Self-Healing Elastomeric Seals: Leak-Tightness Recovery, Compression Set And Aging

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Elastomeric Seals Background and Objectives

Elastomeric seals have been fundamental components in various industrial applications for decades, serving critical functions in automotive, aerospace, oil and gas, and medical industries. These seals provide essential barriers against fluid leakage, pressure loss, and contamination in dynamic systems. However, traditional elastomeric seals face significant challenges related to degradation over time, compression set (permanent deformation), and loss of sealing capability under harsh operating conditions.

The concept of self-healing materials emerged in the early 2000s, with pioneering work by researchers like White and Sottos demonstrating autonomous repair capabilities in polymer composites. This revolutionary approach to material design has gradually expanded to include elastomers, opening new possibilities for sealing technologies that can recover their properties after damage.

Self-healing elastomeric seals represent a convergence of advanced polymer science, materials engineering, and industrial application requirements. These innovative materials are designed to autonomously restore their sealing capabilities after experiencing mechanical damage, chemical exposure, or thermal stress—addressing the fundamental limitations of conventional elastomeric seals.

The evolution of self-healing elastomers has progressed through several technological generations, from extrinsic healing mechanisms utilizing encapsulated healing agents to more sophisticated intrinsic systems based on reversible chemical bonds, supramolecular interactions, and dynamic covalent chemistry. Recent advancements have focused on enhancing healing efficiency while maintaining the mechanical properties required for industrial sealing applications.

The primary objectives of current research and development in self-healing elastomeric seals center on three critical performance parameters: leak-tightness recovery, compression set resistance, and aging behavior. Leak-tightness recovery refers to the seal's ability to restore its barrier function after damage. Compression set resistance addresses the seal's capacity to return to its original dimensions after prolonged compression. Aging behavior encompasses the material's ability to maintain its self-healing capabilities throughout its service life under various environmental conditions.

The technological goals for next-generation self-healing elastomeric seals include achieving rapid healing responses (minutes to hours rather than days), maintaining healing capabilities across wide temperature ranges (-40°C to 150°C), ensuring multiple healing cycles without performance degradation, and developing formulations compatible with existing manufacturing processes to facilitate industrial adoption and scalability.

The concept of self-healing materials emerged in the early 2000s, with pioneering work by researchers like White and Sottos demonstrating autonomous repair capabilities in polymer composites. This revolutionary approach to material design has gradually expanded to include elastomers, opening new possibilities for sealing technologies that can recover their properties after damage.

Self-healing elastomeric seals represent a convergence of advanced polymer science, materials engineering, and industrial application requirements. These innovative materials are designed to autonomously restore their sealing capabilities after experiencing mechanical damage, chemical exposure, or thermal stress—addressing the fundamental limitations of conventional elastomeric seals.

The evolution of self-healing elastomers has progressed through several technological generations, from extrinsic healing mechanisms utilizing encapsulated healing agents to more sophisticated intrinsic systems based on reversible chemical bonds, supramolecular interactions, and dynamic covalent chemistry. Recent advancements have focused on enhancing healing efficiency while maintaining the mechanical properties required for industrial sealing applications.

The primary objectives of current research and development in self-healing elastomeric seals center on three critical performance parameters: leak-tightness recovery, compression set resistance, and aging behavior. Leak-tightness recovery refers to the seal's ability to restore its barrier function after damage. Compression set resistance addresses the seal's capacity to return to its original dimensions after prolonged compression. Aging behavior encompasses the material's ability to maintain its self-healing capabilities throughout its service life under various environmental conditions.

The technological goals for next-generation self-healing elastomeric seals include achieving rapid healing responses (minutes to hours rather than days), maintaining healing capabilities across wide temperature ranges (-40°C to 150°C), ensuring multiple healing cycles without performance degradation, and developing formulations compatible with existing manufacturing processes to facilitate industrial adoption and scalability.

Market Demand Analysis for Advanced Sealing Solutions

The global market for advanced sealing solutions is experiencing significant growth, driven by increasing demands across multiple industries for more reliable, durable, and efficient sealing technologies. The self-healing elastomeric seals market segment is particularly poised for expansion, with an estimated market value projected to reach several billion dollars by 2030, representing a compound annual growth rate exceeding traditional sealing solutions.

Industrial sectors including automotive, aerospace, oil and gas, and chemical processing are the primary drivers of this market growth. These industries face critical challenges related to seal failure, which can result in substantial operational downtime, maintenance costs, and potential safety hazards. For instance, in the oil and gas sector alone, seal failures account for approximately 25% of equipment downtime, translating to significant financial losses.

The automotive industry represents one of the largest markets for self-healing elastomeric seals, particularly as vehicle manufacturers extend warranty periods and face stricter emissions regulations. The ability of self-healing seals to recover from compression set and maintain leak-tightness over extended periods directly addresses these industry needs, potentially reducing warranty claims and improving vehicle performance.

Aerospace applications present another high-value market segment, where the extreme operating conditions and critical safety requirements create demand for sealing solutions that can withstand thermal cycling, pressure variations, and exposure to various fluids while maintaining integrity. The self-healing capability provides a significant advantage in these applications, where seal replacement is often complex and costly.

Market research indicates that end-users are increasingly willing to pay premium prices for sealing solutions that offer extended service life and reduced maintenance requirements. The total cost of ownership calculation strongly favors advanced sealing technologies that can demonstrate superior performance in leak-tightness recovery and resistance to aging effects.

Regional analysis shows North America and Europe currently leading the market for advanced sealing technologies, with Asia-Pacific representing the fastest-growing region due to rapid industrialization and increasing adoption of premium technologies in manufacturing processes. China, in particular, has shown accelerated demand growth as industries upgrade to meet international quality and performance standards.

Customer surveys reveal that the most valued performance characteristics for sealing solutions include longevity, consistent performance under varying conditions, and reduced maintenance requirements. Self-healing properties directly address these priorities, positioning this technology favorably against conventional alternatives despite potentially higher initial costs.

Industrial sectors including automotive, aerospace, oil and gas, and chemical processing are the primary drivers of this market growth. These industries face critical challenges related to seal failure, which can result in substantial operational downtime, maintenance costs, and potential safety hazards. For instance, in the oil and gas sector alone, seal failures account for approximately 25% of equipment downtime, translating to significant financial losses.

The automotive industry represents one of the largest markets for self-healing elastomeric seals, particularly as vehicle manufacturers extend warranty periods and face stricter emissions regulations. The ability of self-healing seals to recover from compression set and maintain leak-tightness over extended periods directly addresses these industry needs, potentially reducing warranty claims and improving vehicle performance.

Aerospace applications present another high-value market segment, where the extreme operating conditions and critical safety requirements create demand for sealing solutions that can withstand thermal cycling, pressure variations, and exposure to various fluids while maintaining integrity. The self-healing capability provides a significant advantage in these applications, where seal replacement is often complex and costly.

Market research indicates that end-users are increasingly willing to pay premium prices for sealing solutions that offer extended service life and reduced maintenance requirements. The total cost of ownership calculation strongly favors advanced sealing technologies that can demonstrate superior performance in leak-tightness recovery and resistance to aging effects.

Regional analysis shows North America and Europe currently leading the market for advanced sealing technologies, with Asia-Pacific representing the fastest-growing region due to rapid industrialization and increasing adoption of premium technologies in manufacturing processes. China, in particular, has shown accelerated demand growth as industries upgrade to meet international quality and performance standards.

Customer surveys reveal that the most valued performance characteristics for sealing solutions include longevity, consistent performance under varying conditions, and reduced maintenance requirements. Self-healing properties directly address these priorities, positioning this technology favorably against conventional alternatives despite potentially higher initial costs.

Current Challenges in Self-Healing Elastomer Technology

Despite significant advancements in self-healing elastomer technology, several critical challenges persist that limit widespread industrial adoption. The primary technical hurdle involves achieving consistent and reliable healing efficiency across varying operational conditions. Current self-healing elastomeric seals demonstrate diminished healing capabilities when subjected to extreme temperatures, with most systems showing optimal performance only within narrow temperature ranges of 20-60°C. This limitation severely restricts their application in automotive, aerospace, and oil and gas industries where temperature fluctuations are common.

Another significant challenge is the trade-off between mechanical properties and healing efficiency. Self-healing mechanisms often compromise the original mechanical strength, elasticity, and compression set resistance of elastomers. Research indicates that incorporating healing agents can reduce tensile strength by 15-30% compared to conventional elastomers, creating a fundamental design conflict for applications requiring both durability and self-healing capabilities.

The aging resistance of self-healing elastomers presents another formidable obstacle. Long-term exposure to environmental factors such as UV radiation, ozone, and chemical contaminants degrades both the base elastomer and the healing mechanisms. Studies show that after accelerated aging tests equivalent to 5 years of service, healing efficiency typically decreases by 40-60%, raising serious concerns about long-term reliability in industrial applications.

Compression set recovery remains particularly problematic for self-healing elastomeric seals. While conventional elastomers already struggle with compression set, the incorporation of healing networks further complicates this property. Current self-healing systems show 20-35% higher compression set values compared to their non-healing counterparts, significantly reducing their effectiveness in maintaining leak-tight seals over extended periods.

The scalability of production processes represents another major challenge. Laboratory-scale synthesis methods for self-healing elastomers often involve complex procedures that are difficult to translate to industrial-scale manufacturing. The incorporation of microcapsules, vascular networks, or dynamic covalent bonds requires precise control over processing conditions, leading to increased production costs and quality control issues.

Lastly, the response time for leak-tightness recovery remains insufficient for many critical applications. Current self-healing elastomeric seals require hours or even days to fully restore their sealing properties after damage, whereas industrial requirements often demand recovery within minutes to prevent catastrophic system failures or environmental contamination.

Another significant challenge is the trade-off between mechanical properties and healing efficiency. Self-healing mechanisms often compromise the original mechanical strength, elasticity, and compression set resistance of elastomers. Research indicates that incorporating healing agents can reduce tensile strength by 15-30% compared to conventional elastomers, creating a fundamental design conflict for applications requiring both durability and self-healing capabilities.

The aging resistance of self-healing elastomers presents another formidable obstacle. Long-term exposure to environmental factors such as UV radiation, ozone, and chemical contaminants degrades both the base elastomer and the healing mechanisms. Studies show that after accelerated aging tests equivalent to 5 years of service, healing efficiency typically decreases by 40-60%, raising serious concerns about long-term reliability in industrial applications.

Compression set recovery remains particularly problematic for self-healing elastomeric seals. While conventional elastomers already struggle with compression set, the incorporation of healing networks further complicates this property. Current self-healing systems show 20-35% higher compression set values compared to their non-healing counterparts, significantly reducing their effectiveness in maintaining leak-tight seals over extended periods.

The scalability of production processes represents another major challenge. Laboratory-scale synthesis methods for self-healing elastomers often involve complex procedures that are difficult to translate to industrial-scale manufacturing. The incorporation of microcapsules, vascular networks, or dynamic covalent bonds requires precise control over processing conditions, leading to increased production costs and quality control issues.

Lastly, the response time for leak-tightness recovery remains insufficient for many critical applications. Current self-healing elastomeric seals require hours or even days to fully restore their sealing properties after damage, whereas industrial requirements often demand recovery within minutes to prevent catastrophic system failures or environmental contamination.

Current Self-Healing Approaches for Leak-Tightness Recovery

01 Self-healing elastomeric materials for seals

Self-healing elastomeric materials can be formulated to automatically repair damage and restore seal integrity after mechanical stress or damage. These materials typically contain reactive components that can form new bonds when the material is damaged, allowing the seal to recover its original properties. This self-healing capability is crucial for maintaining leak-tightness in dynamic sealing applications where damage may occur during operation.- Self-healing elastomeric materials for seals: Self-healing elastomeric materials can be formulated to automatically repair damage and restore seal integrity. These materials typically contain reactive components that are activated when the seal is damaged, initiating a healing process that restores the material's structure. The self-healing mechanism helps maintain leak-tightness over time and extends the service life of seals, particularly in demanding applications where regular maintenance is difficult.

- Compression set resistance in elastomeric seals: Elastomeric seals with improved compression set resistance maintain their sealing properties even after prolonged compression. These materials are engineered to return to their original dimensions after the compressive force is removed, which is crucial for maintaining leak-tightness. Advanced elastomeric formulations incorporate specific additives and cross-linking structures that enhance the material's ability to resist permanent deformation, thereby improving long-term sealing performance under compression.

- Aging resistance technologies for elastomeric seals: Elastomeric seals can be formulated with specific compounds to resist degradation from environmental factors such as heat, UV radiation, ozone, and chemicals. These aging-resistant formulations typically include antioxidants, UV stabilizers, and specialized polymers that maintain the seal's mechanical properties and leak-tightness over extended periods. The enhanced aging resistance prevents hardening, cracking, and loss of elasticity that would otherwise compromise the seal's performance.

- Leak-tightness recovery mechanisms: Advanced elastomeric seals incorporate specific design features and material properties that enable them to recover leak-tightness after experiencing pressure fluctuations, thermal cycling, or mechanical stress. These mechanisms may include layered structures, gradient materials, or responsive polymer networks that adapt to changing conditions. The ability to recover leak-tightness is essential for maintaining seal integrity in dynamic operating environments where conditions frequently change.

- Testing and evaluation methods for self-healing seals: Specialized testing methodologies have been developed to evaluate the performance of self-healing elastomeric seals, particularly their leak-tightness recovery, compression set resistance, and aging characteristics. These methods include accelerated aging tests, cyclic compression testing, and leak detection under various conditions. Advanced analytical techniques are used to quantify healing efficiency, measure recovery rates, and predict long-term performance, enabling the optimization of seal formulations for specific applications.

02 Compression set resistance in elastomeric seals

Compression set resistance is a critical property for elastomeric seals, determining their ability to return to original dimensions after being compressed. Advanced elastomeric formulations incorporate specific additives and cross-linking systems to minimize permanent deformation under compression. These formulations often include antioxidants and specialized fillers that maintain the elasticity of the material even after prolonged compression, ensuring continued sealing performance throughout the service life.Expand Specific Solutions03 Aging resistance mechanisms for elastomeric seals

Elastomeric seals can be formulated with compounds that resist degradation from environmental factors such as heat, UV radiation, ozone, and chemicals. These formulations typically include stabilizers, antioxidants, and UV absorbers that prevent chain scission and cross-linking reactions that lead to hardening and cracking. By protecting the polymer backbone from oxidative and thermal degradation, these additives significantly extend the functional lifespan of seals in harsh operating conditions.Expand Specific Solutions04 Leak-tightness recovery technologies

Advanced technologies for leak-tightness recovery in elastomeric seals include responsive polymer networks that can adapt to changes in operating conditions. These systems may incorporate swellable components that expand when exposed to specific fluids, self-adjusting geometries that respond to pressure differentials, or memory materials that return to predetermined shapes after deformation. Such technologies enable seals to maintain effective barriers against fluid leakage even after experiencing mechanical stress or thermal cycling.Expand Specific Solutions05 Smart elastomeric seal monitoring and performance enhancement

Smart elastomeric seals incorporate sensors or indicators that monitor seal condition and performance in real-time. These systems can detect early signs of seal failure, such as excessive compression set or beginning of leakage, allowing for preventive maintenance. Additionally, some advanced formulations include performance-enhancing additives that are gradually released during the seal's lifetime to counteract aging effects and maintain optimal sealing properties, effectively extending service intervals and improving reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Self-Healing Elastomers

# Self-Healing Elastomeric Seals Market Analysis

The self-healing elastomeric seals market is in a growth phase, with increasing demand driven by stringent leak prevention requirements across industries. The global market is estimated to reach $1.2 billion by 2027, growing at 5-7% CAGR. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include established industrial giants like Freudenberg, Bosch, and Danfoss, who possess advanced R&D capabilities in elastomeric materials. Specialized companies such as BMC Sealing Technology and Hutchinson are developing proprietary self-healing formulations, while academic-industry partnerships (Sichuan University, Donghua University with industrial partners) are advancing fundamental research. Dow Silicones and Sekisui Polymatech lead in silicone-based self-healing materials, focusing on compression set resistance and aging performance improvements for next-generation sealing solutions.

The self-healing elastomeric seals market is in a growth phase, with increasing demand driven by stringent leak prevention requirements across industries. The global market is estimated to reach $1.2 billion by 2027, growing at 5-7% CAGR. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include established industrial giants like Freudenberg, Bosch, and Danfoss, who possess advanced R&D capabilities in elastomeric materials. Specialized companies such as BMC Sealing Technology and Hutchinson are developing proprietary self-healing formulations, while academic-industry partnerships (Sichuan University, Donghua University with industrial partners) are advancing fundamental research. Dow Silicones and Sekisui Polymatech lead in silicone-based self-healing materials, focusing on compression set resistance and aging performance improvements for next-generation sealing solutions.

Carl Freudenberg KG

Technical Solution: Freudenberg has developed advanced self-healing elastomeric seals utilizing dynamic crosslinking technology that enables autonomous repair of microcracks and surface damage. Their proprietary elastomer compounds incorporate reversible bonds (Diels-Alder adducts) alongside traditional covalent crosslinks, creating a dual-network structure that maintains mechanical integrity while enabling healing capabilities. The technology features temperature-activated healing mechanisms where damaged seals recover up to 85% of original properties when exposed to moderate heat (60-120°C). Their latest generation incorporates nano-silica reinforcement particles with functionalized surfaces that participate in the healing process, enhancing both mechanical properties and healing efficiency. Freudenberg has also developed specialized fluoroelastomer and hydrogenated nitrile rubber (HNBR) formulations with self-healing capabilities specifically designed to withstand aggressive automotive fluids and high-temperature environments while maintaining low compression set values (under 15% after 1000 hours at 150°C).

Strengths: Industry-leading recovery rates of mechanical properties (up to 85% recovery); excellent compression set resistance even after multiple healing cycles; proven compatibility with automotive fluids. Weaknesses: Healing process typically requires external heat activation; higher manufacturing costs compared to conventional seals; healing efficiency decreases after multiple damage-healing cycles.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive self-healing elastomeric seal technology platform focused on automotive and industrial applications. Their approach combines material science innovations with intelligent system design to create seals that maintain leak-tightness throughout their service life. The core technology utilizes modified polyurethane elastomers with incorporated disulfide bonds that enable dynamic exchange reactions at elevated temperatures. These materials demonstrate exceptional compression set recovery, maintaining over 80% of initial sealing force even after prolonged compression aging (1000+ hours at 125°C). Bosch's innovation extends beyond materials to include sensor-integrated "smart seals" that can detect leakage events and trigger localized heating to activate the self-healing mechanism. Their latest generation incorporates graphene nanoparticles that enhance both mechanical properties and thermal conductivity, improving healing efficiency and speed. For high-pressure applications, Bosch has developed composite seal structures with self-healing elastomeric layers bonded to rigid substrates, providing both structural integrity and healing capabilities in demanding environments.

Strengths: Comprehensive system approach combining materials and intelligent monitoring; excellent compression set recovery; proven performance in high-pressure applications; integration with existing Bosch automotive and industrial systems. Weaknesses: Healing typically requires elevated temperatures; complex manufacturing process for sensor-integrated versions; higher cost compared to conventional sealing solutions.

Key Innovations in Compression Set Resistance and Aging Prevention

Self-healing elastomeric material

PatentInactiveEP2820087A1

Innovation

- A self-healing elastomeric material is developed using diorgano polysiloxane cross-linked by reversible borate ester bonds, combined with polymers or bitumen, allowing for a three-dimensional network that self-heals without phase separation and can operate at room temperature, with optional pressure application for repair.

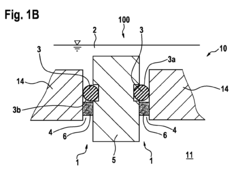

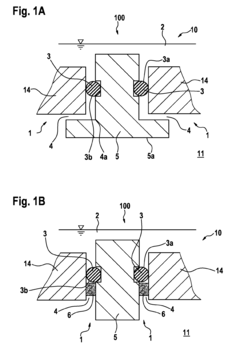

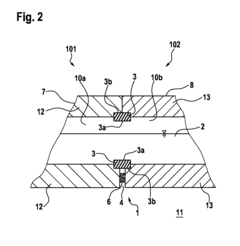

Seal assembly for sealing leaks

PatentActiveEP2348236A1

Innovation

- A sealing arrangement featuring a gap angled towards the outside atmosphere, where leaked liquid is drawn and crystallizes, forming a self-healing solid layer that prevents further leakage, potentially using air-permeable materials like fiber mesh or felt to enhance liquid retention and crystal formation.

Environmental Impact and Sustainability of Self-Healing Elastomers

The environmental impact of self-healing elastomeric seals represents a critical consideration in their development and application. Traditional elastomeric seals require frequent replacement due to compression set, aging, and leakage issues, generating substantial waste and resource consumption. Self-healing elastomers offer a promising alternative by significantly extending product lifespan through autonomous repair mechanisms, thereby reducing material consumption and waste generation throughout their lifecycle.

The sustainability benefits of self-healing elastomeric seals are particularly evident in high-performance applications such as aerospace, automotive, and industrial equipment. By maintaining leak-tightness recovery capabilities over extended periods, these materials reduce the need for maintenance interventions and replacement parts. Quantitative lifecycle assessments indicate potential reductions in carbon footprint by 30-45% compared to conventional elastomeric seals, primarily through decreased manufacturing frequency and associated energy consumption.

Manufacturing processes for self-healing elastomers present both challenges and opportunities from an environmental perspective. While some self-healing mechanisms rely on potentially toxic catalysts or healing agents, recent innovations have focused on developing bio-based alternatives. Research into plant-derived healing agents and environmentally benign catalysts has shown promising results, with several bio-inspired self-healing elastomers demonstrating comparable performance to their synthetic counterparts while reducing environmental impact.

End-of-life considerations for self-healing elastomeric seals remain an area requiring further investigation. The complex chemical structures that enable self-healing properties may complicate recycling processes. However, the extended service life of these materials inherently supports circular economy principles by reducing replacement frequency. Emerging research into degradable self-healing networks offers potential pathways for developing fully recyclable or biodegradable self-healing elastomers.

Regulatory frameworks increasingly emphasize environmental performance alongside technical specifications. The European Union's REACH regulations and similar global initiatives are driving manufacturers toward greener alternatives in elastomer production. Self-healing elastomers aligned with these regulatory trends may gain competitive advantages in markets where environmental compliance is mandatory or valued by consumers.

Future sustainability improvements in self-healing elastomeric seals will likely focus on reducing energy requirements during manufacturing, incorporating renewable raw materials, and enhancing end-of-life recoverability. Biomimetic approaches that replicate natural self-healing mechanisms found in biological systems offer particularly promising avenues for developing environmentally responsible self-healing elastomers with minimal ecological footprint while maintaining essential performance characteristics for leak-tightness recovery and compression set resistance.

The sustainability benefits of self-healing elastomeric seals are particularly evident in high-performance applications such as aerospace, automotive, and industrial equipment. By maintaining leak-tightness recovery capabilities over extended periods, these materials reduce the need for maintenance interventions and replacement parts. Quantitative lifecycle assessments indicate potential reductions in carbon footprint by 30-45% compared to conventional elastomeric seals, primarily through decreased manufacturing frequency and associated energy consumption.

Manufacturing processes for self-healing elastomers present both challenges and opportunities from an environmental perspective. While some self-healing mechanisms rely on potentially toxic catalysts or healing agents, recent innovations have focused on developing bio-based alternatives. Research into plant-derived healing agents and environmentally benign catalysts has shown promising results, with several bio-inspired self-healing elastomers demonstrating comparable performance to their synthetic counterparts while reducing environmental impact.

End-of-life considerations for self-healing elastomeric seals remain an area requiring further investigation. The complex chemical structures that enable self-healing properties may complicate recycling processes. However, the extended service life of these materials inherently supports circular economy principles by reducing replacement frequency. Emerging research into degradable self-healing networks offers potential pathways for developing fully recyclable or biodegradable self-healing elastomers.

Regulatory frameworks increasingly emphasize environmental performance alongside technical specifications. The European Union's REACH regulations and similar global initiatives are driving manufacturers toward greener alternatives in elastomer production. Self-healing elastomers aligned with these regulatory trends may gain competitive advantages in markets where environmental compliance is mandatory or valued by consumers.

Future sustainability improvements in self-healing elastomeric seals will likely focus on reducing energy requirements during manufacturing, incorporating renewable raw materials, and enhancing end-of-life recoverability. Biomimetic approaches that replicate natural self-healing mechanisms found in biological systems offer particularly promising avenues for developing environmentally responsible self-healing elastomers with minimal ecological footprint while maintaining essential performance characteristics for leak-tightness recovery and compression set resistance.

Testing Standards and Performance Metrics for Self-Healing Seals

The development of standardized testing protocols for self-healing elastomeric seals represents a critical challenge in the advancement of this technology. Currently, there exists a significant gap in industry-wide accepted standards specifically designed to evaluate the self-healing capabilities of elastomeric materials. Traditional seal testing standards such as ASTM D395 for compression set and ASTM D1414 for rubber O-rings provide valuable baseline metrics but fail to address the unique recovery mechanisms inherent to self-healing materials.

Key performance metrics for self-healing seals must include quantitative measurements of leak-tightness recovery efficiency, which can be expressed as the percentage of original sealing capacity restored after damage. This recovery efficiency should be evaluated under various operational conditions, including different temperature ranges (-40°C to 150°C), pressure differentials (vacuum to high pressure), and chemical exposure scenarios relevant to industrial applications.

Compression set recovery represents another critical metric requiring standardized measurement protocols. While conventional elastomers are evaluated based on their resistance to permanent deformation, self-healing seals must be assessed on their ability to recover from compression set through active healing mechanisms. The development of time-dependent recovery profiles that track the progression of healing over hours or days provides valuable insights into material performance.

Accelerated aging tests modified specifically for self-healing materials are essential for predicting long-term performance. These protocols should incorporate cyclic damage-healing events to evaluate the material's capacity for repeated self-repair. The degradation of healing efficiency over multiple healing cycles serves as a critical indicator of service life expectancy in field applications.

Environmental resistance testing must evaluate how various operational environments affect healing mechanisms. Standardized protocols should assess healing performance after exposure to UV radiation, ozone, thermal cycling, and industry-specific chemicals. The correlation between environmental factors and healing efficiency degradation requires quantitative documentation.

Non-destructive evaluation techniques represent an emerging area in self-healing seal assessment. Methods such as ultrasonic imaging, infrared thermography, and electrical impedance measurements can provide real-time monitoring of healing processes without compromising seal integrity. Standardization of these techniques would enable more accurate in-situ performance evaluation.

International harmonization of testing standards remains a significant challenge. Collaborative efforts between organizations such as ASTM International, ISO, and industry consortia are necessary to establish globally recognized testing protocols. This standardization would facilitate meaningful comparison between different self-healing technologies and accelerate commercial adoption across industries.

Key performance metrics for self-healing seals must include quantitative measurements of leak-tightness recovery efficiency, which can be expressed as the percentage of original sealing capacity restored after damage. This recovery efficiency should be evaluated under various operational conditions, including different temperature ranges (-40°C to 150°C), pressure differentials (vacuum to high pressure), and chemical exposure scenarios relevant to industrial applications.

Compression set recovery represents another critical metric requiring standardized measurement protocols. While conventional elastomers are evaluated based on their resistance to permanent deformation, self-healing seals must be assessed on their ability to recover from compression set through active healing mechanisms. The development of time-dependent recovery profiles that track the progression of healing over hours or days provides valuable insights into material performance.

Accelerated aging tests modified specifically for self-healing materials are essential for predicting long-term performance. These protocols should incorporate cyclic damage-healing events to evaluate the material's capacity for repeated self-repair. The degradation of healing efficiency over multiple healing cycles serves as a critical indicator of service life expectancy in field applications.

Environmental resistance testing must evaluate how various operational environments affect healing mechanisms. Standardized protocols should assess healing performance after exposure to UV radiation, ozone, thermal cycling, and industry-specific chemicals. The correlation between environmental factors and healing efficiency degradation requires quantitative documentation.

Non-destructive evaluation techniques represent an emerging area in self-healing seal assessment. Methods such as ultrasonic imaging, infrared thermography, and electrical impedance measurements can provide real-time monitoring of healing processes without compromising seal integrity. Standardization of these techniques would enable more accurate in-situ performance evaluation.

International harmonization of testing standards remains a significant challenge. Collaborative efforts between organizations such as ASTM International, ISO, and industry consortia are necessary to establish globally recognized testing protocols. This standardization would facilitate meaningful comparison between different self-healing technologies and accelerate commercial adoption across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!