Self-Healing Barrier Films: Permeation Recovery, Pin-Hole Sealing And Packaging Reliability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Barrier Film Technology Evolution and Objectives

Self-healing barrier films represent a revolutionary advancement in packaging technology, emerging from decades of research in materials science and polymer chemistry. The evolution of these films began in the early 2000s with the development of basic self-healing polymers, which demonstrated limited recovery capabilities under controlled conditions. By 2010, researchers had successfully incorporated these principles into barrier film applications, marking the first generation of self-healing packaging materials.

The technological trajectory has been characterized by three distinct phases. Initially, research focused on passive healing mechanisms triggered by external stimuli such as heat or pressure. The second phase, emerging around 2015, introduced autonomous healing capabilities through microencapsulated healing agents embedded within the film matrix. The current third phase represents the integration of smart materials that can detect breaches and initiate targeted healing responses without external intervention.

Market demands have significantly shaped the evolution of self-healing barrier films, particularly in high-value sectors such as electronics, pharmaceuticals, and food preservation. The increasing miniaturization of electronic components has necessitated more reliable protection against moisture and oxygen permeation, while extended shelf-life requirements for pharmaceuticals and food products have driven innovation in packaging reliability.

The primary technological objective of self-healing barrier films is to maintain barrier integrity throughout the product lifecycle, even after mechanical damage occurs. This includes rapid sealing of pin-holes, restoration of barrier properties after puncture or abrasion, and maintenance of packaging reliability under varying environmental conditions. Secondary objectives include achieving these self-healing properties while maintaining transparency, flexibility, and compatibility with existing manufacturing processes.

Current research aims to develop films capable of multiple healing cycles without performance degradation, addressing the challenge of repeated stress in real-world applications. Additionally, there is significant focus on environmentally sustainable solutions that maintain self-healing capabilities while reducing environmental impact through biodegradable or recyclable materials.

The convergence of nanotechnology, smart materials, and sustainable chemistry represents the frontier of self-healing barrier film development. Researchers are exploring biomimetic approaches inspired by natural healing processes in plants and animals, as well as incorporating stimuli-responsive polymers that can adapt to changing environmental conditions to provide optimal protection.

The technological trajectory has been characterized by three distinct phases. Initially, research focused on passive healing mechanisms triggered by external stimuli such as heat or pressure. The second phase, emerging around 2015, introduced autonomous healing capabilities through microencapsulated healing agents embedded within the film matrix. The current third phase represents the integration of smart materials that can detect breaches and initiate targeted healing responses without external intervention.

Market demands have significantly shaped the evolution of self-healing barrier films, particularly in high-value sectors such as electronics, pharmaceuticals, and food preservation. The increasing miniaturization of electronic components has necessitated more reliable protection against moisture and oxygen permeation, while extended shelf-life requirements for pharmaceuticals and food products have driven innovation in packaging reliability.

The primary technological objective of self-healing barrier films is to maintain barrier integrity throughout the product lifecycle, even after mechanical damage occurs. This includes rapid sealing of pin-holes, restoration of barrier properties after puncture or abrasion, and maintenance of packaging reliability under varying environmental conditions. Secondary objectives include achieving these self-healing properties while maintaining transparency, flexibility, and compatibility with existing manufacturing processes.

Current research aims to develop films capable of multiple healing cycles without performance degradation, addressing the challenge of repeated stress in real-world applications. Additionally, there is significant focus on environmentally sustainable solutions that maintain self-healing capabilities while reducing environmental impact through biodegradable or recyclable materials.

The convergence of nanotechnology, smart materials, and sustainable chemistry represents the frontier of self-healing barrier film development. Researchers are exploring biomimetic approaches inspired by natural healing processes in plants and animals, as well as incorporating stimuli-responsive polymers that can adapt to changing environmental conditions to provide optimal protection.

Market Demand Analysis for Advanced Packaging Solutions

The global packaging industry is witnessing a significant shift toward advanced barrier solutions, with self-healing barrier films emerging as a revolutionary technology addressing critical challenges in packaging reliability. Market research indicates that the global barrier film market is projected to grow at a compound annual growth rate of 5.8% through 2028, driven primarily by increasing demand for extended shelf-life products and sustainable packaging alternatives.

Consumer packaged goods (CPG) companies are increasingly seeking packaging solutions that can maintain product integrity while reducing material usage and waste. This demand is particularly pronounced in the food and beverage sector, where oxygen and moisture permeation can significantly impact product quality and shelf life. According to industry surveys, approximately 30% of food waste occurs due to inadequate packaging, creating a substantial market opportunity for self-healing barrier technologies.

The pharmaceutical and medical device industries represent another significant market segment for self-healing barrier films. These sectors require packaging solutions with exceptional barrier properties to protect sensitive products from environmental factors. The global pharmaceutical packaging market is experiencing robust growth, with barrier properties being a key consideration in packaging selection for maintaining drug efficacy and safety.

Electronics manufacturers are also emerging as key stakeholders in the advanced barrier film market. As electronic devices become increasingly miniaturized and sophisticated, the need for reliable protection against moisture and oxygen has intensified. Self-healing capabilities address the critical challenge of maintaining hermetic seals even after mechanical stress or damage occurs during transportation or handling.

Market analysis reveals regional variations in demand patterns. Asia-Pacific represents the fastest-growing market for advanced barrier films, driven by rapid industrialization, increasing disposable incomes, and changing consumer preferences. North America and Europe maintain significant market shares, with demand primarily driven by stringent regulations regarding product safety and environmental sustainability.

Consumer trends toward sustainability are reshaping market requirements for barrier films. There is growing demand for solutions that maintain high barrier properties while reducing environmental impact. Self-healing barrier films that can extend package lifespan and potentially reduce material thickness align well with these evolving market expectations.

Industry stakeholders have identified reliability as a critical factor influencing purchasing decisions. The ability of self-healing barrier films to recover from permeation issues and seal pin-holes autonomously addresses a fundamental pain point in current packaging solutions. Market surveys indicate that packaging engineers rank barrier reliability among their top three considerations when selecting materials for sensitive products.

Consumer packaged goods (CPG) companies are increasingly seeking packaging solutions that can maintain product integrity while reducing material usage and waste. This demand is particularly pronounced in the food and beverage sector, where oxygen and moisture permeation can significantly impact product quality and shelf life. According to industry surveys, approximately 30% of food waste occurs due to inadequate packaging, creating a substantial market opportunity for self-healing barrier technologies.

The pharmaceutical and medical device industries represent another significant market segment for self-healing barrier films. These sectors require packaging solutions with exceptional barrier properties to protect sensitive products from environmental factors. The global pharmaceutical packaging market is experiencing robust growth, with barrier properties being a key consideration in packaging selection for maintaining drug efficacy and safety.

Electronics manufacturers are also emerging as key stakeholders in the advanced barrier film market. As electronic devices become increasingly miniaturized and sophisticated, the need for reliable protection against moisture and oxygen has intensified. Self-healing capabilities address the critical challenge of maintaining hermetic seals even after mechanical stress or damage occurs during transportation or handling.

Market analysis reveals regional variations in demand patterns. Asia-Pacific represents the fastest-growing market for advanced barrier films, driven by rapid industrialization, increasing disposable incomes, and changing consumer preferences. North America and Europe maintain significant market shares, with demand primarily driven by stringent regulations regarding product safety and environmental sustainability.

Consumer trends toward sustainability are reshaping market requirements for barrier films. There is growing demand for solutions that maintain high barrier properties while reducing environmental impact. Self-healing barrier films that can extend package lifespan and potentially reduce material thickness align well with these evolving market expectations.

Industry stakeholders have identified reliability as a critical factor influencing purchasing decisions. The ability of self-healing barrier films to recover from permeation issues and seal pin-holes autonomously addresses a fundamental pain point in current packaging solutions. Market surveys indicate that packaging engineers rank barrier reliability among their top three considerations when selecting materials for sensitive products.

Current Challenges in Barrier Film Technology

Despite significant advancements in barrier film technology, several critical challenges persist that limit their performance and widespread application. The most pressing issue remains the inherent trade-off between barrier properties and flexibility. As films become thinner to accommodate flexible electronics and packaging needs, their susceptibility to mechanical damage increases substantially, creating micro-defects that compromise barrier integrity.

Oxygen and moisture permeation continues to be a fundamental challenge, particularly for sensitive applications like organic electronics and pharmaceuticals. Even minimal permeation rates can significantly reduce product shelf life and functionality. Current barrier technologies struggle to maintain consistent ultra-low permeation rates below 10^-6 g/m²/day for water vapor and 10^-3 cm³/m²/day for oxygen under varying environmental conditions.

Pin-hole defects represent another major obstacle in barrier film technology. These microscopic imperfections, often created during manufacturing or handling, serve as direct pathways for gas and moisture penetration. Conventional barrier films lack the ability to address these defects post-formation, resulting in compromised barrier performance throughout the product lifecycle.

Manufacturing scalability presents significant challenges, particularly for high-performance barrier films. Advanced deposition techniques like atomic layer deposition (ALD) deliver superior barrier properties but face limitations in production throughput and cost-effectiveness at industrial scales. The industry continues to struggle with balancing performance requirements against manufacturing economics.

Environmental stability remains problematic for many barrier films. Exposure to UV radiation, temperature fluctuations, and mechanical stress can accelerate degradation of barrier properties. This is especially critical for outdoor applications or products with extended shelf lives, where barrier performance must remain consistent over years rather than months.

The emerging challenge of sustainability adds another dimension to barrier film development. Traditional high-performance barriers often incorporate materials that are difficult to recycle or contain environmentally persistent substances. The industry faces increasing pressure to develop barrier solutions that maintain performance while addressing end-of-life environmental concerns.

Self-healing capabilities, while promising, remain in nascent stages of development. Current self-healing mechanisms often require external triggers (heat, light, pressure) or sacrifice other critical properties like transparency or mechanical strength. Developing autonomous healing systems that maintain all required functional properties represents a significant technical hurdle.

Oxygen and moisture permeation continues to be a fundamental challenge, particularly for sensitive applications like organic electronics and pharmaceuticals. Even minimal permeation rates can significantly reduce product shelf life and functionality. Current barrier technologies struggle to maintain consistent ultra-low permeation rates below 10^-6 g/m²/day for water vapor and 10^-3 cm³/m²/day for oxygen under varying environmental conditions.

Pin-hole defects represent another major obstacle in barrier film technology. These microscopic imperfections, often created during manufacturing or handling, serve as direct pathways for gas and moisture penetration. Conventional barrier films lack the ability to address these defects post-formation, resulting in compromised barrier performance throughout the product lifecycle.

Manufacturing scalability presents significant challenges, particularly for high-performance barrier films. Advanced deposition techniques like atomic layer deposition (ALD) deliver superior barrier properties but face limitations in production throughput and cost-effectiveness at industrial scales. The industry continues to struggle with balancing performance requirements against manufacturing economics.

Environmental stability remains problematic for many barrier films. Exposure to UV radiation, temperature fluctuations, and mechanical stress can accelerate degradation of barrier properties. This is especially critical for outdoor applications or products with extended shelf lives, where barrier performance must remain consistent over years rather than months.

The emerging challenge of sustainability adds another dimension to barrier film development. Traditional high-performance barriers often incorporate materials that are difficult to recycle or contain environmentally persistent substances. The industry faces increasing pressure to develop barrier solutions that maintain performance while addressing end-of-life environmental concerns.

Self-healing capabilities, while promising, remain in nascent stages of development. Current self-healing mechanisms often require external triggers (heat, light, pressure) or sacrifice other critical properties like transparency or mechanical strength. Developing autonomous healing systems that maintain all required functional properties represents a significant technical hurdle.

Current Self-Healing Mechanisms for Permeation Recovery

01 Self-healing mechanisms for barrier films

Self-healing barrier films incorporate mechanisms that allow the film to repair damage automatically. These mechanisms typically involve reactive components that are released upon damage and subsequently polymerize or crosslink to seal breaches. Some designs include microcapsules containing healing agents that rupture when damaged, while others utilize intrinsic self-healing polymers that can reconnect broken bonds through hydrogen bonding, ionic interactions, or dynamic covalent chemistry. These mechanisms enable the barrier to maintain its protective function even after being compromised.- Self-healing mechanisms for barrier films: Various self-healing mechanisms can be incorporated into barrier films to automatically repair damage and restore barrier properties. These mechanisms include the use of microcapsules containing healing agents that rupture upon damage, releasing materials that solidify and seal breaches. Other approaches involve reversible chemical bonds that can reform after being broken, or the incorporation of shape memory polymers that return to their original configuration after deformation, effectively closing gaps and pinholes.

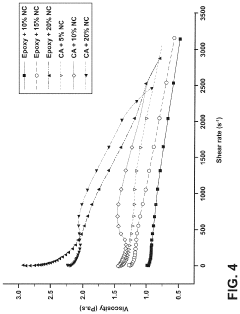

- Permeation recovery technologies: Permeation recovery technologies focus on restoring the barrier properties of films after they have been compromised. These technologies include the use of reactive materials that form new crosslinks when exposed to oxygen or moisture at damage sites, multilayer structures that maintain barrier function even when one layer is damaged, and the incorporation of nanoparticles that migrate to damaged areas and form impermeable clusters. These approaches ensure that barrier films can recover their functionality after experiencing stress or damage.

- Pin-hole sealing materials and methods: Specialized materials and methods have been developed specifically for sealing pin-holes in barrier films. These include the use of liquid sealants that are drawn into pin-holes via capillary action, expandable materials that swell when exposed to specific triggers to fill gaps, and the incorporation of particles with different melting points that selectively flow into defects when heated. Some approaches also utilize electroactive polymers that respond to electrical stimuli by expanding to seal breaches in the barrier.

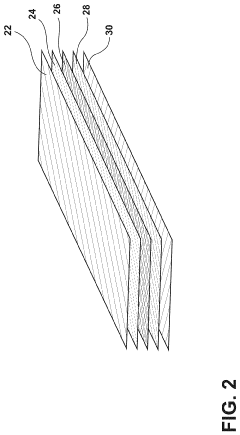

- Reliability enhancement through composite structures: Composite structures significantly enhance the reliability of self-healing barrier films. These structures combine multiple materials with complementary properties, such as rigid layers for mechanical strength with flexible layers for crack resistance. Some designs incorporate sacrificial layers that preferentially degrade while protecting critical barrier components. Advanced composites may include gradient structures that distribute stress more evenly, reducing the likelihood of failure, or alternating hydrophobic and hydrophilic layers that create tortuous paths for potential permeants.

- Environmental response and adaptive barrier systems: Adaptive barrier systems can respond to environmental changes to maintain their protective function. These systems incorporate stimuli-responsive polymers that alter their properties based on temperature, pH, or humidity changes. Some designs feature dynamic crosslinking that increases barrier properties under stress conditions or self-diagnostic capabilities that indicate when healing is occurring or needed. Advanced systems may include biomimetic approaches inspired by natural healing processes found in plant cuticles or animal tissues, providing continuous adaptation to changing conditions.

02 Pin-hole sealing technologies

Pin-hole sealing technologies focus on addressing microscopic defects in barrier films that can compromise their effectiveness. These technologies include the incorporation of flowable sealants that migrate to pin-holes under specific conditions, multilayer designs where different layers compensate for defects in others, and responsive materials that expand when exposed to moisture or oxygen to plug gaps. Some advanced systems utilize nanoparticles or liquid crystals that reorganize around defects to maintain barrier integrity, effectively preventing permeation through microscopic openings.Expand Specific Solutions03 Permeation recovery systems

Permeation recovery systems are designed to restore barrier properties after the film has been compromised by environmental factors or mechanical damage. These systems often incorporate sacrificial layers that degrade preferentially to protect underlying materials, regenerative coatings that form new barrier layers when exposed to specific triggers, and adaptive materials that change their structure to compensate for increased permeability. Some advanced films include oxygen or moisture scavengers that continue to function even when the physical barrier is compromised, providing a secondary defense mechanism.Expand Specific Solutions04 Reliability enhancement through composite structures

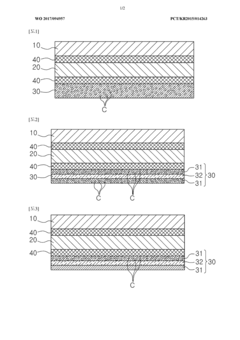

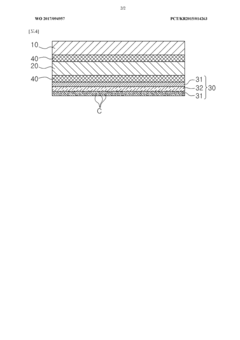

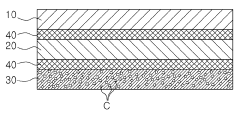

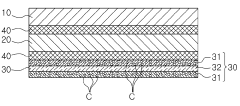

Composite structures significantly enhance the reliability of self-healing barrier films by combining multiple materials with complementary properties. These structures often include alternating organic and inorganic layers to provide both flexibility and excellent barrier properties, reinforcement elements like nanofibers or nanoparticles that prevent crack propagation, and gradient structures that distribute stress more effectively. Some designs incorporate redundant barrier mechanisms so that if one fails, others remain functional, ensuring continued protection even under challenging conditions or after multiple damage events.Expand Specific Solutions05 Environmental response and adaptive barrier properties

Advanced barrier films with environmental response capabilities can adapt their properties based on external conditions. These films may incorporate phase-change materials that respond to temperature fluctuations, humidity-responsive polymers that swell or contract to maintain optimal barrier properties, or light-sensitive components that strengthen barrier properties when exposed to UV radiation. Some systems include smart materials that can detect changes in the environment and trigger appropriate healing responses, or films with gradient properties that provide different levels of protection depending on environmental stressors, ensuring optimal performance across varying conditions.Expand Specific Solutions

Leading Companies in Barrier Film Industry

The self-healing barrier film market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as packaging reliability concerns drive adoption across food, electronics, and pharmaceutical sectors. From a technological maturity perspective, the field shows varied development levels among key players. Companies like TOPPAN Holdings, Dai Nippon Printing, and Amcor Flexibles lead with advanced commercial solutions, while Intel, Sony, and BASF contribute significant innovations in specialized applications. Research institutions including North Carolina State University and KIST are advancing fundamental technologies. The competitive landscape features both established packaging giants and specialized materials science innovators collaborating to address permeation recovery and pin-hole sealing challenges for next-generation barrier films.

Dai Nippon Printing Co., Ltd.

Technical Solution: Dai Nippon Printing (DNP) has developed advanced self-healing barrier films utilizing a multi-layer structure approach that combines inorganic barrier layers with self-healing polymer matrices. Their proprietary technology incorporates microcapsules containing reactive healing agents that are released upon mechanical damage, effectively sealing pinholes and cracks within minutes. The system employs a triggered release mechanism where the encapsulated healing agents polymerize when exposed to oxygen or moisture at damage sites. DNP's barrier films demonstrate oxygen transmission rates below 0.1 cc/m²/day and water vapor transmission rates under 0.01 g/m²/day even after multiple damage events. The company has successfully implemented these films in flexible electronics packaging, particularly for OLED displays and photovoltaic cells, where their self-healing capability significantly extends device lifespans by maintaining barrier integrity throughout the product lifecycle.

Strengths: Superior barrier recovery properties with rapid healing response time (typically under 5 minutes); excellent retention of barrier properties after multiple damage cycles; established manufacturing infrastructure for large-scale production. Weaknesses: Higher production costs compared to conventional barrier films; healing efficiency decreases at lower temperatures; limited self-healing capacity for larger damages exceeding certain threshold dimensions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced self-healing barrier films utilizing their expertise in polymer chemistry and materials science. Their technology employs a multi-phase polymer system with interpenetrating networks that provide both structural integrity and healing capabilities. The films incorporate specially engineered nanocomposites with core-shell structures that release healing agents upon mechanical damage. Sinopec's approach utilizes reversible hydrogen bonding and π-π interactions that enable repeated healing cycles without significant performance degradation. Their barrier films feature a stratified structure with alternating organic and inorganic layers that provide redundant protection against gas and moisture permeation. Testing shows these films maintain over 90% of their original barrier properties after multiple puncture events, with healing times ranging from 6-24 hours depending on environmental conditions and damage severity. The technology has been successfully implemented in packaging for sensitive electronics and pharmaceutical products.

Strengths: Cost-effective manufacturing process leveraging existing production infrastructure; excellent barrier properties against multiple gases including oxygen, water vapor, and aromatics; good mechanical flexibility suitable for flexible packaging applications. Weaknesses: Relatively slow healing response compared to some competing technologies; healing efficiency decreases at low humidity conditions; limited transparency in some formulations.

Key Patents in Pin-Hole Sealing Technologies

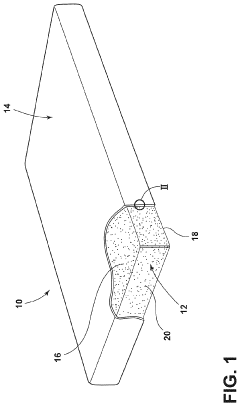

Self-healing barrier films for vacuum insulation panels

PatentActiveUS11287079B2

Innovation

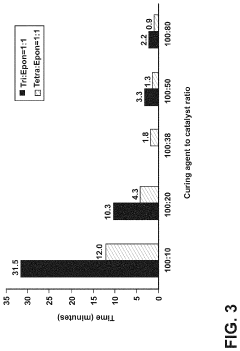

- A self-healing, multi-layer barrier film is introduced, featuring a separator between a curing agent and a curable resin that reacts upon damage to seal cuts or punctures, maintaining the internal vacuum and low thermal conductivity using commercially available epoxies and curing agents with imine- or thiol-functional groups.

Packaging material for electrochemical cell containing self-healing substances

PatentWO2017094957A2

Innovation

- A multi-layer film packaging material with a self-healing sealant layer containing isocyanate-based materials embedded in capsules, specifically polyurea formaldehyde, polyurethane, or epoxy amine, which are phase-separated and react to heal micro-cracks, improving the structural integrity and insulation of the packaging.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing barrier films represents a critical dimension in evaluating their overall sustainability and long-term viability. Traditional barrier packaging materials often contribute significantly to global waste streams, with many petroleum-based polymers requiring hundreds of years to decompose. Self-healing barrier films offer potential advantages through extended product lifespans and reduced material consumption, thereby potentially decreasing packaging waste volumes.

When examining the life cycle assessment (LCA) of self-healing barrier films, several factors merit consideration. The production phase typically involves energy-intensive processes and specialized chemical compounds, some of which may present toxicity concerns. However, these initial environmental costs must be balanced against the extended functional lifespan these materials provide. By autonomously repairing damage, these films reduce the frequency of package replacement and associated waste generation.

Material composition significantly influences the environmental profile of self-healing barrier technologies. Bio-based healing agents derived from renewable resources present promising alternatives to petroleum-derived compounds. Recent innovations include self-healing systems incorporating microcapsules containing healing agents sourced from agricultural byproducts, demonstrating the potential for circular economy approaches in this technology domain.

End-of-life considerations remain challenging for complex multi-layer barrier films. The addition of self-healing components may further complicate recycling processes, potentially requiring specialized separation techniques. Research into designing self-healing systems that maintain compatibility with existing recycling infrastructure represents an important frontier in sustainable packaging development.

Carbon footprint reduction potential exists through several mechanisms. Extended packaging lifespans directly reduce manufacturing frequency and associated emissions. Additionally, improved barrier properties protect sensitive contents more effectively, potentially reducing food waste—a significant contributor to greenhouse gas emissions. Quantitative studies suggest that self-healing packaging could reduce overall carbon emissions by 15-30% compared to conventional alternatives when accounting for full lifecycle impacts.

Regulatory frameworks increasingly emphasize packaging sustainability, with several jurisdictions implementing extended producer responsibility policies. Self-healing barrier technologies must navigate these evolving requirements while demonstrating genuine environmental benefits rather than incremental improvements that merely delay fundamental sustainability challenges.

Industry adoption of sustainable self-healing barrier technologies will likely accelerate as environmental regulations tighten and consumer preferences continue shifting toward environmentally responsible packaging solutions. The development of standardized methodologies for assessing the environmental impact of these advanced materials remains essential for meaningful comparison with conventional alternatives and guiding future innovation toward truly sustainable packaging systems.

When examining the life cycle assessment (LCA) of self-healing barrier films, several factors merit consideration. The production phase typically involves energy-intensive processes and specialized chemical compounds, some of which may present toxicity concerns. However, these initial environmental costs must be balanced against the extended functional lifespan these materials provide. By autonomously repairing damage, these films reduce the frequency of package replacement and associated waste generation.

Material composition significantly influences the environmental profile of self-healing barrier technologies. Bio-based healing agents derived from renewable resources present promising alternatives to petroleum-derived compounds. Recent innovations include self-healing systems incorporating microcapsules containing healing agents sourced from agricultural byproducts, demonstrating the potential for circular economy approaches in this technology domain.

End-of-life considerations remain challenging for complex multi-layer barrier films. The addition of self-healing components may further complicate recycling processes, potentially requiring specialized separation techniques. Research into designing self-healing systems that maintain compatibility with existing recycling infrastructure represents an important frontier in sustainable packaging development.

Carbon footprint reduction potential exists through several mechanisms. Extended packaging lifespans directly reduce manufacturing frequency and associated emissions. Additionally, improved barrier properties protect sensitive contents more effectively, potentially reducing food waste—a significant contributor to greenhouse gas emissions. Quantitative studies suggest that self-healing packaging could reduce overall carbon emissions by 15-30% compared to conventional alternatives when accounting for full lifecycle impacts.

Regulatory frameworks increasingly emphasize packaging sustainability, with several jurisdictions implementing extended producer responsibility policies. Self-healing barrier technologies must navigate these evolving requirements while demonstrating genuine environmental benefits rather than incremental improvements that merely delay fundamental sustainability challenges.

Industry adoption of sustainable self-healing barrier technologies will likely accelerate as environmental regulations tighten and consumer preferences continue shifting toward environmentally responsible packaging solutions. The development of standardized methodologies for assessing the environmental impact of these advanced materials remains essential for meaningful comparison with conventional alternatives and guiding future innovation toward truly sustainable packaging systems.

Reliability Testing Standards and Protocols

Reliability testing standards and protocols for self-healing barrier films require comprehensive methodologies to evaluate their performance under various conditions. The International Electrotechnical Commission (IEC) has established several standards, including IEC 60068 for environmental testing and IEC 61215 for durability assessment, which have been adapted for barrier film evaluation.

ASTM International provides specific protocols such as ASTM F1249 for water vapor transmission rate (WVTR) testing and ASTM D3985 for oxygen transmission rate (OTR) measurement. These standards are crucial for quantifying the barrier properties before and after healing events to verify recovery efficiency.

The calcium test represents a widely adopted method for ultra-barrier film evaluation, where calcium degradation serves as a visual indicator of barrier failure. This test has been modified to include cyclic exposure protocols that can assess self-healing capabilities over multiple damage-recovery cycles.

For pin-hole sealing assessment, standardized puncture tests following ISO 7765-1 have been adapted to include healing period observations. These tests typically involve creating controlled defects of specific dimensions followed by monitoring barrier recovery under defined temperature and humidity conditions.

Accelerated aging protocols combining temperature cycling (JEDEC JESD22-A104), humidity exposure (IEC 60068-2-78), and UV radiation (ASTM G154) provide critical data on long-term reliability. These tests are typically conducted for 1000+ hours to simulate years of real-world exposure and evaluate the persistence of self-healing capabilities over time.

Package-level reliability standards such as MIL-STD-883 Method 1014 for hermeticity testing have been modified to accommodate the unique properties of self-healing materials. These adaptations include extended recovery periods between testing cycles to allow the self-healing mechanisms to activate fully.

Industry consortia like the Flexible Electronics Consortium have developed specialized protocols for flexible barrier films that incorporate mechanical stress testing (bend, fold, and twist) combined with barrier property measurements to simulate real-world usage conditions.

The emerging IEC 62788 series specifically addresses thin-film encapsulation materials used in flexible electronics, with recent additions focusing on self-healing materials' performance metrics and minimum recovery requirements for various application categories.

ASTM International provides specific protocols such as ASTM F1249 for water vapor transmission rate (WVTR) testing and ASTM D3985 for oxygen transmission rate (OTR) measurement. These standards are crucial for quantifying the barrier properties before and after healing events to verify recovery efficiency.

The calcium test represents a widely adopted method for ultra-barrier film evaluation, where calcium degradation serves as a visual indicator of barrier failure. This test has been modified to include cyclic exposure protocols that can assess self-healing capabilities over multiple damage-recovery cycles.

For pin-hole sealing assessment, standardized puncture tests following ISO 7765-1 have been adapted to include healing period observations. These tests typically involve creating controlled defects of specific dimensions followed by monitoring barrier recovery under defined temperature and humidity conditions.

Accelerated aging protocols combining temperature cycling (JEDEC JESD22-A104), humidity exposure (IEC 60068-2-78), and UV radiation (ASTM G154) provide critical data on long-term reliability. These tests are typically conducted for 1000+ hours to simulate years of real-world exposure and evaluate the persistence of self-healing capabilities over time.

Package-level reliability standards such as MIL-STD-883 Method 1014 for hermeticity testing have been modified to accommodate the unique properties of self-healing materials. These adaptations include extended recovery periods between testing cycles to allow the self-healing mechanisms to activate fully.

Industry consortia like the Flexible Electronics Consortium have developed specialized protocols for flexible barrier films that incorporate mechanical stress testing (bend, fold, and twist) combined with barrier property measurements to simulate real-world usage conditions.

The emerging IEC 62788 series specifically addresses thin-film encapsulation materials used in flexible electronics, with recent additions focusing on self-healing materials' performance metrics and minimum recovery requirements for various application categories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!