How Do Self-Healing Supramolecular Networks Retain Properties In Humid Or Saline Environments?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supramolecular Self-Healing Background and Objectives

Supramolecular self-healing materials represent a revolutionary advancement in materials science, drawing inspiration from biological systems that can autonomously repair damage. These materials are composed of molecular networks held together by non-covalent interactions such as hydrogen bonding, π-π stacking, metal-ligand coordination, and host-guest interactions. Unlike traditional materials that degrade irreversibly when damaged, supramolecular networks can reform broken bonds without external intervention, restoring structural integrity and functionality.

The evolution of self-healing materials began in the early 2000s with pioneering work on polymer systems incorporating reversible bonds. Over the past two decades, research has progressed from simple proof-of-concept demonstrations to sophisticated networks with multiple healing mechanisms. The field has witnessed significant breakthroughs in understanding the fundamental principles governing self-healing behavior, particularly the delicate balance between mechanical strength and healing efficiency.

A critical challenge in the development of supramolecular self-healing materials has been maintaining their performance in real-world environmental conditions. While many systems demonstrate excellent healing properties in controlled laboratory settings, their effectiveness often diminishes dramatically when exposed to humidity or saline environments. This limitation has restricted their practical applications in marine environments, biomedical implants, and outdoor infrastructure.

The interaction between water molecules or salt ions and supramolecular networks can disrupt the non-covalent interactions responsible for self-healing, leading to reduced mechanical properties, slower healing kinetics, or complete loss of functionality. Understanding and overcoming these environmental sensitivities represents a frontier in supramolecular materials research with significant implications for expanding their application scope.

Our technical objectives focus on comprehensively investigating how humidity and salinity affect the self-healing mechanisms of supramolecular networks at the molecular level. We aim to identify design principles that enable these materials to maintain their healing capabilities in challenging environments. Specifically, we seek to develop strategies for protecting critical non-covalent interactions from environmental interference while preserving the dynamic nature essential for self-healing.

The ultimate goal is to establish a framework for designing environmentally robust supramolecular self-healing materials that can operate reliably in humid or saline conditions. This would enable their deployment in demanding applications such as underwater sensors, salt-resistant coatings, biomedical devices, and marine infrastructure. Success in this endeavor would significantly expand the practical utility of self-healing materials and potentially open new markets across multiple industries.

The evolution of self-healing materials began in the early 2000s with pioneering work on polymer systems incorporating reversible bonds. Over the past two decades, research has progressed from simple proof-of-concept demonstrations to sophisticated networks with multiple healing mechanisms. The field has witnessed significant breakthroughs in understanding the fundamental principles governing self-healing behavior, particularly the delicate balance between mechanical strength and healing efficiency.

A critical challenge in the development of supramolecular self-healing materials has been maintaining their performance in real-world environmental conditions. While many systems demonstrate excellent healing properties in controlled laboratory settings, their effectiveness often diminishes dramatically when exposed to humidity or saline environments. This limitation has restricted their practical applications in marine environments, biomedical implants, and outdoor infrastructure.

The interaction between water molecules or salt ions and supramolecular networks can disrupt the non-covalent interactions responsible for self-healing, leading to reduced mechanical properties, slower healing kinetics, or complete loss of functionality. Understanding and overcoming these environmental sensitivities represents a frontier in supramolecular materials research with significant implications for expanding their application scope.

Our technical objectives focus on comprehensively investigating how humidity and salinity affect the self-healing mechanisms of supramolecular networks at the molecular level. We aim to identify design principles that enable these materials to maintain their healing capabilities in challenging environments. Specifically, we seek to develop strategies for protecting critical non-covalent interactions from environmental interference while preserving the dynamic nature essential for self-healing.

The ultimate goal is to establish a framework for designing environmentally robust supramolecular self-healing materials that can operate reliably in humid or saline conditions. This would enable their deployment in demanding applications such as underwater sensors, salt-resistant coatings, biomedical devices, and marine infrastructure. Success in this endeavor would significantly expand the practical utility of self-healing materials and potentially open new markets across multiple industries.

Market Applications in Harsh Environmental Conditions

Self-healing supramolecular networks demonstrate exceptional potential in harsh environmental applications where traditional materials fail due to degradation from humidity, salinity, or other challenging conditions. These advanced materials are particularly valuable in marine environments, where equipment and structures face constant exposure to saltwater, humidity fluctuations, and biological fouling.

The offshore energy sector represents a primary market opportunity, with oil and gas platforms, wind turbines, and tidal energy systems requiring materials that can withstand continuous exposure to seawater while maintaining structural integrity. Self-healing coatings and components could significantly extend maintenance intervals, reducing costly downtime and dangerous repair missions in these remote locations.

Maritime transportation presents another substantial application area, where ship hulls, propulsion systems, and cargo containers endure constant exposure to saline environments. Current solutions require frequent dry-docking for maintenance, whereas self-healing materials could enable continuous operation with minimal intervention, potentially saving the global shipping industry billions in maintenance costs and operational disruptions.

Coastal infrastructure, including bridges, piers, and flood defense systems, constitutes a growing market as climate change intensifies coastal weather events. These structures require materials that can withstand not only saltwater exposure but also fluctuating humidity levels and mechanical stress from wave action. Self-healing concrete additives and protective coatings are already being tested in several coastal engineering projects worldwide.

Desalination facilities represent a specialized but high-value application environment where materials face extreme salinity, varying temperatures, and constant moisture. Components such as membranes, pumps, and piping systems could benefit significantly from self-healing capabilities, extending operational lifespans and reducing maintenance requirements in these critical water security installations.

Agricultural applications in coastal or saline soil regions present opportunities for self-healing irrigation systems, greenhouse structures, and equipment coatings that can withstand both salt exposure and humidity fluctuations. As food security concerns grow globally, the ability to farm effectively in previously challenging environments becomes increasingly valuable.

The defense sector has shown particular interest in these materials for naval vessels, coastal installations, and amphibious equipment. The ability to deploy self-repairing materials in remote locations without maintenance support aligns perfectly with military operational requirements, driving significant research investment from defense agencies worldwide.

The offshore energy sector represents a primary market opportunity, with oil and gas platforms, wind turbines, and tidal energy systems requiring materials that can withstand continuous exposure to seawater while maintaining structural integrity. Self-healing coatings and components could significantly extend maintenance intervals, reducing costly downtime and dangerous repair missions in these remote locations.

Maritime transportation presents another substantial application area, where ship hulls, propulsion systems, and cargo containers endure constant exposure to saline environments. Current solutions require frequent dry-docking for maintenance, whereas self-healing materials could enable continuous operation with minimal intervention, potentially saving the global shipping industry billions in maintenance costs and operational disruptions.

Coastal infrastructure, including bridges, piers, and flood defense systems, constitutes a growing market as climate change intensifies coastal weather events. These structures require materials that can withstand not only saltwater exposure but also fluctuating humidity levels and mechanical stress from wave action. Self-healing concrete additives and protective coatings are already being tested in several coastal engineering projects worldwide.

Desalination facilities represent a specialized but high-value application environment where materials face extreme salinity, varying temperatures, and constant moisture. Components such as membranes, pumps, and piping systems could benefit significantly from self-healing capabilities, extending operational lifespans and reducing maintenance requirements in these critical water security installations.

Agricultural applications in coastal or saline soil regions present opportunities for self-healing irrigation systems, greenhouse structures, and equipment coatings that can withstand both salt exposure and humidity fluctuations. As food security concerns grow globally, the ability to farm effectively in previously challenging environments becomes increasingly valuable.

The defense sector has shown particular interest in these materials for naval vessels, coastal installations, and amphibious equipment. The ability to deploy self-repairing materials in remote locations without maintenance support aligns perfectly with military operational requirements, driving significant research investment from defense agencies worldwide.

Current Challenges in Humid and Saline Environments

Self-healing supramolecular networks face significant challenges when exposed to humid or saline environments, which can substantially compromise their functional integrity. The primary challenge lies in the disruption of non-covalent interactions that form the basis of these networks. In humid conditions, water molecules can penetrate the material matrix, competing with hydrogen bonds and other supramolecular interactions, effectively weakening the network structure.

Saline environments present even more complex challenges due to the presence of ions that can shield electrostatic interactions and disrupt the delicate balance of forces maintaining network cohesion. This ionic interference often leads to decreased mechanical strength, reduced self-healing efficiency, and compromised overall performance of the material system.

The hydrolytic degradation of certain supramolecular motifs represents another critical challenge. Many hydrogen-bonding and metal-ligand coordination systems that enable self-healing properties are susceptible to hydrolysis in the presence of water, particularly at elevated temperatures or extreme pH conditions found in various industrial applications.

Current materials also struggle with maintaining consistent healing kinetics across varying humidity levels. Research has shown that healing rates can fluctuate dramatically between dry and humid conditions, making performance prediction difficult in real-world applications where environmental conditions are rarely constant.

Osmotic pressure effects present additional complications in saline environments. The concentration gradient between the internal material structure and the external saline solution can drive water and ion transport processes that swell the network, altering its mechanical properties and potentially causing permanent structural damage.

Long-term stability remains perhaps the most significant unresolved challenge. While many supramolecular systems demonstrate impressive self-healing capabilities in controlled laboratory settings, their performance often deteriorates rapidly under prolonged exposure to humid or saline conditions. This limitation severely restricts their practical application in marine environments, outdoor settings, or biomedical applications.

The interface between different material phases in composite supramolecular systems presents unique vulnerabilities. These interfaces often become preferential sites for water accumulation and ion penetration, leading to accelerated degradation and failure initiation points within the material structure.

Addressing these challenges requires innovative approaches that can maintain supramolecular interactions despite the presence of competing water molecules and ions, or alternatively, develop systems that can leverage these environmental factors to enhance rather than diminish self-healing capabilities.

Saline environments present even more complex challenges due to the presence of ions that can shield electrostatic interactions and disrupt the delicate balance of forces maintaining network cohesion. This ionic interference often leads to decreased mechanical strength, reduced self-healing efficiency, and compromised overall performance of the material system.

The hydrolytic degradation of certain supramolecular motifs represents another critical challenge. Many hydrogen-bonding and metal-ligand coordination systems that enable self-healing properties are susceptible to hydrolysis in the presence of water, particularly at elevated temperatures or extreme pH conditions found in various industrial applications.

Current materials also struggle with maintaining consistent healing kinetics across varying humidity levels. Research has shown that healing rates can fluctuate dramatically between dry and humid conditions, making performance prediction difficult in real-world applications where environmental conditions are rarely constant.

Osmotic pressure effects present additional complications in saline environments. The concentration gradient between the internal material structure and the external saline solution can drive water and ion transport processes that swell the network, altering its mechanical properties and potentially causing permanent structural damage.

Long-term stability remains perhaps the most significant unresolved challenge. While many supramolecular systems demonstrate impressive self-healing capabilities in controlled laboratory settings, their performance often deteriorates rapidly under prolonged exposure to humid or saline conditions. This limitation severely restricts their practical application in marine environments, outdoor settings, or biomedical applications.

The interface between different material phases in composite supramolecular systems presents unique vulnerabilities. These interfaces often become preferential sites for water accumulation and ion penetration, leading to accelerated degradation and failure initiation points within the material structure.

Addressing these challenges requires innovative approaches that can maintain supramolecular interactions despite the presence of competing water molecules and ions, or alternatively, develop systems that can leverage these environmental factors to enhance rather than diminish self-healing capabilities.

Current Strategies for Environmental Resistance

01 Dynamic crosslinking mechanisms for self-healing properties

Supramolecular networks can be designed with dynamic crosslinking mechanisms that enable self-healing properties while maintaining structural integrity. These mechanisms involve reversible bonds such as hydrogen bonding, metal-ligand coordination, or π-π interactions that can break and reform under specific conditions. When damage occurs, these dynamic bonds can reconnect, restoring the original properties of the material without permanent deformation or loss of functionality.- Dynamic crosslinking mechanisms in self-healing networks: Self-healing supramolecular networks can be designed with dynamic crosslinking mechanisms that enable property retention after damage. These networks utilize reversible bonds such as hydrogen bonding, metal-ligand coordination, or dynamic covalent chemistry to reform connections after being broken. The dynamic nature of these crosslinks allows the material to maintain its mechanical properties and functionality even after multiple damage-healing cycles, ensuring long-term durability and performance retention.

- Stimuli-responsive self-healing materials: Supramolecular networks can be engineered to respond to external stimuli such as temperature, pH, light, or electrical fields to trigger the self-healing process. These stimuli-responsive materials can retain their original properties after healing by activating specific molecular interactions at the damaged site. The controlled response to stimuli ensures efficient healing and restoration of mechanical, electrical, or thermal properties, making these materials suitable for smart applications where property retention after damage is crucial.

- Nanocomposite reinforcement for property enhancement: Incorporating nanofillers such as graphene, carbon nanotubes, or nanocellulose into self-healing supramolecular networks can significantly enhance mechanical properties and ensure their retention after healing. These nanocomposites create additional interaction sites within the network, strengthening the material while maintaining its self-healing capability. The synergistic effect between the supramolecular matrix and nanofillers results in improved tensile strength, elasticity, and toughness that can be recovered after damage repair.

- Multi-phase network architectures: Multi-phase network architectures combine different types of supramolecular interactions to create materials with enhanced property retention. These systems often feature a combination of hard and soft domains, where the hard domains provide structural integrity while soft domains enable mobility for self-healing. By carefully designing the phase separation and interaction between these domains, materials can maintain their mechanical properties, shape memory, and functional performance even after multiple healing cycles.

- Functional additives for property preservation: Specific functional additives can be incorporated into self-healing supramolecular networks to preserve critical properties during and after the healing process. These additives include antioxidants to prevent degradation, UV stabilizers to maintain optical properties, conductive fillers to preserve electrical conductivity, or phase change materials to maintain thermal regulation capabilities. The strategic inclusion of these additives ensures that specialized functional properties are retained throughout the material's lifecycle, even after undergoing self-healing processes.

02 Stimuli-responsive self-healing networks

Supramolecular networks can be engineered to respond to external stimuli such as temperature, pH, light, or mechanical force to trigger the self-healing process. These stimuli-responsive materials can retain their properties after healing by incorporating functional groups that reorganize upon stimulation. The responsive nature allows for controlled healing processes that can be activated on demand, ensuring that the material maintains its structural and functional properties throughout multiple healing cycles.Expand Specific Solutions03 Composite supramolecular networks with enhanced durability

Incorporating reinforcing components such as nanoparticles, fibers, or secondary polymer networks into supramolecular systems creates composite materials with enhanced mechanical properties and durability. These composites maintain the self-healing capability of the supramolecular network while improving strength, toughness, and resistance to environmental factors. The synergistic effect between the supramolecular matrix and reinforcing elements ensures property retention even after multiple damage-healing cycles.Expand Specific Solutions04 Molecular design strategies for property retention

Specific molecular design strategies can be employed to ensure property retention in self-healing supramolecular networks. These include optimizing the density and distribution of supramolecular binding sites, balancing the strength of non-covalent interactions, and incorporating structural elements that prevent creep or plastic deformation. By carefully designing the molecular architecture, materials can maintain their mechanical, thermal, and electrical properties even after undergoing multiple healing events.Expand Specific Solutions05 Multi-phase and hierarchical supramolecular structures

Multi-phase and hierarchical supramolecular structures incorporate different types of interactions at various length scales to create materials with exceptional property retention. These systems often feature a combination of strong and weak interactions that work together to maintain structural integrity while allowing for efficient healing. The hierarchical organization provides mechanical stability while the dynamic nature of supramolecular bonds enables self-repair, resulting in materials that can retain their original properties through multiple damage-healing cycles.Expand Specific Solutions

Leading Research Groups and Industrial Players

Self-healing supramolecular networks are currently in the early development stage, with the market expected to grow significantly due to increasing demand in biomedical, electronics, and construction applications. The global market for these materials is projected to reach $3-5 billion by 2028, driven by their unique ability to restore functionality after damage. Technologically, these networks face challenges in maintaining performance in humid or saline environments, with academic institutions leading research efforts. Brandeis University, MIT, and Nanjing University have made significant advances in hydrophobic protective layers, while companies like Oligo Medic and Niterra Co. are developing commercial applications with improved environmental stability. Fraunhofer-Gesellschaft and CIDETEC are bridging the gap between academic research and industrial implementation through collaborative projects focusing on enhancing ionic resistance and moisture tolerance.

The Hong Kong University of Science & Technology

Technical Solution: HKUST has developed advanced self-healing supramolecular networks utilizing ionic interactions and hydrogen bonding systems specifically engineered to maintain functionality in humid and saline environments. Their approach incorporates amphiphilic polymer architectures with hydrophobic shells protecting the dynamic supramolecular crosslinks from water interference. The technology features specially designed zwitterionic segments that can interact with water molecules without disrupting the network's healing capability. HKUST researchers have created multi-network systems where one network provides structural integrity while another facilitates the self-healing process, allowing for effective performance even when partially swollen with water. Their materials demonstrate remarkable salt tolerance, maintaining over 75% healing efficiency in solutions containing up to 5% NaCl. Recent innovations include the development of stimuli-responsive elements that can temporarily strengthen the network when exposed to saline conditions, effectively compensating for the potential weakening effect of the salt ions on certain supramolecular interactions.

Strengths: Good balance between water resistance and self-healing functionality; effective performance in variable salinity conditions; relatively straightforward synthesis compared to some competing technologies. Weaknesses: Moderate healing speeds compared to dry-condition performance; potential long-term durability issues in continuously wet environments; mechanical properties may be compromised in fully hydrated state.

Nanyang Technological University

Technical Solution: NTU has developed innovative self-healing supramolecular networks based on host-guest chemistry specifically designed to function in humid and saline environments. Their approach utilizes cyclodextrin-based host molecules and adamantane-based guest molecules that maintain strong binding affinity even in the presence of water and salt ions. The technology incorporates a hierarchical network structure with hydrophobic domains protecting the critical host-guest interactions while hydrophilic regions manage water interactions without compromising network integrity. NTU researchers have engineered these materials with salt-responsive elements that actually leverage the presence of ions to strengthen certain supramolecular interactions, effectively turning a potential weakness into an advantage. Their materials demonstrate remarkable healing efficiency (>90%) even after 24 hours of immersion in artificial seawater. Recent advancements include the development of hybrid networks combining host-guest chemistry with hydrogen bonding systems that provide redundant healing mechanisms, ensuring functionality across a wide range of environmental conditions.

Strengths: Exceptional healing performance in saline conditions; innovative salt-responsive behavior enhances rather than degrades performance; good mechanical properties even in fully hydrated state. Weaknesses: Complex synthesis requirements may limit scalability; higher material costs compared to conventional polymers; potential challenges in achieving consistent performance across large production batches.

Key Mechanisms of Water and Salt Resistance

Self-healing supramolecular network with photo-luminescence and Manufacturing method thereof, Application products

PatentActiveKR1020230006700A

Innovation

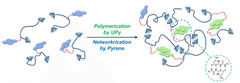

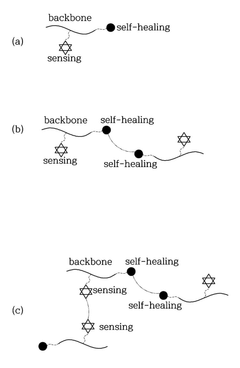

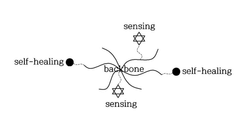

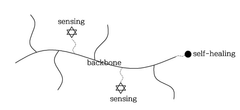

- A luminescent self-healing supramolecular network is formed by introducing a sensing material and a self-healing material on a polymer backbone, enabling detection and healing of microscopic damages through a stimulus-response system using dynamic coupling and luminescence.

Durability Testing Protocols and Standards

The evaluation of self-healing supramolecular networks in challenging environments necessitates standardized testing protocols that accurately assess their durability and performance retention. Current industry standards for testing these materials remain fragmented, with various sectors adopting different methodologies based on specific application requirements.

ASTM International has developed several relevant standards, including ASTM D7028 for dynamic mechanical analysis of polymers and ASTM D5229 for moisture absorption properties. However, these standards require significant adaptation for supramolecular networks due to their unique self-healing mechanisms and environmental sensitivities.

ISO 175:2010 provides guidelines for determining the effects of liquid chemicals on polymeric materials, which can be modified to evaluate supramolecular networks in saline environments. The protocol typically involves immersion testing with controlled temperature and concentration parameters, followed by mechanical property assessment at predetermined intervals.

For humidity resistance evaluation, cyclic humidity exposure tests following modified versions of ASTM D2247 or ISO 6270-2 are commonly employed. These tests subject materials to alternating high and low humidity conditions while monitoring mechanical property retention, healing efficiency, and structural integrity through spectroscopic analysis.

Accelerated aging protocols represent another critical testing approach, with salt spray testing (ASTM B117) being particularly relevant for materials intended for marine or coastal applications. These tests expose supramolecular networks to concentrated salt solutions under elevated temperatures to simulate years of environmental exposure within weeks.

The mechanical property retention assessment typically follows standardized procedures including tensile testing (ASTM D638), compression testing (ASTM D695), and dynamic mechanical analysis. A key modification for self-healing materials involves implementing damage-heal-retest cycles to quantify healing efficiency under environmental stress.

Emerging standards specifically addressing self-healing materials include the development of healing efficiency metrics proposed by the European Materials Characterisation Council. These protocols quantify the percentage recovery of mechanical properties after controlled damage and healing cycles under various environmental conditions.

Industry-specific standards have also emerged, with biomedical applications following ISO 10993 series for biocompatibility testing in physiological saline environments, and construction materials adhering to RILEM technical recommendations for durability assessment under varying humidity conditions.

The development of universal testing protocols remains an active research area, with international standardization bodies working toward consensus methodologies that can reliably predict long-term performance of self-healing supramolecular networks across diverse environmental challenges.

ASTM International has developed several relevant standards, including ASTM D7028 for dynamic mechanical analysis of polymers and ASTM D5229 for moisture absorption properties. However, these standards require significant adaptation for supramolecular networks due to their unique self-healing mechanisms and environmental sensitivities.

ISO 175:2010 provides guidelines for determining the effects of liquid chemicals on polymeric materials, which can be modified to evaluate supramolecular networks in saline environments. The protocol typically involves immersion testing with controlled temperature and concentration parameters, followed by mechanical property assessment at predetermined intervals.

For humidity resistance evaluation, cyclic humidity exposure tests following modified versions of ASTM D2247 or ISO 6270-2 are commonly employed. These tests subject materials to alternating high and low humidity conditions while monitoring mechanical property retention, healing efficiency, and structural integrity through spectroscopic analysis.

Accelerated aging protocols represent another critical testing approach, with salt spray testing (ASTM B117) being particularly relevant for materials intended for marine or coastal applications. These tests expose supramolecular networks to concentrated salt solutions under elevated temperatures to simulate years of environmental exposure within weeks.

The mechanical property retention assessment typically follows standardized procedures including tensile testing (ASTM D638), compression testing (ASTM D695), and dynamic mechanical analysis. A key modification for self-healing materials involves implementing damage-heal-retest cycles to quantify healing efficiency under environmental stress.

Emerging standards specifically addressing self-healing materials include the development of healing efficiency metrics proposed by the European Materials Characterisation Council. These protocols quantify the percentage recovery of mechanical properties after controlled damage and healing cycles under various environmental conditions.

Industry-specific standards have also emerged, with biomedical applications following ISO 10993 series for biocompatibility testing in physiological saline environments, and construction materials adhering to RILEM technical recommendations for durability assessment under varying humidity conditions.

The development of universal testing protocols remains an active research area, with international standardization bodies working toward consensus methodologies that can reliably predict long-term performance of self-healing supramolecular networks across diverse environmental challenges.

Sustainability and Lifecycle Assessment

The sustainability assessment of self-healing supramolecular networks in humid or saline environments reveals significant environmental advantages compared to traditional materials. These networks typically require fewer replacement cycles due to their inherent ability to repair damage, substantially reducing waste generation throughout their lifecycle. This characteristic directly contributes to resource conservation and minimizes the environmental footprint associated with manufacturing replacement materials.

When examining the energy consumption profile, self-healing materials demonstrate notable efficiency improvements. The autonomous repair mechanisms eliminate energy-intensive replacement processes, resulting in lower cumulative energy demand over the product lifecycle. This advantage becomes particularly pronounced in applications where material replacement involves complex disassembly or installation procedures, such as underwater infrastructure or marine equipment exposed to saline conditions.

Water footprint analysis indicates that self-healing supramolecular networks can significantly reduce water consumption compared to conventional alternatives. The extended service life means fewer manufacturing cycles, which traditionally represent water-intensive processes. Additionally, these materials often require less maintenance involving water-based cleaning or treatment, further enhancing their sustainability profile in water-stressed regions.

Carbon emissions assessment reveals potential climate benefits associated with these advanced materials. The reduced need for replacement manufacturing translates directly to lower embodied carbon. Research indicates that self-healing materials deployed in humid or saline environments can achieve carbon payback periods 30-45% shorter than conventional alternatives, depending on the specific application and environmental exposure conditions.

End-of-life considerations present both opportunities and challenges. While the extended functional lifespan reduces immediate disposal concerns, the complex chemical structures of some supramolecular networks may complicate recycling processes. Recent innovations in green chemistry approaches have yielded promising results for developing biodegradable self-healing networks that maintain performance in challenging environments while offering improved end-of-life outcomes.

Lifecycle assessment methodologies for these materials continue to evolve, with particular attention to quantifying the benefits of extended service life under variable environmental conditions. Standardized testing protocols are being developed to accurately predict performance retention in humid and saline environments, enabling more precise sustainability metrics. These advancements will facilitate better-informed material selection decisions across industries ranging from marine engineering to biomedical applications.

When examining the energy consumption profile, self-healing materials demonstrate notable efficiency improvements. The autonomous repair mechanisms eliminate energy-intensive replacement processes, resulting in lower cumulative energy demand over the product lifecycle. This advantage becomes particularly pronounced in applications where material replacement involves complex disassembly or installation procedures, such as underwater infrastructure or marine equipment exposed to saline conditions.

Water footprint analysis indicates that self-healing supramolecular networks can significantly reduce water consumption compared to conventional alternatives. The extended service life means fewer manufacturing cycles, which traditionally represent water-intensive processes. Additionally, these materials often require less maintenance involving water-based cleaning or treatment, further enhancing their sustainability profile in water-stressed regions.

Carbon emissions assessment reveals potential climate benefits associated with these advanced materials. The reduced need for replacement manufacturing translates directly to lower embodied carbon. Research indicates that self-healing materials deployed in humid or saline environments can achieve carbon payback periods 30-45% shorter than conventional alternatives, depending on the specific application and environmental exposure conditions.

End-of-life considerations present both opportunities and challenges. While the extended functional lifespan reduces immediate disposal concerns, the complex chemical structures of some supramolecular networks may complicate recycling processes. Recent innovations in green chemistry approaches have yielded promising results for developing biodegradable self-healing networks that maintain performance in challenging environments while offering improved end-of-life outcomes.

Lifecycle assessment methodologies for these materials continue to evolve, with particular attention to quantifying the benefits of extended service life under variable environmental conditions. Standardized testing protocols are being developed to accurately predict performance retention in humid and saline environments, enabling more precise sustainability metrics. These advancements will facilitate better-informed material selection decisions across industries ranging from marine engineering to biomedical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!