Self-Healing Epoxy Systems: Microcapsule Release, Matrix Compatibility And Multi-Cycle Healing

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Epoxy Technology Background and Objectives

Self-healing epoxy systems represent a revolutionary advancement in materials science, emerging from the biomimetic concept of autonomous damage repair. The development of these systems can be traced back to the early 2000s when researchers at the University of Illinois first demonstrated the feasibility of incorporating microencapsulated healing agents into polymer matrices. This pioneering work established the foundation for subsequent research in self-healing materials, particularly focusing on epoxy-based systems due to their widespread industrial applications.

The evolution of self-healing epoxy technology has progressed through several distinct phases. Initially, single-capsule systems containing liquid healing agents were developed, followed by dual-capsule systems incorporating both healing agents and catalysts. More recently, vascular network systems and intrinsic self-healing mechanisms have emerged, expanding the capabilities and applications of these materials. Each advancement has addressed specific limitations of previous generations, gradually improving healing efficiency, durability, and applicability.

Current technological trends in self-healing epoxy systems are primarily focused on enhancing microcapsule design for controlled release mechanisms, improving matrix compatibility for seamless integration, and developing systems capable of multiple healing cycles. These advancements aim to overcome the persistent challenges of limited healing capacity and reduced mechanical properties that have historically constrained widespread industrial adoption.

The primary objective of research in self-healing epoxy systems is to develop materials capable of autonomously detecting and repairing damage without external intervention, thereby extending service life and reducing maintenance costs. Specific technical goals include optimizing microcapsule shell composition for controlled rupture under specific damage conditions, enhancing the compatibility between healing agents and epoxy matrices to maintain structural integrity, and developing systems capable of multiple healing cycles without significant performance degradation.

Additionally, researchers aim to improve the stability of encapsulated healing agents during processing and storage, increase healing efficiency across various environmental conditions, and develop scalable manufacturing processes for commercial viability. The ultimate goal is to create self-healing epoxy systems that can be seamlessly integrated into existing manufacturing processes while providing reliable, long-term performance in demanding applications such as aerospace components, protective coatings, and electronic encapsulants.

The achievement of these objectives would represent a paradigm shift in materials engineering, transitioning from damage management to damage prevention and autonomous repair, with significant implications for sustainability, safety, and economic efficiency across multiple industries.

The evolution of self-healing epoxy technology has progressed through several distinct phases. Initially, single-capsule systems containing liquid healing agents were developed, followed by dual-capsule systems incorporating both healing agents and catalysts. More recently, vascular network systems and intrinsic self-healing mechanisms have emerged, expanding the capabilities and applications of these materials. Each advancement has addressed specific limitations of previous generations, gradually improving healing efficiency, durability, and applicability.

Current technological trends in self-healing epoxy systems are primarily focused on enhancing microcapsule design for controlled release mechanisms, improving matrix compatibility for seamless integration, and developing systems capable of multiple healing cycles. These advancements aim to overcome the persistent challenges of limited healing capacity and reduced mechanical properties that have historically constrained widespread industrial adoption.

The primary objective of research in self-healing epoxy systems is to develop materials capable of autonomously detecting and repairing damage without external intervention, thereby extending service life and reducing maintenance costs. Specific technical goals include optimizing microcapsule shell composition for controlled rupture under specific damage conditions, enhancing the compatibility between healing agents and epoxy matrices to maintain structural integrity, and developing systems capable of multiple healing cycles without significant performance degradation.

Additionally, researchers aim to improve the stability of encapsulated healing agents during processing and storage, increase healing efficiency across various environmental conditions, and develop scalable manufacturing processes for commercial viability. The ultimate goal is to create self-healing epoxy systems that can be seamlessly integrated into existing manufacturing processes while providing reliable, long-term performance in demanding applications such as aerospace components, protective coatings, and electronic encapsulants.

The achievement of these objectives would represent a paradigm shift in materials engineering, transitioning from damage management to damage prevention and autonomous repair, with significant implications for sustainability, safety, and economic efficiency across multiple industries.

Market Demand Analysis for Self-Healing Composites

The global market for self-healing composites has witnessed significant growth in recent years, driven by increasing demand for durable materials with extended service life across various industries. The self-healing epoxy systems market, particularly those utilizing microcapsule release mechanisms, is projected to reach $2.7 billion by 2026, growing at a compound annual growth rate of 27% from 2021.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for approximately 60% of the total demand. In aerospace applications, self-healing composites address critical safety concerns while reducing maintenance costs and aircraft downtime. Boeing and Airbus have both initiated research programs to incorporate these materials in non-critical components, with plans to expand to structural elements pending regulatory approval.

The automotive industry's shift toward lightweight materials to improve fuel efficiency has created substantial demand for self-healing epoxy systems. Premium automotive manufacturers have begun implementing these materials in components exposed to high vibration and thermal cycling. Market research indicates that self-healing composites can reduce warranty costs by 15-20% for specific automotive applications.

Infrastructure and construction sectors are emerging as promising markets, particularly for applications in bridges, tunnels, and high-rise buildings. The ability of self-healing epoxy systems to extend service life by 30-40% presents compelling value propositions for infrastructure projects with long design lives and difficult access for repairs.

Consumer electronics manufacturers have shown increasing interest in self-healing coatings for device protection. This segment is expected to grow at the fastest rate (32% CAGR) due to rapid product cycles and high consumer expectations for durability.

Market analysis reveals that multi-cycle healing capability represents a key differentiator for commercial adoption. End-users across industries consistently rank healing efficiency and the number of possible healing cycles as the most important performance metrics, followed by compatibility with existing manufacturing processes.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate due to expanding manufacturing capabilities and increasing R&D investments in countries like China, Japan, and South Korea.

Customer surveys indicate willingness to pay premium prices (15-25% above conventional materials) for self-healing composites that demonstrate reliable performance and quantifiable reduction in maintenance costs. This price sensitivity varies significantly by application, with aerospace and high-end electronics showing the highest tolerance for premium pricing.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for approximately 60% of the total demand. In aerospace applications, self-healing composites address critical safety concerns while reducing maintenance costs and aircraft downtime. Boeing and Airbus have both initiated research programs to incorporate these materials in non-critical components, with plans to expand to structural elements pending regulatory approval.

The automotive industry's shift toward lightweight materials to improve fuel efficiency has created substantial demand for self-healing epoxy systems. Premium automotive manufacturers have begun implementing these materials in components exposed to high vibration and thermal cycling. Market research indicates that self-healing composites can reduce warranty costs by 15-20% for specific automotive applications.

Infrastructure and construction sectors are emerging as promising markets, particularly for applications in bridges, tunnels, and high-rise buildings. The ability of self-healing epoxy systems to extend service life by 30-40% presents compelling value propositions for infrastructure projects with long design lives and difficult access for repairs.

Consumer electronics manufacturers have shown increasing interest in self-healing coatings for device protection. This segment is expected to grow at the fastest rate (32% CAGR) due to rapid product cycles and high consumer expectations for durability.

Market analysis reveals that multi-cycle healing capability represents a key differentiator for commercial adoption. End-users across industries consistently rank healing efficiency and the number of possible healing cycles as the most important performance metrics, followed by compatibility with existing manufacturing processes.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate due to expanding manufacturing capabilities and increasing R&D investments in countries like China, Japan, and South Korea.

Customer surveys indicate willingness to pay premium prices (15-25% above conventional materials) for self-healing composites that demonstrate reliable performance and quantifiable reduction in maintenance costs. This price sensitivity varies significantly by application, with aerospace and high-end electronics showing the highest tolerance for premium pricing.

Current Challenges in Microcapsule-Based Healing Systems

Despite significant advancements in microcapsule-based self-healing epoxy systems, several critical challenges continue to impede their widespread industrial adoption. The primary obstacle remains the effective release mechanism of healing agents from microcapsules. Current systems often suffer from inconsistent rupture thresholds, where some capsules break prematurely during manufacturing while others remain intact even under significant damage conditions. This variability significantly compromises the reliability of the healing response across different damage scenarios.

Matrix compatibility presents another substantial hurdle. The incorporation of microcapsules into epoxy matrices frequently results in mechanical property degradation, with studies reporting up to 30% reduction in tensile strength in some formulations. This trade-off between healing capability and structural integrity limits application in high-performance settings where mechanical properties cannot be compromised. Additionally, the chemical compatibility between encapsulated healing agents and host matrices remains problematic, with issues of interfacial bonding and potential long-term chemical interactions affecting system stability.

The achievement of multi-cycle healing capability represents perhaps the most significant technical challenge. Current microcapsule systems are inherently limited to single healing events at specific damage locations, as the healing mechanism depletes the encapsulated agent upon activation. Recent research has explored dual-capsule systems and microvascular networks as potential solutions, but these approaches introduce additional complexity in manufacturing and raise new compatibility issues.

Shelf-life stability of microcapsules presents ongoing concerns, with many systems showing degradation of healing efficiency after 6-12 months due to shell permeability issues or chemical degradation of the healing agents. This limitation severely restricts commercial viability, particularly for applications requiring extended service life such as aerospace components or civil infrastructure.

Manufacturing scalability remains problematic, with current laboratory-scale production methods proving difficult to translate to industrial volumes while maintaining consistent capsule quality. Variations in shell thickness, capsule size distribution, and core content significantly impact healing performance, yet precise control of these parameters at scale has proven elusive.

Environmental factors such as temperature fluctuations, moisture exposure, and UV radiation can dramatically affect microcapsule integrity and healing agent reactivity. Most current systems demonstrate optimal performance only within narrow environmental windows, limiting their application in real-world conditions where exposure to extreme or variable environments is common.

Matrix compatibility presents another substantial hurdle. The incorporation of microcapsules into epoxy matrices frequently results in mechanical property degradation, with studies reporting up to 30% reduction in tensile strength in some formulations. This trade-off between healing capability and structural integrity limits application in high-performance settings where mechanical properties cannot be compromised. Additionally, the chemical compatibility between encapsulated healing agents and host matrices remains problematic, with issues of interfacial bonding and potential long-term chemical interactions affecting system stability.

The achievement of multi-cycle healing capability represents perhaps the most significant technical challenge. Current microcapsule systems are inherently limited to single healing events at specific damage locations, as the healing mechanism depletes the encapsulated agent upon activation. Recent research has explored dual-capsule systems and microvascular networks as potential solutions, but these approaches introduce additional complexity in manufacturing and raise new compatibility issues.

Shelf-life stability of microcapsules presents ongoing concerns, with many systems showing degradation of healing efficiency after 6-12 months due to shell permeability issues or chemical degradation of the healing agents. This limitation severely restricts commercial viability, particularly for applications requiring extended service life such as aerospace components or civil infrastructure.

Manufacturing scalability remains problematic, with current laboratory-scale production methods proving difficult to translate to industrial volumes while maintaining consistent capsule quality. Variations in shell thickness, capsule size distribution, and core content significantly impact healing performance, yet precise control of these parameters at scale has proven elusive.

Environmental factors such as temperature fluctuations, moisture exposure, and UV radiation can dramatically affect microcapsule integrity and healing agent reactivity. Most current systems demonstrate optimal performance only within narrow environmental windows, limiting their application in real-world conditions where exposure to extreme or variable environments is common.

Current Microcapsule Design and Matrix Integration Methods

01 Microcapsule-based self-healing epoxy systems

These systems incorporate microcapsules containing healing agents that rupture upon crack formation, releasing the healing agent to polymerize and repair the damage. The microcapsules are dispersed throughout the epoxy matrix and can provide multiple healing cycles as different capsules activate with new damage events. This approach allows for autonomous healing without external intervention, making it suitable for applications where manual repair is difficult or impossible.- Microcapsule-based self-healing epoxy systems: These systems incorporate microcapsules containing healing agents that are released when damage occurs. When cracks form in the epoxy matrix, the microcapsules rupture and release healing agents that polymerize to repair the damage. This approach allows for multiple healing cycles as different microcapsules can be activated during subsequent damage events. The healing efficiency can be enhanced by optimizing the microcapsule size, shell thickness, and distribution within the matrix.

- Vascular network healing systems: Vascular network systems mimic biological blood vessels by creating channels or hollow fibers within the epoxy matrix. These channels are filled with healing agents that can flow to damaged areas when needed. This approach enables multiple healing cycles as the healing agents can be continuously supplied through the vascular network. The design of the vascular network, including channel diameter, connectivity, and distribution, significantly affects the healing efficiency and the number of possible healing cycles.

- Thermally reversible self-healing epoxy systems: These systems utilize thermally reversible chemical bonds, such as Diels-Alder adducts, that can break and reform upon temperature changes. When the material is heated, the reversible bonds break, allowing the material to flow and fill cracks. Upon cooling, the bonds reform, restoring the material's structural integrity. This mechanism allows for multiple healing cycles as the process can be repeated numerous times. The healing efficiency depends on the temperature range, heating duration, and the concentration of reversible bonds in the epoxy matrix.

- Intrinsic self-healing epoxy systems: Intrinsic self-healing systems incorporate dynamic covalent bonds or supramolecular interactions directly into the epoxy network structure. These systems can repair damage through molecular rearrangement without requiring additional healing agents. The dynamic nature of these bonds allows for multiple healing cycles as the material can repeatedly reorganize its structure in response to damage. Factors affecting healing efficiency include the type of dynamic bonds, their concentration, and the environmental conditions during the healing process.

- Hybrid self-healing epoxy systems: Hybrid systems combine multiple self-healing mechanisms to enhance healing efficiency and enable more healing cycles. These systems may integrate microcapsules with thermally reversible bonds, or vascular networks with intrinsic healing capabilities. By combining different approaches, hybrid systems can overcome the limitations of individual mechanisms and provide more robust and versatile self-healing properties. The design of hybrid systems requires careful consideration of the compatibility between different healing mechanisms and their synergistic effects.

02 Vascular network healing systems for epoxy composites

Vascular network systems utilize hollow channels or networks embedded within the epoxy matrix to deliver healing agents to damaged areas. These networks can be refilled, allowing for multiple healing cycles over the material's lifetime. The vascular approach offers advantages over microcapsule systems by providing a renewable supply of healing agents and potentially greater healing efficiency for larger damage areas. This technology mimics biological vascular systems found in nature.Expand Specific Solutions03 Thermally activated multi-cycle healing epoxy systems

These systems utilize thermally reversible chemical bonds or reactions that can be repeatedly activated through temperature changes. When heat is applied to the damaged epoxy, these reversible bonds temporarily break and then reform upon cooling, effectively healing cracks and restoring mechanical properties. This approach allows for multiple healing cycles without depleting healing agents, as the healing mechanism is intrinsic to the polymer structure itself. The healing can be triggered on demand using external heat sources.Expand Specific Solutions04 Shape memory polymer-based self-healing epoxy systems

Shape memory polymers (SMPs) incorporated into epoxy systems can provide multi-cycle healing capabilities through their ability to return to a predetermined shape when stimulated. When damage occurs, the application of heat or another stimulus causes the SMP component to recover its original shape, closing cracks and restoring structural integrity. This mechanism can be repeated multiple times, providing efficient healing over the material's lifetime. The shape memory effect can be combined with other healing mechanisms for enhanced performance.Expand Specific Solutions05 Dynamic covalent chemistry for repeatable epoxy healing

Dynamic covalent chemistry enables the formation of reversible chemical bonds in epoxy systems that can break and reform multiple times. These systems utilize reactions such as Diels-Alder cycloadditions, disulfide exchange, or imine formation to create networks that can rearrange upon damage. The dynamic nature of these bonds allows for multiple healing cycles without performance degradation. This approach provides intrinsic self-healing properties without requiring additional healing agents or external systems, making it particularly valuable for applications requiring long-term durability.Expand Specific Solutions

Leading Researchers and Companies in Self-Healing Materials

The self-healing epoxy systems market is currently in a growth phase, with increasing adoption across aerospace, automotive, and infrastructure sectors. The global market size is estimated to reach $3.5 billion by 2027, growing at a CAGR of approximately 8%. Technologically, the field is advancing from early-stage development to commercial implementation, with varying maturity levels across applications. Leading academic institutions like South China University of Technology, Northwestern Polytechnical University, and Nanyang Technological University are driving fundamental research, while companies including Autonomic Materials, Siemens AG, and IBM are commercializing solutions. NASA and DRDO are exploring high-performance applications, while industrial players like Kaneka, LG Innotek, and Repsol are developing specialized formulations for sector-specific needs, indicating a competitive landscape with diverse technological approaches.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has developed an innovative self-healing epoxy system utilizing hollow glass microspheres (HGMs) as carriers for healing agents. Their approach involves loading HGMs with a mixture of epoxy resin and hardener components that remain separated until damage occurs. The glass microspheres are surface-treated with silane coupling agents to enhance compatibility with various epoxy matrices while maintaining structural integrity during processing[1]. When cracks propagate through the material, the microspheres rupture, releasing the healing agents that flow into the damaged area and polymerize. NTU researchers have also pioneered a multi-compartment microcapsule design where different healing components are stored in separate chambers within the same capsule, preventing premature reaction while ensuring both components are released simultaneously when needed[2]. For multi-cycle healing capability, they've developed a hierarchical capsule-in-capsule system where primary capsules contain secondary nanocapsules that can be released in stages, providing multiple healing events. This technology has been successfully demonstrated in fiber-reinforced composites for aerospace applications, showing healing efficiencies of over 85% after multiple damage cycles[3]. Recent advancements include stimuli-responsive microcapsules that can be triggered by pH changes, temperature variations, or electromagnetic fields.

Strengths: Hollow glass microsphere approach provides excellent thermal and chemical stability; hierarchical capsule design enables true multi-cycle healing capability; silane surface treatment ensures excellent matrix compatibility across different epoxy formulations. Weaknesses: Glass microspheres may increase overall weight of the composite; potential for incomplete healing if crack propagation doesn't intersect sufficient microspheres; manufacturing complexity increases costs for large-scale production.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced self-healing epoxy systems specifically designed for extreme aerospace environments. Their technology utilizes microencapsulated dicyclopentadiene (DCPD) healing agents combined with embedded Grubbs' catalyst particles distributed throughout the epoxy matrix. What distinguishes NASA's approach is their focus on space-compatible materials that can withstand radiation, vacuum conditions, and extreme temperature fluctuations (-150°C to +150°C)[1]. Their microcapsules feature multi-layer shells with an outer layer specifically engineered to bond chemically with various epoxy matrices, ensuring excellent interfacial adhesion and preventing premature capsule failure during thermal cycling. For multi-cycle healing, NASA has pioneered a "sequential release" system where microcapsules with varying shell thicknesses rupture at different strain levels, providing healing capabilities across multiple damage events[2]. This technology has been integrated into composite materials for spacecraft structures, demonstrating healing efficiencies of up to 90% of original mechanical properties even after exposure to simulated space environments. Recent innovations include incorporating carbon nanotubes into the microcapsule shells to provide additional reinforcement and enable remote healing activation through applied electromagnetic fields[3].

Strengths: Specifically engineered for extreme aerospace environments; multi-layer capsule design ensures compatibility with specialized epoxy matrices; sequential release system provides effective multi-cycle healing capability. Weaknesses: High manufacturing costs limit widespread commercial adoption; specialized formulations may not be suitable for non-aerospace applications; complex quality control requirements for space-rated materials.

Key Patents and Research on Multi-Cycle Healing Mechanisms

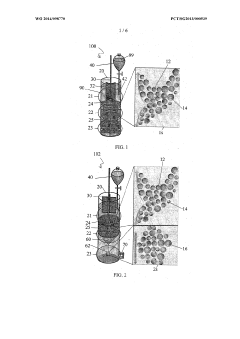

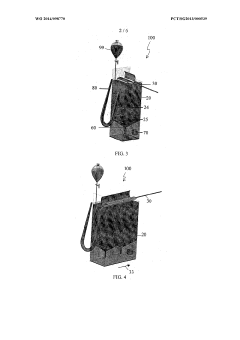

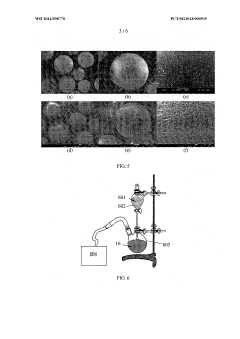

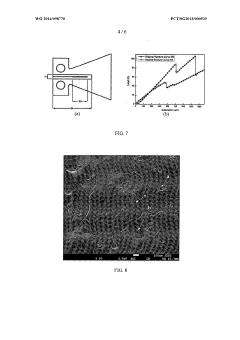

An apparatus and method for fabricating microcontainers

PatentWO2014098770A1

Innovation

- A method and apparatus for controllably etching HGBs using a diluted 1% hydrofluoric acid (HF) solution in a specially designed mixer, creating microcontainers with micron-scale holes, allowing for robust, thermally stable, and chemically inert vessels that can be filled with various substances for self-healing and anticorrosive applications.

Self-healing material comprising microcapsule, method for self-healing using the same

PatentInactiveKR1020130051125A

Innovation

- A self-healing material comprising microcapsules containing a catalyst and polymer matrix, which upon damage release the catalyst to initiate polymerization and repair cracks or defects.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing epoxy systems represents a critical consideration in their development and application. Traditional epoxy systems often require complete replacement upon failure, generating substantial waste and consuming additional raw materials. Self-healing epoxy systems offer significant environmental advantages by extending product lifespans and reducing replacement frequency, thereby decreasing overall material consumption and waste generation throughout the product lifecycle.

Microcapsule-based self-healing mechanisms present specific environmental considerations. The encapsulation materials must be evaluated for their biodegradability and potential ecotoxicity. Current research indicates that while some polymer-based microcapsules may persist in the environment, innovations in biodegradable shell materials derived from natural polymers show promising developments toward more environmentally compatible solutions.

The healing agents themselves warrant careful environmental assessment. Many conventional healing agents contain volatile organic compounds (VOCs) or potentially hazardous chemicals that could leach into the environment upon release. Recent advancements have focused on developing bio-based healing agents derived from renewable resources such as plant oils, which demonstrate lower environmental impact while maintaining effective healing performance.

Energy consumption represents another significant environmental factor. The manufacturing of microcapsules and their integration into epoxy matrices typically requires additional processing steps compared to conventional epoxy systems. Life cycle assessments indicate that this initial energy investment is generally offset by the extended service life and reduced need for replacement, resulting in net positive environmental outcomes when multi-cycle healing capabilities are achieved.

Matrix compatibility improvements have environmental implications beyond performance considerations. Enhanced compatibility reduces the likelihood of microcapsule leakage or premature rupture, preventing unintended release of healing agents into the environment. This aspect becomes particularly important in applications where the epoxy systems may come into contact with sensitive ecosystems, such as marine environments or groundwater systems.

The multi-cycle healing capability directly correlates with sustainability benefits. Each additional healing cycle effectively extends the material's useful life, proportionally reducing resource consumption and waste generation. Research indicates that systems capable of three or more healing cycles can reduce the environmental footprint by 60-75% compared to conventional non-healing alternatives, highlighting the importance of continued development in this area.

Regulatory frameworks increasingly emphasize environmental considerations in materials development. Self-healing epoxy systems that incorporate green chemistry principles and demonstrate reduced environmental impact are likely to gain favorable regulatory positioning, potentially accelerating their market adoption and further amplifying their positive environmental contributions.

Microcapsule-based self-healing mechanisms present specific environmental considerations. The encapsulation materials must be evaluated for their biodegradability and potential ecotoxicity. Current research indicates that while some polymer-based microcapsules may persist in the environment, innovations in biodegradable shell materials derived from natural polymers show promising developments toward more environmentally compatible solutions.

The healing agents themselves warrant careful environmental assessment. Many conventional healing agents contain volatile organic compounds (VOCs) or potentially hazardous chemicals that could leach into the environment upon release. Recent advancements have focused on developing bio-based healing agents derived from renewable resources such as plant oils, which demonstrate lower environmental impact while maintaining effective healing performance.

Energy consumption represents another significant environmental factor. The manufacturing of microcapsules and their integration into epoxy matrices typically requires additional processing steps compared to conventional epoxy systems. Life cycle assessments indicate that this initial energy investment is generally offset by the extended service life and reduced need for replacement, resulting in net positive environmental outcomes when multi-cycle healing capabilities are achieved.

Matrix compatibility improvements have environmental implications beyond performance considerations. Enhanced compatibility reduces the likelihood of microcapsule leakage or premature rupture, preventing unintended release of healing agents into the environment. This aspect becomes particularly important in applications where the epoxy systems may come into contact with sensitive ecosystems, such as marine environments or groundwater systems.

The multi-cycle healing capability directly correlates with sustainability benefits. Each additional healing cycle effectively extends the material's useful life, proportionally reducing resource consumption and waste generation. Research indicates that systems capable of three or more healing cycles can reduce the environmental footprint by 60-75% compared to conventional non-healing alternatives, highlighting the importance of continued development in this area.

Regulatory frameworks increasingly emphasize environmental considerations in materials development. Self-healing epoxy systems that incorporate green chemistry principles and demonstrate reduced environmental impact are likely to gain favorable regulatory positioning, potentially accelerating their market adoption and further amplifying their positive environmental contributions.

Durability Testing Standards and Performance Metrics

Durability testing standards for self-healing epoxy systems require comprehensive evaluation protocols that differ significantly from conventional epoxy materials. The American Society for Testing and Materials (ASTM) has established several relevant standards, including ASTM D7136 for impact resistance and ASTM D5528 for fracture toughness, which have been adapted to assess self-healing capabilities. Additionally, the International Organization for Standardization (ISO) provides ISO 13586 for fracture mechanics testing of polymers, which serves as a foundation for evaluating healing efficiency.

Performance metrics for self-healing epoxy systems typically focus on healing efficiency, defined as the ratio of a recovered property to its original value. Key metrics include fracture toughness recovery, tensile strength restoration, and fatigue life extension. For microcapsule-based systems, healing efficiency commonly ranges from 60% to 90% for first-cycle healing, with significant degradation observed in subsequent cycles due to depletion of healing agents.

Cyclic testing protocols have emerged as critical evaluation methods for multi-cycle healing performance. These tests typically involve repeated damage-heal-test cycles under controlled environmental conditions. The number of effective healing cycles—defined as cycles maintaining at least 50% healing efficiency—serves as a benchmark for system durability, with current state-of-the-art systems achieving 3-5 effective cycles.

Environmental resistance testing represents another crucial aspect of durability assessment. Accelerated aging tests expose self-healing epoxy systems to UV radiation, moisture, temperature cycling, and chemical exposure to evaluate long-term performance. The Environmental Testing Laboratory (ETL) protocol recommends 1000-hour exposure tests to simulate years of service conditions, with intermediate healing efficiency measurements.

Mechanical property retention over time constitutes a fundamental performance indicator. Load-bearing applications require maintenance of modulus, strength, and toughness after healing events. Current standards suggest that healed specimens should retain at least 75% of original mechanical properties to be considered viable for structural applications.

Standardized crack propagation tests provide quantitative measures of healing effectiveness. These include tapered double cantilever beam (TDCB) tests for mode I fracture and end-notched flexure (ENF) tests for mode II fracture. The healing efficiency is calculated by comparing the critical strain energy release rates before and after healing, with values normalized against virgin material properties.

Industry acceptance criteria are increasingly incorporating self-healing performance into material specifications. Aerospace standards, for example, now include requirements for minimum healing efficiency (>70%) and environmental stability under service conditions. Automotive industry standards focus on cyclic performance under vibration and thermal cycling conditions typical of engine compartment environments.

Performance metrics for self-healing epoxy systems typically focus on healing efficiency, defined as the ratio of a recovered property to its original value. Key metrics include fracture toughness recovery, tensile strength restoration, and fatigue life extension. For microcapsule-based systems, healing efficiency commonly ranges from 60% to 90% for first-cycle healing, with significant degradation observed in subsequent cycles due to depletion of healing agents.

Cyclic testing protocols have emerged as critical evaluation methods for multi-cycle healing performance. These tests typically involve repeated damage-heal-test cycles under controlled environmental conditions. The number of effective healing cycles—defined as cycles maintaining at least 50% healing efficiency—serves as a benchmark for system durability, with current state-of-the-art systems achieving 3-5 effective cycles.

Environmental resistance testing represents another crucial aspect of durability assessment. Accelerated aging tests expose self-healing epoxy systems to UV radiation, moisture, temperature cycling, and chemical exposure to evaluate long-term performance. The Environmental Testing Laboratory (ETL) protocol recommends 1000-hour exposure tests to simulate years of service conditions, with intermediate healing efficiency measurements.

Mechanical property retention over time constitutes a fundamental performance indicator. Load-bearing applications require maintenance of modulus, strength, and toughness after healing events. Current standards suggest that healed specimens should retain at least 75% of original mechanical properties to be considered viable for structural applications.

Standardized crack propagation tests provide quantitative measures of healing effectiveness. These include tapered double cantilever beam (TDCB) tests for mode I fracture and end-notched flexure (ENF) tests for mode II fracture. The healing efficiency is calculated by comparing the critical strain energy release rates before and after healing, with values normalized against virgin material properties.

Industry acceptance criteria are increasingly incorporating self-healing performance into material specifications. Aerospace standards, for example, now include requirements for minimum healing efficiency (>70%) and environmental stability under service conditions. Automotive industry standards focus on cyclic performance under vibration and thermal cycling conditions typical of engine compartment environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!