How Sodium Acetate Enhances Industrial Waste Management?

JUN 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate in Waste Management: Background and Objectives

Sodium acetate has emerged as a promising agent in the field of industrial waste management, offering innovative solutions to longstanding environmental challenges. The evolution of waste management technologies has been driven by the increasing global focus on sustainability and environmental protection. In this context, sodium acetate presents a unique opportunity to address several key issues in waste treatment and disposal.

The primary objective of utilizing sodium acetate in waste management is to enhance the efficiency and effectiveness of various treatment processes. This compound, with its unique chemical properties, has shown potential in areas such as wastewater treatment, landfill leachate management, and industrial sludge processing. By incorporating sodium acetate into these processes, industries aim to reduce environmental impact, improve resource recovery, and achieve compliance with increasingly stringent environmental regulations.

Historically, waste management has evolved from simple disposal methods to complex, integrated systems designed to minimize environmental harm and maximize resource recovery. The introduction of sodium acetate into this field represents a continuation of this trend towards more sophisticated and environmentally friendly waste management solutions. Its application aligns with the broader goals of circular economy principles, where waste is viewed as a potential resource rather than a problem to be disposed of.

The technical goals associated with sodium acetate in waste management are multifaceted. Firstly, there is a focus on improving the efficiency of biological treatment processes in wastewater management. Sodium acetate serves as an excellent carbon source for microorganisms, potentially enhancing the performance of biological treatment systems. Secondly, researchers are exploring its role in heavy metal removal from industrial effluents, leveraging its ability to form complexes with metal ions.

Another significant objective is the optimization of anaerobic digestion processes in organic waste treatment. Sodium acetate can act as a precursor for methane production, potentially increasing biogas yields in anaerobic digesters. This aligns with the growing interest in waste-to-energy technologies and the broader push towards renewable energy sources.

Furthermore, the use of sodium acetate in waste management is being investigated for its potential to improve the stability and safety of landfills. By influencing the chemical environment within landfills, it may help in reducing the production of harmful leachates and mitigating the release of greenhouse gases.

As research in this field progresses, the overarching goal is to develop comprehensive, sustainable waste management solutions that integrate sodium acetate into existing and new technologies. This involves not only technical advancements but also considerations of economic viability, scalability, and long-term environmental impact. The ongoing exploration of sodium acetate's applications in waste management reflects the industry's commitment to innovation and environmental stewardship.

The primary objective of utilizing sodium acetate in waste management is to enhance the efficiency and effectiveness of various treatment processes. This compound, with its unique chemical properties, has shown potential in areas such as wastewater treatment, landfill leachate management, and industrial sludge processing. By incorporating sodium acetate into these processes, industries aim to reduce environmental impact, improve resource recovery, and achieve compliance with increasingly stringent environmental regulations.

Historically, waste management has evolved from simple disposal methods to complex, integrated systems designed to minimize environmental harm and maximize resource recovery. The introduction of sodium acetate into this field represents a continuation of this trend towards more sophisticated and environmentally friendly waste management solutions. Its application aligns with the broader goals of circular economy principles, where waste is viewed as a potential resource rather than a problem to be disposed of.

The technical goals associated with sodium acetate in waste management are multifaceted. Firstly, there is a focus on improving the efficiency of biological treatment processes in wastewater management. Sodium acetate serves as an excellent carbon source for microorganisms, potentially enhancing the performance of biological treatment systems. Secondly, researchers are exploring its role in heavy metal removal from industrial effluents, leveraging its ability to form complexes with metal ions.

Another significant objective is the optimization of anaerobic digestion processes in organic waste treatment. Sodium acetate can act as a precursor for methane production, potentially increasing biogas yields in anaerobic digesters. This aligns with the growing interest in waste-to-energy technologies and the broader push towards renewable energy sources.

Furthermore, the use of sodium acetate in waste management is being investigated for its potential to improve the stability and safety of landfills. By influencing the chemical environment within landfills, it may help in reducing the production of harmful leachates and mitigating the release of greenhouse gases.

As research in this field progresses, the overarching goal is to develop comprehensive, sustainable waste management solutions that integrate sodium acetate into existing and new technologies. This involves not only technical advancements but also considerations of economic viability, scalability, and long-term environmental impact. The ongoing exploration of sodium acetate's applications in waste management reflects the industry's commitment to innovation and environmental stewardship.

Market Demand for Advanced Waste Treatment Solutions

The global market for advanced waste treatment solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns, stringent regulations, and the need for sustainable waste management practices. The demand for innovative technologies that can effectively treat and manage industrial waste is particularly high, as industries seek to reduce their environmental footprint and comply with evolving regulatory standards.

Sodium acetate, a versatile compound with various industrial applications, has emerged as a promising solution in the field of industrial waste management. Its unique properties make it an attractive option for enhancing waste treatment processes, particularly in addressing challenges related to heavy metal contamination, pH stabilization, and organic waste decomposition.

The market for sodium acetate-based waste treatment solutions is expected to grow substantially in the coming years, as industries across sectors such as manufacturing, chemical processing, and mining look for more efficient and cost-effective ways to manage their waste streams. This growth is further fueled by the increasing adoption of circular economy principles, which emphasize the importance of resource recovery and waste minimization.

One of the key drivers of market demand for sodium acetate in waste management is its ability to act as a buffering agent, helping to stabilize pH levels in industrial effluents. This property is particularly valuable in industries that generate acidic or alkaline waste streams, as it allows for more effective treatment and safer disposal of these materials.

Additionally, sodium acetate has shown promise in the removal of heavy metals from industrial wastewater. As regulations around heavy metal discharge become more stringent globally, industries are actively seeking solutions that can efficiently and cost-effectively remove these contaminants from their waste streams. Sodium acetate's ability to form complexes with heavy metal ions makes it an attractive option for this purpose.

The growing focus on sustainable waste management practices has also contributed to the increased demand for sodium acetate-based solutions. As industries strive to reduce their environmental impact and improve their sustainability credentials, there is a growing interest in technologies that can not only treat waste effectively but also potentially recover valuable resources from waste streams.

Furthermore, the market demand for advanced waste treatment solutions incorporating sodium acetate is being driven by the need for more efficient and less energy-intensive treatment processes. Traditional waste treatment methods often require significant energy inputs, contributing to higher operational costs and environmental impacts. Sodium acetate-based solutions offer the potential for more streamlined and energy-efficient treatment processes, aligning with industry goals for cost reduction and improved sustainability.

Sodium acetate, a versatile compound with various industrial applications, has emerged as a promising solution in the field of industrial waste management. Its unique properties make it an attractive option for enhancing waste treatment processes, particularly in addressing challenges related to heavy metal contamination, pH stabilization, and organic waste decomposition.

The market for sodium acetate-based waste treatment solutions is expected to grow substantially in the coming years, as industries across sectors such as manufacturing, chemical processing, and mining look for more efficient and cost-effective ways to manage their waste streams. This growth is further fueled by the increasing adoption of circular economy principles, which emphasize the importance of resource recovery and waste minimization.

One of the key drivers of market demand for sodium acetate in waste management is its ability to act as a buffering agent, helping to stabilize pH levels in industrial effluents. This property is particularly valuable in industries that generate acidic or alkaline waste streams, as it allows for more effective treatment and safer disposal of these materials.

Additionally, sodium acetate has shown promise in the removal of heavy metals from industrial wastewater. As regulations around heavy metal discharge become more stringent globally, industries are actively seeking solutions that can efficiently and cost-effectively remove these contaminants from their waste streams. Sodium acetate's ability to form complexes with heavy metal ions makes it an attractive option for this purpose.

The growing focus on sustainable waste management practices has also contributed to the increased demand for sodium acetate-based solutions. As industries strive to reduce their environmental impact and improve their sustainability credentials, there is a growing interest in technologies that can not only treat waste effectively but also potentially recover valuable resources from waste streams.

Furthermore, the market demand for advanced waste treatment solutions incorporating sodium acetate is being driven by the need for more efficient and less energy-intensive treatment processes. Traditional waste treatment methods often require significant energy inputs, contributing to higher operational costs and environmental impacts. Sodium acetate-based solutions offer the potential for more streamlined and energy-efficient treatment processes, aligning with industry goals for cost reduction and improved sustainability.

Current State and Challenges in Industrial Waste Management

Industrial waste management is currently facing significant challenges as global industrial activities continue to expand. The traditional methods of waste disposal, such as landfilling and incineration, are becoming increasingly unsustainable due to environmental concerns and limited capacity. Many countries are struggling to cope with the growing volume of industrial waste, which includes hazardous materials, chemical byproducts, and non-biodegradable substances.

One of the primary challenges in industrial waste management is the lack of efficient and cost-effective treatment technologies. While some advanced treatment methods exist, they are often expensive to implement on a large scale, making them inaccessible to many industries, particularly in developing countries. This has led to a continued reliance on outdated and environmentally harmful disposal practices.

Another significant issue is the complexity of waste streams in modern industrial processes. As manufacturing becomes more sophisticated, the variety of waste materials produced has increased, making it difficult to develop universal treatment solutions. This diversity requires specialized approaches for different types of waste, further complicating management efforts.

Regulatory frameworks also present a challenge in many regions. While some countries have implemented strict waste management regulations, others lack comprehensive policies or enforcement mechanisms. This inconsistency creates a global imbalance in waste management practices and can lead to the illegal dumping or export of hazardous waste to less regulated areas.

The current state of industrial waste management is characterized by a growing emphasis on circular economy principles. Many industries are exploring ways to reduce waste generation at the source, reuse materials within their processes, and recycle waste into valuable resources. However, the implementation of these practices is still in its early stages and faces numerous technical and economic barriers.

In this context, the potential of sodium acetate in enhancing industrial waste management is gaining attention. Sodium acetate, a versatile compound with various industrial applications, is being explored for its ability to treat and stabilize certain types of industrial waste. Its properties make it particularly promising for neutralizing acidic waste streams and as a potential additive in waste solidification processes.

However, the widespread adoption of sodium acetate in waste management faces several challenges. These include the need for further research to fully understand its effectiveness across different waste types, potential environmental impacts of its large-scale use, and the development of cost-effective production methods to make it economically viable for widespread industrial application.

As the industrial sector continues to evolve, there is an urgent need for innovative solutions that can address the complex challenges of waste management. The exploration of compounds like sodium acetate represents a step towards more sustainable and efficient waste treatment methods, but it must be part of a broader, integrated approach to industrial waste management that encompasses technological innovation, policy reform, and a shift towards more circular economic models.

One of the primary challenges in industrial waste management is the lack of efficient and cost-effective treatment technologies. While some advanced treatment methods exist, they are often expensive to implement on a large scale, making them inaccessible to many industries, particularly in developing countries. This has led to a continued reliance on outdated and environmentally harmful disposal practices.

Another significant issue is the complexity of waste streams in modern industrial processes. As manufacturing becomes more sophisticated, the variety of waste materials produced has increased, making it difficult to develop universal treatment solutions. This diversity requires specialized approaches for different types of waste, further complicating management efforts.

Regulatory frameworks also present a challenge in many regions. While some countries have implemented strict waste management regulations, others lack comprehensive policies or enforcement mechanisms. This inconsistency creates a global imbalance in waste management practices and can lead to the illegal dumping or export of hazardous waste to less regulated areas.

The current state of industrial waste management is characterized by a growing emphasis on circular economy principles. Many industries are exploring ways to reduce waste generation at the source, reuse materials within their processes, and recycle waste into valuable resources. However, the implementation of these practices is still in its early stages and faces numerous technical and economic barriers.

In this context, the potential of sodium acetate in enhancing industrial waste management is gaining attention. Sodium acetate, a versatile compound with various industrial applications, is being explored for its ability to treat and stabilize certain types of industrial waste. Its properties make it particularly promising for neutralizing acidic waste streams and as a potential additive in waste solidification processes.

However, the widespread adoption of sodium acetate in waste management faces several challenges. These include the need for further research to fully understand its effectiveness across different waste types, potential environmental impacts of its large-scale use, and the development of cost-effective production methods to make it economically viable for widespread industrial application.

As the industrial sector continues to evolve, there is an urgent need for innovative solutions that can address the complex challenges of waste management. The exploration of compounds like sodium acetate represents a step towards more sustainable and efficient waste treatment methods, but it must be part of a broader, integrated approach to industrial waste management that encompasses technological innovation, policy reform, and a shift towards more circular economic models.

Existing Sodium Acetate Applications in Waste Management

01 Use of sodium acetate in chemical processes

Sodium acetate is widely used in various chemical processes, including as a catalyst, pH regulator, and reagent in organic synthesis. It plays a crucial role in industrial applications, particularly in the production of chemicals and pharmaceuticals.- Use of sodium acetate in chemical processes: Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications and laboratory settings.

- Application in heat storage and thermal management: Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes phase changes at specific temperatures, allowing it to store and release heat effectively. This property is exploited in heating pads, building materials, and energy storage solutions.

- Use in food and beverage industry: Sodium acetate serves as a food additive and preservative in the food and beverage industry. It acts as a acidity regulator, flavoring agent, and antimicrobial preservative. Its use helps extend shelf life and maintain product quality in various food products.

- Application in textile and leather processing: Sodium acetate is employed in textile and leather processing industries. It is used in dyeing processes, as a mordant for certain dyes, and in leather tanning operations. Its properties contribute to improved color fastness and leather quality.

- Use in pharmaceutical and medical applications: Sodium acetate finds applications in pharmaceutical formulations and medical treatments. It is used as a buffering agent in intravenous fluids, dialysis solutions, and as an electrolyte replacement. Its role in maintaining pH balance makes it valuable in various medical contexts.

02 Application in heat storage and thermal management

Sodium acetate is utilized in heat storage systems and thermal management applications. Its phase change properties make it suitable for use in heat packs, thermal energy storage devices, and temperature regulation systems.Expand Specific Solutions03 Use in food preservation and flavoring

Sodium acetate finds applications in the food industry as a preservative and flavoring agent. It helps extend the shelf life of various food products and can be used to enhance or modify flavors in certain food preparations.Expand Specific Solutions04 Application in textile and leather industries

Sodium acetate is employed in textile and leather processing. It serves as a neutralizing agent, buffering solution, and assists in dyeing processes. Its use helps improve the quality and durability of textiles and leather products.Expand Specific Solutions05 Environmental and waste treatment applications

Sodium acetate is utilized in environmental and waste treatment processes. It can be used in wastewater treatment, as a de-icing agent for roads, and in certain pollution control applications. Its biodegradability makes it an environmentally friendly option for various treatments.Expand Specific Solutions

Key Players in Industrial Waste Treatment Industry

The sodium acetate market in industrial waste management is in a growth phase, driven by increasing environmental regulations and the need for sustainable waste treatment solutions. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, sodium acetate applications are maturing, with ongoing research focused on enhancing efficiency and reducing costs. Key players like China Petroleum & Chemical Corp., Solvay Chemicals, Inc., and Ecolab GmbH & Co. oHG are investing in R&D to improve sodium acetate-based waste management solutions. Academic institutions such as Nanjing Tech University and Harbin Institute of Technology are contributing to technological advancements, fostering industry-academia collaborations for innovative waste treatment methods.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a sodium acetate-based technology for industrial waste management in the petrochemical industry. Their approach involves using sodium acetate as a pH buffer and corrosion inhibitor in various refining and chemical production processes. Sinopec has implemented sodium acetate-based solutions in their wastewater treatment systems to enhance the removal of oil, grease, and other organic contaminants[2]. The company has also explored the use of sodium acetate in catalytic processes, where it acts as a promoter to improve the selectivity and yield of certain chemical reactions, potentially reducing waste generation[4]. Additionally, Sinopec has investigated the application of sodium acetate in enhanced oil recovery techniques, where it can help to modify the properties of injection fluids and improve oil displacement efficiency[5].

Strengths: Effective in petrochemical industry applications; Enhances oil and organic contaminant removal; Potential for improving chemical process efficiency. Weaknesses: May require industry-specific adaptations; Effectiveness may vary depending on the complexity of waste streams.

Ecolab GmbH & Co. oHG

Technical Solution: Ecolab has developed a sodium acetate-based technology for industrial waste management, focusing on its application in cooling water systems and boiler water treatment. Their approach utilizes sodium acetate as a corrosion inhibitor and scale control agent, helping to extend the life of industrial equipment and reduce maintenance costs. The company has also explored the use of sodium acetate in combination with other chemicals to create more effective and environmentally friendly cleaning solutions for industrial processes[2]. Ecolab's research has shown that sodium acetate-based treatments can significantly reduce water consumption in industrial processes by allowing for increased cycles of concentration in cooling systems[4].

Strengths: Effective corrosion and scale control; Reduces water consumption in industrial processes; Environmentally friendly cleaning solutions. Weaknesses: May require specialized equipment for optimal application; Effectiveness may be limited in certain high-temperature or high-pressure systems.

Core Innovations in Sodium Acetate-based Waste Treatment

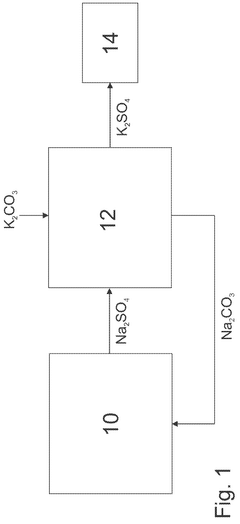

Pretreatment of sodium and potassium ions containing wastes and residues

PatentInactiveEP0479670A1

Innovation

- The use of phosphoric acid manufacturing waste residues, specifically fluorosilicic acid, to precipitate and separate alkali metal ions from alkaline wastes through mixing and subsequent decantation or filtration, allowing for the reduction of alkaline ion content before further treatment.

A method for treating waste sodium sulphate obtained from an industrial process, use of waste sodium sulphate obtained from an industrial process and an industrial processing plant

PatentWO2025133462A1

Innovation

- A method involving the reaction of waste sodium sulphate with potassium carbonate to produce potassium sulphate and sodium carbonate, which can be recovered and reused in industrial processes, thereby achieving a zero-waste, low-temperature process.

Environmental Impact Assessment of Sodium Acetate Use

The environmental impact assessment of sodium acetate use in industrial waste management reveals both positive and negative effects on ecosystems and human health. Sodium acetate, when used as a de-icing agent or in wastewater treatment, can significantly reduce the environmental burden compared to traditional methods.

In terms of water quality, sodium acetate demonstrates lower toxicity to aquatic life than conventional de-icers like sodium chloride. Its biodegradability ensures that it breaks down more rapidly in water bodies, minimizing long-term accumulation. However, the introduction of sodium acetate into aquatic ecosystems can temporarily increase biochemical oxygen demand (BOD), potentially leading to short-term oxygen depletion in receiving waters.

Soil impacts are generally less severe with sodium acetate compared to chloride-based alternatives. It does not contribute to soil salinization, which is a significant advantage in areas prone to salt accumulation. Nevertheless, excessive use may lead to soil alkalinization, affecting pH-sensitive plant species and soil microorganisms.

Air quality benefits from sodium acetate use are notable, particularly in urban environments. Unlike some de-icing agents, it does not contribute to particulate matter emissions or the formation of corrosive aerosols, thereby improving local air quality and reducing respiratory health risks.

The carbon footprint associated with sodium acetate production and use is an important consideration. While its manufacture requires energy input, the overall lifecycle emissions may be lower than those of alternatives when considering the reduced corrosion and infrastructure damage it causes.

Biodiversity impacts are generally favorable. The lower toxicity and faster degradation of sodium acetate reduce the risk of bioaccumulation in food chains. This can help preserve ecosystem balance, particularly in sensitive areas near water bodies or in regions with high ecological value.

Human health considerations are largely positive. The use of sodium acetate in place of more hazardous chemicals in industrial processes can reduce worker exposure to harmful substances. Additionally, its application in de-icing can decrease the risk of accidents due to ice formation, indirectly benefiting public safety.

In conclusion, while sodium acetate presents some environmental challenges, particularly in terms of potential short-term oxygen depletion in water bodies and soil alkalinization, its overall environmental profile is generally more favorable than many alternatives in industrial waste management applications. Proper management and application protocols are crucial to maximize its benefits while minimizing potential negative impacts on ecosystems and human health.

In terms of water quality, sodium acetate demonstrates lower toxicity to aquatic life than conventional de-icers like sodium chloride. Its biodegradability ensures that it breaks down more rapidly in water bodies, minimizing long-term accumulation. However, the introduction of sodium acetate into aquatic ecosystems can temporarily increase biochemical oxygen demand (BOD), potentially leading to short-term oxygen depletion in receiving waters.

Soil impacts are generally less severe with sodium acetate compared to chloride-based alternatives. It does not contribute to soil salinization, which is a significant advantage in areas prone to salt accumulation. Nevertheless, excessive use may lead to soil alkalinization, affecting pH-sensitive plant species and soil microorganisms.

Air quality benefits from sodium acetate use are notable, particularly in urban environments. Unlike some de-icing agents, it does not contribute to particulate matter emissions or the formation of corrosive aerosols, thereby improving local air quality and reducing respiratory health risks.

The carbon footprint associated with sodium acetate production and use is an important consideration. While its manufacture requires energy input, the overall lifecycle emissions may be lower than those of alternatives when considering the reduced corrosion and infrastructure damage it causes.

Biodiversity impacts are generally favorable. The lower toxicity and faster degradation of sodium acetate reduce the risk of bioaccumulation in food chains. This can help preserve ecosystem balance, particularly in sensitive areas near water bodies or in regions with high ecological value.

Human health considerations are largely positive. The use of sodium acetate in place of more hazardous chemicals in industrial processes can reduce worker exposure to harmful substances. Additionally, its application in de-icing can decrease the risk of accidents due to ice formation, indirectly benefiting public safety.

In conclusion, while sodium acetate presents some environmental challenges, particularly in terms of potential short-term oxygen depletion in water bodies and soil alkalinization, its overall environmental profile is generally more favorable than many alternatives in industrial waste management applications. Proper management and application protocols are crucial to maximize its benefits while minimizing potential negative impacts on ecosystems and human health.

Regulatory Framework for Chemical Waste Treatment Methods

The regulatory framework for chemical waste treatment methods plays a crucial role in ensuring the safe and effective management of industrial waste, including the use of sodium acetate. This framework encompasses a complex network of laws, regulations, and guidelines at international, national, and local levels.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for the management of hazardous waste. This convention sets standards for the classification, handling, and disposal of chemical waste, including those treated with sodium acetate.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing chemical waste treatment. The Resource Conservation and Recovery Act (RCRA) establishes the framework for the proper management of hazardous waste from cradle to grave. Under RCRA, sodium acetate-based treatment methods must comply with specific guidelines for waste characterization, treatment, storage, and disposal.

The European Union has implemented the Waste Framework Directive (2008/98/EC), which sets the basic concepts and definitions related to waste management. This directive emphasizes the waste hierarchy, promoting prevention, reuse, and recycling over disposal. Treatment methods using sodium acetate must align with these principles and meet the stringent requirements for waste classification and handling.

Many countries have adopted their own regulatory frameworks, often based on or influenced by international standards. For instance, China's Solid Waste Pollution Prevention and Control Law governs the management of industrial waste, including chemical treatment methods. Japan's Waste Management and Public Cleansing Law similarly regulates the treatment and disposal of industrial waste.

Regulatory bodies often require detailed documentation and reporting on waste treatment processes. This includes maintaining records of waste characterization, treatment methodologies, and disposal practices. For sodium acetate-based treatments, companies must demonstrate compliance with specific parameters such as pH levels, chemical concentrations, and treatment efficacy.

Environmental impact assessments are frequently mandated for chemical waste treatment facilities. These assessments evaluate the potential effects of treatment methods, including those utilizing sodium acetate, on air quality, water resources, soil contamination, and biodiversity. Regulatory approval often hinges on the results of these assessments and the implementation of mitigation measures.

Occupational health and safety regulations also form an integral part of the regulatory framework. These regulations set standards for worker protection, including requirements for personal protective equipment, training programs, and emergency response procedures when handling chemical waste and treatment agents like sodium acetate.

As environmental concerns grow and technology advances, regulatory frameworks continue to evolve. Emerging trends include increased focus on circular economy principles, stricter limits on hazardous substances, and greater emphasis on sustainable waste management practices. Treatment methods incorporating sodium acetate must adapt to these changing regulatory landscapes to remain compliant and effective in industrial waste management.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for the management of hazardous waste. This convention sets standards for the classification, handling, and disposal of chemical waste, including those treated with sodium acetate.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing chemical waste treatment. The Resource Conservation and Recovery Act (RCRA) establishes the framework for the proper management of hazardous waste from cradle to grave. Under RCRA, sodium acetate-based treatment methods must comply with specific guidelines for waste characterization, treatment, storage, and disposal.

The European Union has implemented the Waste Framework Directive (2008/98/EC), which sets the basic concepts and definitions related to waste management. This directive emphasizes the waste hierarchy, promoting prevention, reuse, and recycling over disposal. Treatment methods using sodium acetate must align with these principles and meet the stringent requirements for waste classification and handling.

Many countries have adopted their own regulatory frameworks, often based on or influenced by international standards. For instance, China's Solid Waste Pollution Prevention and Control Law governs the management of industrial waste, including chemical treatment methods. Japan's Waste Management and Public Cleansing Law similarly regulates the treatment and disposal of industrial waste.

Regulatory bodies often require detailed documentation and reporting on waste treatment processes. This includes maintaining records of waste characterization, treatment methodologies, and disposal practices. For sodium acetate-based treatments, companies must demonstrate compliance with specific parameters such as pH levels, chemical concentrations, and treatment efficacy.

Environmental impact assessments are frequently mandated for chemical waste treatment facilities. These assessments evaluate the potential effects of treatment methods, including those utilizing sodium acetate, on air quality, water resources, soil contamination, and biodiversity. Regulatory approval often hinges on the results of these assessments and the implementation of mitigation measures.

Occupational health and safety regulations also form an integral part of the regulatory framework. These regulations set standards for worker protection, including requirements for personal protective equipment, training programs, and emergency response procedures when handling chemical waste and treatment agents like sodium acetate.

As environmental concerns grow and technology advances, regulatory frameworks continue to evolve. Emerging trends include increased focus on circular economy principles, stricter limits on hazardous substances, and greater emphasis on sustainable waste management practices. Treatment methods incorporating sodium acetate must adapt to these changing regulatory landscapes to remain compliant and effective in industrial waste management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!