Self-Healing Antifog Coatings: Optical Clarity Recovery, Water Condensation And Durability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifog Coating Technology Evolution and Objectives

Antifog coatings have evolved significantly since their inception in the 1970s, initially developed for optical applications such as eyeglasses and mirrors. The fundamental challenge these coatings address is the formation of water droplets on surfaces that scatter light and reduce visibility. Early antifog solutions were simple hydrophilic coatings that spread water into thin films rather than allowing droplet formation.

The 1990s marked a significant advancement with the introduction of more durable polymer-based coatings incorporating surfactants. These formulations provided longer-lasting antifog properties but still required periodic reapplication. By the early 2000s, researchers began exploring nanostructured surfaces that could maintain antifog properties through physical surface modifications rather than chemical additives alone.

The concept of self-healing in antifog coatings emerged around 2010, representing a paradigm shift in the field. These advanced materials were designed to restore their functional properties after damage through various mechanisms including thermally-activated healing, light-responsive materials, or embedded healing agents. This innovation addressed the critical limitation of coating durability in real-world applications.

Current technological objectives focus on developing antifog coatings that combine multiple performance characteristics: self-healing capabilities, optical clarity recovery after damage, effective water condensation management, and enhanced durability under various environmental conditions. The ideal coating should maintain transparency while preventing fog formation through repeated cycles of use and environmental exposure.

Research trends indicate growing interest in biomimetic approaches, drawing inspiration from natural antifog surfaces like insect eyes and plant leaves. These bio-inspired designs often incorporate hierarchical micro and nanostructures that provide superior antifog properties through controlled wettability patterns.

The integration of smart materials responsive to environmental triggers represents another frontier, with coatings that can adapt their properties based on humidity, temperature, or light conditions. This adaptive functionality aims to provide optimal performance across varying environments without manual intervention.

The ultimate technological goal is to develop a universal self-healing antifog coating that maintains perfect optical clarity under all conditions, effectively manages water condensation through controlled surface energy, demonstrates exceptional durability against mechanical abrasion and chemical exposure, and requires minimal maintenance throughout its lifecycle. Such a coating would revolutionize applications in automotive, medical, optical, and architectural industries where visibility and clarity are paramount.

The 1990s marked a significant advancement with the introduction of more durable polymer-based coatings incorporating surfactants. These formulations provided longer-lasting antifog properties but still required periodic reapplication. By the early 2000s, researchers began exploring nanostructured surfaces that could maintain antifog properties through physical surface modifications rather than chemical additives alone.

The concept of self-healing in antifog coatings emerged around 2010, representing a paradigm shift in the field. These advanced materials were designed to restore their functional properties after damage through various mechanisms including thermally-activated healing, light-responsive materials, or embedded healing agents. This innovation addressed the critical limitation of coating durability in real-world applications.

Current technological objectives focus on developing antifog coatings that combine multiple performance characteristics: self-healing capabilities, optical clarity recovery after damage, effective water condensation management, and enhanced durability under various environmental conditions. The ideal coating should maintain transparency while preventing fog formation through repeated cycles of use and environmental exposure.

Research trends indicate growing interest in biomimetic approaches, drawing inspiration from natural antifog surfaces like insect eyes and plant leaves. These bio-inspired designs often incorporate hierarchical micro and nanostructures that provide superior antifog properties through controlled wettability patterns.

The integration of smart materials responsive to environmental triggers represents another frontier, with coatings that can adapt their properties based on humidity, temperature, or light conditions. This adaptive functionality aims to provide optimal performance across varying environments without manual intervention.

The ultimate technological goal is to develop a universal self-healing antifog coating that maintains perfect optical clarity under all conditions, effectively manages water condensation through controlled surface energy, demonstrates exceptional durability against mechanical abrasion and chemical exposure, and requires minimal maintenance throughout its lifecycle. Such a coating would revolutionize applications in automotive, medical, optical, and architectural industries where visibility and clarity are paramount.

Market Analysis for Self-Healing Optical Coatings

The global market for self-healing optical coatings is experiencing significant growth, driven by increasing demand across multiple industries including automotive, electronics, eyewear, and architectural glass. Current market valuations indicate that the broader smart coatings market exceeds $5 billion, with self-healing optical coatings representing a rapidly expanding segment projected to grow at a compound annual growth rate of 18% through 2028.

Consumer electronics represents the largest application sector, with smartphone manufacturers increasingly incorporating anti-fog and self-healing technologies into display screens. This trend is particularly evident in premium device segments where optical clarity is a key differentiator. Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring advanced protective coatings that maintain visual clarity over time.

The automotive industry presents another substantial market opportunity, particularly in the luxury and mid-premium segments. Advanced driver assistance systems (ADAS) and autonomous driving technologies rely heavily on optical sensors and cameras, creating demand for coatings that can maintain consistent performance in varying environmental conditions. Major automotive suppliers have begun incorporating self-healing antifog coatings in sensor housings and displays, with adoption rates increasing by approximately 25% annually.

Healthcare applications represent an emerging high-value segment, particularly for medical imaging equipment and diagnostic devices. The pandemic has accelerated interest in antimicrobial properties that can be integrated with self-healing optical coatings, creating multifunctional surfaces that address both clarity and hygiene concerns. This segment is expected to grow at over 20% annually for the next five years.

Regional analysis reveals that North America and Europe currently lead in adoption, accounting for approximately 65% of market share. However, Asia-Pacific represents the fastest-growing region, with China and South Korea making significant investments in manufacturing capabilities for advanced optical coatings. Japan maintains technological leadership in certain specialized applications, particularly for high-precision optical instruments.

Market challenges include price sensitivity in mass-market applications and the need for coatings that can withstand increasingly demanding environmental conditions. Consumer expectations for durability continue to rise, with warranty periods becoming a key competitive factor. Additionally, regulatory requirements regarding chemical composition and environmental impact are becoming more stringent, particularly in European markets where REACH compliance is mandatory.

Consumer electronics represents the largest application sector, with smartphone manufacturers increasingly incorporating anti-fog and self-healing technologies into display screens. This trend is particularly evident in premium device segments where optical clarity is a key differentiator. Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring advanced protective coatings that maintain visual clarity over time.

The automotive industry presents another substantial market opportunity, particularly in the luxury and mid-premium segments. Advanced driver assistance systems (ADAS) and autonomous driving technologies rely heavily on optical sensors and cameras, creating demand for coatings that can maintain consistent performance in varying environmental conditions. Major automotive suppliers have begun incorporating self-healing antifog coatings in sensor housings and displays, with adoption rates increasing by approximately 25% annually.

Healthcare applications represent an emerging high-value segment, particularly for medical imaging equipment and diagnostic devices. The pandemic has accelerated interest in antimicrobial properties that can be integrated with self-healing optical coatings, creating multifunctional surfaces that address both clarity and hygiene concerns. This segment is expected to grow at over 20% annually for the next five years.

Regional analysis reveals that North America and Europe currently lead in adoption, accounting for approximately 65% of market share. However, Asia-Pacific represents the fastest-growing region, with China and South Korea making significant investments in manufacturing capabilities for advanced optical coatings. Japan maintains technological leadership in certain specialized applications, particularly for high-precision optical instruments.

Market challenges include price sensitivity in mass-market applications and the need for coatings that can withstand increasingly demanding environmental conditions. Consumer expectations for durability continue to rise, with warranty periods becoming a key competitive factor. Additionally, regulatory requirements regarding chemical composition and environmental impact are becoming more stringent, particularly in European markets where REACH compliance is mandatory.

Technical Challenges in Antifog Coating Development

The development of self-healing antifog coatings faces numerous technical challenges that have hindered widespread commercial adoption. One of the primary obstacles is achieving long-term durability while maintaining antifog properties. Current antifog coatings often degrade rapidly under environmental stressors such as UV radiation, temperature fluctuations, and repeated cleaning cycles, leading to diminished performance over relatively short timeframes.

Water condensation management presents another significant challenge. While hydrophilic coatings spread water into transparent films, they can become saturated in high humidity environments, reducing their effectiveness. Conversely, superhydrophobic coatings repel water droplets but may create optical distortions due to the formation of microscopic water droplets that scatter light.

The self-healing mechanism itself introduces complex engineering challenges. Creating materials that can autonomously repair surface damage without external intervention requires sophisticated molecular design. Current approaches using dynamic covalent bonds or supramolecular interactions often compromise other essential properties like mechanical strength or optical clarity when optimized for self-healing capabilities.

Optical clarity recovery after damage remains problematic. Many self-healing materials exhibit incomplete restoration of transparency, resulting in haze or distortion that persists after the healing process. This is particularly critical for applications requiring high optical precision, such as camera lenses or medical devices.

Manufacturing scalability presents additional hurdles. Laboratory-scale successes often employ complex synthesis procedures or expensive materials that prove challenging to scale for industrial production. The precise control of nanoscale structures necessary for optimal antifog and self-healing properties is difficult to maintain in large-scale manufacturing environments.

Adhesion to diverse substrate materials constitutes another technical barrier. Creating universal coatings that bond effectively to glass, polymers, and metals while maintaining flexibility and resistance to delamination requires sophisticated interface engineering that has not been fully resolved.

Environmental and health considerations further complicate development efforts. Many effective antifog formulations contain potentially harmful components like fluorinated compounds or volatile organic solvents. Developing environmentally benign alternatives that match performance specifications remains challenging, especially as regulatory frameworks become increasingly stringent worldwide.

Cross-functional performance requirements add complexity, as coatings must simultaneously resist scratching, chemical exposure, and microbial growth while maintaining their primary antifog and self-healing functions. This multi-property optimization problem represents one of the most significant barriers to creating commercially viable solutions.

Water condensation management presents another significant challenge. While hydrophilic coatings spread water into transparent films, they can become saturated in high humidity environments, reducing their effectiveness. Conversely, superhydrophobic coatings repel water droplets but may create optical distortions due to the formation of microscopic water droplets that scatter light.

The self-healing mechanism itself introduces complex engineering challenges. Creating materials that can autonomously repair surface damage without external intervention requires sophisticated molecular design. Current approaches using dynamic covalent bonds or supramolecular interactions often compromise other essential properties like mechanical strength or optical clarity when optimized for self-healing capabilities.

Optical clarity recovery after damage remains problematic. Many self-healing materials exhibit incomplete restoration of transparency, resulting in haze or distortion that persists after the healing process. This is particularly critical for applications requiring high optical precision, such as camera lenses or medical devices.

Manufacturing scalability presents additional hurdles. Laboratory-scale successes often employ complex synthesis procedures or expensive materials that prove challenging to scale for industrial production. The precise control of nanoscale structures necessary for optimal antifog and self-healing properties is difficult to maintain in large-scale manufacturing environments.

Adhesion to diverse substrate materials constitutes another technical barrier. Creating universal coatings that bond effectively to glass, polymers, and metals while maintaining flexibility and resistance to delamination requires sophisticated interface engineering that has not been fully resolved.

Environmental and health considerations further complicate development efforts. Many effective antifog formulations contain potentially harmful components like fluorinated compounds or volatile organic solvents. Developing environmentally benign alternatives that match performance specifications remains challenging, especially as regulatory frameworks become increasingly stringent worldwide.

Cross-functional performance requirements add complexity, as coatings must simultaneously resist scratching, chemical exposure, and microbial growth while maintaining their primary antifog and self-healing functions. This multi-property optimization problem represents one of the most significant barriers to creating commercially viable solutions.

Current Self-Healing Antifog Solutions

01 Hydrophilic polymer-based self-healing antifog coatings

These coatings utilize hydrophilic polymers that attract water molecules and spread them into a transparent film rather than allowing them to form light-scattering droplets. The self-healing properties come from the polymer's ability to reorganize its structure after damage, maintaining antifog performance over time. These materials typically contain functional groups that can form hydrogen bonds with water molecules, ensuring consistent wetting behavior and optical clarity even after repeated exposure to moisture and mechanical stress.- Hydrophilic polymer-based self-healing antifog coatings: These coatings utilize hydrophilic polymers that attract water molecules and spread them evenly across the surface, preventing the formation of light-scattering water droplets. The self-healing properties come from the polymer's ability to reorganize its structure after damage, maintaining antifog performance over time. These materials can absorb water vapor and create a uniform water layer that doesn't interfere with light transmission, thus preserving optical clarity even in high humidity conditions.

- Nanoparticle-enhanced durable antifog coatings: Incorporating nanoparticles such as silica, titanium dioxide, or zinc oxide into coating formulations significantly enhances durability and scratch resistance while maintaining antifog properties. These nanoparticles create a textured surface at the nanoscale that helps maintain the coating's hydrophilicity even after mechanical abrasion. The nanostructured surface also facilitates water spreading and prevents droplet formation, ensuring consistent optical clarity in varying environmental conditions.

- Stimuli-responsive self-healing mechanisms: These advanced coatings incorporate materials that respond to external stimuli such as temperature, humidity, or light to trigger self-healing processes. When damage occurs to the coating surface, these stimuli activate molecular rearrangement or chemical reactions that repair the damaged areas, restoring antifog functionality. Some formulations include microcapsules containing healing agents that release when the coating is scratched or damaged, automatically repairing the surface and maintaining optical clarity.

- Superhydrophilic surface treatments for condensation management: These treatments create extremely water-loving surfaces with contact angles approaching zero degrees, causing water to spread into an invisible sheet rather than forming droplets. By managing condensation through superhydrophilicity, these coatings maintain optical clarity even in rapidly changing temperature and humidity conditions. The surface chemistry is designed to maximize water spreading and minimize light scattering, with some formulations incorporating micro-texturing to enhance the superhydrophilic effect and improve durability.

- Multi-layer coating systems with self-regenerating properties: These sophisticated coating systems utilize multiple functional layers that work together to provide long-lasting antifog performance. Typically consisting of a durable base layer, active middle layer with self-healing components, and a renewable top layer, these systems can continuously regenerate their surface properties. The layered approach allows for specialized functionality at different depths, with some formulations incorporating gradual release mechanisms that continuously renew the surface's antifog properties over extended periods, ensuring consistent optical clarity and water management.

02 Nanoparticle-enhanced antifog coatings with durability features

Incorporating nanoparticles such as silica, titanium dioxide, or zinc oxide into coating formulations significantly enhances durability and self-healing capabilities. These nanoparticles create a hierarchical surface structure that maintains hydrophilicity while improving abrasion resistance. The nanoparticles can also provide additional functionality such as photocatalytic self-cleaning properties that decompose organic contaminants, thereby extending the effective lifetime of the antifog properties and allowing for optical clarity recovery after contamination.Expand Specific Solutions03 Stimuli-responsive self-healing mechanisms for antifog recovery

These advanced coatings incorporate materials that respond to external stimuli such as temperature, humidity, or light to trigger self-healing processes. When damaged, these coatings can autonomously repair microscopic scratches or chemical degradation through mechanisms like molecular diffusion, reversible chemical bonds, or phase transitions. This approach ensures that optical clarity can be recovered without manual intervention, maintaining antifog performance even after exposure to harsh environmental conditions or mechanical abrasion.Expand Specific Solutions04 Water condensation management through surface energy control

These coatings manage water condensation by precisely controlling surface energy through a combination of hydrophilic and hydrophobic domains. The engineered surface topography creates preferential pathways for water to spread evenly rather than forming droplets. This approach often utilizes amphiphilic copolymers or gradient surfaces that can adapt to changing humidity conditions, maintaining optimal wetting behavior across a wide range of environmental conditions and ensuring consistent optical clarity even during rapid temperature or humidity fluctuations.Expand Specific Solutions05 Cross-linkable coating systems with enhanced durability

These formulations utilize cross-linking chemistry to create durable networks that resist degradation while maintaining antifog properties. The cross-linked structure provides mechanical stability and abrasion resistance while specialized functional groups ensure continued hydrophilicity. Some systems incorporate self-healing moieties within the cross-linked network, such as dynamic covalent bonds or supramolecular interactions, allowing the coating to repair damage while maintaining its integrated structure. This approach is particularly effective for applications requiring long-term durability under challenging environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The self-healing antifog coating market is in its growth phase, with increasing demand driven by applications in optical, automotive, and medical industries. The global market for advanced coatings is projected to reach $15-20 billion by 2027, with antifog solutions representing a significant segment. Leading research institutions like MIT, Swiss Federal Institute of Technology, and Southeast University are advancing fundamental technologies, while commercial players including PPG Industries, 3M Innovative Properties, and TOTO Ltd. are developing market-ready solutions. Companies like Nano Magic LLC and AKITA INNOVATIONS specialize in niche antifog applications, while larger corporations such as EssilorLuxottica and FUJIFILM are integrating these technologies into consumer products. The technology is approaching maturity with recent breakthroughs in self-healing mechanisms, though durability and cost-effectiveness remain challenges.

Massachusetts Institute of Technology

Technical Solution: MIT has developed innovative self-healing antifog coatings based on lubricant-infused polymer networks. Their approach utilizes a dual-layer system where a porous polymer network is infused with a compatible lubricant that can migrate to the surface when damaged. The coating maintains optical clarity by preventing water droplet formation through the creation of a stable lubricant overlayer that water cannot penetrate. MIT researchers have engineered these coatings to recover their antifog properties after physical damage through capillary-driven lubricant replenishment mechanisms. Their technology incorporates fluorinated lubricants with low surface energy that create a slippery interface, allowing condensed water to slide off rather than forming light-scattering droplets. The coatings demonstrate remarkable durability with maintained performance after multiple abrasion cycles and extended exposure to humid conditions.

Strengths: Superior self-healing capabilities through lubricant replenishment mechanisms; excellent optical clarity maintenance; strong fundamental research backing. Weaknesses: Potential environmental concerns with fluorinated compounds; may require specialized application processes; higher cost compared to conventional coatings.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed advanced self-healing antifog coatings utilizing proprietary hydrophilic polymer technology combined with dynamic crosslinking networks. Their solution incorporates specially engineered polymer chains with both hydrophilic and hydrophobic segments that reorganize upon damage to restore surface functionality. The coating prevents fogging by spreading water into a uniform, non-scattering film rather than discrete droplets. PPG's technology employs reversible chemical bonds that can reform after being broken, allowing the coating to recover from scratches and abrasion. Their industrial-scale manufacturing process ensures consistent quality across large production volumes, with coatings that maintain over 95% optical clarity even after repeated condensation cycles. PPG has integrated UV-stabilizers and anti-oxidants to enhance durability under harsh environmental conditions, addressing a key challenge in commercial applications.

Strengths: Established manufacturing infrastructure for commercial-scale production; extensive experience in coating technologies for various industries; strong durability in real-world applications. Weaknesses: May require specific environmental conditions for optimal self-healing; healing process could be slower than some competing technologies.

Key Patents and Innovations in Antifog Recovery

Antifog coating

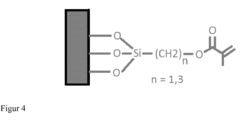

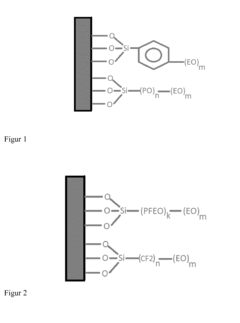

PatentActiveEP2664659A1

Innovation

- A permanent anti-fog coating is achieved by covalently attaching a silane derivative with a specific structure to the optical component's surface, featuring a hydrophobic group and a terminal hydrophilic group, which enhances hydrolytic stability and reduces water contact angle, allowing for increased coverage and prolonged effectiveness without compromising the anti-reflective layer.

coatings

PatentInactiveEP2748265A1

Innovation

- A hydrophilic antifog layer by layer coating using molecularly blended hydrophilic polymers, such as chitosan and poly(acrylic acid)-co-poly(ethylene oxide), is applied through a layer-by-layer assembly process, providing a durable and biocompatible anticondensation effect that resists both fogging and frosting.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing antifog coatings represents a critical consideration in their development and deployment. Traditional antifog solutions often contain volatile organic compounds (VOCs) and fluorinated substances that pose significant environmental hazards through their production, application, and disposal processes. In contrast, newer self-healing antifog technologies are increasingly incorporating biodegradable polymers and environmentally benign components, substantially reducing their ecological footprint.

Water consumption patterns associated with these coatings merit particular attention. Self-healing antifog coatings that effectively manage water condensation can potentially reduce the frequency of cleaning and maintenance operations, thereby conserving water resources. This efficiency becomes especially significant in large-scale applications such as greenhouse agriculture, where substantial water savings can be achieved through optimized condensation management.

The durability aspect of these coatings directly influences their sustainability profile. Extended functional lifespans translate to reduced replacement frequency, minimizing waste generation and resource consumption. Life cycle assessments (LCAs) of various self-healing antifog formulations indicate that despite potentially higher initial production impacts, their extended service life often results in net environmental benefits compared to conventional alternatives requiring frequent replacement.

Manufacturing processes for these advanced coatings are evolving toward more sustainable practices. Innovations include solvent-free application methods, room-temperature curing systems, and reduced energy requirements during production. These improvements significantly decrease the carbon footprint associated with coating manufacture and application, aligning with global carbon reduction initiatives.

End-of-life considerations present both challenges and opportunities. While some self-healing materials incorporate complex chemical structures that may complicate recycling efforts, research is advancing toward designs that facilitate material recovery and reprocessing. Biodegradable variants are particularly promising, offering pathways to closed-loop material systems that minimize environmental impact.

Regulatory frameworks worldwide are increasingly emphasizing the environmental aspects of coating technologies. The European Union's REACH regulations and similar initiatives globally are driving the transition away from environmentally persistent substances in coating formulations. This regulatory landscape is accelerating innovation in environmentally compatible self-healing antifog technologies, creating market advantages for compliant solutions.

The potential for these coatings to improve energy efficiency in applications such as building windows, vehicle windshields, and optical sensors represents an additional environmental benefit. By maintaining optimal optical clarity without energy-intensive heating or frequent replacement, these coatings contribute to overall energy conservation in their application contexts.

Water consumption patterns associated with these coatings merit particular attention. Self-healing antifog coatings that effectively manage water condensation can potentially reduce the frequency of cleaning and maintenance operations, thereby conserving water resources. This efficiency becomes especially significant in large-scale applications such as greenhouse agriculture, where substantial water savings can be achieved through optimized condensation management.

The durability aspect of these coatings directly influences their sustainability profile. Extended functional lifespans translate to reduced replacement frequency, minimizing waste generation and resource consumption. Life cycle assessments (LCAs) of various self-healing antifog formulations indicate that despite potentially higher initial production impacts, their extended service life often results in net environmental benefits compared to conventional alternatives requiring frequent replacement.

Manufacturing processes for these advanced coatings are evolving toward more sustainable practices. Innovations include solvent-free application methods, room-temperature curing systems, and reduced energy requirements during production. These improvements significantly decrease the carbon footprint associated with coating manufacture and application, aligning with global carbon reduction initiatives.

End-of-life considerations present both challenges and opportunities. While some self-healing materials incorporate complex chemical structures that may complicate recycling efforts, research is advancing toward designs that facilitate material recovery and reprocessing. Biodegradable variants are particularly promising, offering pathways to closed-loop material systems that minimize environmental impact.

Regulatory frameworks worldwide are increasingly emphasizing the environmental aspects of coating technologies. The European Union's REACH regulations and similar initiatives globally are driving the transition away from environmentally persistent substances in coating formulations. This regulatory landscape is accelerating innovation in environmentally compatible self-healing antifog technologies, creating market advantages for compliant solutions.

The potential for these coatings to improve energy efficiency in applications such as building windows, vehicle windshields, and optical sensors represents an additional environmental benefit. By maintaining optimal optical clarity without energy-intensive heating or frequent replacement, these coatings contribute to overall energy conservation in their application contexts.

Performance Testing Standards and Certification Requirements

Standardized testing protocols are essential for evaluating the performance of self-healing antifog coatings across various applications. The American Society for Testing and Materials (ASTM) has developed several relevant standards, including ASTM D1003 for measuring optical clarity and haze, and ASTM D3359 for assessing coating adhesion. These standards provide consistent methodologies for quantifying key performance metrics that determine coating effectiveness.

For antifog properties specifically, ISO 13666 outlines procedures for evaluating fog resistance on optical surfaces, while ASTM F659 addresses condensation testing methodologies. These standards typically involve controlled temperature and humidity cycling to simulate real-world conditions where fogging occurs. Performance is generally measured by light transmission reduction or visual assessment using standardized scales.

Durability testing represents another critical dimension, with standards such as ASTM G154 for accelerated weathering and ASTM D4060 for abrasion resistance. Self-healing coatings require additional specialized protocols to evaluate recovery capabilities after damage. The healing efficiency is typically quantified by comparing optical clarity before damage, immediately after damage, and following the healing period under controlled conditions.

Water condensation behavior testing follows standards like ASTM D4585, which evaluates coating performance under condensing humidity conditions. For self-healing antifog coatings, measurements of contact angle, contact angle hysteresis, and sliding angle provide critical data on hydrophilicity/hydrophobicity balance that influences both antifog properties and self-healing mechanisms.

Certification requirements vary by application sector. Medical device coatings must comply with ISO 10993 for biocompatibility, while automotive applications follow SAE J576 for interior materials. Consumer electronics typically require compliance with IEC 60068 environmental testing standards. Additionally, many regions mandate environmental compliance certifications such as RoHS and REACH, restricting certain chemical components in coating formulations.

Emerging certification trends include lifecycle assessment requirements (ISO 14040) and sustainability metrics that evaluate environmental impact throughout the coating's production, use, and disposal phases. These standards are increasingly important as regulatory frameworks evolve toward more stringent environmental protection measures.

Industry-specific performance benchmarks are also developing, with organizations like the Anti-Fog Coatings Alliance establishing minimum performance thresholds for different application categories. These benchmarks typically specify minimum optical clarity retention percentages, maximum recovery times after damage, and minimum durability cycles required for certification in specific use cases.

For antifog properties specifically, ISO 13666 outlines procedures for evaluating fog resistance on optical surfaces, while ASTM F659 addresses condensation testing methodologies. These standards typically involve controlled temperature and humidity cycling to simulate real-world conditions where fogging occurs. Performance is generally measured by light transmission reduction or visual assessment using standardized scales.

Durability testing represents another critical dimension, with standards such as ASTM G154 for accelerated weathering and ASTM D4060 for abrasion resistance. Self-healing coatings require additional specialized protocols to evaluate recovery capabilities after damage. The healing efficiency is typically quantified by comparing optical clarity before damage, immediately after damage, and following the healing period under controlled conditions.

Water condensation behavior testing follows standards like ASTM D4585, which evaluates coating performance under condensing humidity conditions. For self-healing antifog coatings, measurements of contact angle, contact angle hysteresis, and sliding angle provide critical data on hydrophilicity/hydrophobicity balance that influences both antifog properties and self-healing mechanisms.

Certification requirements vary by application sector. Medical device coatings must comply with ISO 10993 for biocompatibility, while automotive applications follow SAE J576 for interior materials. Consumer electronics typically require compliance with IEC 60068 environmental testing standards. Additionally, many regions mandate environmental compliance certifications such as RoHS and REACH, restricting certain chemical components in coating formulations.

Emerging certification trends include lifecycle assessment requirements (ISO 14040) and sustainability metrics that evaluate environmental impact throughout the coating's production, use, and disposal phases. These standards are increasingly important as regulatory frameworks evolve toward more stringent environmental protection measures.

Industry-specific performance benchmarks are also developing, with organizations like the Anti-Fog Coatings Alliance establishing minimum performance thresholds for different application categories. These benchmarks typically specify minimum optical clarity retention percentages, maximum recovery times after damage, and minimum durability cycles required for certification in specific use cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!