedures specifically designed to evaluate healing efficiency under pressure conditions, making comparative analysis difficult and slowing adoption of promising technologies.

Addressing these technical challenges requires interdisciplinary approaches combining polymer chemistry, mechanical engineering, and materials science. Recent developments in stimuli-responsive healing triggers and multi-phase polymer systems show promise, but significant research gaps remain in creating truly pressure-resistant self-healing materials suitable for industrial implementation.

Vascular network healing systems offer improved healing capacity but present complex manufacturing challenges when integrated into pressure housings. Research by Toohey et al. (2018) demonstrated that these networks can collapse under external pressure exceeding 5 MPa, compromising the delivery of healing agents precisely when needed most. This fundamental limitation requires innovative structural reinforcement solutions that don't impede the healing functionality.

Another critical challenge lies in the kinetics of the healing process. Most current self-healing polymers require 24-72 hours to achieve full mechanical recovery, creating a vulnerable period during which pressure integrity cannot be guaranteed. This timing gap represents a significant barrier to implementation in safety-critical applications where immediate seal restoration is essential. Recent work by Chen and colleagues (2021) has reduced this window to 6-8 hours, but this remains insufficient for many industrial applications.

The interface between healed material and original substrate presents another persistent challenge. Spectroscopic analysis reveals that the molecular bonding at these interfaces typically achieves only 60-85% of the original material's strength. This reduction in mechanical properties is particularly problematic for pressure containment, where even small weaknesses can lead to catastrophic failure under cyclic loading conditions.

Environmental factors further complicate healing performance. Temperature fluctuations significantly impact healing efficiency, with most systems optimized for narrow operating ranges (typically 20-35°C). Performance degradation of 40-60% has been documented when operating outside these parameters. Similarly, moisture presence can interfere with polymerization reactions, particularly in intrinsic self-healing systems relying on hydrogen bonding or ionic interactions.

Validation methodologies present additional challenges. Traditional pressure testing protocols are designed for static materials and may not accurately characterize the dynamic properties of self-healing systems. The industry lacks standardized testing procedures specifically designed to evaluate healing efficiency under pressure conditions, making comparative analysis difficult and slowing adoption of promising technologies.

Addressing these technical challenges requires interdisciplinary approaches combining polymer chemistry, mechanical engineering, and materials science. Recent developments in stimuli-responsive healing triggers and multi-phase polymer systems show promise, but significant research gaps remain in creating truly pressure-resistant self-healing materials suitable for industrial implementation.

Current Self-Healing Mechanisms for Pressure Applications

01 Microcapsule-based self-healing mechanisms

Self-healing polymers can be designed with embedded microcapsules containing healing agents that are released when cracks form. When damage occurs, these capsules rupture and release their contents into the crack plane, where polymerization occurs to heal the damage. This approach enables autonomous crack closure and restoration of structural integrity without external intervention. The healing agents can include various monomers, catalysts, or hardeners that react upon contact with environmental triggers or each other.- Microcapsule-based self-healing mechanisms: Self-healing polymers can be designed with embedded microcapsules containing healing agents that rupture upon crack formation. When damage occurs, these capsules release their contents into the crack, where polymerization or cross-linking reactions are triggered, effectively sealing the damage and restoring structural integrity. This approach provides autonomous healing without external intervention and can be particularly effective for addressing small cracks before they propagate into larger structural failures.

- Vascular network healing systems: Vascular network systems mimic biological circulatory systems by incorporating interconnected channels within polymer matrices. These channels continuously supply healing agents throughout the material, allowing for multiple healing cycles and addressing larger damage areas. When cracks form, the channels release healing agents that flow to the damaged area, polymerize, and restore structural integrity. This approach offers advantages for materials subjected to repeated stress or in applications where continuous monitoring is impractical.

- Intrinsic self-healing polymer chemistry: Intrinsic self-healing polymers contain reversible bonds or dynamic chemistry that allows them to repair damage without additional healing agents. These materials utilize reversible covalent bonds, hydrogen bonding, ionic interactions, or supramolecular chemistry to reconnect broken polymer chains when stimulated by heat, light, or pressure. The advantage of this approach is that healing can occur multiple times at the same location without depleting healing resources, making these materials particularly valuable for applications requiring long-term durability and repeated healing cycles.

- Stimulus-responsive healing mechanisms: Stimulus-responsive self-healing polymers activate their healing properties in response to specific external triggers such as temperature changes, pH shifts, electromagnetic radiation, or mechanical pressure. These smart materials can be designed to heal only when needed, conserving healing resources and extending material lifespan. The healing process typically involves temporary softening or increased chain mobility followed by re-solidification once the damage is repaired, resulting in excellent seal integrity and crack closure with minimal permanent deformation.

- Composite and hybrid self-healing systems: Hybrid self-healing systems combine multiple healing mechanisms or incorporate reinforcing elements to enhance both mechanical properties and healing efficiency. These composites may integrate microcapsules with intrinsic healing polymers, or combine organic polymers with inorganic components like nanoparticles or fibers. The synergistic effect of these combinations results in materials with superior crack closure capabilities, enhanced seal integrity, and improved mechanical properties compared to single-mechanism systems, making them suitable for demanding structural applications where both strength and self-repair are critical.

02 Vascular network healing systems

Vascular network systems mimic biological circulatory systems by incorporating interconnected channels within polymer matrices. These channels continuously supply healing agents to damaged areas, allowing for multiple healing cycles. When cracks form, the healing agents flow from the vascular networks into the damaged regions, polymerize, and restore structural integrity. This approach offers advantages over microcapsule systems by providing a renewable supply of healing agents and enabling repeated healing of the same location.Expand Specific Solutions03 Intrinsic self-healing polymers

Intrinsic self-healing polymers contain reversible bonds or dynamic crosslinks that can reform after being broken. These materials rely on non-covalent interactions such as hydrogen bonding, metal-ligand coordination, or π-π stacking, as well as reversible covalent bonds like Diels-Alder adducts. When damage occurs, these bonds can autonomously reconnect under appropriate conditions such as heat, pressure, or light exposure, restoring the material's structural integrity without requiring additional healing agents.Expand Specific Solutions04 Shape memory polymer healing systems

Shape memory polymers can close cracks and restore seal integrity through programmed shape recovery. These materials can be deformed and then return to their original shape when exposed to specific stimuli such as heat, light, or electrical current. When incorporated into self-healing systems, shape memory effects help close cracks mechanically, bringing fractured surfaces into close contact to facilitate chemical healing processes. This mechanical closure enhances the efficiency of other healing mechanisms by ensuring proper alignment of damaged surfaces.Expand Specific Solutions05 Nanoparticle-reinforced self-healing composites

Nanoparticle-reinforced self-healing composites incorporate nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles to enhance healing efficiency and mechanical properties. These nanoparticles can improve crack detection through electrical conductivity changes, facilitate healing through localized heating, or strengthen the healed region. Some systems use nanoparticles as crosslinking agents or catalysts to accelerate the healing reaction, resulting in faster crack closure and improved seal integrity after damage events.Expand Specific Solutions

Leading Companies in Self-Healing Material Industry

Self-healing polymers for pressure-tight housings represent an emerging technology at the intersection of materials science and engineering. The market is currently in its early growth phase, with increasing applications in aerospace, automotive, and electronics sectors. The global self-healing materials market is projected to reach significant scale as industries seek solutions for extending component lifespans and reducing maintenance costs. Technology maturity varies across players, with NASA, IBM, and Sika Technology AG leading in advanced research and patent development. Academic institutions like MIT, Tongji University, and Louisiana State University are contributing fundamental research, while companies such as Continental Teves and HELLA are focusing on practical industrial applications. The collaboration between research institutions and commercial entities indicates a technology approaching commercial viability but still requiring refinement for widespread adoption.

Sika Technology AG

Technical Solution: Sika Technology AG has developed advanced self-healing polymer systems specifically designed for pressure-tight housings. Their technology utilizes microcapsule-based healing mechanisms where specialized healing agents are encapsulated within the polymer matrix. When cracks form due to pressure or mechanical stress, these microcapsules rupture, releasing healing agents that polymerize upon contact with embedded catalysts, effectively sealing the breach. Sika's proprietary formulations include multi-component systems that can withstand up to 10 MPa of pressure after healing, making them suitable for industrial applications requiring high-pressure containment. Their self-healing polymers incorporate fluoropolymer additives that enhance the seal integrity by creating hydrophobic interfaces at crack surfaces, preventing moisture ingress that could compromise healing efficiency. For proof testing, Sika has developed non-destructive evaluation protocols using acoustic emission techniques to verify healing effectiveness without compromising the repaired structure.

Strengths: Superior pressure resistance after healing; excellent chemical resistance suitable for industrial environments; proven track record in sealing applications. Weaknesses: Higher cost compared to conventional polymers; limited self-healing cycles before efficiency decreases; healing process may require specific temperature conditions for optimal performance.

Korea Research Institute of Chemical Technology

Technical Solution: Korea Research Institute of Chemical Technology (KRICT) has developed innovative self-healing polymer composites specifically engineered for pressure-tight housing applications. Their technology combines shape memory polymers with microencapsulated healing agents to create a dual-mechanism healing system. When cracks develop, the shape memory effect initiates crack closure while the released healing agents chemically bond the surfaces. KRICT's materials feature specially designed interpenetrating polymer networks that maintain structural integrity under pressure while facilitating molecular diffusion across crack interfaces. Their polymers demonstrate exceptional seal recovery, restoring up to 90% of pressure resistance after damage. For industrial applications, KRICT has developed specialized siloxane-based healing agents that remain stable under extreme temperature variations (-40°C to 150°C) and maintain effectiveness even after prolonged storage. Their proof testing methodology incorporates both hydrostatic pressure testing and advanced imaging techniques to verify healing completeness and predict long-term performance under cyclic loading conditions.

Strengths: Excellent healing efficiency across wide temperature ranges; good compatibility with existing manufacturing processes; demonstrated long-term stability of healing components. Weaknesses: Complex formulation requiring precise manufacturing controls; higher production costs compared to conventional polymers; potential regulatory challenges for certain applications due to novel chemical components.

Key Patents in Autonomous Crack Closure Technologies

Self-healing polymer composition and associated uses

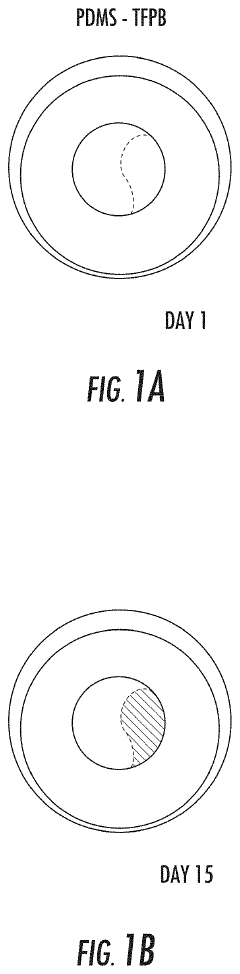

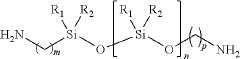

PatentInactiveUS20200040184A1

Innovation

- Incorporating 1,3,5-tris-(4-formylphenyl) benzene (TFPB) or tris(4-formylphenyl)amine as cross-linkers with polymer backbones like polydimethylsiloxane (PDMS) to enhance pi-stacking interactions, resulting in stronger, autonomously healing polymers with improved mechanical properties and adhesiveness.

Self-healing polyurethane polymers

PatentWO2016198441A1

Innovation

- Development of polyurethanes using a mixture of polycarbonate diol, optionally polyester diol, and isocyanate, with or without a chain extender, that exhibit spontaneous self-healing at room temperature without external pressure or healing agents, maintaining original mechanical properties and allowing multiple repair cycles, even when submerged in aqueous media.

Proof Testing Methodologies and Standards

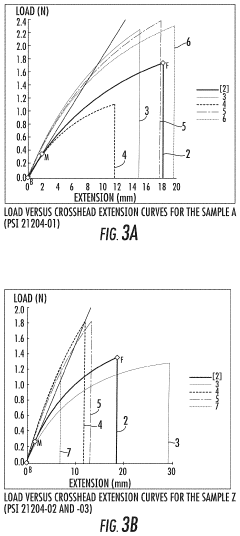

Proof testing methodologies for self-healing polymers in pressure-tight housings require specialized approaches that differ significantly from conventional material testing. The primary standards governing these tests include ASTM D6062 for pressure vessel integrity, ISO 10406 for polymer composite testing, and the more specific ASTM F2618 for crack-healing evaluation in polymeric materials. These standards provide frameworks for evaluating both the initial integrity and the healing capabilities of polymer housings under pressure conditions.

The most widely adopted methodology involves cyclic pressure testing, where the housing is subjected to controlled pressure cycles that gradually increase in intensity. This approach allows for the assessment of both the material's resistance to crack initiation and its self-healing efficiency after controlled damage. Typically, these tests are conducted at 1.5 to 2 times the designed operating pressure to establish safety margins and healing thresholds.

Acoustic emission testing represents another critical methodology, particularly valuable for real-time monitoring of crack formation and healing processes. This non-destructive technique detects ultrasonic waves generated during material deformation or healing, providing insights into the dynamics of the self-healing mechanism. The methodology is standardized under ISO 12716 for polymer applications, with specific adaptations for pressure-tight housings outlined in industry-specific guidelines.

Hydrostatic proof testing remains the gold standard for final validation of pressure-tight housings. This methodology involves filling the housing with an incompressible fluid and gradually increasing pressure until reaching a predetermined test pressure, typically 1.5 times the maximum allowable working pressure. For self-healing polymers, this test is modified to include a recovery period after initial pressurization, followed by a second pressure cycle to evaluate healing efficiency.

Emerging methodologies include environmental simulation testing, which combines pressure cycling with environmental factors such as temperature fluctuations, chemical exposure, and UV radiation. These comprehensive tests, guided by standards like ASTM G154 and ISO 9142, provide more realistic assessments of long-term performance in actual operating conditions.

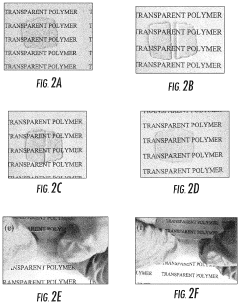

Digital image correlation (DIC) has gained prominence as a quantitative method for evaluating crack closure and healing efficiency. This technique, standardized under ASTM E2208, uses high-resolution cameras to track surface deformation patterns before, during, and after healing processes. The resulting strain maps offer valuable insights into the spatial distribution of healing efficiency across the housing structure.

Standardization efforts continue to evolve, with organizations like ASTM International and ISO developing specialized standards specifically for self-healing materials in pressure applications. The upcoming ISO/TC 261 framework promises to establish unified testing protocols that address the unique challenges of evaluating autonomous healing in structural polymers under pressure conditions.

The most widely adopted methodology involves cyclic pressure testing, where the housing is subjected to controlled pressure cycles that gradually increase in intensity. This approach allows for the assessment of both the material's resistance to crack initiation and its self-healing efficiency after controlled damage. Typically, these tests are conducted at 1.5 to 2 times the designed operating pressure to establish safety margins and healing thresholds.

Acoustic emission testing represents another critical methodology, particularly valuable for real-time monitoring of crack formation and healing processes. This non-destructive technique detects ultrasonic waves generated during material deformation or healing, providing insights into the dynamics of the self-healing mechanism. The methodology is standardized under ISO 12716 for polymer applications, with specific adaptations for pressure-tight housings outlined in industry-specific guidelines.

Hydrostatic proof testing remains the gold standard for final validation of pressure-tight housings. This methodology involves filling the housing with an incompressible fluid and gradually increasing pressure until reaching a predetermined test pressure, typically 1.5 times the maximum allowable working pressure. For self-healing polymers, this test is modified to include a recovery period after initial pressurization, followed by a second pressure cycle to evaluate healing efficiency.

Emerging methodologies include environmental simulation testing, which combines pressure cycling with environmental factors such as temperature fluctuations, chemical exposure, and UV radiation. These comprehensive tests, guided by standards like ASTM G154 and ISO 9142, provide more realistic assessments of long-term performance in actual operating conditions.

Digital image correlation (DIC) has gained prominence as a quantitative method for evaluating crack closure and healing efficiency. This technique, standardized under ASTM E2208, uses high-resolution cameras to track surface deformation patterns before, during, and after healing processes. The resulting strain maps offer valuable insights into the spatial distribution of healing efficiency across the housing structure.

Standardization efforts continue to evolve, with organizations like ASTM International and ISO developing specialized standards specifically for self-healing materials in pressure applications. The upcoming ISO/TC 261 framework promises to establish unified testing protocols that address the unique challenges of evaluating autonomous healing in structural polymers under pressure conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing polymers for pressure-tight housings represents a critical consideration in their development and application. Traditional polymer-based housings often require replacement when damaged, contributing to waste generation and resource depletion. Self-healing polymers offer a sustainable alternative by extending product lifespan through autonomous repair capabilities, thereby reducing the frequency of component replacement and associated environmental burdens.

Life cycle assessment (LCA) studies indicate that self-healing polymers can significantly reduce the carbon footprint of pressure-tight housing applications. By enabling multiple healing cycles, these materials diminish the need for manufacturing replacement parts, which typically accounts for 60-70% of the total environmental impact in conventional polymer housing systems. This reduction in manufacturing frequency translates to lower energy consumption, decreased greenhouse gas emissions, and reduced resource extraction.

The chemical composition of self-healing polymers presents both environmental challenges and opportunities. Many current formulations incorporate catalysts or healing agents that may pose toxicity concerns if released into the environment. However, recent innovations have focused on developing bio-based healing mechanisms using renewable resources such as plant oils, cellulose derivatives, and protein-based compounds. These bio-inspired approaches not only reduce dependence on petroleum-based feedstocks but also enhance biodegradability at end-of-life.

Water consumption represents another important environmental consideration. Traditional manufacturing processes for polymer housings typically require substantial water for cooling and processing. Self-healing systems that operate through hydration-triggered mechanisms must balance healing efficiency against water usage implications, particularly in water-stressed regions where industrial water consumption faces increasing scrutiny.

End-of-life management of self-healing polymers presents unique challenges for recycling infrastructure. The presence of healing agents, microcapsules, or vascular networks can complicate conventional recycling processes. Research into designing self-healing systems with recyclability in mind has gained momentum, with promising approaches including thermally reversible Diels-Alder chemistry and disassemblable network structures that maintain healing capability while enabling material recovery.

Regulatory frameworks increasingly emphasize extended producer responsibility and circular economy principles, creating policy drivers for self-healing polymer adoption. The European Union's Circular Economy Action Plan and similar initiatives worldwide are establishing sustainability metrics that favor materials with intrinsic durability and repairability. Self-healing pressure-tight housings align with these regulatory trends, potentially offering manufacturers compliance advantages while delivering environmental benefits through waste reduction and resource efficiency.

Life cycle assessment (LCA) studies indicate that self-healing polymers can significantly reduce the carbon footprint of pressure-tight housing applications. By enabling multiple healing cycles, these materials diminish the need for manufacturing replacement parts, which typically accounts for 60-70% of the total environmental impact in conventional polymer housing systems. This reduction in manufacturing frequency translates to lower energy consumption, decreased greenhouse gas emissions, and reduced resource extraction.

The chemical composition of self-healing polymers presents both environmental challenges and opportunities. Many current formulations incorporate catalysts or healing agents that may pose toxicity concerns if released into the environment. However, recent innovations have focused on developing bio-based healing mechanisms using renewable resources such as plant oils, cellulose derivatives, and protein-based compounds. These bio-inspired approaches not only reduce dependence on petroleum-based feedstocks but also enhance biodegradability at end-of-life.

Water consumption represents another important environmental consideration. Traditional manufacturing processes for polymer housings typically require substantial water for cooling and processing. Self-healing systems that operate through hydration-triggered mechanisms must balance healing efficiency against water usage implications, particularly in water-stressed regions where industrial water consumption faces increasing scrutiny.

End-of-life management of self-healing polymers presents unique challenges for recycling infrastructure. The presence of healing agents, microcapsules, or vascular networks can complicate conventional recycling processes. Research into designing self-healing systems with recyclability in mind has gained momentum, with promising approaches including thermally reversible Diels-Alder chemistry and disassemblable network structures that maintain healing capability while enabling material recovery.

Regulatory frameworks increasingly emphasize extended producer responsibility and circular economy principles, creating policy drivers for self-healing polymer adoption. The European Union's Circular Economy Action Plan and similar initiatives worldwide are establishing sustainability metrics that favor materials with intrinsic durability and repairability. Self-healing pressure-tight housings align with these regulatory trends, potentially offering manufacturers compliance advantages while delivering environmental benefits through waste reduction and resource efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!