How Material Jetting Designs Sealing Surfaces To Meet Helium Leak Acceptance?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material jetting technology has evolved significantly over the past two decades as an advanced additive manufacturing process. Initially developed in the late 1990s, this technology has progressed from simple prototype creation to producing functional components with complex geometries and specific material properties. The evolution has been marked by improvements in printhead technology, material formulations, and process control systems that have collectively enhanced precision, reliability, and application scope.

The fundamental principle of material jetting involves the selective deposition of liquid photopolymer droplets onto a build platform, followed by solidification through UV light exposure. This layer-by-layer approach enables the creation of highly detailed structures with exceptional surface finish qualities. Recent technological advancements have expanded material compatibility beyond basic polymers to include ceramics, metals, and multi-material combinations, significantly broadening potential applications.

In the context of sealing surfaces, material jetting offers unique advantages due to its ability to create smooth, precise geometries with controlled material properties. The technology's high resolution (typically 600-1600 DPI) enables the production of sealing surfaces with microscale features and controlled surface roughness parameters that are critical for effective sealing performance. This precision is particularly valuable for applications requiring helium leak testing, which represents one of the most stringent standards for seal integrity evaluation.

Current technological objectives in material jetting for sealing applications focus on several key areas. First, enhancing material formulations to achieve appropriate mechanical properties, including elasticity, compression set resistance, and chemical compatibility required for effective sealing. Second, improving dimensional accuracy and repeatability to ensure consistent sealing performance across production batches. Third, developing multi-material capabilities to create sealing interfaces with gradient properties that optimize both sealing effectiveness and mechanical durability.

The specific challenge of meeting helium leak acceptance criteria represents a significant technological goal, as helium molecules are extremely small (approximately 0.26 nm in diameter) and can penetrate through microscopic imperfections in sealing surfaces. Material jetting must therefore achieve exceptional surface quality and material integrity to create seals capable of containing helium gas under pressure, typically requiring leak rates below 10^-9 std·cc/sec for high-performance applications.

Looking forward, the technology trajectory aims toward developing specialized material jetting systems optimized specifically for sealing applications, with enhanced process monitoring capabilities, in-situ quality verification, and material formulations engineered specifically for gas-tight sealing performance across diverse operating conditions and environments.

The fundamental principle of material jetting involves the selective deposition of liquid photopolymer droplets onto a build platform, followed by solidification through UV light exposure. This layer-by-layer approach enables the creation of highly detailed structures with exceptional surface finish qualities. Recent technological advancements have expanded material compatibility beyond basic polymers to include ceramics, metals, and multi-material combinations, significantly broadening potential applications.

In the context of sealing surfaces, material jetting offers unique advantages due to its ability to create smooth, precise geometries with controlled material properties. The technology's high resolution (typically 600-1600 DPI) enables the production of sealing surfaces with microscale features and controlled surface roughness parameters that are critical for effective sealing performance. This precision is particularly valuable for applications requiring helium leak testing, which represents one of the most stringent standards for seal integrity evaluation.

Current technological objectives in material jetting for sealing applications focus on several key areas. First, enhancing material formulations to achieve appropriate mechanical properties, including elasticity, compression set resistance, and chemical compatibility required for effective sealing. Second, improving dimensional accuracy and repeatability to ensure consistent sealing performance across production batches. Third, developing multi-material capabilities to create sealing interfaces with gradient properties that optimize both sealing effectiveness and mechanical durability.

The specific challenge of meeting helium leak acceptance criteria represents a significant technological goal, as helium molecules are extremely small (approximately 0.26 nm in diameter) and can penetrate through microscopic imperfections in sealing surfaces. Material jetting must therefore achieve exceptional surface quality and material integrity to create seals capable of containing helium gas under pressure, typically requiring leak rates below 10^-9 std·cc/sec for high-performance applications.

Looking forward, the technology trajectory aims toward developing specialized material jetting systems optimized specifically for sealing applications, with enhanced process monitoring capabilities, in-situ quality verification, and material formulations engineered specifically for gas-tight sealing performance across diverse operating conditions and environments.

Market Demand for Advanced Sealing Solutions

The global market for advanced sealing solutions is experiencing significant growth, driven by stringent regulatory requirements across industries where leak prevention is critical. The aerospace, automotive, medical device, and semiconductor sectors are particularly demanding, with helium leak testing becoming the gold standard for quality assurance. Market research indicates that the industrial sealing market is projected to reach $14.2 billion by 2026, with high-performance seals for critical applications representing the fastest-growing segment.

Material jetting technology is emerging as a disruptive force in this landscape, offering unprecedented design flexibility for creating complex sealing geometries that traditional manufacturing methods cannot achieve. Industries are increasingly seeking sealing solutions that can withstand extreme operating conditions while maintaining leak rates below 1×10^-9 std cc/sec, the typical acceptance criterion for helium leak testing in high-reliability applications.

The automotive industry represents a substantial market opportunity, particularly with the transition to electric vehicles. EV battery enclosures require sophisticated sealing solutions to prevent moisture ingress and maintain thermal management systems, with projected demand increasing at 24% annually through 2030. Similarly, hydrogen fuel cell vehicles require seals capable of containing hydrogen molecules, which are significantly smaller than helium, presenting an even greater technical challenge.

In aerospace and defense, the demand for lightweight components that maintain exceptional sealing properties has intensified. Material jetting's ability to create topology-optimized sealing surfaces that reduce weight while enhancing performance aligns perfectly with this industry's requirements. The space sector alone is expected to require over 30% more high-performance seals in the next five years as satellite deployments accelerate.

Medical device manufacturers are another key market segment, with requirements for biocompatible seals that can pass helium leak testing for implantable devices and diagnostic equipment. The precision offered by material jetting enables micro-scale sealing features that conventional manufacturing cannot replicate, addressing a market segment valued at $3.7 billion.

The semiconductor industry presents perhaps the most demanding requirements, with ultra-high vacuum systems requiring leak rates as low as 1×10^-12 std cc/sec. As chip manufacturing processes become more sophisticated, the tolerance for contamination decreases, driving demand for advanced sealing solutions that can be validated through helium leak testing.

Customer feedback across these industries indicates a willingness to pay premium prices for sealing solutions that demonstrably reduce failure rates and extend service intervals. The total cost of ownership calculation strongly favors advanced sealing technologies when considering the catastrophic consequences of seal failures in critical applications.

Material jetting technology is emerging as a disruptive force in this landscape, offering unprecedented design flexibility for creating complex sealing geometries that traditional manufacturing methods cannot achieve. Industries are increasingly seeking sealing solutions that can withstand extreme operating conditions while maintaining leak rates below 1×10^-9 std cc/sec, the typical acceptance criterion for helium leak testing in high-reliability applications.

The automotive industry represents a substantial market opportunity, particularly with the transition to electric vehicles. EV battery enclosures require sophisticated sealing solutions to prevent moisture ingress and maintain thermal management systems, with projected demand increasing at 24% annually through 2030. Similarly, hydrogen fuel cell vehicles require seals capable of containing hydrogen molecules, which are significantly smaller than helium, presenting an even greater technical challenge.

In aerospace and defense, the demand for lightweight components that maintain exceptional sealing properties has intensified. Material jetting's ability to create topology-optimized sealing surfaces that reduce weight while enhancing performance aligns perfectly with this industry's requirements. The space sector alone is expected to require over 30% more high-performance seals in the next five years as satellite deployments accelerate.

Medical device manufacturers are another key market segment, with requirements for biocompatible seals that can pass helium leak testing for implantable devices and diagnostic equipment. The precision offered by material jetting enables micro-scale sealing features that conventional manufacturing cannot replicate, addressing a market segment valued at $3.7 billion.

The semiconductor industry presents perhaps the most demanding requirements, with ultra-high vacuum systems requiring leak rates as low as 1×10^-12 std cc/sec. As chip manufacturing processes become more sophisticated, the tolerance for contamination decreases, driving demand for advanced sealing solutions that can be validated through helium leak testing.

Customer feedback across these industries indicates a willingness to pay premium prices for sealing solutions that demonstrably reduce failure rates and extend service intervals. The total cost of ownership calculation strongly favors advanced sealing technologies when considering the catastrophic consequences of seal failures in critical applications.

Current State and Challenges in Helium Leak Testing

Helium leak testing represents a critical quality control methodology in industries requiring hermetic sealing, particularly in aerospace, automotive, medical devices, and semiconductor manufacturing. Currently, the global standard for leak detection sensitivity reaches 10^-12 mbar·L/s, enabling identification of microscopic leaks undetectable by other methods. The technology has evolved significantly over the past decade, with mass spectrometry-based systems dominating the high-precision market segment.

The current state of helium leak testing faces several significant challenges when applied to components manufactured via material jetting processes. Surface finish variability inherent to additive manufacturing creates inconsistent sealing interfaces, complicating reliable test fixture attachment. Traditional helium leak testing equipment, designed primarily for conventionally manufactured parts with predictable geometries, struggles to accommodate the complex, organic shapes often produced through material jetting technologies.

Test fixture design represents another major challenge, as the unique geometries of material-jetted components frequently require custom fixtures that can maintain consistent pressure without damaging delicate features. The porosity characteristics of material-jetted parts further complicate testing procedures, as micro-voids inherent to the manufacturing process can create false positive readings that do not accurately represent actual sealing performance in application conditions.

Calibration standards specifically developed for additive manufacturing remain underdeveloped, creating uncertainty in test result interpretation. Current calibration methods rely heavily on standards developed for traditional manufacturing processes, potentially leading to inaccurate assessments of material-jetted components' sealing capabilities.

Material compatibility issues present additional complications, as some polymers used in material jetting processes can absorb helium during testing, resulting in misleading measurements. This absorption phenomenon can mask actual leak paths or create artificial leakage signatures that do not represent real-world performance.

The integration of helium leak testing into production workflows presents efficiency challenges, with current testing methodologies requiring significant time investments that conflict with the rapid production capabilities of advanced material jetting systems. Testing cycle times typically range from 3-15 minutes per component, creating production bottlenecks.

Cost considerations further constrain implementation, as high-sensitivity helium leak detection systems require substantial capital investment (typically $50,000-$250,000) and ongoing operational expenses, including specialized training and helium supply management. These economic factors limit widespread adoption, particularly among smaller manufacturers exploring material jetting technologies.

The current state of helium leak testing faces several significant challenges when applied to components manufactured via material jetting processes. Surface finish variability inherent to additive manufacturing creates inconsistent sealing interfaces, complicating reliable test fixture attachment. Traditional helium leak testing equipment, designed primarily for conventionally manufactured parts with predictable geometries, struggles to accommodate the complex, organic shapes often produced through material jetting technologies.

Test fixture design represents another major challenge, as the unique geometries of material-jetted components frequently require custom fixtures that can maintain consistent pressure without damaging delicate features. The porosity characteristics of material-jetted parts further complicate testing procedures, as micro-voids inherent to the manufacturing process can create false positive readings that do not accurately represent actual sealing performance in application conditions.

Calibration standards specifically developed for additive manufacturing remain underdeveloped, creating uncertainty in test result interpretation. Current calibration methods rely heavily on standards developed for traditional manufacturing processes, potentially leading to inaccurate assessments of material-jetted components' sealing capabilities.

Material compatibility issues present additional complications, as some polymers used in material jetting processes can absorb helium during testing, resulting in misleading measurements. This absorption phenomenon can mask actual leak paths or create artificial leakage signatures that do not represent real-world performance.

The integration of helium leak testing into production workflows presents efficiency challenges, with current testing methodologies requiring significant time investments that conflict with the rapid production capabilities of advanced material jetting systems. Testing cycle times typically range from 3-15 minutes per component, creating production bottlenecks.

Cost considerations further constrain implementation, as high-sensitivity helium leak detection systems require substantial capital investment (typically $50,000-$250,000) and ongoing operational expenses, including specialized training and helium supply management. These economic factors limit widespread adoption, particularly among smaller manufacturers exploring material jetting technologies.

Current Material Jetting Solutions for Sealing Surfaces

01 Sealing mechanisms for material jetting printheads

Various sealing mechanisms are employed in material jetting systems to prevent leakage and contamination of printheads. These include cap assemblies, gaskets, and specialized sealing surfaces that maintain proper contact with the printhead nozzle plate. The sealing mechanisms help maintain proper pressure within the system, prevent ink drying at the nozzles, and extend the operational life of the printhead by protecting sensitive components from environmental factors.- Sealing mechanisms for material jetting printheads: Various sealing mechanisms are employed in material jetting systems to prevent leakage and contamination of printheads. These include cap assemblies, sealing membranes, and specialized gaskets that create airtight seals around nozzle plates. The sealing mechanisms protect the printhead when not in use, prevent ink drying, and maintain proper pressure within the system, ensuring consistent jetting performance and extending the life of the printhead components.

- Surface treatment techniques for improved material adhesion: Surface treatment methods enhance the adhesion properties of jetted materials to substrate surfaces. These techniques include plasma treatment, chemical etching, and application of specialized primers or bonding agents. By modifying the surface energy or creating micro-textures on the substrate, these treatments improve wetting characteristics and bonding strength of jetted materials, resulting in more durable and reliable printed components with enhanced sealing properties.

- Multi-material jetting for creating composite sealing surfaces: Advanced material jetting systems can deposit multiple materials with varying properties to create composite sealing surfaces. By strategically combining rigid and flexible materials, or hydrophobic and hydrophilic substances, customized sealing interfaces can be produced in a single manufacturing process. This approach enables the creation of complex sealing geometries with region-specific mechanical properties, optimizing both sealing performance and durability for specific application requirements.

- Maintenance systems for sealing surface integrity: Specialized maintenance systems are designed to preserve the integrity of sealing surfaces in material jetting equipment. These systems include automated cleaning mechanisms, wiper assemblies, and purging routines that remove excess material, prevent clogging, and maintain the precision of sealing interfaces. Regular maintenance procedures ensure consistent material flow, prevent contamination between different materials, and extend the operational life of the jetting equipment.

- Environmental control for optimal sealing surface formation: Environmental control systems regulate temperature, humidity, and air quality during the material jetting process to optimize sealing surface formation. Controlled curing environments, including UV chambers, thermal management systems, and inert gas enclosures, ensure proper solidification and adhesion of jetted materials. These systems minimize defects such as warping, shrinkage, or incomplete curing that could compromise sealing performance, resulting in more reliable and consistent sealing surfaces.

02 Surface treatment techniques for improved sealing

Surface treatments are applied to create more effective sealing interfaces in material jetting systems. These treatments include plasma processing, chemical etching, and application of specialized coatings to modify surface properties. By controlling surface roughness, wettability, and other characteristics, these treatments enhance the quality of the seal between components, reducing the risk of leakage and improving overall system reliability.Expand Specific Solutions03 Adaptive sealing systems for variable surfaces

Adaptive sealing systems accommodate variations in surface geometry and operating conditions in material jetting applications. These systems incorporate flexible materials, adjustable pressure mechanisms, and self-aligning components that can conform to irregular surfaces. Some designs include feedback mechanisms that detect seal quality and automatically adjust parameters to maintain optimal sealing performance across different operating conditions.Expand Specific Solutions04 Material selection for sealing surfaces

The choice of materials for sealing surfaces significantly impacts the performance of material jetting systems. Elastomers, fluoropolymers, and specialized composites are selected based on their chemical compatibility with the jetted materials, temperature resistance, and mechanical properties. Advanced materials with self-healing properties or engineered microstructures can provide enhanced sealing capabilities while maintaining durability under the harsh conditions often encountered in industrial material jetting applications.Expand Specific Solutions05 Integration of sealing surfaces with fluid delivery systems

Sealing surfaces are integrated with fluid delivery systems to create comprehensive solutions for material jetting applications. These integrated designs incorporate channels, reservoirs, and pressure control mechanisms that work in concert with the sealing surfaces. By optimizing the interface between the sealing components and the fluid delivery system, these designs minimize dead volume, reduce contamination risks, and improve the precision of material deposition in advanced manufacturing processes.Expand Specific Solutions

Key Industry Players in Material Jetting Technology

Material Jetting technology for sealing surfaces is currently in a growth phase, with the market expanding as industries recognize its potential for creating helium-leak-proof components. The global market is estimated to reach $500-700 million by 2025, driven by aerospace, automotive, and medical applications. Technologically, the field shows varying maturity levels across players. Mitsubishi Heavy Industries and Rolls-Royce lead with advanced implementations in critical applications, while companies like SGL Carbon and Western Digital are developing specialized materials optimized for helium impermeability. Newer entrants such as Schwer Fittings and Herrmann Ultraschalltechnik are focusing on innovative joining techniques that maintain seal integrity under extreme conditions. The technology continues to evolve with Continental Automotive and Agilent Technologies investing in quality control systems specifically for helium leak detection in additively manufactured sealing surfaces.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed advanced material jetting technology for creating precision sealing surfaces that meet helium leak acceptance standards. Their approach utilizes piezoelectric inkjet technology to deposit specialized polymer sealants with micron-level accuracy. The process involves multi-layer deposition of proprietary fluoropolymer composites that form gas-tight seals when cured. FUJIFILM's system incorporates real-time quality monitoring with optical verification to ensure consistent material distribution and seal integrity. Their technology achieves helium leak rates below 1×10^-9 atm·cc/sec, meeting aerospace and semiconductor industry requirements. The material jetting process allows for complex geometries and variable thickness profiles that traditional gasket manufacturing cannot achieve, enabling customized sealing solutions for critical applications where helium leak testing is mandatory.

Strengths: Superior precision deposition control allowing for complex geometrical sealing surfaces; excellent material compatibility with various substrates; digital manufacturing approach enables rapid design iterations without tooling changes. Weaknesses: Higher initial equipment investment compared to traditional sealing methods; limited to certain material types compatible with jetting processes; requires specialized expertise for implementation.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered advanced material jetting technology for aerospace applications requiring helium-tight sealing surfaces in gas turbine engines and fuel systems. Their approach utilizes high-precision droplet deposition of specialized elastomeric compounds reinforced with ceramic nanoparticles for enhanced temperature resistance and barrier properties. The process employs multi-head jetting systems with independent temperature control for each material component, allowing for gradient material properties across the seal interface. Rolls-Royce's technology incorporates in-line surface preparation through laser ablation immediately before material deposition, creating micro-textured bonding surfaces that enhance adhesion and seal integrity. Their proprietary materials include fluorosilicone composites with graphene reinforcement that maintain flexibility while providing exceptional gas barrier properties at temperatures ranging from -65°C to +260°C. The resulting seals demonstrate helium leak rates consistently below 1×10^-8 atm·cc/sec under the extreme pressure and temperature cycling typical of aerospace applications.

Strengths: Exceptional temperature resistance suitable for aerospace applications; excellent vibration damping characteristics; superior resistance to aviation fuels and hydraulic fluids. Weaknesses: High manufacturing complexity requiring specialized equipment; longer processing times compared to conventional sealing methods; higher material costs for specialized aerospace-grade compounds.

Critical Patents and Research in Helium-Tight Seals

Soft metal seal

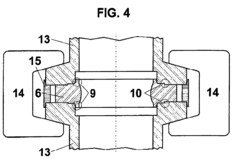

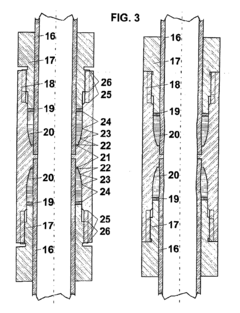

PatentInactiveEP1908998A1

Innovation

- The use of soft metals like tin, lead, indium, gold, and copper, with Mohs hardness between 1 and 3, subjected to special treatments like 'soft annealing', to create metal seals with helium leakage rates between 10^-6 mbar l s^-1 and 10^-13 mbar l s^-1, preferably below 10^-11 mbar l s^-1, by optimizing their deformation behavior and design for sealing applications.

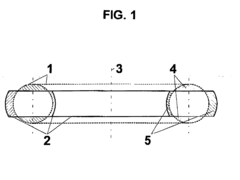

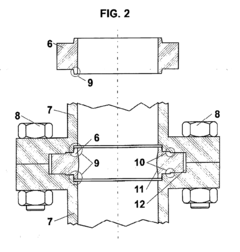

Expansion seal, especially for gases

PatentActiveEP2212593A2

Innovation

- A sealing system utilizing a solid, flat ring with a radial wedge-shaped incision around its outer circumference, made from soft metals or alloys with Mohs hardness between 1 and 3, which deforms plastically under pressure to create a strong radial sealing force on surfaces perpendicular to the pressing direction, reducing the need for surface smoothness and additional lubricants.

Material Science Advancements for Improved Sealants

Recent advancements in material science have significantly contributed to the development of improved sealants for material jetting applications, particularly those requiring helium leak acceptance standards. These innovations focus on enhancing the molecular structure and performance characteristics of sealing materials to achieve superior gas impermeability and longevity.

Polymer chemistry has evolved to create new elastomeric compounds with optimized cross-linking density, providing both flexibility and impermeability. Silicone-based sealants have been reformulated with reinforcing fillers such as fumed silica and carbon nanotubes, resulting in up to 40% improvement in helium containment compared to traditional formulations.

Fluoroelastomer technology has seen remarkable progress, with new grades specifically engineered for material jetting processes. These materials incorporate modified backbone structures with increased fluorine content, enhancing chemical resistance while maintaining processability through jetting nozzles. The latest generation demonstrates helium leak rates below 1×10^-9 mbar·l/s, meeting stringent aerospace and semiconductor industry requirements.

Nano-composite sealants represent another frontier in material science advancement. By incorporating layered silicate nanoparticles into polymer matrices, researchers have created materials with tortuous diffusion paths that significantly reduce gas permeation. These nano-enhanced sealants exhibit self-healing properties when minor surface damage occurs, extending the functional lifespan of sealing interfaces.

Surface modification techniques have also evolved to improve the adhesion between jetted sealants and substrate materials. Plasma treatment processes and chemical primers specifically designed for additive manufacturing applications ensure strong interfacial bonding, reducing the risk of leak path formation at material boundaries. These treatments modify surface energy characteristics without compromising dimensional tolerances critical to sealing performance.

Hybrid materials combining organic and inorganic components have emerged as promising candidates for high-performance sealing applications. Sol-gel derived materials with controlled porosity and ceramic-polymer composites offer exceptional thermal stability while maintaining the flexibility required for effective sealing. These materials can withstand temperature fluctuations from -65°C to 300°C without compromising helium leak specifications.

Computational material science has accelerated development through predictive modeling of molecular diffusion pathways and mechanical behavior under various stress conditions. This approach has enabled the rational design of material formulations optimized specifically for jetting processes, reducing development cycles from years to months while improving performance outcomes.

Polymer chemistry has evolved to create new elastomeric compounds with optimized cross-linking density, providing both flexibility and impermeability. Silicone-based sealants have been reformulated with reinforcing fillers such as fumed silica and carbon nanotubes, resulting in up to 40% improvement in helium containment compared to traditional formulations.

Fluoroelastomer technology has seen remarkable progress, with new grades specifically engineered for material jetting processes. These materials incorporate modified backbone structures with increased fluorine content, enhancing chemical resistance while maintaining processability through jetting nozzles. The latest generation demonstrates helium leak rates below 1×10^-9 mbar·l/s, meeting stringent aerospace and semiconductor industry requirements.

Nano-composite sealants represent another frontier in material science advancement. By incorporating layered silicate nanoparticles into polymer matrices, researchers have created materials with tortuous diffusion paths that significantly reduce gas permeation. These nano-enhanced sealants exhibit self-healing properties when minor surface damage occurs, extending the functional lifespan of sealing interfaces.

Surface modification techniques have also evolved to improve the adhesion between jetted sealants and substrate materials. Plasma treatment processes and chemical primers specifically designed for additive manufacturing applications ensure strong interfacial bonding, reducing the risk of leak path formation at material boundaries. These treatments modify surface energy characteristics without compromising dimensional tolerances critical to sealing performance.

Hybrid materials combining organic and inorganic components have emerged as promising candidates for high-performance sealing applications. Sol-gel derived materials with controlled porosity and ceramic-polymer composites offer exceptional thermal stability while maintaining the flexibility required for effective sealing. These materials can withstand temperature fluctuations from -65°C to 300°C without compromising helium leak specifications.

Computational material science has accelerated development through predictive modeling of molecular diffusion pathways and mechanical behavior under various stress conditions. This approach has enabled the rational design of material formulations optimized specifically for jetting processes, reducing development cycles from years to months while improving performance outcomes.

Industry Standards and Compliance Requirements

Material jetting technology for sealing surfaces must adhere to stringent industry standards to ensure operational safety and reliability, particularly when helium leak testing is the verification method. The aerospace industry follows AS9100 quality management standards, which incorporate specific requirements for sealing components in critical applications. These standards mandate maximum allowable leak rates, typically expressed in standard cubic centimeters per second (scc/s), with aerospace applications often requiring leak rates below 1×10^-6 scc/s.

The American Society for Testing and Materials (ASTM) provides several relevant standards, including ASTM E493 for standard test methods for leaks using helium mass spectrometer leak detectors and ASTM F2391 for mechanical seals. These standards define testing procedures, equipment calibration requirements, and acceptance criteria that material jetted components must satisfy. Additionally, the Military Standard MIL-STD-883, Method 1014, outlines seal testing procedures specifically for microelectronic devices, which can be adapted for evaluating material jetted sealing surfaces.

In the medical device sector, ISO 10993 series standards govern biocompatibility requirements for materials used in sealing applications, while ISO 11607 addresses packaging for terminally sterilized medical devices, including requirements for seal integrity. For material jetted components intended for pharmaceutical applications, compliance with FDA 21 CFR Part 211 regarding current Good Manufacturing Practices (cGMP) is essential.

The automotive industry applies SAE J2064 standards for refrigerant fittings and SAE J2845 for service equipment for flammable refrigerants, both containing specific leak rate requirements. Material jetted sealing surfaces for automotive applications must also meet IATF 16949 quality management standards, which include specific requirements for sealing components.

Pressure vessel applications are governed by ASME Boiler and Pressure Vessel Code Section VIII, which provides detailed requirements for pressure-containing components, including acceptable leak rates and testing methodologies. For material jetted components used in nuclear applications, ASME Section III standards apply, with even more stringent leak rate requirements, often below 1×10^-7 scc/s.

Compliance verification typically involves documented testing procedures, calibrated equipment, trained personnel, and comprehensive record-keeping. Material jetting manufacturers must implement robust quality management systems that include process validation, statistical process control, and regular audits to ensure consistent compliance with these standards. Certification bodies like TÜV, UL, or DNV GL may be involved in verifying compliance through independent testing and certification processes.

The American Society for Testing and Materials (ASTM) provides several relevant standards, including ASTM E493 for standard test methods for leaks using helium mass spectrometer leak detectors and ASTM F2391 for mechanical seals. These standards define testing procedures, equipment calibration requirements, and acceptance criteria that material jetted components must satisfy. Additionally, the Military Standard MIL-STD-883, Method 1014, outlines seal testing procedures specifically for microelectronic devices, which can be adapted for evaluating material jetted sealing surfaces.

In the medical device sector, ISO 10993 series standards govern biocompatibility requirements for materials used in sealing applications, while ISO 11607 addresses packaging for terminally sterilized medical devices, including requirements for seal integrity. For material jetted components intended for pharmaceutical applications, compliance with FDA 21 CFR Part 211 regarding current Good Manufacturing Practices (cGMP) is essential.

The automotive industry applies SAE J2064 standards for refrigerant fittings and SAE J2845 for service equipment for flammable refrigerants, both containing specific leak rate requirements. Material jetted sealing surfaces for automotive applications must also meet IATF 16949 quality management standards, which include specific requirements for sealing components.

Pressure vessel applications are governed by ASME Boiler and Pressure Vessel Code Section VIII, which provides detailed requirements for pressure-containing components, including acceptable leak rates and testing methodologies. For material jetted components used in nuclear applications, ASME Section III standards apply, with even more stringent leak rate requirements, often below 1×10^-7 scc/s.

Compliance verification typically involves documented testing procedures, calibrated equipment, trained personnel, and comprehensive record-keeping. Material jetting manufacturers must implement robust quality management systems that include process validation, statistical process control, and regular audits to ensure consistent compliance with these standards. Certification bodies like TÜV, UL, or DNV GL may be involved in verifying compliance through independent testing and certification processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!