How Ethylene Vinyl Acetate Surpasses Current Limitations?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material with a rich history of technological evolution. Initially developed in the 1950s, EVA has undergone significant advancements to address various industrial and consumer needs. The primary objective in EVA technology has been to enhance its properties and expand its applications across multiple sectors.

The evolution of EVA technology can be traced through several key milestones. Early developments focused on improving the material's flexibility and durability, making it suitable for footwear and packaging applications. As research progressed, scientists discovered methods to fine-tune the vinyl acetate content, allowing for a wide range of properties from soft and rubber-like to rigid and transparent.

In recent years, the focus has shifted towards overcoming the limitations of traditional EVA formulations. One major objective has been to enhance the material's heat resistance, a critical factor in expanding its use in automotive and construction industries. Researchers have explored various additives and cross-linking techniques to improve EVA's thermal stability without compromising its desirable properties.

Another significant goal in EVA technology development has been to increase its environmental sustainability. This has led to efforts in creating bio-based EVA alternatives and improving the material's recyclability. The push towards more eco-friendly EVA formulations aligns with global trends in sustainable materials and circular economy principles.

The medical and pharmaceutical industries have also driven EVA technology evolution, with objectives centered on enhancing biocompatibility and controlled release properties. This has resulted in the development of specialized EVA grades suitable for drug delivery systems and medical devices.

In the energy sector, EVA has gained prominence in photovoltaic applications, particularly as an encapsulant material for solar panels. The technological goals here include improving UV resistance, reducing yellowing, and enhancing overall panel efficiency and longevity.

As we look towards the future, the objectives for EVA technology continue to evolve. Current research is focused on developing smart EVA materials with self-healing properties, improved electrical conductivity for wearable electronics, and enhanced barrier properties for packaging applications. These advancements aim to position EVA as a cutting-edge material capable of meeting the demands of emerging technologies and industries.

The ongoing evolution of EVA technology demonstrates its potential to surpass current limitations. By addressing challenges in thermal stability, environmental impact, and specialized applications, researchers and industry leaders are paving the way for EVA to remain a relevant and innovative material in the years to come.

The evolution of EVA technology can be traced through several key milestones. Early developments focused on improving the material's flexibility and durability, making it suitable for footwear and packaging applications. As research progressed, scientists discovered methods to fine-tune the vinyl acetate content, allowing for a wide range of properties from soft and rubber-like to rigid and transparent.

In recent years, the focus has shifted towards overcoming the limitations of traditional EVA formulations. One major objective has been to enhance the material's heat resistance, a critical factor in expanding its use in automotive and construction industries. Researchers have explored various additives and cross-linking techniques to improve EVA's thermal stability without compromising its desirable properties.

Another significant goal in EVA technology development has been to increase its environmental sustainability. This has led to efforts in creating bio-based EVA alternatives and improving the material's recyclability. The push towards more eco-friendly EVA formulations aligns with global trends in sustainable materials and circular economy principles.

The medical and pharmaceutical industries have also driven EVA technology evolution, with objectives centered on enhancing biocompatibility and controlled release properties. This has resulted in the development of specialized EVA grades suitable for drug delivery systems and medical devices.

In the energy sector, EVA has gained prominence in photovoltaic applications, particularly as an encapsulant material for solar panels. The technological goals here include improving UV resistance, reducing yellowing, and enhancing overall panel efficiency and longevity.

As we look towards the future, the objectives for EVA technology continue to evolve. Current research is focused on developing smart EVA materials with self-healing properties, improved electrical conductivity for wearable electronics, and enhanced barrier properties for packaging applications. These advancements aim to position EVA as a cutting-edge material capable of meeting the demands of emerging technologies and industries.

The ongoing evolution of EVA technology demonstrates its potential to surpass current limitations. By addressing challenges in thermal stability, environmental impact, and specialized applications, researchers and industry leaders are paving the way for EVA to remain a relevant and innovative material in the years to come.

Market Demand Analysis for EVA Applications

The market demand for Ethylene Vinyl Acetate (EVA) applications has been steadily growing across various industries, driven by its unique properties and versatility. EVA's exceptional flexibility, durability, and resistance to UV radiation and stress-cracking have positioned it as a preferred material in numerous sectors.

In the solar energy industry, EVA has become indispensable as an encapsulant material for photovoltaic modules. The global push towards renewable energy sources has significantly boosted the demand for EVA in this sector. As solar panel installations continue to increase worldwide, the market for EVA in solar applications is expected to expand substantially in the coming years.

The footwear industry represents another major market for EVA applications. The material's lightweight nature, shock-absorption properties, and ease of molding make it ideal for shoe soles and insoles. With the growing emphasis on comfort and performance in athletic and casual footwear, EVA's market share in this sector continues to rise.

In the packaging industry, EVA copolymers are increasingly used in flexible packaging solutions. The material's excellent sealing properties, transparency, and compatibility with various additives make it suitable for food packaging, medical packaging, and other specialized applications. As consumer preferences shift towards convenient and sustainable packaging options, the demand for EVA in this sector is projected to grow.

The automotive industry has also embraced EVA for various applications, including wire and cable insulation, gaskets, and interior components. The material's resistance to high temperatures and chemicals, coupled with its sound-dampening properties, makes it valuable in automotive manufacturing. As vehicle production increases and electric vehicles gain popularity, the demand for EVA in automotive applications is expected to surge.

In the medical field, EVA's biocompatibility and flexibility have led to its adoption in medical devices, tubing, and drug delivery systems. The growing healthcare sector and increasing focus on advanced medical technologies are driving the demand for EVA in medical applications.

The construction industry utilizes EVA in adhesives, sealants, and waterproofing materials. The material's weather resistance and bonding properties make it suitable for various construction applications, contributing to its market growth in this sector.

As industries continue to seek materials that offer improved performance, sustainability, and cost-effectiveness, EVA's market demand is expected to expand further. The material's ability to be customized through copolymerization and blending with other polymers opens up new possibilities for tailored solutions across different applications, potentially leading to the development of new markets and increased demand in existing ones.

In the solar energy industry, EVA has become indispensable as an encapsulant material for photovoltaic modules. The global push towards renewable energy sources has significantly boosted the demand for EVA in this sector. As solar panel installations continue to increase worldwide, the market for EVA in solar applications is expected to expand substantially in the coming years.

The footwear industry represents another major market for EVA applications. The material's lightweight nature, shock-absorption properties, and ease of molding make it ideal for shoe soles and insoles. With the growing emphasis on comfort and performance in athletic and casual footwear, EVA's market share in this sector continues to rise.

In the packaging industry, EVA copolymers are increasingly used in flexible packaging solutions. The material's excellent sealing properties, transparency, and compatibility with various additives make it suitable for food packaging, medical packaging, and other specialized applications. As consumer preferences shift towards convenient and sustainable packaging options, the demand for EVA in this sector is projected to grow.

The automotive industry has also embraced EVA for various applications, including wire and cable insulation, gaskets, and interior components. The material's resistance to high temperatures and chemicals, coupled with its sound-dampening properties, makes it valuable in automotive manufacturing. As vehicle production increases and electric vehicles gain popularity, the demand for EVA in automotive applications is expected to surge.

In the medical field, EVA's biocompatibility and flexibility have led to its adoption in medical devices, tubing, and drug delivery systems. The growing healthcare sector and increasing focus on advanced medical technologies are driving the demand for EVA in medical applications.

The construction industry utilizes EVA in adhesives, sealants, and waterproofing materials. The material's weather resistance and bonding properties make it suitable for various construction applications, contributing to its market growth in this sector.

As industries continue to seek materials that offer improved performance, sustainability, and cost-effectiveness, EVA's market demand is expected to expand further. The material's ability to be customized through copolymerization and blending with other polymers opens up new possibilities for tailored solutions across different applications, potentially leading to the development of new markets and increased demand in existing ones.

Current EVA Limitations and Challenges

Ethylene Vinyl Acetate (EVA) has gained significant traction in various industries due to its versatile properties. However, despite its widespread use, EVA still faces several limitations and challenges that hinder its full potential in certain applications.

One of the primary limitations of EVA is its thermal stability. At higher temperatures, EVA tends to degrade, leading to a loss of mechanical properties and potential release of acetic acid. This thermal instability restricts its use in high-temperature applications and limits its long-term durability in certain environments.

Another challenge is the moisture sensitivity of EVA. When exposed to high humidity or water, EVA can absorb moisture, which may lead to dimensional changes and a decrease in its mechanical properties. This characteristic limits its use in applications where water resistance is crucial.

The relatively low mechanical strength of EVA compared to some other polymers poses challenges in applications requiring high load-bearing capacity. While EVA offers excellent flexibility and elasticity, its tensile strength and modulus are lower than some competing materials, limiting its use in structural applications.

EVA's resistance to chemicals and solvents is another area of concern. Although it performs well against some chemicals, it can be susceptible to degradation when exposed to certain organic solvents, oils, and strong acids or bases. This limitation restricts its use in harsh chemical environments.

The processing of EVA can also present challenges. The material's low melting point and tendency to stick to processing equipment can make it difficult to handle during manufacturing processes. This can lead to increased production costs and potential quality issues in the final product.

EVA's weatherability is another limitation, particularly in outdoor applications. Prolonged exposure to UV radiation and environmental factors can cause degradation, leading to discoloration, loss of mechanical properties, and potential material failure over time.

The recyclability of EVA is also a growing concern in the context of sustainability. While EVA can be recycled, the process is often more challenging compared to other thermoplastics due to its crosslinked structure in some formulations.

Lastly, the variability in EVA properties based on its vinyl acetate content presents both opportunities and challenges. While this allows for customization, it also means that achieving consistent properties across different batches or suppliers can be difficult, potentially impacting product quality and performance.

Addressing these limitations and challenges is crucial for expanding the application range of EVA and improving its overall performance. Ongoing research and development efforts are focused on enhancing EVA's thermal stability, chemical resistance, mechanical properties, and processability to overcome these current constraints and unlock new possibilities for this versatile material.

One of the primary limitations of EVA is its thermal stability. At higher temperatures, EVA tends to degrade, leading to a loss of mechanical properties and potential release of acetic acid. This thermal instability restricts its use in high-temperature applications and limits its long-term durability in certain environments.

Another challenge is the moisture sensitivity of EVA. When exposed to high humidity or water, EVA can absorb moisture, which may lead to dimensional changes and a decrease in its mechanical properties. This characteristic limits its use in applications where water resistance is crucial.

The relatively low mechanical strength of EVA compared to some other polymers poses challenges in applications requiring high load-bearing capacity. While EVA offers excellent flexibility and elasticity, its tensile strength and modulus are lower than some competing materials, limiting its use in structural applications.

EVA's resistance to chemicals and solvents is another area of concern. Although it performs well against some chemicals, it can be susceptible to degradation when exposed to certain organic solvents, oils, and strong acids or bases. This limitation restricts its use in harsh chemical environments.

The processing of EVA can also present challenges. The material's low melting point and tendency to stick to processing equipment can make it difficult to handle during manufacturing processes. This can lead to increased production costs and potential quality issues in the final product.

EVA's weatherability is another limitation, particularly in outdoor applications. Prolonged exposure to UV radiation and environmental factors can cause degradation, leading to discoloration, loss of mechanical properties, and potential material failure over time.

The recyclability of EVA is also a growing concern in the context of sustainability. While EVA can be recycled, the process is often more challenging compared to other thermoplastics due to its crosslinked structure in some formulations.

Lastly, the variability in EVA properties based on its vinyl acetate content presents both opportunities and challenges. While this allows for customization, it also means that achieving consistent properties across different batches or suppliers can be difficult, potentially impacting product quality and performance.

Addressing these limitations and challenges is crucial for expanding the application range of EVA and improving its overall performance. Ongoing research and development efforts are focused on enhancing EVA's thermal stability, chemical resistance, mechanical properties, and processability to overcome these current constraints and unlock new possibilities for this versatile material.

Current EVA Enhancement Solutions

01 Thermal limitations of EVA

Ethylene Vinyl Acetate (EVA) has limitations in terms of thermal stability and performance at high temperatures. This can affect its use in applications requiring heat resistance or prolonged exposure to elevated temperatures. Improvements in thermal properties often involve modifications to the polymer structure or the addition of stabilizers.- Thermal limitations of EVA: Ethylene Vinyl Acetate (EVA) has limitations in terms of thermal stability and performance at high temperatures. This can affect its use in applications requiring heat resistance or prolonged exposure to elevated temperatures. Improvements in thermal properties often involve modifications to the polymer structure or the addition of stabilizers.

- Mechanical property limitations: EVA copolymers may have limitations in mechanical properties such as tensile strength, impact resistance, and creep resistance. These limitations can restrict their use in certain high-performance applications. Researchers have explored various methods to enhance mechanical properties, including blending with other polymers or incorporating reinforcing agents.

- Processing limitations: EVA can present challenges during processing, particularly at high vinyl acetate content levels. Issues such as melt flow instability, die swell, and adhesion to processing equipment may occur. Developing specialized processing techniques or modifying the polymer composition can help overcome these limitations.

- Chemical resistance limitations: EVA copolymers may have limited resistance to certain chemicals, oils, and solvents. This can restrict their use in environments where exposure to these substances is common. Researchers have explored methods to improve chemical resistance through copolymerization with other monomers or surface treatments.

- Weathering and UV resistance limitations: EVA materials can be susceptible to degradation when exposed to outdoor conditions, particularly UV radiation. This can lead to discoloration, loss of mechanical properties, and reduced lifespan. Efforts to improve weathering resistance often involve the incorporation of UV stabilizers or the development of specialized EVA grades for outdoor applications.

02 Mechanical property limitations

EVA copolymers may have limitations in mechanical properties such as tensile strength, tear resistance, and hardness. These limitations can restrict their use in certain applications requiring high mechanical performance. Efforts to enhance mechanical properties often involve blending with other polymers or incorporating reinforcing agents.Expand Specific Solutions03 Processing limitations

EVA can present challenges during processing, including issues with melt flow behavior, adhesion to certain substrates, and compatibility with other materials. These limitations can affect the manufacturing processes and end-use applications of EVA-based products. Improving processability often involves adjusting the vinyl acetate content or using processing aids.Expand Specific Solutions04 Chemical resistance limitations

EVA may have limited resistance to certain chemicals, oils, and solvents, which can restrict its use in specific environments or applications requiring high chemical resistance. Enhancing chemical resistance often involves surface treatments or the incorporation of additives to improve the polymer's barrier properties.Expand Specific Solutions05 Environmental and aging limitations

EVA can be susceptible to degradation from environmental factors such as UV radiation, moisture, and oxidation. This can lead to changes in properties over time, affecting the long-term performance and durability of EVA-based products. Addressing these limitations often involves the use of stabilizers, UV absorbers, or protective coatings.Expand Specific Solutions

Key Players in EVA Industry

The ethylene vinyl acetate (EVA) market is in a mature growth stage, characterized by steady demand across various industries. The global market size is substantial, estimated to be in the billions of dollars, driven by applications in packaging, footwear, and solar panels. Technologically, EVA is well-established, with ongoing innovations focused on enhancing performance and sustainability. Key players like DuPont, Celanese, and Kuraray are at the forefront of EVA development, leveraging their extensive R&D capabilities. Chinese companies such as Sinopec and Wanhua Chemical are also making significant strides, particularly in expanding production capacity and improving product quality. The competitive landscape is marked by a mix of established multinational corporations and emerging regional players, all vying for market share through product differentiation and technological advancements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies to overcome current limitations. Their process utilizes a high-pressure tubular reactor system with improved catalyst formulations, achieving conversion rates of up to 15% and VA content ranging from 10-40%[1]. The company has also implemented a proprietary separation and purification process that enhances product quality and reduces energy consumption by approximately 20% compared to conventional methods[2]. Additionally, Sinopec has introduced a novel copolymerization technique that allows for better control of EVA's molecular weight distribution, resulting in enhanced mechanical properties and thermal stability[3].

Strengths: High conversion rates, wide VA content range, improved energy efficiency, and enhanced product properties. Weaknesses: High capital investment required for advanced reactor systems and potential scalability challenges for novel copolymerization techniques.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed a unique solution-based process for producing high-performance EVA, addressing limitations in traditional suspension polymerization methods. Their patented technology utilizes a specialized solvent system that enables better control of molecular weight and VA content distribution[4]. This process allows for the production of EVA with VA contents up to 80%, significantly expanding the material's application range[5]. Kuraray has also implemented a continuous production system that increases throughput by 30% while maintaining consistent product quality[6]. Furthermore, the company has developed a proprietary crosslinking technology that enhances the thermal and chemical resistance of EVA products, making them suitable for demanding applications in the automotive and electronics industries[7].

Strengths: High VA content capabilities, improved product consistency, and enhanced material properties. Weaknesses: Potential environmental concerns related to solvent use and higher production costs compared to traditional methods.

Innovative EVA Formulations

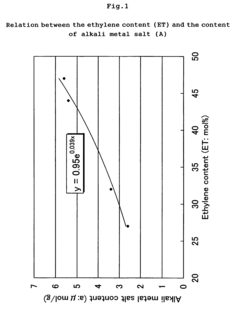

Ethylene-vinyl alcohol copolymer resin compositions and process for production thereof

PatentInactiveUS7524895B2

Innovation

- A method involving an aqueous solution containing carbon dioxide gas and additives like alkali metal salts and boron compounds is used to produce EVOH resin compositions, reducing carboxylate radical content and improving long-run workability, while minimizing acetic acid release and odor emission.

Innerliner for pneumatic tires and pneumatic tire

PatentInactiveUS20040089388A1

Innovation

- A modified ethylene-vinyl alcohol copolymer is developed by reacting an epoxy compound with an ethylene-vinyl alcohol copolymer, which reduces the elastic modulus and improves flexing resistance, combined with an auxiliary elastomer layer for enhanced adhesion and crack resistance, maintaining gas barrier properties even at reduced thickness.

Environmental Impact of EVA

Ethylene Vinyl Acetate (EVA) has gained significant attention in various industries due to its versatile properties and potential to address current material limitations. However, its environmental impact is a crucial aspect that requires thorough examination. EVA's production process involves the copolymerization of ethylene and vinyl acetate, which can have both positive and negative environmental implications.

One of the primary environmental benefits of EVA is its potential for recyclability. Unlike some traditional plastics, EVA can be recycled and reprocessed multiple times without significant degradation of its properties. This characteristic contributes to reducing waste and promoting a circular economy. Additionally, EVA's durability and long lifespan in certain applications can lead to reduced material consumption and waste generation over time.

However, the production of EVA does have some environmental drawbacks. The manufacturing process requires significant energy inputs, contributing to greenhouse gas emissions. The use of fossil fuel-derived raw materials in EVA production also raises concerns about resource depletion and carbon footprint. Furthermore, the vinyl acetate component of EVA can potentially release volatile organic compounds (VOCs) during production and use, which may have negative impacts on air quality and human health.

In terms of end-of-life considerations, while EVA is recyclable, the current recycling infrastructure for this material is not as well-established as for other common plastics. This can lead to improper disposal and potential environmental contamination. Additionally, when EVA is not recycled, it may persist in the environment for extended periods, contributing to plastic pollution in ecosystems.

The use of EVA in certain applications, such as solar panel encapsulation, presents a mixed environmental profile. On one hand, it contributes to the production of renewable energy, potentially offsetting its own environmental impact. On the other hand, the long-term environmental effects of large-scale EVA use in solar panels, particularly regarding end-of-life disposal and potential leaching of chemicals, are still being studied.

Recent research has focused on developing more environmentally friendly EVA formulations and production methods. This includes exploring bio-based alternatives for raw materials, improving energy efficiency in manufacturing processes, and enhancing the material's biodegradability without compromising its performance characteristics. These advancements aim to address the current environmental limitations of EVA and position it as a more sustainable material option for various industries.

One of the primary environmental benefits of EVA is its potential for recyclability. Unlike some traditional plastics, EVA can be recycled and reprocessed multiple times without significant degradation of its properties. This characteristic contributes to reducing waste and promoting a circular economy. Additionally, EVA's durability and long lifespan in certain applications can lead to reduced material consumption and waste generation over time.

However, the production of EVA does have some environmental drawbacks. The manufacturing process requires significant energy inputs, contributing to greenhouse gas emissions. The use of fossil fuel-derived raw materials in EVA production also raises concerns about resource depletion and carbon footprint. Furthermore, the vinyl acetate component of EVA can potentially release volatile organic compounds (VOCs) during production and use, which may have negative impacts on air quality and human health.

In terms of end-of-life considerations, while EVA is recyclable, the current recycling infrastructure for this material is not as well-established as for other common plastics. This can lead to improper disposal and potential environmental contamination. Additionally, when EVA is not recycled, it may persist in the environment for extended periods, contributing to plastic pollution in ecosystems.

The use of EVA in certain applications, such as solar panel encapsulation, presents a mixed environmental profile. On one hand, it contributes to the production of renewable energy, potentially offsetting its own environmental impact. On the other hand, the long-term environmental effects of large-scale EVA use in solar panels, particularly regarding end-of-life disposal and potential leaching of chemicals, are still being studied.

Recent research has focused on developing more environmentally friendly EVA formulations and production methods. This includes exploring bio-based alternatives for raw materials, improving energy efficiency in manufacturing processes, and enhancing the material's biodegradability without compromising its performance characteristics. These advancements aim to address the current environmental limitations of EVA and position it as a more sustainable material option for various industries.

EVA Regulatory Landscape

The regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and multifaceted, reflecting the material's widespread use across various industries. As EVA continues to surpass current limitations in performance and applications, regulatory bodies worldwide have adapted their frameworks to ensure safety, quality, and environmental compliance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA, particularly in food contact applications. The FDA has established specific guidelines for EVA copolymers used in food packaging, ensuring they meet stringent safety standards. These regulations cover aspects such as composition, manufacturing processes, and migration limits of potential contaminants.

The European Union has implemented comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers and importers of EVA must register their substances and provide detailed safety information. This regulatory approach aims to protect human health and the environment while promoting innovation in the chemical industry.

In Asia, countries like China and Japan have also developed their own regulatory frameworks for EVA. China's Ministry of Ecology and Environment has established environmental protection standards for EVA production, focusing on emissions control and waste management. Japan's regulatory approach emphasizes product safety and quality control, with specific guidelines for EVA used in consumer products.

The global nature of EVA production and trade has led to efforts towards harmonization of regulatory standards. International organizations such as the International Organization for Standardization (ISO) have developed standards for EVA testing and quality control, facilitating cross-border trade and ensuring consistent product quality worldwide.

As EVA continues to evolve and find new applications, regulatory bodies are adapting their approaches to address emerging concerns. For instance, the increasing use of EVA in renewable energy applications, such as solar panel encapsulation, has prompted the development of new standards and certifications specific to these applications.

Environmental regulations have also significantly impacted the EVA industry. Many countries have implemented policies to promote the use of recyclable and biodegradable materials, influencing the development of more environmentally friendly EVA formulations. This regulatory push has driven innovation in EVA recycling technologies and the exploration of bio-based alternatives.

The regulatory landscape for EVA is dynamic, with ongoing discussions and revisions to existing frameworks. As the material continues to surpass its current limitations, regulators are working to balance innovation with safety and environmental protection. This evolving regulatory environment presents both challenges and opportunities for the EVA industry, driving continuous improvement in product quality, safety, and sustainability.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA, particularly in food contact applications. The FDA has established specific guidelines for EVA copolymers used in food packaging, ensuring they meet stringent safety standards. These regulations cover aspects such as composition, manufacturing processes, and migration limits of potential contaminants.

The European Union has implemented comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers and importers of EVA must register their substances and provide detailed safety information. This regulatory approach aims to protect human health and the environment while promoting innovation in the chemical industry.

In Asia, countries like China and Japan have also developed their own regulatory frameworks for EVA. China's Ministry of Ecology and Environment has established environmental protection standards for EVA production, focusing on emissions control and waste management. Japan's regulatory approach emphasizes product safety and quality control, with specific guidelines for EVA used in consumer products.

The global nature of EVA production and trade has led to efforts towards harmonization of regulatory standards. International organizations such as the International Organization for Standardization (ISO) have developed standards for EVA testing and quality control, facilitating cross-border trade and ensuring consistent product quality worldwide.

As EVA continues to evolve and find new applications, regulatory bodies are adapting their approaches to address emerging concerns. For instance, the increasing use of EVA in renewable energy applications, such as solar panel encapsulation, has prompted the development of new standards and certifications specific to these applications.

Environmental regulations have also significantly impacted the EVA industry. Many countries have implemented policies to promote the use of recyclable and biodegradable materials, influencing the development of more environmentally friendly EVA formulations. This regulatory push has driven innovation in EVA recycling technologies and the exploration of bio-based alternatives.

The regulatory landscape for EVA is dynamic, with ongoing discussions and revisions to existing frameworks. As the material continues to surpass its current limitations, regulators are working to balance innovation with safety and environmental protection. This evolving regulatory environment presents both challenges and opportunities for the EVA industry, driving continuous improvement in product quality, safety, and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!