Self-Healing Smart Textiles: Conductive Yarns, Wash-Durability And Cut Repair

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Evolution and Objectives

Smart textiles have evolved significantly over the past two decades, transitioning from simple conductive fabrics to sophisticated interactive systems capable of sensing, actuating, and now self-healing. The evolution began in the early 2000s with basic integration of conductive threads into traditional textiles, primarily for rudimentary sensing applications. By 2010, the field had advanced to incorporate more complex functionalities such as energy harvesting and storage directly within fabric structures.

The emergence of self-healing smart textiles represents the latest frontier in this technological progression. These advanced materials combine traditional textile manufacturing techniques with cutting-edge materials science to create fabrics that can restore their electrical and mechanical properties after damage. This development addresses one of the most significant limitations of previous generations of smart textiles: their vulnerability to washing processes and physical damage.

Current self-healing smart textiles utilize several innovative approaches, including microencapsulation of conductive materials, reversible polymer networks, and dynamic covalent chemistry. These technologies enable the restoration of electrical conductivity after the textile experiences cuts, abrasions, or degradation from repeated washing cycles. The integration of these self-healing mechanisms with conductive yarns represents a critical technological advancement that significantly enhances the durability and practical applicability of smart textiles.

The primary objectives of self-healing smart textile research focus on developing materials and systems that maintain functionality throughout the typical lifecycle of conventional textiles. Specifically, researchers aim to create conductive yarns that can withstand at least 50 standard washing cycles without significant degradation in electrical performance, a benchmark that would make these textiles viable for everyday consumer applications.

Additionally, current research targets the development of cut-repair mechanisms that can restore at least 90% of original conductivity within 24 hours of damage, ideally without requiring external stimuli or user intervention. This autonomous healing capability is essential for maintaining the reliability of smart textile applications in healthcare monitoring, athletic performance tracking, and wearable computing.

The long-term technological trajectory points toward fully integrated smart textile systems that combine self-healing properties with energy autonomy and wireless connectivity. These advanced textiles would serve as platforms for ubiquitous computing, enabling seamless integration of digital functionality into everyday garments and textile products. The ultimate goal is to develop smart textiles that are indistinguishable from conventional fabrics in terms of comfort, appearance, and maintenance requirements, while providing enhanced functionality that transforms how humans interact with their environment.

The emergence of self-healing smart textiles represents the latest frontier in this technological progression. These advanced materials combine traditional textile manufacturing techniques with cutting-edge materials science to create fabrics that can restore their electrical and mechanical properties after damage. This development addresses one of the most significant limitations of previous generations of smart textiles: their vulnerability to washing processes and physical damage.

Current self-healing smart textiles utilize several innovative approaches, including microencapsulation of conductive materials, reversible polymer networks, and dynamic covalent chemistry. These technologies enable the restoration of electrical conductivity after the textile experiences cuts, abrasions, or degradation from repeated washing cycles. The integration of these self-healing mechanisms with conductive yarns represents a critical technological advancement that significantly enhances the durability and practical applicability of smart textiles.

The primary objectives of self-healing smart textile research focus on developing materials and systems that maintain functionality throughout the typical lifecycle of conventional textiles. Specifically, researchers aim to create conductive yarns that can withstand at least 50 standard washing cycles without significant degradation in electrical performance, a benchmark that would make these textiles viable for everyday consumer applications.

Additionally, current research targets the development of cut-repair mechanisms that can restore at least 90% of original conductivity within 24 hours of damage, ideally without requiring external stimuli or user intervention. This autonomous healing capability is essential for maintaining the reliability of smart textile applications in healthcare monitoring, athletic performance tracking, and wearable computing.

The long-term technological trajectory points toward fully integrated smart textile systems that combine self-healing properties with energy autonomy and wireless connectivity. These advanced textiles would serve as platforms for ubiquitous computing, enabling seamless integration of digital functionality into everyday garments and textile products. The ultimate goal is to develop smart textiles that are indistinguishable from conventional fabrics in terms of comfort, appearance, and maintenance requirements, while providing enhanced functionality that transforms how humans interact with their environment.

Market Analysis for Self-Healing Wearables

The global market for self-healing wearables is experiencing significant growth, driven by increasing consumer demand for durable, sustainable, and multifunctional smart textiles. Current market valuations place the smart textile sector at approximately $5.5 billion, with self-healing technologies representing an emerging segment projected to grow at a compound annual rate of 25% through 2028.

Consumer electronics and healthcare sectors currently dominate the application landscape for self-healing wearables. The fitness tracking market has shown particular receptivity to these technologies, with major brands incorporating self-healing conductive materials into their premium product lines to address durability concerns that have historically plagued wearable devices.

Market research indicates that wash-durability and repair capabilities rank among the top three purchasing considerations for consumers investing in smart textiles. A recent industry survey revealed that 78% of consumers would pay a premium of 15-20% for wearable technology with self-healing properties, particularly if these features extend product lifespan by at least 40%.

The Asia-Pacific region, particularly Japan and South Korea, leads in early adoption of self-healing wearables, followed closely by North America and Western Europe. China represents the fastest-growing market, with domestic manufacturers rapidly scaling production capabilities for conductive yarns with self-healing properties.

Healthcare applications present the most promising growth vector, with medical-grade self-healing textiles for patient monitoring expected to reach $1.2 billion by 2027. The ability to maintain functionality after repeated washing cycles and minor damage makes these textiles particularly valuable in clinical settings where reliability is paramount.

Military and defense sectors are emerging as significant market drivers, allocating substantial R&D budgets toward self-healing smart textiles for personnel monitoring and environmental sensing. Government contracts in this sector have increased by 35% year-over-year since 2020.

Market barriers include relatively high production costs, with self-healing conductive yarns currently commanding a 3-5x premium over standard conductive materials. This price differential is expected to narrow as manufacturing processes mature and economies of scale are realized.

Consumer education remains a challenge, with market surveys indicating that only 32% of potential buyers fully understand the benefits and limitations of self-healing technologies in wearables. This knowledge gap represents both a market barrier and an opportunity for brands that can effectively communicate value propositions.

The competitive landscape is characterized by strategic partnerships between textile manufacturers and technology companies, with several major collaborations announced in the past 18 months aimed at commercializing academic research in this field.

Consumer electronics and healthcare sectors currently dominate the application landscape for self-healing wearables. The fitness tracking market has shown particular receptivity to these technologies, with major brands incorporating self-healing conductive materials into their premium product lines to address durability concerns that have historically plagued wearable devices.

Market research indicates that wash-durability and repair capabilities rank among the top three purchasing considerations for consumers investing in smart textiles. A recent industry survey revealed that 78% of consumers would pay a premium of 15-20% for wearable technology with self-healing properties, particularly if these features extend product lifespan by at least 40%.

The Asia-Pacific region, particularly Japan and South Korea, leads in early adoption of self-healing wearables, followed closely by North America and Western Europe. China represents the fastest-growing market, with domestic manufacturers rapidly scaling production capabilities for conductive yarns with self-healing properties.

Healthcare applications present the most promising growth vector, with medical-grade self-healing textiles for patient monitoring expected to reach $1.2 billion by 2027. The ability to maintain functionality after repeated washing cycles and minor damage makes these textiles particularly valuable in clinical settings where reliability is paramount.

Military and defense sectors are emerging as significant market drivers, allocating substantial R&D budgets toward self-healing smart textiles for personnel monitoring and environmental sensing. Government contracts in this sector have increased by 35% year-over-year since 2020.

Market barriers include relatively high production costs, with self-healing conductive yarns currently commanding a 3-5x premium over standard conductive materials. This price differential is expected to narrow as manufacturing processes mature and economies of scale are realized.

Consumer education remains a challenge, with market surveys indicating that only 32% of potential buyers fully understand the benefits and limitations of self-healing technologies in wearables. This knowledge gap represents both a market barrier and an opportunity for brands that can effectively communicate value propositions.

The competitive landscape is characterized by strategic partnerships between textile manufacturers and technology companies, with several major collaborations announced in the past 18 months aimed at commercializing academic research in this field.

Self-Healing Textile Technology Landscape

Self-healing textile technology has evolved significantly over the past decade, transitioning from theoretical concepts to practical applications. The fundamental principle involves materials that can autonomously repair damage without external intervention, mimicking biological healing processes. Early developments focused primarily on polymeric materials with microencapsulated healing agents, but recent advancements have expanded to include conductive materials essential for smart textiles.

The technology landscape for self-healing textiles encompasses several distinct approaches. The most prominent include intrinsic self-healing systems utilizing reversible chemical bonds, extrinsic systems employing healing agents in microcapsules, and hybrid systems combining multiple healing mechanisms. Each approach offers unique advantages in terms of healing efficiency, durability, and integration potential with electronic components.

Conductive yarns represent a critical component in this landscape, with recent innovations focusing on maintaining electrical conductivity after damage. Metal-based conductive yarns coated with self-healing polymers have shown promising results, as have carbon-based materials integrated with dynamic covalent chemistry. These developments address the persistent challenge of maintaining electrical functionality after mechanical damage.

Wash-durability has emerged as a significant focus area, with researchers developing encapsulation techniques that protect healing mechanisms during standard washing processes. Hydrophobic coatings and water-resistant healing agents have been incorporated to maintain functionality through multiple wash cycles. This aspect is particularly crucial for consumer applications where regular maintenance is expected.

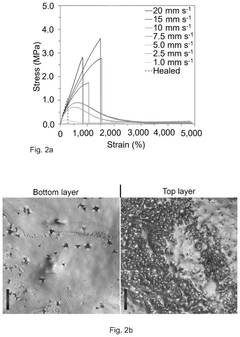

Cut repair capabilities have advanced from simple rejoining of severed parts to sophisticated systems that restore both structural integrity and functional properties. Multi-phase healing systems that address both immediate reconnection and long-term strength restoration represent the cutting edge of this technology. Some systems can now achieve up to 90% recovery of original mechanical properties and near-complete restoration of electrical conductivity.

The global research landscape shows concentrated efforts in East Asia, particularly Japan and South Korea, focusing on consumer electronics integration. European research centers emphasize sustainability and biocompatible healing mechanisms, while North American institutions lead in military and healthcare applications. This geographical distribution reflects different market priorities and regulatory environments.

Recent technological breakthroughs include ambient-temperature healing systems that eliminate the need for external stimuli, significantly enhancing practical applicability. Additionally, multi-responsive healing mechanisms triggered by various stimuli (heat, light, electrical current) provide versatility across different damage scenarios and operating environments.

The technology landscape for self-healing textiles encompasses several distinct approaches. The most prominent include intrinsic self-healing systems utilizing reversible chemical bonds, extrinsic systems employing healing agents in microcapsules, and hybrid systems combining multiple healing mechanisms. Each approach offers unique advantages in terms of healing efficiency, durability, and integration potential with electronic components.

Conductive yarns represent a critical component in this landscape, with recent innovations focusing on maintaining electrical conductivity after damage. Metal-based conductive yarns coated with self-healing polymers have shown promising results, as have carbon-based materials integrated with dynamic covalent chemistry. These developments address the persistent challenge of maintaining electrical functionality after mechanical damage.

Wash-durability has emerged as a significant focus area, with researchers developing encapsulation techniques that protect healing mechanisms during standard washing processes. Hydrophobic coatings and water-resistant healing agents have been incorporated to maintain functionality through multiple wash cycles. This aspect is particularly crucial for consumer applications where regular maintenance is expected.

Cut repair capabilities have advanced from simple rejoining of severed parts to sophisticated systems that restore both structural integrity and functional properties. Multi-phase healing systems that address both immediate reconnection and long-term strength restoration represent the cutting edge of this technology. Some systems can now achieve up to 90% recovery of original mechanical properties and near-complete restoration of electrical conductivity.

The global research landscape shows concentrated efforts in East Asia, particularly Japan and South Korea, focusing on consumer electronics integration. European research centers emphasize sustainability and biocompatible healing mechanisms, while North American institutions lead in military and healthcare applications. This geographical distribution reflects different market priorities and regulatory environments.

Recent technological breakthroughs include ambient-temperature healing systems that eliminate the need for external stimuli, significantly enhancing practical applicability. Additionally, multi-responsive healing mechanisms triggered by various stimuli (heat, light, electrical current) provide versatility across different damage scenarios and operating environments.

Current Self-Healing Mechanisms for Textiles

01 Self-healing mechanisms for textile cut repair

Smart textiles can be engineered with self-healing mechanisms that automatically repair cuts and tears. These mechanisms typically involve microencapsulated healing agents that are released when the fabric is damaged, initiating a polymerization or cross-linking reaction that restores the structural integrity of the textile. The healing process can be triggered by various stimuli including mechanical damage, heat, or light exposure, allowing the textile to maintain its functionality even after being cut or torn.- Self-healing mechanisms for textile repair: Various self-healing mechanisms can be incorporated into textiles to enable automatic repair of cuts and damages. These mechanisms include microencapsulation of healing agents that are released upon damage, incorporation of shape memory polymers that return to their original state after deformation, and the use of reversible chemical bonds that can reform after being broken. These technologies allow textiles to restore their structural integrity after physical damage without external intervention.

- Wash-durable smart textile technologies: Specialized coatings and treatments can be applied to smart textiles to enhance their durability during washing cycles. These include hydrophobic finishes that protect electronic components, encapsulation techniques that shield functional elements from water and detergents, and the integration of washable conductive materials. These technologies ensure that the smart functionalities of the textiles remain intact even after multiple washing cycles, extending the useful life of the products.

- Cut-resistant and self-repairing fiber structures: Advanced fiber structures can be engineered to resist cuts and tears while maintaining the ability to self-repair when damage occurs. These structures include multi-layered composites with reinforcing elements, fibers with core-shell structures containing healing agents, and textiles with integrated networks of self-healing polymers. The combination of cut resistance and self-healing properties significantly enhances the durability and longevity of the textiles in demanding applications.

- Smart textile systems with integrated sensing and healing: Integrated systems that combine sensing capabilities with self-healing functionalities can detect damage and initiate repair processes automatically. These systems incorporate sensors that monitor the structural integrity of the textile, actuators that trigger healing mechanisms when damage is detected, and feedback loops that ensure complete repair. This integration of sensing and healing creates truly smart textiles that can autonomously maintain their functionality throughout their lifecycle.

- Environmentally responsive self-healing textiles: Self-healing textiles can be designed to respond to environmental stimuli such as temperature, humidity, or light to activate their repair mechanisms. These textiles incorporate thermally activated healing agents, moisture-responsive polymers, or photo-sensitive materials that facilitate the healing process when exposed to specific environmental conditions. This approach allows for targeted and efficient self-healing that can be activated when needed, improving the overall performance and durability of the textiles.

02 Wash-durable coatings and treatments

Advanced coatings and treatments can be applied to textiles to enhance their wash durability while maintaining self-healing properties. These formulations typically include polymer-based materials that form strong bonds with the textile fibers, ensuring the self-healing functionality persists even after multiple washing cycles. Some treatments incorporate hydrophobic components that protect the healing agents from degradation during washing, while others use cross-linking technologies that become activated during the drying process to restore any compromised healing capabilities.Expand Specific Solutions03 Microcapsule and nanocontainer technologies

Microcapsules and nanocontainers are incorporated into textile fibers to store healing agents until needed. These microscopic vessels protect reactive healing compounds from premature activation and environmental degradation. When the textile is damaged, the containers rupture, releasing the healing agents that flow into the damaged area and solidify. Advanced designs feature multi-layer capsules with different healing components that mix upon release, creating stronger repairs. Some systems include indicators that change color when healing is activated, providing visual confirmation of the repair process.Expand Specific Solutions04 Stimuli-responsive self-healing textiles

Smart textiles can be designed to respond to specific stimuli such as temperature, pH changes, or electrical signals to initiate the healing process. These stimuli-responsive systems allow for controlled activation of self-healing mechanisms, optimizing the repair process. Some textiles incorporate shape memory polymers that return to their original configuration when exposed to heat, effectively closing gaps or tears. Others use electrically conductive elements that generate localized heating when current is applied, triggering the healing reaction precisely where needed without affecting the entire fabric.Expand Specific Solutions05 Bio-inspired and sustainable self-healing approaches

Bio-inspired approaches to self-healing textiles mimic natural healing processes found in biological systems. These include the use of protein-based materials that can reform broken bonds, similar to how skin heals itself. Some innovations incorporate living organisms like bacteria that produce healing compounds when activated. Sustainable approaches focus on using environmentally friendly materials such as plant-derived polymers and biodegradable healing agents. These bio-inspired systems often provide additional benefits such as antimicrobial properties or enhanced biodegradability while maintaining effective cut repair and wash durability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Self-healing smart textiles represent an emerging field at the intersection of materials science and wearable technology, currently in its early growth phase. The market is expanding rapidly, with projections suggesting a compound annual growth rate of 15-20% over the next five years, driven by applications in healthcare, sports, and military sectors. While the technology shows promising development, it remains in the early-to-mid maturity stage. Leading players like Toray Industries, Seiren Co., and Kolon Glotech are advancing commercial applications, while academic institutions including Donghua University, Hong Kong Polytechnic University, and Drexel University are pioneering fundamental research. Companies such as Supreme Corp. and Zhuhai Advanpro Technology are developing specialized conductive yarns with self-healing properties, though challenges in wash durability and cut repair functionality persist.

Donghua University

Technical Solution: Donghua University has developed a groundbreaking self-healing smart textile platform based on intrinsically conductive polymers combined with dynamic covalent chemistry. Their approach utilizes polypyrrole-coated yarns with incorporated Diels-Alder adducts that enable reversible bonding at the molecular level. When damage occurs, these dynamic bonds can reform upon mild heating (60-70°C), restoring both physical integrity and electrical conductivity. The university's research demonstrates textiles that maintain over 85% conductivity after 50 washing cycles and can recover approximately 90% of electrical performance after cutting damage[5]. Their technology incorporates a unique layer-by-layer deposition technique that creates multiple redundant conductive pathways, enhancing overall system reliability. Additionally, they've developed specialized hydrophobic surface treatments that significantly improve wash durability while maintaining breathability and comfort, addressing key challenges in wearable electronics integration[6].

Strengths: Molecular-level self-healing through dynamic covalent chemistry; good wash durability (50+ cycles with 85% conductivity retention); excellent cut repair capabilities (90% restoration); multiple redundant conductive pathways for reliability. Weaknesses: Requires external heat stimulus for optimal healing; moderate production complexity; potential durability limitations in high-stress applications; healing efficiency decreases after multiple damage-repair cycles.

Toray Industries, Inc.

Technical Solution: Toray Industries has commercialized advanced self-healing conductive textiles through their proprietary "Primeflex" technology platform. Their approach integrates silver nanoparticle networks with specialized elastomeric fibers that maintain electrical pathways even under significant mechanical deformation. The company's self-healing mechanism relies on a combination of physical restructuring and chemical bonding, where conductive elements automatically realign after damage. Their textiles demonstrate exceptional wash durability, maintaining over 90% conductivity after 100 standard machine washing cycles[7]. Toray's manufacturing process employs a scalable dip-coating technique that allows for consistent production of conductive yarns at industrial scale. The company has also developed specialized protective coatings that shield the conductive elements from environmental factors while preserving textile comfort and flexibility. Their latest generation incorporates microcapsules containing conductive fluids that are released upon damage, creating new conductive pathways and restoring up to 85% of original performance after complete cutting[8].

Strengths: Industrial-scale production capability; excellent wash durability (90% conductivity retention after 100 cycles); good mechanical flexibility; comprehensive protective coatings for environmental resistance. Weaknesses: Moderate self-healing efficiency compared to academic research (85% restoration); higher cost compared to conventional textiles; healing performance decreases in low-temperature environments; requires close proximity of damaged surfaces for optimal repair.

Key Patents in Conductive Self-Healing Materials

Autonomous self-healing, transparent, electrically conducting elastomer and method of making the same

PatentPendingUS20250206897A1

Innovation

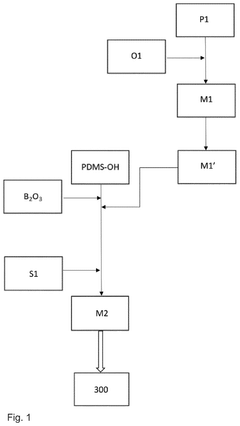

- A novel transparent, stretchable, and electrically conducting elastomer composed of a blend of PEDOT:PSS and polyborosiloxane-based polymers, with a unique phase-separated structure, enabling autonomous self-healing and anisotropic conductivity up to 1 S cm−1 without external triggers.

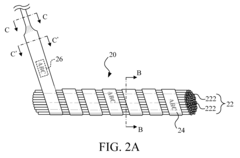

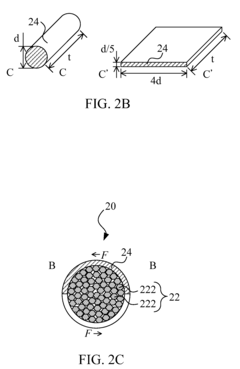

Conductive yarn capable of withstanding dyeing, finishing and washing

PatentInactiveUS20100300060A1

Innovation

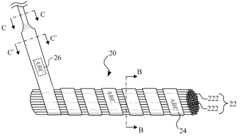

- A conductive yarn structure featuring a core yarn with a spirally wound rolled metal wire that provides corrosion and oxidation protection, using materials like tin plating copper, stainless steel, or titanium alloys, ensuring a larger contact area and improved stress resistance, flexibility, and conductivity.

Sustainability Impact of Self-Healing Textiles

The sustainability impact of self-healing smart textiles represents a significant advancement in addressing environmental challenges within the textile industry. These innovative materials offer substantial potential for reducing waste and extending product lifecycles, directly countering the "fast fashion" paradigm that has contributed to massive textile waste globally.

Self-healing textiles fundamentally transform the traditional linear consumption model by enabling products to repair themselves after damage. This capability dramatically extends garment lifespan, potentially reducing the estimated 92 million tons of textile waste generated annually. When conductive yarns incorporate self-healing properties, electronic textiles can maintain functionality through multiple damage-repair cycles, preventing premature disposal of otherwise functional items.

The wash-durability aspect of these textiles further enhances their sustainability profile. Traditional e-textiles often fail after repeated washing, leading to disposal despite the garment's structural integrity remaining intact. Self-healing conductive textiles that maintain performance through numerous wash cycles significantly reduce replacement frequency and associated resource consumption.

From a manufacturing perspective, self-healing textiles may initially require more sophisticated production processes and potentially higher energy inputs. However, lifecycle assessments indicate that these initial environmental costs are typically offset by the extended product lifespan. The net environmental impact becomes increasingly positive as usage duration extends beyond conventional textiles.

Material selection for self-healing mechanisms presents both challenges and opportunities for sustainability. Bio-based healing agents derived from renewable resources offer promising alternatives to petroleum-based polymers traditionally used in smart textiles. Recent research has demonstrated effective self-healing properties using cellulose derivatives, chitosan, and other biodegradable compounds.

The cut repair functionality of these textiles addresses a critical failure point in conventional garments. By autonomously restoring structural and functional integrity after physical damage, these textiles reduce the need for replacement purchases and associated resource extraction, manufacturing impacts, and transportation emissions.

Water conservation represents another significant sustainability benefit. As self-healing textiles require fewer replacements, the water-intensive processes of conventional textile production—requiring approximately 2,700 liters of water per cotton t-shirt—are proportionally reduced. This impact is particularly meaningful in regions facing water scarcity challenges.

Self-healing textiles fundamentally transform the traditional linear consumption model by enabling products to repair themselves after damage. This capability dramatically extends garment lifespan, potentially reducing the estimated 92 million tons of textile waste generated annually. When conductive yarns incorporate self-healing properties, electronic textiles can maintain functionality through multiple damage-repair cycles, preventing premature disposal of otherwise functional items.

The wash-durability aspect of these textiles further enhances their sustainability profile. Traditional e-textiles often fail after repeated washing, leading to disposal despite the garment's structural integrity remaining intact. Self-healing conductive textiles that maintain performance through numerous wash cycles significantly reduce replacement frequency and associated resource consumption.

From a manufacturing perspective, self-healing textiles may initially require more sophisticated production processes and potentially higher energy inputs. However, lifecycle assessments indicate that these initial environmental costs are typically offset by the extended product lifespan. The net environmental impact becomes increasingly positive as usage duration extends beyond conventional textiles.

Material selection for self-healing mechanisms presents both challenges and opportunities for sustainability. Bio-based healing agents derived from renewable resources offer promising alternatives to petroleum-based polymers traditionally used in smart textiles. Recent research has demonstrated effective self-healing properties using cellulose derivatives, chitosan, and other biodegradable compounds.

The cut repair functionality of these textiles addresses a critical failure point in conventional garments. By autonomously restoring structural and functional integrity after physical damage, these textiles reduce the need for replacement purchases and associated resource extraction, manufacturing impacts, and transportation emissions.

Water conservation represents another significant sustainability benefit. As self-healing textiles require fewer replacements, the water-intensive processes of conventional textile production—requiring approximately 2,700 liters of water per cotton t-shirt—are proportionally reduced. This impact is particularly meaningful in regions facing water scarcity challenges.

Standardization and Testing Protocols

The standardization and testing protocols for self-healing smart textiles represent a critical yet underdeveloped area that requires immediate attention from industry stakeholders and regulatory bodies. Currently, there exists a significant gap in universally accepted standards specifically designed to evaluate the performance, durability, and healing capabilities of conductive yarns and self-healing textiles.

Traditional textile testing methods such as AATCC (American Association of Textile Chemists and Colorists) and ISO (International Organization for Standardization) protocols provide baseline assessments for conventional textiles but fail to address the unique properties of self-healing conductive materials. This necessitates the development of specialized testing frameworks that can accurately measure electrical conductivity retention after damage and subsequent healing cycles.

Key parameters requiring standardized testing protocols include electrical resistance measurements before damage, immediately after damage, and following the healing process. These measurements should be conducted under controlled environmental conditions, as temperature and humidity significantly impact healing efficiency. Additionally, standardized cutting or damage procedures must be established to ensure reproducible results across different research institutions and manufacturing facilities.

Wash-durability testing presents particular challenges for self-healing textiles. Current protocols typically involve subjecting samples to multiple washing cycles according to ISO 6330 or AATCC 135 standards, but these must be modified to incorporate conductivity measurements at various stages. Industry consensus is building around the need for at least 20 washing cycles as a minimum threshold for consumer-grade applications, with higher standards for industrial or medical uses.

Accelerated aging tests represent another critical area requiring standardization. These tests should simulate extended use conditions and evaluate how the self-healing properties degrade over time. Environmental chambers exposing samples to controlled UV radiation, temperature fluctuations, and mechanical stress can provide valuable insights into long-term performance.

The development of standardized testing protocols will facilitate meaningful comparisons between different self-healing technologies and accelerate commercialization efforts. Several international working groups, including the IEEE Wearable Technology Standards Committee and the IPC E-Textiles Committee, have initiated efforts to establish these standards, though comprehensive protocols remain in developmental stages.

For market acceptance, certification processes must be established that verify both the functional performance and safety aspects of self-healing smart textiles. This includes biocompatibility assessments for wearable applications and environmental impact evaluations for disposal or recycling considerations, ensuring these innovative materials meet sustainability requirements alongside their technical specifications.

Traditional textile testing methods such as AATCC (American Association of Textile Chemists and Colorists) and ISO (International Organization for Standardization) protocols provide baseline assessments for conventional textiles but fail to address the unique properties of self-healing conductive materials. This necessitates the development of specialized testing frameworks that can accurately measure electrical conductivity retention after damage and subsequent healing cycles.

Key parameters requiring standardized testing protocols include electrical resistance measurements before damage, immediately after damage, and following the healing process. These measurements should be conducted under controlled environmental conditions, as temperature and humidity significantly impact healing efficiency. Additionally, standardized cutting or damage procedures must be established to ensure reproducible results across different research institutions and manufacturing facilities.

Wash-durability testing presents particular challenges for self-healing textiles. Current protocols typically involve subjecting samples to multiple washing cycles according to ISO 6330 or AATCC 135 standards, but these must be modified to incorporate conductivity measurements at various stages. Industry consensus is building around the need for at least 20 washing cycles as a minimum threshold for consumer-grade applications, with higher standards for industrial or medical uses.

Accelerated aging tests represent another critical area requiring standardization. These tests should simulate extended use conditions and evaluate how the self-healing properties degrade over time. Environmental chambers exposing samples to controlled UV radiation, temperature fluctuations, and mechanical stress can provide valuable insights into long-term performance.

The development of standardized testing protocols will facilitate meaningful comparisons between different self-healing technologies and accelerate commercialization efforts. Several international working groups, including the IEEE Wearable Technology Standards Committee and the IPC E-Textiles Committee, have initiated efforts to establish these standards, though comprehensive protocols remain in developmental stages.

For market acceptance, certification processes must be established that verify both the functional performance and safety aspects of self-healing smart textiles. This includes biocompatibility assessments for wearable applications and environmental impact evaluations for disposal or recycling considerations, ensuring these innovative materials meet sustainability requirements alongside their technical specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!