Self-Healing Polymers For Smart Windows: Scratch Recovery, Transparency And Weathering

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymer Technology Background and Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage and restore their original properties without external intervention. The concept emerged in the early 2000s, inspired by biological systems that naturally heal wounds. Over the past two decades, this technology has evolved from laboratory curiosities to commercially viable solutions, with significant advancements in healing efficiency, mechanical properties, and environmental stability.

The development trajectory of self-healing polymers has been characterized by several key innovations: first-generation systems relied on microencapsulated healing agents, followed by vascular networks for continuous healing, and more recently, intrinsic healing mechanisms based on reversible chemical bonds. Each generation has expanded the potential applications while addressing limitations of previous approaches.

For smart window applications, self-healing polymers present a particularly promising frontier. Windows in buildings and vehicles are constantly exposed to environmental stresses that cause scratches, reducing visibility and aesthetic appeal. Traditional solutions require replacement or professional restoration, resulting in significant economic and environmental costs.

The technical objectives for self-healing polymers in smart window applications are multifaceted. Primary goals include developing materials with rapid scratch recovery capabilities (ideally within minutes to hours), maintaining optical clarity throughout the healing process, and ensuring long-term durability under diverse weather conditions including UV radiation, temperature fluctuations, and moisture exposure.

Additionally, these materials must balance competing requirements: sufficient mechanical strength to function as protective barriers while maintaining the molecular mobility necessary for effective self-healing. The healing mechanism should ideally operate at ambient conditions without requiring external stimuli, though some advanced systems may incorporate responsive healing triggered by specific environmental changes.

Current research is increasingly focused on environmentally sustainable formulations, moving away from petroleum-based precursors toward bio-derived alternatives. This shift aligns with broader industry trends toward green chemistry and circular economy principles.

The ultimate objective is to create a new generation of smart windows with extended service life, reduced maintenance requirements, and enhanced user experience. Such windows would maintain optimal transparency and appearance throughout their lifecycle, potentially incorporating additional functionalities such as energy efficiency, privacy control, or even energy harvesting capabilities.

Success in this domain would represent not only a significant technological achievement but also contribute to sustainability goals by reducing material waste and energy consumption associated with window replacement and maintenance.

The development trajectory of self-healing polymers has been characterized by several key innovations: first-generation systems relied on microencapsulated healing agents, followed by vascular networks for continuous healing, and more recently, intrinsic healing mechanisms based on reversible chemical bonds. Each generation has expanded the potential applications while addressing limitations of previous approaches.

For smart window applications, self-healing polymers present a particularly promising frontier. Windows in buildings and vehicles are constantly exposed to environmental stresses that cause scratches, reducing visibility and aesthetic appeal. Traditional solutions require replacement or professional restoration, resulting in significant economic and environmental costs.

The technical objectives for self-healing polymers in smart window applications are multifaceted. Primary goals include developing materials with rapid scratch recovery capabilities (ideally within minutes to hours), maintaining optical clarity throughout the healing process, and ensuring long-term durability under diverse weather conditions including UV radiation, temperature fluctuations, and moisture exposure.

Additionally, these materials must balance competing requirements: sufficient mechanical strength to function as protective barriers while maintaining the molecular mobility necessary for effective self-healing. The healing mechanism should ideally operate at ambient conditions without requiring external stimuli, though some advanced systems may incorporate responsive healing triggered by specific environmental changes.

Current research is increasingly focused on environmentally sustainable formulations, moving away from petroleum-based precursors toward bio-derived alternatives. This shift aligns with broader industry trends toward green chemistry and circular economy principles.

The ultimate objective is to create a new generation of smart windows with extended service life, reduced maintenance requirements, and enhanced user experience. Such windows would maintain optimal transparency and appearance throughout their lifecycle, potentially incorporating additional functionalities such as energy efficiency, privacy control, or even energy harvesting capabilities.

Success in this domain would represent not only a significant technological achievement but also contribute to sustainability goals by reducing material waste and energy consumption associated with window replacement and maintenance.

Smart Window Market Analysis and Growth Potential

The global smart window market is experiencing robust growth, driven by increasing demand for energy-efficient building solutions and technological advancements in materials science. Current market valuations place the smart window sector at approximately 5.8 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 12.4% through 2030, potentially reaching 13.2 billion USD by the end of the forecast period.

Self-healing polymer technologies for smart windows represent a particularly promising segment within this expanding market. The integration of scratch recovery capabilities addresses a critical pain point in conventional window technologies, potentially extending product lifecycles by 30-50% compared to traditional alternatives. This longevity factor significantly enhances the value proposition for commercial building developers and institutional clients.

Market penetration of self-healing smart window technologies remains relatively low at present, estimated at less than 8% of the total smart window installations globally. However, adoption rates are accelerating, particularly in premium commercial construction, luxury automotive applications, and high-end residential developments. North America currently leads market consumption at 42% of global demand, followed by Europe (31%) and Asia-Pacific (21%).

The commercial building sector represents the largest application segment, accounting for approximately 58% of market demand. This is attributed to the compelling energy savings potential, with buildings implementing advanced smart window technologies reporting 15-25% reductions in HVAC-related energy consumption. The automotive sector follows at 22% market share, with residential applications comprising 15%.

Key growth drivers include increasingly stringent building energy efficiency regulations worldwide, rising awareness of sustainable construction practices, and declining production costs as manufacturing processes mature. The integration of self-healing polymers specifically addresses durability concerns that have historically limited wider adoption of smart window technologies.

Potential market constraints include relatively high initial installation costs compared to conventional alternatives, technical challenges in maintaining optical clarity through multiple healing cycles, and limited consumer awareness of the technology's benefits. Additionally, regional variations in building codes and construction standards present market entry barriers in certain territories.

The forecast period (2023-2030) is expected to witness significant market expansion as production scales increase and material costs decrease. Emerging economies, particularly in Southeast Asia and the Middle East, represent high-growth potential markets with increasing investments in smart building infrastructure and sustainable urban development initiatives.

Self-healing polymer technologies for smart windows represent a particularly promising segment within this expanding market. The integration of scratch recovery capabilities addresses a critical pain point in conventional window technologies, potentially extending product lifecycles by 30-50% compared to traditional alternatives. This longevity factor significantly enhances the value proposition for commercial building developers and institutional clients.

Market penetration of self-healing smart window technologies remains relatively low at present, estimated at less than 8% of the total smart window installations globally. However, adoption rates are accelerating, particularly in premium commercial construction, luxury automotive applications, and high-end residential developments. North America currently leads market consumption at 42% of global demand, followed by Europe (31%) and Asia-Pacific (21%).

The commercial building sector represents the largest application segment, accounting for approximately 58% of market demand. This is attributed to the compelling energy savings potential, with buildings implementing advanced smart window technologies reporting 15-25% reductions in HVAC-related energy consumption. The automotive sector follows at 22% market share, with residential applications comprising 15%.

Key growth drivers include increasingly stringent building energy efficiency regulations worldwide, rising awareness of sustainable construction practices, and declining production costs as manufacturing processes mature. The integration of self-healing polymers specifically addresses durability concerns that have historically limited wider adoption of smart window technologies.

Potential market constraints include relatively high initial installation costs compared to conventional alternatives, technical challenges in maintaining optical clarity through multiple healing cycles, and limited consumer awareness of the technology's benefits. Additionally, regional variations in building codes and construction standards present market entry barriers in certain territories.

The forecast period (2023-2030) is expected to witness significant market expansion as production scales increase and material costs decrease. Emerging economies, particularly in Southeast Asia and the Middle East, represent high-growth potential markets with increasing investments in smart building infrastructure and sustainable urban development initiatives.

Current Challenges in Self-Healing Polymer Development

Despite significant advancements in self-healing polymer technology, several critical challenges persist in developing optimal materials for smart window applications. The primary obstacle remains achieving rapid and efficient healing mechanisms while maintaining optical clarity. Current self-healing polymers often require external stimuli such as heat or UV light to activate the healing process, which limits their practical application in real-world window scenarios where immediate autonomous healing is desired.

The balance between mechanical durability and self-healing efficiency presents another significant challenge. Polymers with excellent scratch resistance typically contain rigid molecular structures that inherently restrict chain mobility, thereby impeding the self-healing process. Conversely, materials with superior healing capabilities often demonstrate insufficient mechanical properties to withstand daily wear and environmental stresses experienced by window surfaces.

Transparency maintenance during the healing process constitutes a critical hurdle. Many self-healing mechanisms involve chemical reactions or physical transformations that temporarily alter the material's optical properties, resulting in haze, discoloration, or reduced light transmission during healing. This compromises the primary function of windows as transparent barriers.

Weathering resistance represents perhaps the most formidable challenge for outdoor applications. Self-healing polymers must withstand prolonged exposure to UV radiation, temperature fluctuations, moisture, and atmospheric pollutants without degrading their healing capabilities or optical properties. Current materials often show significant performance deterioration after extended environmental exposure, with healing efficiency decreasing markedly over time.

The integration of multiple functionalities—such as energy efficiency, switchable opacity, and self-cleaning properties—alongside self-healing capabilities introduces additional complexity. These combined requirements often create competing material design parameters that are difficult to optimize simultaneously within a single polymer system.

Manufacturing scalability and cost-effectiveness remain significant barriers to commercial adoption. Many promising self-healing polymers rely on complex synthesis procedures or expensive raw materials, making large-scale production economically unfeasible for widespread window applications. Additionally, processing techniques must be developed that can produce these materials in the large, optically perfect sheets required for window manufacturing.

Standardization of testing protocols presents another challenge, as there are currently no universally accepted methods to quantify and compare healing efficiency, transparency recovery, and weathering resistance across different self-healing polymer systems. This lack of standardization hampers meaningful comparison between emerging technologies and slows industry adoption.

The balance between mechanical durability and self-healing efficiency presents another significant challenge. Polymers with excellent scratch resistance typically contain rigid molecular structures that inherently restrict chain mobility, thereby impeding the self-healing process. Conversely, materials with superior healing capabilities often demonstrate insufficient mechanical properties to withstand daily wear and environmental stresses experienced by window surfaces.

Transparency maintenance during the healing process constitutes a critical hurdle. Many self-healing mechanisms involve chemical reactions or physical transformations that temporarily alter the material's optical properties, resulting in haze, discoloration, or reduced light transmission during healing. This compromises the primary function of windows as transparent barriers.

Weathering resistance represents perhaps the most formidable challenge for outdoor applications. Self-healing polymers must withstand prolonged exposure to UV radiation, temperature fluctuations, moisture, and atmospheric pollutants without degrading their healing capabilities or optical properties. Current materials often show significant performance deterioration after extended environmental exposure, with healing efficiency decreasing markedly over time.

The integration of multiple functionalities—such as energy efficiency, switchable opacity, and self-cleaning properties—alongside self-healing capabilities introduces additional complexity. These combined requirements often create competing material design parameters that are difficult to optimize simultaneously within a single polymer system.

Manufacturing scalability and cost-effectiveness remain significant barriers to commercial adoption. Many promising self-healing polymers rely on complex synthesis procedures or expensive raw materials, making large-scale production economically unfeasible for widespread window applications. Additionally, processing techniques must be developed that can produce these materials in the large, optically perfect sheets required for window manufacturing.

Standardization of testing protocols presents another challenge, as there are currently no universally accepted methods to quantify and compare healing efficiency, transparency recovery, and weathering resistance across different self-healing polymer systems. This lack of standardization hampers meaningful comparison between emerging technologies and slows industry adoption.

Current Self-Healing Polymer Solutions for Transparency

01 Self-healing polymer compositions with scratch recovery properties

Various polymer compositions have been developed with intrinsic self-healing capabilities that enable scratch recovery. These compositions often include dynamic covalent bonds or supramolecular interactions that can reform after being broken during scratching. The self-healing mechanism allows the polymer to restore its original appearance and mechanical properties after damage, making these materials particularly valuable for applications requiring durability and aesthetic maintenance.- Self-healing polymer compositions with scratch recovery properties: Various polymer compositions have been developed with intrinsic self-healing capabilities that enable scratch recovery. These compositions often include dynamic covalent bonds or supramolecular interactions that can reform after being broken during scratching. The self-healing mechanism is typically triggered by external stimuli such as heat, light, or pressure, allowing the material to restore its original appearance and mechanical properties after damage.

- Transparent self-healing polymers for optical applications: Transparent self-healing polymers have been formulated specifically for applications requiring optical clarity, such as displays, lenses, and protective coatings. These materials maintain high transparency while incorporating self-healing functionality through carefully designed polymer networks. The healing mechanisms are engineered to restore optical properties after damage without compromising the material's clarity, making them suitable for electronic devices and automotive applications.

- Weather-resistant self-healing polymer coatings: Self-healing polymer coatings with enhanced resistance to environmental factors such as UV radiation, temperature fluctuations, and moisture have been developed. These coatings incorporate stabilizers, UV absorbers, and specialized polymer architectures that maintain their self-healing capabilities even after prolonged exposure to harsh weather conditions. The formulations are designed to prevent degradation of the healing mechanism while providing long-term protection for the underlying substrate.

- Multi-functional self-healing polymers with combined properties: Advanced self-healing polymer systems have been designed to simultaneously address multiple performance requirements including scratch recovery, transparency, and weathering resistance. These multi-functional materials incorporate various chemical components that work synergistically to provide comprehensive protection and restoration capabilities. The formulations often include combinations of different healing mechanisms to ensure effective performance under diverse damage scenarios and environmental conditions.

- Novel triggering mechanisms for self-healing polymers: Innovative triggering mechanisms have been developed to initiate the self-healing process in polymers more efficiently. These include photo-responsive systems that activate healing upon exposure to specific wavelengths of light, thermo-responsive polymers that heal when subjected to temperature changes, and pressure-sensitive materials that repair damage upon mechanical stimulation. These advanced triggering mechanisms allow for more controlled and rapid healing responses, improving the overall performance and reliability of self-healing polymer systems.

02 Transparent self-healing polymers for optical applications

Transparent self-healing polymers combine optical clarity with damage recovery capabilities, making them ideal for protective coatings on displays, lenses, and other optical components. These materials maintain high light transmission while incorporating self-healing functionality through carefully designed polymer networks. The transparency is preserved during and after the healing process, ensuring consistent optical performance even after the material has been damaged and repaired.Expand Specific Solutions03 Weather-resistant self-healing polymer systems

Self-healing polymers with enhanced resistance to environmental factors such as UV radiation, moisture, and temperature fluctuations have been developed for outdoor applications. These materials incorporate stabilizers, UV absorbers, and specialized chemical structures that maintain the self-healing functionality even after prolonged exposure to harsh weather conditions. The weathering resistance ensures long-term durability and sustained self-healing capabilities in exterior applications.Expand Specific Solutions04 Multi-functional self-healing coatings with combined properties

Advanced self-healing coating systems that combine scratch recovery with additional functional properties such as anti-fouling, anti-fingerprint, or anti-reflective characteristics have been developed. These multi-functional coatings utilize complex polymer architectures and additives to achieve multiple performance benefits simultaneously. The integration of various properties into a single self-healing system enhances the overall value and application range of these materials.Expand Specific Solutions05 Stimuli-responsive self-healing mechanisms

Self-healing polymers that respond to specific external stimuli such as heat, light, or electrical current have been engineered to enable controlled healing processes. These materials contain responsive elements that activate the healing mechanism only when the appropriate stimulus is applied, allowing for on-demand repair of scratches and damage. The stimuli-responsive approach provides greater control over the healing process and can lead to more efficient and complete recovery of material properties.Expand Specific Solutions

Leading Companies in Smart Window Technology

The self-healing polymer market for smart windows is in an early growth phase, with increasing demand driven by sustainability trends and advanced material requirements. The global market size is projected to expand significantly as smart building technologies gain traction. Technologically, the field is advancing rapidly but remains in development, with varying maturity levels across applications. Key players include established corporations like EssilorLuxottica and DuPont developing commercial applications, while research institutions such as South China University of Technology and Louisiana State University are pioneering fundamental innovations. Academic-industry partnerships, particularly involving NASA and Autonomic Materials, are accelerating development of scratch-resistant, transparent polymers with enhanced weathering resistance, positioning this technology at the intersection of materials science and sustainable construction.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking self-healing polymer platform for smart window applications based on dynamic covalent chemistry. Their approach utilizes Diels-Alder (DA) cycloaddition reactions to create reversible crosslinks within transparent polymer networks. These DA adducts can break and reform in response to temperature changes, allowing for repeated healing cycles. The UC system incorporates furan and maleimide functional groups into polyurethane and polyacrylate backbones, creating optically clear materials (>90% transparency) with excellent mechanical properties. Their research demonstrates complete scratch recovery within 1-3 hours at moderate temperatures (70-90°C) and partial recovery at ambient conditions over 24-48 hours. A key innovation is their multi-layer design that combines a hard, scratch-resistant outer layer with a self-healing underlayer, providing both damage prevention and repair capabilities. The materials show excellent weatherability, maintaining optical clarity and healing efficiency after UV exposure equivalent to 5+ years of outdoor conditions. Recent developments include incorporating photocatalytic triggers that accelerate healing under sunlight exposure.

Strengths: Exceptional healing efficiency with multiple healing cycles possible; fundamental research approach with broad patent protection; versatile chemistry platform adaptable to various polymer systems. Weaknesses: Currently at research/prototype stage rather than commercial production; healing at ambient temperatures is relatively slow; potential scalability challenges for large-scale manufacturing.

Autonomic Materials, Inc.

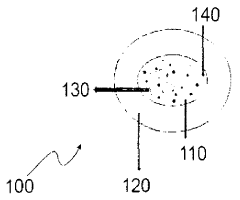

Technical Solution: Autonomic Materials has developed proprietary microencapsulation technology for self-healing polymers specifically designed for smart window applications. Their approach involves embedding microcapsules containing healing agents within polymer matrices used in window coatings. When scratches occur, these capsules rupture, releasing the healing agents that polymerize upon contact with embedded catalysts, effectively restoring the damaged area. Their technology incorporates UV-stabilized healing agents that maintain transparency after healing while providing protection against weathering. The company has demonstrated healing efficiencies exceeding 85% in optical clarity restoration after scratch damage, with healing times ranging from minutes to hours depending on environmental conditions. Their formulations are specifically engineered to withstand temperature fluctuations (-40°C to 80°C) typical in exterior window applications while maintaining self-healing capabilities.

Strengths: Proven commercial viability with products already in market; proprietary microencapsulation technology offers controlled release of healing agents; formulations specifically optimized for window applications with high transparency retention. Weaknesses: Capsule-based systems may have limited healing cycles; potential for optical distortion from microcapsules in transparent applications; healing efficiency decreases with multiple damage events at the same location.

Key Patents in Scratch-Resistant Self-Healing Materials

Self-healing polymers

PatentInactiveUS8063171B2

Innovation

- The study identifies key factors such as impact strength, controlled crystallinity, low melting point, and melt flow ability as essential for self-healing polymers, with specific polymers like very low density polyethylene and aliphatic polyesters demonstrating self-healing capabilities by synthesizing new materials that tailor melting points and crystallinity to enhance recovery.

Self-healing materials

PatentInactiveIN434MUM2013A

Innovation

- A method for producing self-healing polymer materials involving a polymer matrix with nano-sized reinforcing agents and an outer coating that senses mechanical impact, releasing a healing agent to facilitate automatic repair without the need for external curing agents or catalysts, using polymers like thermosetting, thermoplastic elastomers, and smart materials with thermal stability.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing polymers for smart windows represents a critical consideration in their development and deployment. These materials offer significant sustainability advantages through extended product lifecycles, potentially reducing the frequency of window replacements and associated waste generation. By autonomously repairing scratches and damage, self-healing windows can maintain optimal performance for longer periods, decreasing the embodied carbon footprint associated with manufacturing and installing replacement units.

The production processes for self-healing polymers merit careful environmental assessment. Current manufacturing methods often involve energy-intensive procedures and potentially hazardous chemical precursors. Research indicates that some self-healing mechanisms rely on catalysts or additives that may present environmental concerns if improperly managed. The industry is increasingly focused on developing greener synthesis routes that minimize solvent use and reduce energy consumption during polymerization and processing stages.

End-of-life considerations for these advanced materials present both challenges and opportunities. While conventional windows contribute significantly to construction waste streams, self-healing polymers may introduce new complexities for recycling infrastructure. The chemical complexity of these materials—particularly those incorporating microcapsules or vascular networks—can complicate separation and recovery processes. However, emerging research demonstrates promising approaches for designing self-healing systems with recyclability and biodegradability as primary objectives.

The operational environmental benefits of self-healing smart windows extend beyond material considerations. These windows can contribute to building energy efficiency through dynamic light transmission properties, potentially reducing heating, cooling, and lighting demands. Studies suggest that optimized smart window technologies could reduce building energy consumption by 10-20% in appropriate climate zones, representing a substantial contribution to carbon emission reduction goals in the built environment sector.

Water consumption represents another important environmental dimension. Traditional window manufacturing and cleaning processes can be water-intensive, while certain self-healing mechanisms may reduce cleaning requirements through hydrophobic or anti-fouling properties. However, the synthesis of specialized polymers may introduce different water quality concerns that require careful management throughout the production lifecycle.

As regulatory frameworks increasingly emphasize lifecycle assessment and circular economy principles, manufacturers of self-healing polymer windows face growing pressure to document and improve their environmental performance. Leading companies in this space are adopting comprehensive sustainability metrics that consider raw material sourcing, manufacturing efficiency, use-phase benefits, and end-of-life management strategies to position these innovative materials as environmentally responsible alternatives to conventional glazing solutions.

The production processes for self-healing polymers merit careful environmental assessment. Current manufacturing methods often involve energy-intensive procedures and potentially hazardous chemical precursors. Research indicates that some self-healing mechanisms rely on catalysts or additives that may present environmental concerns if improperly managed. The industry is increasingly focused on developing greener synthesis routes that minimize solvent use and reduce energy consumption during polymerization and processing stages.

End-of-life considerations for these advanced materials present both challenges and opportunities. While conventional windows contribute significantly to construction waste streams, self-healing polymers may introduce new complexities for recycling infrastructure. The chemical complexity of these materials—particularly those incorporating microcapsules or vascular networks—can complicate separation and recovery processes. However, emerging research demonstrates promising approaches for designing self-healing systems with recyclability and biodegradability as primary objectives.

The operational environmental benefits of self-healing smart windows extend beyond material considerations. These windows can contribute to building energy efficiency through dynamic light transmission properties, potentially reducing heating, cooling, and lighting demands. Studies suggest that optimized smart window technologies could reduce building energy consumption by 10-20% in appropriate climate zones, representing a substantial contribution to carbon emission reduction goals in the built environment sector.

Water consumption represents another important environmental dimension. Traditional window manufacturing and cleaning processes can be water-intensive, while certain self-healing mechanisms may reduce cleaning requirements through hydrophobic or anti-fouling properties. However, the synthesis of specialized polymers may introduce different water quality concerns that require careful management throughout the production lifecycle.

As regulatory frameworks increasingly emphasize lifecycle assessment and circular economy principles, manufacturers of self-healing polymer windows face growing pressure to document and improve their environmental performance. Leading companies in this space are adopting comprehensive sustainability metrics that consider raw material sourcing, manufacturing efficiency, use-phase benefits, and end-of-life management strategies to position these innovative materials as environmentally responsible alternatives to conventional glazing solutions.

Durability Testing Methods and Performance Standards

Durability testing for self-healing polymers in smart window applications requires comprehensive methodologies that evaluate both the healing capabilities and long-term performance under various environmental conditions. Standard accelerated weathering tests, such as ASTM G154 and ISO 4892, provide frameworks for UV exposure assessment, while ASTM D1003 establishes protocols for measuring optical transparency retention after healing cycles.

The scratch resistance evaluation typically employs pencil hardness tests (ASTM D3363) and nano-indentation methods to quantify the material's resistance to surface damage. More specialized tests include the Taber abraser test (ASTM D4060) which measures abrasion resistance through weight loss and haze increase after a predetermined number of cycles. For self-healing polymers specifically, modified versions of these tests incorporate healing periods between damage cycles to assess recovery efficiency.

Thermal cycling tests (ASTM D6944) evaluate the material's ability to maintain structural integrity and healing capabilities across temperature fluctuations typical of window applications (-30°C to 80°C). These tests are particularly critical for smart windows deployed in regions with extreme seasonal variations.

Humidity resistance testing follows ASTM D2247 protocols, exposing samples to controlled high-humidity environments (95% RH) for extended periods to evaluate moisture-induced degradation and its impact on the healing mechanism. Salt spray testing (ASTM B117) assesses corrosion resistance, particularly important for coastal applications.

Performance standards for self-healing polymers in smart windows typically require 80-90% scratch recovery efficiency after multiple healing cycles, with transparency retention above 85% of the original value. Weathering standards demand less than 5% yellowing index increase after 2000 hours of accelerated weathering, and maintenance of healing capability after exposure to at least 500 thermal cycles.

Chemical resistance standards require materials to withstand exposure to common window cleaning agents without degradation of optical or healing properties. The healing activation mechanism must remain functional after 5-7 years of simulated environmental exposure, with healing times not exceeding 24 hours at ambient conditions or 1 hour under controlled stimuli.

Industry benchmarks are increasingly incorporating sustainability metrics, evaluating the environmental impact of these materials throughout their lifecycle. This includes assessment of energy consumption during production, potential for recycling, and end-of-life biodegradability, aligning with global trends toward greener building materials.

The scratch resistance evaluation typically employs pencil hardness tests (ASTM D3363) and nano-indentation methods to quantify the material's resistance to surface damage. More specialized tests include the Taber abraser test (ASTM D4060) which measures abrasion resistance through weight loss and haze increase after a predetermined number of cycles. For self-healing polymers specifically, modified versions of these tests incorporate healing periods between damage cycles to assess recovery efficiency.

Thermal cycling tests (ASTM D6944) evaluate the material's ability to maintain structural integrity and healing capabilities across temperature fluctuations typical of window applications (-30°C to 80°C). These tests are particularly critical for smart windows deployed in regions with extreme seasonal variations.

Humidity resistance testing follows ASTM D2247 protocols, exposing samples to controlled high-humidity environments (95% RH) for extended periods to evaluate moisture-induced degradation and its impact on the healing mechanism. Salt spray testing (ASTM B117) assesses corrosion resistance, particularly important for coastal applications.

Performance standards for self-healing polymers in smart windows typically require 80-90% scratch recovery efficiency after multiple healing cycles, with transparency retention above 85% of the original value. Weathering standards demand less than 5% yellowing index increase after 2000 hours of accelerated weathering, and maintenance of healing capability after exposure to at least 500 thermal cycles.

Chemical resistance standards require materials to withstand exposure to common window cleaning agents without degradation of optical or healing properties. The healing activation mechanism must remain functional after 5-7 years of simulated environmental exposure, with healing times not exceeding 24 hours at ambient conditions or 1 hour under controlled stimuli.

Industry benchmarks are increasingly incorporating sustainability metrics, evaluating the environmental impact of these materials throughout their lifecycle. This includes assessment of energy consumption during production, potential for recycling, and end-of-life biodegradability, aligning with global trends toward greener building materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!