How Ethylene Vinyl Acetate Meets Technological Advancements?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution and Objectives

Ethylene Vinyl Acetate (EVA) has undergone significant technological advancements since its introduction in the 1960s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA has evolved to meet diverse industrial needs across multiple sectors. The primary objective of EVA technology has been to enhance its versatility, performance, and sustainability to address emerging market demands.

The evolution of EVA technology can be traced through several key milestones. In the early stages, researchers focused on optimizing the copolymerization process to achieve better control over the vinyl acetate content, which directly influences the material's properties. This led to the development of EVA grades with varying levels of flexibility, transparency, and adhesion strength.

As industrial applications expanded, EVA technology progressed to incorporate advanced additives and fillers. These innovations aimed to improve specific characteristics such as UV resistance, flame retardancy, and thermal stability. The introduction of crosslinking techniques in the 1980s marked a significant leap forward, enabling the production of foam grades with enhanced mechanical properties and temperature resistance.

In recent years, the focus of EVA technology has shifted towards sustainability and environmental compatibility. Researchers have been working on developing bio-based EVA alternatives and improving the recyclability of EVA products. This aligns with the growing global emphasis on circular economy principles and reduced carbon footprint.

The current technological objectives for EVA revolve around several key areas. First, there is a push for even greater customization of EVA properties to meet specific application requirements in emerging fields such as 3D printing, wearable electronics, and advanced packaging. Second, researchers are exploring novel processing techniques to enhance production efficiency and reduce energy consumption.

Another critical objective is the development of EVA composites and nanocomposites. By incorporating nanomaterials or other polymers, scientists aim to create hybrid materials with superior mechanical, thermal, and barrier properties. This could potentially open up new applications in aerospace, automotive, and medical industries.

Furthermore, there is an ongoing effort to improve the long-term performance and durability of EVA-based products, particularly in challenging environments. This includes enhancing resistance to weathering, chemical exposure, and mechanical stress, which is crucial for applications in solar panels, construction materials, and automotive components.

As EVA technology continues to evolve, the overarching goal is to position this versatile material at the forefront of innovative solutions for future technological challenges. By addressing these objectives, EVA is poised to meet the demands of technological advancements across various industries, cementing its role as a key material in the development of next-generation products and applications.

The evolution of EVA technology can be traced through several key milestones. In the early stages, researchers focused on optimizing the copolymerization process to achieve better control over the vinyl acetate content, which directly influences the material's properties. This led to the development of EVA grades with varying levels of flexibility, transparency, and adhesion strength.

As industrial applications expanded, EVA technology progressed to incorporate advanced additives and fillers. These innovations aimed to improve specific characteristics such as UV resistance, flame retardancy, and thermal stability. The introduction of crosslinking techniques in the 1980s marked a significant leap forward, enabling the production of foam grades with enhanced mechanical properties and temperature resistance.

In recent years, the focus of EVA technology has shifted towards sustainability and environmental compatibility. Researchers have been working on developing bio-based EVA alternatives and improving the recyclability of EVA products. This aligns with the growing global emphasis on circular economy principles and reduced carbon footprint.

The current technological objectives for EVA revolve around several key areas. First, there is a push for even greater customization of EVA properties to meet specific application requirements in emerging fields such as 3D printing, wearable electronics, and advanced packaging. Second, researchers are exploring novel processing techniques to enhance production efficiency and reduce energy consumption.

Another critical objective is the development of EVA composites and nanocomposites. By incorporating nanomaterials or other polymers, scientists aim to create hybrid materials with superior mechanical, thermal, and barrier properties. This could potentially open up new applications in aerospace, automotive, and medical industries.

Furthermore, there is an ongoing effort to improve the long-term performance and durability of EVA-based products, particularly in challenging environments. This includes enhancing resistance to weathering, chemical exposure, and mechanical stress, which is crucial for applications in solar panels, construction materials, and automotive components.

As EVA technology continues to evolve, the overarching goal is to position this versatile material at the forefront of innovative solutions for future technological challenges. By addressing these objectives, EVA is poised to meet the demands of technological advancements across various industries, cementing its role as a key material in the development of next-generation products and applications.

Market Demand Analysis for EVA Applications

The market demand for Ethylene Vinyl Acetate (EVA) applications has been steadily growing across various industries, driven by its versatile properties and technological advancements. The global EVA market size was valued at USD 7.9 billion in 2020 and is projected to reach USD 11.4 billion by 2026, exhibiting a compound annual growth rate (CAGR) of 6.2% during the forecast period.

One of the primary drivers of EVA market growth is the increasing demand in the photovoltaic (PV) industry. As solar energy adoption continues to rise globally, EVA's use as an encapsulant material in solar panels has surged. The material's excellent transparency, weather resistance, and adhesion properties make it ideal for protecting solar cells from environmental factors, thereby enhancing the longevity and efficiency of solar panels.

The packaging industry represents another significant market for EVA applications. With the e-commerce boom and growing consumer awareness about sustainable packaging, there is a rising demand for flexible and eco-friendly packaging solutions. EVA's properties, such as flexibility, toughness, and low-temperature sealing capability, make it an attractive option for manufacturers looking to develop innovative packaging materials.

In the footwear industry, EVA has gained substantial traction due to its lightweight nature, shock absorption capabilities, and durability. The material is widely used in the production of sports shoes, casual footwear, and orthopedic shoes. As consumer preferences shift towards comfortable and performance-oriented footwear, the demand for EVA in this sector is expected to grow significantly.

The automotive sector is another key market for EVA applications. The material is used in various automotive components, including gaskets, hoses, and wire and cable insulation. With the increasing focus on lightweight materials to improve fuel efficiency and reduce emissions, EVA's adoption in automotive applications is projected to rise.

The healthcare industry has also shown growing interest in EVA applications. The material's biocompatibility and flexibility make it suitable for medical devices, pharmaceutical packaging, and prosthetics. As healthcare technologies advance and the need for specialized medical products increases, the demand for EVA in this sector is expected to expand.

Geographically, Asia Pacific dominates the EVA market, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs in countries like China, India, and Japan. North America and Europe follow, with significant demand coming from the automotive, packaging, and renewable energy sectors.

One of the primary drivers of EVA market growth is the increasing demand in the photovoltaic (PV) industry. As solar energy adoption continues to rise globally, EVA's use as an encapsulant material in solar panels has surged. The material's excellent transparency, weather resistance, and adhesion properties make it ideal for protecting solar cells from environmental factors, thereby enhancing the longevity and efficiency of solar panels.

The packaging industry represents another significant market for EVA applications. With the e-commerce boom and growing consumer awareness about sustainable packaging, there is a rising demand for flexible and eco-friendly packaging solutions. EVA's properties, such as flexibility, toughness, and low-temperature sealing capability, make it an attractive option for manufacturers looking to develop innovative packaging materials.

In the footwear industry, EVA has gained substantial traction due to its lightweight nature, shock absorption capabilities, and durability. The material is widely used in the production of sports shoes, casual footwear, and orthopedic shoes. As consumer preferences shift towards comfortable and performance-oriented footwear, the demand for EVA in this sector is expected to grow significantly.

The automotive sector is another key market for EVA applications. The material is used in various automotive components, including gaskets, hoses, and wire and cable insulation. With the increasing focus on lightweight materials to improve fuel efficiency and reduce emissions, EVA's adoption in automotive applications is projected to rise.

The healthcare industry has also shown growing interest in EVA applications. The material's biocompatibility and flexibility make it suitable for medical devices, pharmaceutical packaging, and prosthetics. As healthcare technologies advance and the need for specialized medical products increases, the demand for EVA in this sector is expected to expand.

Geographically, Asia Pacific dominates the EVA market, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs in countries like China, India, and Japan. North America and Europe follow, with significant demand coming from the automotive, packaging, and renewable energy sectors.

EVA Technical Challenges and Limitations

Despite its widespread use and versatility, Ethylene Vinyl Acetate (EVA) faces several technical challenges and limitations that hinder its ability to fully meet technological advancements. One of the primary concerns is its thermal stability. EVA tends to degrade at high temperatures, which limits its application in environments requiring heat resistance. This thermal instability can lead to the release of acetic acid, potentially causing corrosion in surrounding materials or equipment.

Another significant challenge is EVA's limited barrier properties. While it offers good resistance to certain substances, it falls short in providing effective barriers against gases and moisture. This limitation restricts its use in packaging applications that require high barrier performance, particularly in the food and pharmaceutical industries where product protection is crucial.

EVA's mechanical properties also present challenges in some advanced applications. Although it offers good flexibility and impact resistance, its tensile strength and hardness are relatively low compared to other polymers. This can be a drawback in applications requiring high structural integrity or resistance to wear and tear.

The material's susceptibility to UV degradation is another limitation. When exposed to sunlight for extended periods, EVA can yellow and become brittle, affecting both its aesthetic appeal and functional properties. This poses challenges in outdoor applications or products that require long-term UV stability.

Furthermore, EVA's chemical resistance is not uniform across all substances. While it performs well against certain chemicals, it can be vulnerable to others, particularly organic solvents. This selective chemical resistance limits its use in some industrial and chemical processing applications.

The crosslinking process of EVA, which is crucial for enhancing its properties, can be challenging to control precisely. Achieving consistent and optimal crosslinking across different production batches can be difficult, potentially leading to variations in product quality and performance.

Lastly, as environmental concerns grow, the non-biodegradable nature of EVA becomes increasingly problematic. Its persistence in the environment after disposal raises sustainability issues, challenging its long-term viability in an era of growing environmental consciousness.

These technical challenges and limitations highlight the need for ongoing research and development in EVA technology. Addressing these issues is crucial for expanding EVA's applicability in advanced technological fields and ensuring its continued relevance in the face of evolving material requirements and environmental standards.

Another significant challenge is EVA's limited barrier properties. While it offers good resistance to certain substances, it falls short in providing effective barriers against gases and moisture. This limitation restricts its use in packaging applications that require high barrier performance, particularly in the food and pharmaceutical industries where product protection is crucial.

EVA's mechanical properties also present challenges in some advanced applications. Although it offers good flexibility and impact resistance, its tensile strength and hardness are relatively low compared to other polymers. This can be a drawback in applications requiring high structural integrity or resistance to wear and tear.

The material's susceptibility to UV degradation is another limitation. When exposed to sunlight for extended periods, EVA can yellow and become brittle, affecting both its aesthetic appeal and functional properties. This poses challenges in outdoor applications or products that require long-term UV stability.

Furthermore, EVA's chemical resistance is not uniform across all substances. While it performs well against certain chemicals, it can be vulnerable to others, particularly organic solvents. This selective chemical resistance limits its use in some industrial and chemical processing applications.

The crosslinking process of EVA, which is crucial for enhancing its properties, can be challenging to control precisely. Achieving consistent and optimal crosslinking across different production batches can be difficult, potentially leading to variations in product quality and performance.

Lastly, as environmental concerns grow, the non-biodegradable nature of EVA becomes increasingly problematic. Its persistence in the environment after disposal raises sustainability issues, challenging its long-term viability in an era of growing environmental consciousness.

These technical challenges and limitations highlight the need for ongoing research and development in EVA technology. Addressing these issues is crucial for expanding EVA's applicability in advanced technological fields and ensuring its continued relevance in the face of evolving material requirements and environmental standards.

Current EVA Solutions and Applications

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and thermal properties can be tailored by adjusting the vinyl acetate content and molecular weight of the EVA.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be crosslinked or expanded to create closed-cell foams for applications such as footwear, sports equipment, and building insulation.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. The material helps protect solar cells from environmental factors and ensures long-term performance of the solar panels.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and the addition of fillers or compatibilizers. These modifications can improve mechanical strength, thermal stability, flame retardancy, or other desired characteristics of the material.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base for other adhesive systems. The material's low melting point and good flow characteristics make it suitable for bonding applications in industries such as packaging and woodworking.Expand Specific Solutions03 EVA in foam and insulation products

EVA is utilized in the production of foam and insulation materials due to its closed-cell structure and thermal insulation properties. It can be crosslinked to improve its heat resistance and compression set properties, making it suitable for applications in footwear, sports equipment, and building insulation.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. Its transparency, weather resistance, and ability to protect solar cells from moisture and mechanical stress make it an ideal choice for solar panel manufacturing. The material can be formulated with additives to enhance UV stability and prevent yellowing over time.Expand Specific Solutions05 EVA in wire and cable applications

EVA is employed in the production of wire and cable insulation and jacketing materials. Its flexibility, electrical insulation properties, and resistance to environmental factors make it suitable for both indoor and outdoor cable applications. The material can be compounded with various additives to enhance flame retardancy and other specific properties required in the electrical industry.Expand Specific Solutions

Key Players in EVA Industry

The ethylene vinyl acetate (EVA) market is in a mature growth phase, characterized by steady demand across various industries. The global market size for EVA is projected to reach significant levels, driven by its versatile applications in sectors such as packaging, footwear, and solar panels. Technologically, EVA production is well-established, with major players like China Petroleum & Chemical Corp., Celanese International Corp., and DuPont de Nemours, Inc. continuously innovating to improve product performance and sustainability. Companies like Kuraray Co., Ltd. and Wacker Chemie AG are focusing on developing specialized EVA grades for emerging applications, while others such as LG Chem Ltd. and Hanwha Chemical Co., Ltd. are expanding their production capacities to meet growing demand.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies, including a proprietary high-pressure tubular reactor process. This technology allows for precise control of vinyl acetate content and molecular weight distribution, resulting in EVA with superior properties[1]. Sinopec has also implemented a continuous solution polymerization process, which enables the production of high-quality EVA with vinyl acetate content ranging from 10% to 40%[2]. The company has further invested in research to improve EVA's thermal stability and adhesion properties, making it suitable for advanced applications in photovoltaic encapsulants and high-performance adhesives[3].

Strengths: Proprietary high-pressure tubular reactor technology; wide range of VA content capabilities; improved thermal stability. Weaknesses: Potential higher production costs due to advanced technology; dependency on petrochemical feedstocks.

Celanese International Corp.

Technical Solution: Celanese has developed a cutting-edge EVA production process that utilizes a combination of high-pressure polymerization and advanced catalyst systems. This technology allows for the production of EVA with precisely controlled vinyl acetate content, ranging from 2% to 40%[4]. The company has also introduced a novel crosslinking technology that enhances the thermal and mechanical properties of EVA, making it suitable for demanding applications such as wire and cable insulation[5]. Additionally, Celanese has invested in sustainable EVA solutions, developing bio-based EVA grades that incorporate renewable resources, reducing the carbon footprint of their products[6].

Strengths: Precise control of VA content; advanced crosslinking technology; development of sustainable EVA grades. Weaknesses: Potentially higher costs associated with bio-based materials; market acceptance of new sustainable grades.

Innovative EVA Formulations and Properties

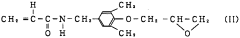

Graft ethylene-vinyl acetate copolymer and resin composition containing the same

PatentWO1997002302A1

Innovation

- A graft-modified ethylene-vinyl acetate copolymer is developed by incorporating a glycidyl group-containing compound and unsaturated glycidyl ester, along with a radical initiator, to enhance thermal stability and adhesion, and is blended with polyamide or polyester resins to improve mechanical and thermal properties.

Method for preparing ethylene-vinyl acetate with low melt index

PatentWO2014181991A1

Innovation

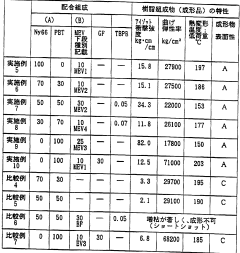

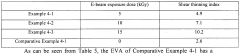

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

Environmental Impact of EVA Production

The production of Ethylene Vinyl Acetate (EVA) has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of petrochemical feedstocks, which are derived from non-renewable resources. This reliance on fossil fuels contributes to the depletion of natural resources and increases the carbon footprint associated with EVA production.

During the polymerization process, volatile organic compounds (VOCs) are emitted, which can contribute to air pollution and the formation of ground-level ozone. These emissions may have adverse effects on local air quality and potentially impact human health if not properly controlled. Additionally, the energy-intensive nature of EVA production leads to increased greenhouse gas emissions, primarily carbon dioxide, further exacerbating climate change concerns.

Water usage and wastewater management are also critical environmental aspects of EVA production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Proper treatment and disposal of wastewater are essential to prevent contamination of local water bodies and ecosystems.

The disposal of EVA products at the end of their lifecycle presents another environmental challenge. While EVA is recyclable, the recycling process is not widely implemented due to technical and economic constraints. As a result, a significant portion of EVA waste ends up in landfills or is incinerated, contributing to soil and air pollution.

However, technological advancements are addressing some of these environmental concerns. Improved production techniques have led to more efficient use of raw materials and energy, reducing waste and emissions. The development of bio-based EVA alternatives, using renewable feedstocks, shows promise in decreasing the reliance on fossil fuels and lowering the overall environmental impact.

Furthermore, advancements in recycling technologies are making it increasingly feasible to recycle EVA products, potentially creating a more circular economy for this material. Innovations in product design are also focusing on improving the recyclability and biodegradability of EVA-based products, aiming to reduce their environmental footprint throughout their lifecycle.

As environmental regulations become more stringent, EVA manufacturers are investing in cleaner production technologies, such as closed-loop systems and advanced emission control equipment. These measures help to minimize the release of pollutants and improve overall environmental performance.

In conclusion, while the production of EVA does have significant environmental impacts, ongoing technological advancements are continually improving its sustainability profile. The industry's focus on innovation and sustainability is driving progress towards more environmentally friendly production methods and end-of-life solutions for EVA products.

During the polymerization process, volatile organic compounds (VOCs) are emitted, which can contribute to air pollution and the formation of ground-level ozone. These emissions may have adverse effects on local air quality and potentially impact human health if not properly controlled. Additionally, the energy-intensive nature of EVA production leads to increased greenhouse gas emissions, primarily carbon dioxide, further exacerbating climate change concerns.

Water usage and wastewater management are also critical environmental aspects of EVA production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Proper treatment and disposal of wastewater are essential to prevent contamination of local water bodies and ecosystems.

The disposal of EVA products at the end of their lifecycle presents another environmental challenge. While EVA is recyclable, the recycling process is not widely implemented due to technical and economic constraints. As a result, a significant portion of EVA waste ends up in landfills or is incinerated, contributing to soil and air pollution.

However, technological advancements are addressing some of these environmental concerns. Improved production techniques have led to more efficient use of raw materials and energy, reducing waste and emissions. The development of bio-based EVA alternatives, using renewable feedstocks, shows promise in decreasing the reliance on fossil fuels and lowering the overall environmental impact.

Furthermore, advancements in recycling technologies are making it increasingly feasible to recycle EVA products, potentially creating a more circular economy for this material. Innovations in product design are also focusing on improving the recyclability and biodegradability of EVA-based products, aiming to reduce their environmental footprint throughout their lifecycle.

As environmental regulations become more stringent, EVA manufacturers are investing in cleaner production technologies, such as closed-loop systems and advanced emission control equipment. These measures help to minimize the release of pollutants and improve overall environmental performance.

In conclusion, while the production of EVA does have significant environmental impacts, ongoing technological advancements are continually improving its sustainability profile. The industry's focus on innovation and sustainability is driving progress towards more environmentally friendly production methods and end-of-life solutions for EVA products.

EVA in Emerging Technologies

Ethylene Vinyl Acetate (EVA) is increasingly finding its place in emerging technologies, demonstrating its versatility and adaptability to modern technological advancements. As a copolymer of ethylene and vinyl acetate, EVA's unique properties make it an ideal material for various innovative applications across multiple industries.

In the field of renewable energy, EVA has become a crucial component in the manufacturing of solar panels. Its excellent transparency, low-temperature toughness, and weather resistance make it an ideal encapsulant material for photovoltaic modules. As the solar industry continues to grow and evolve, EVA plays a significant role in improving the efficiency and durability of solar cells, contributing to the advancement of sustainable energy technologies.

The electronics industry has also embraced EVA in the development of flexible and wearable devices. Its flexibility, electrical insulation properties, and ability to be formulated with conductive additives make it suitable for creating stretchable electronics and sensors. This application aligns with the growing trend of Internet of Things (IoT) devices and smart wearables, where EVA's properties enable the creation of comfortable, durable, and functional electronic components.

In the medical field, EVA is making strides in drug delivery systems and biomedical devices. Its biocompatibility and controlled release properties make it an excellent material for transdermal patches, implants, and other drug delivery mechanisms. As personalized medicine and targeted therapies advance, EVA's role in creating innovative drug delivery platforms becomes increasingly important.

The automotive industry is leveraging EVA's properties in the development of electric vehicles (EVs) and advanced safety systems. EVA foams are used in battery insulation and vibration dampening, contributing to the overall performance and safety of EVs. Additionally, its impact resistance and energy absorption capabilities make it valuable in the design of automotive safety components.

In the realm of 3D printing and additive manufacturing, EVA filaments are gaining popularity due to their flexibility and ease of processing. This allows for the creation of complex, customized parts with rubber-like properties, opening up new possibilities in rapid prototyping and small-scale manufacturing across various industries.

As nanotechnology progresses, EVA is being explored as a matrix material for nanocomposites. By incorporating nanoparticles or nanofibers into EVA, researchers are developing materials with enhanced mechanical, thermal, and barrier properties. These nanocomposites have potential applications in packaging, aerospace, and advanced materials industries.

In the field of renewable energy, EVA has become a crucial component in the manufacturing of solar panels. Its excellent transparency, low-temperature toughness, and weather resistance make it an ideal encapsulant material for photovoltaic modules. As the solar industry continues to grow and evolve, EVA plays a significant role in improving the efficiency and durability of solar cells, contributing to the advancement of sustainable energy technologies.

The electronics industry has also embraced EVA in the development of flexible and wearable devices. Its flexibility, electrical insulation properties, and ability to be formulated with conductive additives make it suitable for creating stretchable electronics and sensors. This application aligns with the growing trend of Internet of Things (IoT) devices and smart wearables, where EVA's properties enable the creation of comfortable, durable, and functional electronic components.

In the medical field, EVA is making strides in drug delivery systems and biomedical devices. Its biocompatibility and controlled release properties make it an excellent material for transdermal patches, implants, and other drug delivery mechanisms. As personalized medicine and targeted therapies advance, EVA's role in creating innovative drug delivery platforms becomes increasingly important.

The automotive industry is leveraging EVA's properties in the development of electric vehicles (EVs) and advanced safety systems. EVA foams are used in battery insulation and vibration dampening, contributing to the overall performance and safety of EVs. Additionally, its impact resistance and energy absorption capabilities make it valuable in the design of automotive safety components.

In the realm of 3D printing and additive manufacturing, EVA filaments are gaining popularity due to their flexibility and ease of processing. This allows for the creation of complex, customized parts with rubber-like properties, opening up new possibilities in rapid prototyping and small-scale manufacturing across various industries.

As nanotechnology progresses, EVA is being explored as a matrix material for nanocomposites. By incorporating nanoparticles or nanofibers into EVA, researchers are developing materials with enhanced mechanical, thermal, and barrier properties. These nanocomposites have potential applications in packaging, aerospace, and advanced materials industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!