How Sodium Acetate Boosts Probiotic Manufacturing Processes?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Probiotic Manufacturing Evolution and Objectives

Probiotic manufacturing has undergone significant evolution over the past few decades, driven by increasing consumer demand for health-promoting products and advancements in biotechnology. The journey began with traditional fermentation methods used in dairy products and has since expanded to include a wide range of probiotic strains and delivery formats.

In the early stages, probiotic production was primarily focused on yogurt and other fermented dairy products. As research revealed the potential health benefits of specific bacterial strains, manufacturers began to isolate and cultivate these microorganisms in controlled environments. This shift marked the beginning of modern probiotic manufacturing processes.

The advent of freeze-drying technology in the mid-20th century revolutionized probiotic production, allowing for the preservation of live bacteria in a stable, shelf-stable form. This innovation paved the way for probiotic supplements and enabled the incorporation of probiotics into a variety of non-dairy food products.

Recent years have seen a surge in research and development efforts aimed at enhancing probiotic viability, stability, and efficacy. Manufacturers have explored various techniques to protect probiotic strains during production, storage, and transit through the digestive system. These include microencapsulation, novel delivery systems, and the use of prebiotics to support probiotic growth.

The current objectives in probiotic manufacturing center around several key areas. Firstly, there is a focus on improving the scalability and efficiency of production processes to meet growing global demand. This involves optimizing fermentation conditions, developing more robust strains, and streamlining downstream processing.

Secondly, manufacturers are striving to enhance the stability and shelf life of probiotic products. This includes investigating new preservation methods, packaging innovations, and formulation techniques that can maintain probiotic viability under various environmental conditions.

Another critical objective is to expand the range of probiotic strains that can be effectively manufactured and delivered to consumers. This involves identifying and characterizing novel probiotic candidates, as well as developing tailored production methods for each strain.

Furthermore, there is a growing emphasis on sustainability in probiotic manufacturing. Companies are exploring ways to reduce energy consumption, minimize waste, and utilize eco-friendly materials in their production processes and packaging.

In the context of sodium acetate's role in boosting probiotic manufacturing processes, the industry is continually seeking innovative approaches to enhance bacterial growth, survival, and functionality. The use of sodium acetate as a potential growth promoter or stabilizing agent represents one such avenue of exploration, aligning with the broader objectives of improving production efficiency and product quality in the evolving landscape of probiotic manufacturing.

In the early stages, probiotic production was primarily focused on yogurt and other fermented dairy products. As research revealed the potential health benefits of specific bacterial strains, manufacturers began to isolate and cultivate these microorganisms in controlled environments. This shift marked the beginning of modern probiotic manufacturing processes.

The advent of freeze-drying technology in the mid-20th century revolutionized probiotic production, allowing for the preservation of live bacteria in a stable, shelf-stable form. This innovation paved the way for probiotic supplements and enabled the incorporation of probiotics into a variety of non-dairy food products.

Recent years have seen a surge in research and development efforts aimed at enhancing probiotic viability, stability, and efficacy. Manufacturers have explored various techniques to protect probiotic strains during production, storage, and transit through the digestive system. These include microencapsulation, novel delivery systems, and the use of prebiotics to support probiotic growth.

The current objectives in probiotic manufacturing center around several key areas. Firstly, there is a focus on improving the scalability and efficiency of production processes to meet growing global demand. This involves optimizing fermentation conditions, developing more robust strains, and streamlining downstream processing.

Secondly, manufacturers are striving to enhance the stability and shelf life of probiotic products. This includes investigating new preservation methods, packaging innovations, and formulation techniques that can maintain probiotic viability under various environmental conditions.

Another critical objective is to expand the range of probiotic strains that can be effectively manufactured and delivered to consumers. This involves identifying and characterizing novel probiotic candidates, as well as developing tailored production methods for each strain.

Furthermore, there is a growing emphasis on sustainability in probiotic manufacturing. Companies are exploring ways to reduce energy consumption, minimize waste, and utilize eco-friendly materials in their production processes and packaging.

In the context of sodium acetate's role in boosting probiotic manufacturing processes, the industry is continually seeking innovative approaches to enhance bacterial growth, survival, and functionality. The use of sodium acetate as a potential growth promoter or stabilizing agent represents one such avenue of exploration, aligning with the broader objectives of improving production efficiency and product quality in the evolving landscape of probiotic manufacturing.

Market Demand for Enhanced Probiotic Production

The global probiotic market has been experiencing significant growth, driven by increasing consumer awareness of the health benefits associated with probiotic consumption. This trend has created a substantial demand for enhanced probiotic production processes, particularly those that can improve efficiency, yield, and product quality.

The market for probiotics is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. This growth is fueled by factors such as the rising prevalence of digestive disorders, growing interest in preventive healthcare, and the expanding application of probiotics in various industries beyond traditional food and beverages.

Consumer preferences are shifting towards more potent and diverse probiotic strains, creating a need for advanced manufacturing techniques that can deliver higher concentrations of viable bacteria. This demand is particularly evident in the functional food and dietary supplement sectors, where consumers are seeking products with enhanced probiotic content and improved shelf stability.

The pharmaceutical industry is also contributing to the increased demand for enhanced probiotic production. As research continues to uncover new potential therapeutic applications for probiotics, there is a growing need for manufacturing processes that can meet the stringent quality and purity requirements of pharmaceutical-grade probiotics.

In the food and beverage industry, manufacturers are looking for ways to incorporate probiotics into a wider range of products while maintaining their viability throughout the production process and shelf life. This has led to a demand for innovative manufacturing techniques that can protect probiotic strains during processing and storage.

The dairy industry, traditionally a major player in the probiotic market, is seeking methods to increase the probiotic content in yogurts, kefirs, and other fermented products. This is in response to consumer demand for products with higher concentrations of beneficial bacteria and longer shelf lives.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid growth in probiotic consumption, driven by increasing disposable incomes and growing health consciousness. This geographical expansion is creating new opportunities for probiotic manufacturers and driving the need for scalable and cost-effective production methods.

The demand for enhanced probiotic production is also being influenced by sustainability concerns. Consumers and regulatory bodies are increasingly focused on environmentally friendly manufacturing processes, creating a market for production methods that reduce waste, energy consumption, and overall environmental impact.

The market for probiotics is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. This growth is fueled by factors such as the rising prevalence of digestive disorders, growing interest in preventive healthcare, and the expanding application of probiotics in various industries beyond traditional food and beverages.

Consumer preferences are shifting towards more potent and diverse probiotic strains, creating a need for advanced manufacturing techniques that can deliver higher concentrations of viable bacteria. This demand is particularly evident in the functional food and dietary supplement sectors, where consumers are seeking products with enhanced probiotic content and improved shelf stability.

The pharmaceutical industry is also contributing to the increased demand for enhanced probiotic production. As research continues to uncover new potential therapeutic applications for probiotics, there is a growing need for manufacturing processes that can meet the stringent quality and purity requirements of pharmaceutical-grade probiotics.

In the food and beverage industry, manufacturers are looking for ways to incorporate probiotics into a wider range of products while maintaining their viability throughout the production process and shelf life. This has led to a demand for innovative manufacturing techniques that can protect probiotic strains during processing and storage.

The dairy industry, traditionally a major player in the probiotic market, is seeking methods to increase the probiotic content in yogurts, kefirs, and other fermented products. This is in response to consumer demand for products with higher concentrations of beneficial bacteria and longer shelf lives.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid growth in probiotic consumption, driven by increasing disposable incomes and growing health consciousness. This geographical expansion is creating new opportunities for probiotic manufacturers and driving the need for scalable and cost-effective production methods.

The demand for enhanced probiotic production is also being influenced by sustainability concerns. Consumers and regulatory bodies are increasingly focused on environmentally friendly manufacturing processes, creating a market for production methods that reduce waste, energy consumption, and overall environmental impact.

Sodium Acetate in Probiotic Manufacturing: Current Status

Sodium acetate has emerged as a crucial component in enhancing probiotic manufacturing processes, offering significant benefits to the industry. Currently, its application is widespread across various stages of probiotic production, from fermentation to preservation. The compound's ability to act as a pH buffer and nutrient source has made it an invaluable tool for optimizing growth conditions and maintaining the viability of probiotic strains.

In fermentation processes, sodium acetate serves as an effective growth promoter for many probiotic species. It provides a readily available source of acetate, which can be metabolized by bacteria to generate energy and biomass. This property has led to its incorporation in many commercial growth media formulations, resulting in improved yields and reduced production times. Additionally, the buffering capacity of sodium acetate helps maintain optimal pH levels during fermentation, preventing the detrimental effects of acid accumulation on probiotic viability.

The preservative properties of sodium acetate are also being leveraged in the current probiotic manufacturing landscape. Its ability to inhibit the growth of undesirable microorganisms while maintaining the viability of beneficial probiotic strains has made it a preferred choice for extending the shelf life of probiotic products. This dual functionality addresses one of the major challenges in probiotic manufacturing – maintaining product stability and efficacy throughout the supply chain.

Recent advancements in probiotic encapsulation techniques have further expanded the role of sodium acetate in manufacturing processes. It is being used as a component in microencapsulation matrices, providing an additional layer of protection for probiotic cells against harsh environmental conditions. This application has shown promise in improving the survival rates of probiotics during processing, storage, and gastrointestinal transit.

The current status of sodium acetate in probiotic manufacturing also reflects a growing trend towards sustainable and cost-effective production methods. As a relatively inexpensive and readily available compound, sodium acetate offers manufacturers a means to optimize their processes without significantly increasing production costs. This aligns well with the industry's efforts to make probiotic products more accessible to a broader consumer base.

However, it is important to note that the use of sodium acetate is not without challenges. Regulatory considerations and consumer preferences for "clean label" products have prompted ongoing research into optimizing its usage levels and exploring natural alternatives. Despite these challenges, the current status of sodium acetate in probiotic manufacturing remains strong, with continued innovation and research aimed at further enhancing its applications and addressing any limitations.

In fermentation processes, sodium acetate serves as an effective growth promoter for many probiotic species. It provides a readily available source of acetate, which can be metabolized by bacteria to generate energy and biomass. This property has led to its incorporation in many commercial growth media formulations, resulting in improved yields and reduced production times. Additionally, the buffering capacity of sodium acetate helps maintain optimal pH levels during fermentation, preventing the detrimental effects of acid accumulation on probiotic viability.

The preservative properties of sodium acetate are also being leveraged in the current probiotic manufacturing landscape. Its ability to inhibit the growth of undesirable microorganisms while maintaining the viability of beneficial probiotic strains has made it a preferred choice for extending the shelf life of probiotic products. This dual functionality addresses one of the major challenges in probiotic manufacturing – maintaining product stability and efficacy throughout the supply chain.

Recent advancements in probiotic encapsulation techniques have further expanded the role of sodium acetate in manufacturing processes. It is being used as a component in microencapsulation matrices, providing an additional layer of protection for probiotic cells against harsh environmental conditions. This application has shown promise in improving the survival rates of probiotics during processing, storage, and gastrointestinal transit.

The current status of sodium acetate in probiotic manufacturing also reflects a growing trend towards sustainable and cost-effective production methods. As a relatively inexpensive and readily available compound, sodium acetate offers manufacturers a means to optimize their processes without significantly increasing production costs. This aligns well with the industry's efforts to make probiotic products more accessible to a broader consumer base.

However, it is important to note that the use of sodium acetate is not without challenges. Regulatory considerations and consumer preferences for "clean label" products have prompted ongoing research into optimizing its usage levels and exploring natural alternatives. Despite these challenges, the current status of sodium acetate in probiotic manufacturing remains strong, with continued innovation and research aimed at further enhancing its applications and addressing any limitations.

Sodium Acetate Integration in Probiotic Production

01 Sodium acetate as a heat storage material

Sodium acetate trihydrate is used as a phase change material for thermal energy storage. It has a high latent heat of fusion and can store and release heat effectively during phase transitions. This property makes it suitable for various applications in heating and cooling systems.- Sodium acetate as a heat storage material: Sodium acetate is utilized as a phase change material for thermal energy storage. Its ability to absorb and release heat during phase transitions makes it effective for heat storage applications, such as in heating pads or thermal management systems.

- Sodium acetate in chemical synthesis: Sodium acetate is employed as a reagent or catalyst in various chemical synthesis processes. It can be used to boost reaction rates, adjust pH, or serve as a source of acetate ions in organic and inorganic reactions.

- Sodium acetate in food preservation: Sodium acetate is used as a food preservative and flavor enhancer. It can help extend the shelf life of food products by inhibiting microbial growth and maintaining pH balance.

- Sodium acetate in textile processing: Sodium acetate is utilized in textile processing as a pH regulator and dyeing auxiliary. It can improve dye uptake, color fastness, and overall fabric quality in various textile treatments.

- Sodium acetate in environmental applications: Sodium acetate is employed in environmental remediation and wastewater treatment processes. It can serve as a carbon source for microbial growth in bioremediation or as a pH buffer in water treatment systems.

02 Sodium acetate in food preservation

Sodium acetate is utilized as a food preservative and pH regulator in various food products. It helps extend shelf life by inhibiting microbial growth and maintaining the desired acidity level in foods. This application is particularly useful in processed and packaged food industries.Expand Specific Solutions03 Sodium acetate in chemical synthesis

Sodium acetate serves as a reagent or catalyst in various chemical synthesis processes. It is used in organic reactions, such as esterification and condensation, and can act as a base or buffer in certain chemical transformations. This versatility makes it valuable in pharmaceutical and industrial chemical production.Expand Specific Solutions04 Sodium acetate in textile industry

Sodium acetate finds applications in the textile industry, particularly in dyeing and printing processes. It can act as a buffer, pH regulator, or fixing agent for dyes. This helps improve color fastness and overall quality of textile products.Expand Specific Solutions05 Sodium acetate in environmental applications

Sodium acetate is used in various environmental applications, including wastewater treatment and air pollution control. It can serve as a carbon source for denitrification processes in wastewater treatment plants and as a de-icing agent for roads and runways, offering a more environmentally friendly alternative to traditional salt-based de-icers.Expand Specific Solutions

Key Players in Probiotic and Sodium Acetate Industries

The sodium acetate market for probiotic manufacturing is in a growth phase, driven by increasing demand for probiotics in various industries. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the use of sodium acetate in probiotic production is relatively mature, with companies like Ajinomoto Co., Inc. and DSM IP Assets BV leading in innovation. However, there's room for advancement in optimizing yield and stability. Emerging players such as Wecare Probiotics Co., Ltd. and Master Supplements, Inc. are also contributing to market dynamics, focusing on specialized applications and niche products. The competitive landscape is characterized by a mix of established multinational corporations and specialized probiotic manufacturers, indicating a diverse and evolving market.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto has pioneered a sodium acetate-based probiotic enhancement system that focuses on improving the stress resistance of probiotic strains during manufacturing and storage. Their approach involves a two-step process: first, incorporating sodium acetate into the growth medium to stimulate the production of stress-response proteins in probiotic cells[4]. Second, they use a proprietary encapsulation technique that creates a protective layer around the probiotics, with sodium acetate integrated into this layer[5]. This dual approach not only boosts probiotic growth but also significantly enhances their survival rates during processing and storage. Ajinomoto reports a 40% increase in probiotic survival rates after 12 months of storage compared to conventional methods[6].

Strengths: Enhanced probiotic stability and shelf-life, improved stress resistance. Weaknesses: Complex manufacturing process, may increase production costs.

Master Supplements, Inc.

Technical Solution: Master Supplements has focused on leveraging sodium acetate to enhance the acid tolerance of probiotic strains, particularly for products designed to survive the harsh gastric environment. Their proprietary process involves a gradual adaptation of probiotic cultures to increasing concentrations of sodium acetate during fermentation[10]. This adaptation process triggers changes in the cell membrane composition and stress response mechanisms of the probiotics, making them more resilient to acidic conditions. Additionally, Master Supplements has developed a sodium acetate-based microencapsulation technique that provides an extra layer of protection for the probiotics[11]. The company reports that probiotics produced using this method show a 60% higher survival rate in simulated gastric conditions compared to conventionally produced strains[12].

Strengths: Significantly improved probiotic survival in acidic environments, potential for targeted delivery to the intestines. Weaknesses: Longer production time due to adaptation process, may limit the types of probiotic strains that can be used.

Innovations in Sodium Acetate-Enhanced Probiotic Cultivation

Novel process for producing lactobacillus rhamnosus

PatentWO2024252019A1

Innovation

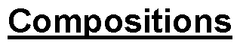

- A novel process involving fermentation in a lactose-free medium with ammonium acetate present, using sodium hydroxide and/or potassium hydroxide to control pH, aiming for an end pH of 3.0 or higher, to enhance the CFU/gram and viable cell count of Lactobacillus rhamnosus.

Powder comprising lactate-coated particles and method for the preparation thereof

PatentWO2021136787A1

Innovation

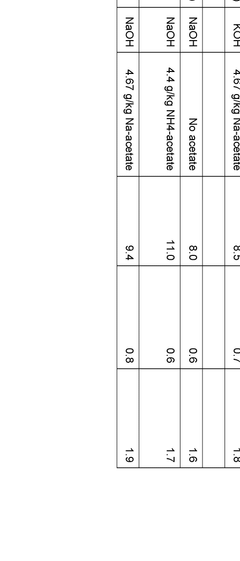

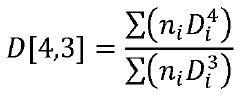

- A lactate-coated powder is produced by coating C1-2 alkane carboxylate particles with a sodium lactate layer, resulting in improved flowability, stability, and homogeneity, with a smaller particle size range of 40 to 1500 μm, and a weight ratio of C1-2 alkane carboxylates to sodium lactate between 1:2 to 2:1.

Regulatory Framework for Probiotic Manufacturing Additives

The regulatory framework for probiotic manufacturing additives is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of probiotic products. In the context of sodium acetate's use in probiotic manufacturing processes, regulatory bodies worldwide have established guidelines and standards to govern its application.

The United States Food and Drug Administration (FDA) classifies sodium acetate as Generally Recognized as Safe (GRAS) when used as a food ingredient. However, its specific use in probiotic manufacturing requires adherence to Good Manufacturing Practices (GMPs) and may necessitate additional documentation to demonstrate its safety and efficacy in this context.

In the European Union, the European Food Safety Authority (EFSA) oversees the regulation of food additives, including those used in probiotic manufacturing. Sodium acetate is listed as an approved food additive (E262) under Regulation (EC) No 1333/2008. Manufacturers must comply with specific purity criteria and usage limits set forth by the EFSA.

The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. These standards include guidelines for the use of food additives in probiotic products, which manufacturers must consider when incorporating sodium acetate into their processes.

Regulatory bodies in other major markets, such as Japan's Ministry of Health, Labour and Welfare and Health Canada, have their own frameworks for assessing and approving additives used in probiotic manufacturing. These often involve rigorous safety assessments and may require pre-market approval for novel applications of additives like sodium acetate.

It is important to note that regulations surrounding probiotic manufacturing additives are not static. As new research emerges and manufacturing techniques evolve, regulatory bodies continually update their guidelines. This dynamic nature of the regulatory landscape necessitates that manufacturers stay informed about the latest developments and maintain open communication with regulatory authorities.

Compliance with these regulatory frameworks is essential for manufacturers seeking to incorporate sodium acetate into their probiotic production processes. This includes maintaining detailed documentation of the additive's sourcing, quality control measures, and its specific role in enhancing probiotic viability and stability. Manufacturers must also be prepared to demonstrate that the use of sodium acetate does not compromise the safety or efficacy of the final probiotic product.

The United States Food and Drug Administration (FDA) classifies sodium acetate as Generally Recognized as Safe (GRAS) when used as a food ingredient. However, its specific use in probiotic manufacturing requires adherence to Good Manufacturing Practices (GMPs) and may necessitate additional documentation to demonstrate its safety and efficacy in this context.

In the European Union, the European Food Safety Authority (EFSA) oversees the regulation of food additives, including those used in probiotic manufacturing. Sodium acetate is listed as an approved food additive (E262) under Regulation (EC) No 1333/2008. Manufacturers must comply with specific purity criteria and usage limits set forth by the EFSA.

The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. These standards include guidelines for the use of food additives in probiotic products, which manufacturers must consider when incorporating sodium acetate into their processes.

Regulatory bodies in other major markets, such as Japan's Ministry of Health, Labour and Welfare and Health Canada, have their own frameworks for assessing and approving additives used in probiotic manufacturing. These often involve rigorous safety assessments and may require pre-market approval for novel applications of additives like sodium acetate.

It is important to note that regulations surrounding probiotic manufacturing additives are not static. As new research emerges and manufacturing techniques evolve, regulatory bodies continually update their guidelines. This dynamic nature of the regulatory landscape necessitates that manufacturers stay informed about the latest developments and maintain open communication with regulatory authorities.

Compliance with these regulatory frameworks is essential for manufacturers seeking to incorporate sodium acetate into their probiotic production processes. This includes maintaining detailed documentation of the additive's sourcing, quality control measures, and its specific role in enhancing probiotic viability and stability. Manufacturers must also be prepared to demonstrate that the use of sodium acetate does not compromise the safety or efficacy of the final probiotic product.

Environmental Impact of Sodium Acetate in Probiotic Production

The environmental impact of sodium acetate in probiotic production is a crucial aspect to consider as the industry continues to grow. Sodium acetate, while beneficial for boosting probiotic manufacturing processes, can have both positive and negative effects on the environment.

One of the primary environmental benefits of using sodium acetate in probiotic production is its potential to reduce overall energy consumption. By enhancing the growth and survival rates of probiotic bacteria, sodium acetate allows for more efficient production processes. This increased efficiency can lead to shorter fermentation times and lower energy requirements for maintaining optimal growth conditions.

However, the production of sodium acetate itself may contribute to environmental concerns. The manufacturing process typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These chemical processes can generate waste products and consume energy, potentially offsetting some of the environmental gains achieved in probiotic production.

Water usage is another environmental factor to consider. While sodium acetate can improve the stability of probiotics in aqueous solutions, its use may lead to increased water consumption during the manufacturing process. This could strain local water resources, especially in areas where water scarcity is a concern.

The disposal of sodium acetate-containing waste from probiotic production facilities also requires careful management. If not properly treated, these waste streams could potentially impact local ecosystems, particularly aquatic environments. Elevated levels of sodium and acetate ions in water bodies can disrupt natural pH balances and affect aquatic life.

On the positive side, the use of sodium acetate in probiotic production can contribute to reduced food waste. By extending the shelf life of probiotic products, it helps minimize spoilage and the need for frequent product replacements. This indirectly reduces the environmental impact associated with food production and distribution.

Furthermore, the enhanced viability of probiotics facilitated by sodium acetate can lead to more effective products. This improved efficacy may result in reduced consumption of other less environmentally friendly alternatives, such as certain antibiotics or chemical preservatives in food products.

In terms of land use, the efficiency gains from sodium acetate usage in probiotic manufacturing could potentially reduce the need for expanding production facilities. This may help preserve natural habitats and minimize the environmental footprint of the industry's physical infrastructure.

As the probiotic industry continues to expand, it is essential to conduct comprehensive life cycle assessments of sodium acetate use in production processes. These assessments should consider factors such as raw material sourcing, energy consumption, waste generation, and potential impacts on biodiversity. By understanding the full environmental implications, manufacturers can make informed decisions to optimize their processes and minimize negative ecological impacts.

One of the primary environmental benefits of using sodium acetate in probiotic production is its potential to reduce overall energy consumption. By enhancing the growth and survival rates of probiotic bacteria, sodium acetate allows for more efficient production processes. This increased efficiency can lead to shorter fermentation times and lower energy requirements for maintaining optimal growth conditions.

However, the production of sodium acetate itself may contribute to environmental concerns. The manufacturing process typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These chemical processes can generate waste products and consume energy, potentially offsetting some of the environmental gains achieved in probiotic production.

Water usage is another environmental factor to consider. While sodium acetate can improve the stability of probiotics in aqueous solutions, its use may lead to increased water consumption during the manufacturing process. This could strain local water resources, especially in areas where water scarcity is a concern.

The disposal of sodium acetate-containing waste from probiotic production facilities also requires careful management. If not properly treated, these waste streams could potentially impact local ecosystems, particularly aquatic environments. Elevated levels of sodium and acetate ions in water bodies can disrupt natural pH balances and affect aquatic life.

On the positive side, the use of sodium acetate in probiotic production can contribute to reduced food waste. By extending the shelf life of probiotic products, it helps minimize spoilage and the need for frequent product replacements. This indirectly reduces the environmental impact associated with food production and distribution.

Furthermore, the enhanced viability of probiotics facilitated by sodium acetate can lead to more effective products. This improved efficacy may result in reduced consumption of other less environmentally friendly alternatives, such as certain antibiotics or chemical preservatives in food products.

In terms of land use, the efficiency gains from sodium acetate usage in probiotic manufacturing could potentially reduce the need for expanding production facilities. This may help preserve natural habitats and minimize the environmental footprint of the industry's physical infrastructure.

As the probiotic industry continues to expand, it is essential to conduct comprehensive life cycle assessments of sodium acetate use in production processes. These assessments should consider factors such as raw material sourcing, energy consumption, waste generation, and potential impacts on biodiversity. By understanding the full environmental implications, manufacturers can make informed decisions to optimize their processes and minimize negative ecological impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!