How Sodium Acetate Innovates Renewable Energy Storage?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Energy Storage Background

Sodium acetate, a compound formed by the combination of sodium and acetic acid, has emerged as a promising candidate for innovative renewable energy storage solutions. This technology leverages the unique properties of sodium acetate trihydrate, particularly its ability to store and release thermal energy through phase change processes.

The concept of using sodium acetate for energy storage dates back to the 1980s when researchers first recognized its potential as a phase change material (PCM). However, it is only in recent years that significant advancements have been made in harnessing its full capabilities for large-scale energy storage applications.

Sodium acetate's journey in the energy sector began with its use in small-scale thermal storage devices, such as hand warmers and heat packs. These applications demonstrated the material's ability to store heat effectively and release it on demand. As the global focus shifted towards renewable energy and the need for efficient energy storage solutions grew, researchers and engineers started exploring sodium acetate's potential for larger-scale implementations.

The compound's unique properties make it particularly suitable for thermal energy storage. When heated, sodium acetate trihydrate melts and absorbs a significant amount of energy. This molten state can be maintained for extended periods, effectively storing the thermal energy. When triggered, the material rapidly crystallizes, releasing the stored heat in an exothermic reaction.

One of the key advantages of sodium acetate as an energy storage medium is its high energy density. Compared to traditional storage methods, such as water-based systems, sodium acetate can store significantly more energy per unit volume. This characteristic makes it an attractive option for applications where space is at a premium or where high-capacity storage is required.

Furthermore, sodium acetate is non-toxic, non-flammable, and relatively inexpensive to produce. These attributes address many of the safety and cost concerns associated with other energy storage technologies, such as lithium-ion batteries or molten salt systems.

The development of sodium acetate energy storage technology has been driven by the growing need for efficient and sustainable energy storage solutions in the renewable energy sector. As wind and solar power generation continue to expand, the intermittent nature of these sources necessitates robust storage systems to ensure a stable and reliable energy supply.

The concept of using sodium acetate for energy storage dates back to the 1980s when researchers first recognized its potential as a phase change material (PCM). However, it is only in recent years that significant advancements have been made in harnessing its full capabilities for large-scale energy storage applications.

Sodium acetate's journey in the energy sector began with its use in small-scale thermal storage devices, such as hand warmers and heat packs. These applications demonstrated the material's ability to store heat effectively and release it on demand. As the global focus shifted towards renewable energy and the need for efficient energy storage solutions grew, researchers and engineers started exploring sodium acetate's potential for larger-scale implementations.

The compound's unique properties make it particularly suitable for thermal energy storage. When heated, sodium acetate trihydrate melts and absorbs a significant amount of energy. This molten state can be maintained for extended periods, effectively storing the thermal energy. When triggered, the material rapidly crystallizes, releasing the stored heat in an exothermic reaction.

One of the key advantages of sodium acetate as an energy storage medium is its high energy density. Compared to traditional storage methods, such as water-based systems, sodium acetate can store significantly more energy per unit volume. This characteristic makes it an attractive option for applications where space is at a premium or where high-capacity storage is required.

Furthermore, sodium acetate is non-toxic, non-flammable, and relatively inexpensive to produce. These attributes address many of the safety and cost concerns associated with other energy storage technologies, such as lithium-ion batteries or molten salt systems.

The development of sodium acetate energy storage technology has been driven by the growing need for efficient and sustainable energy storage solutions in the renewable energy sector. As wind and solar power generation continue to expand, the intermittent nature of these sources necessitates robust storage systems to ensure a stable and reliable energy supply.

Market Demand Analysis

The market demand for innovative renewable energy storage solutions has been steadily increasing, driven by the global shift towards sustainable energy sources and the need for efficient grid management. Sodium acetate, a compound traditionally used in various industrial applications, has emerged as a promising candidate for thermal energy storage, particularly in the context of renewable energy systems.

The renewable energy sector has experienced significant growth in recent years, with global investments reaching record levels. This expansion has created a parallel demand for advanced energy storage technologies to address the intermittent nature of renewable sources like solar and wind. The market for energy storage solutions is projected to grow substantially, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years.

Sodium acetate-based energy storage systems offer several advantages that align with market needs. These systems can store excess energy during peak production periods and release it when demand is high, effectively smoothing out the supply-demand curve for renewable energy. This capability is particularly valuable for grid operators and utilities seeking to enhance grid stability and reduce reliance on fossil fuel-based peaker plants.

The industrial sector represents a significant potential market for sodium acetate energy storage. Many industrial processes require consistent heat supply, which can be efficiently provided by sodium acetate-based thermal storage systems. This application could lead to substantial energy savings and reduced carbon emissions in energy-intensive industries.

Residential and commercial buildings also present a growing market opportunity for sodium acetate energy storage. As building energy efficiency standards become more stringent, there is an increasing demand for innovative heating and cooling solutions. Sodium acetate-based systems can potentially provide thermal energy storage for space heating and domestic hot water, aligning with the trend towards net-zero energy buildings.

The transportation sector, particularly electric vehicle (EV) charging infrastructure, could benefit from sodium acetate energy storage. As EV adoption accelerates, there is a growing need for fast-charging stations that can manage high power demands without straining the grid. Sodium acetate-based thermal storage could help buffer these peak loads, making EV charging more efficient and grid-friendly.

Despite the promising market potential, challenges remain in scaling up sodium acetate energy storage technology. These include optimizing system designs for different applications, reducing costs, and addressing any potential environmental concerns related to large-scale deployment. However, as research and development efforts intensify, these challenges are likely to be overcome, paving the way for wider market adoption.

In conclusion, the market demand for sodium acetate as an innovative renewable energy storage solution is poised for significant growth across multiple sectors. Its ability to address key challenges in renewable energy integration, coupled with its versatility and potential cost-effectiveness, positions it as a technology of interest for investors, policymakers, and industry stakeholders in the evolving energy landscape.

The renewable energy sector has experienced significant growth in recent years, with global investments reaching record levels. This expansion has created a parallel demand for advanced energy storage technologies to address the intermittent nature of renewable sources like solar and wind. The market for energy storage solutions is projected to grow substantially, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years.

Sodium acetate-based energy storage systems offer several advantages that align with market needs. These systems can store excess energy during peak production periods and release it when demand is high, effectively smoothing out the supply-demand curve for renewable energy. This capability is particularly valuable for grid operators and utilities seeking to enhance grid stability and reduce reliance on fossil fuel-based peaker plants.

The industrial sector represents a significant potential market for sodium acetate energy storage. Many industrial processes require consistent heat supply, which can be efficiently provided by sodium acetate-based thermal storage systems. This application could lead to substantial energy savings and reduced carbon emissions in energy-intensive industries.

Residential and commercial buildings also present a growing market opportunity for sodium acetate energy storage. As building energy efficiency standards become more stringent, there is an increasing demand for innovative heating and cooling solutions. Sodium acetate-based systems can potentially provide thermal energy storage for space heating and domestic hot water, aligning with the trend towards net-zero energy buildings.

The transportation sector, particularly electric vehicle (EV) charging infrastructure, could benefit from sodium acetate energy storage. As EV adoption accelerates, there is a growing need for fast-charging stations that can manage high power demands without straining the grid. Sodium acetate-based thermal storage could help buffer these peak loads, making EV charging more efficient and grid-friendly.

Despite the promising market potential, challenges remain in scaling up sodium acetate energy storage technology. These include optimizing system designs for different applications, reducing costs, and addressing any potential environmental concerns related to large-scale deployment. However, as research and development efforts intensify, these challenges are likely to be overcome, paving the way for wider market adoption.

In conclusion, the market demand for sodium acetate as an innovative renewable energy storage solution is poised for significant growth across multiple sectors. Its ability to address key challenges in renewable energy integration, coupled with its versatility and potential cost-effectiveness, positions it as a technology of interest for investors, policymakers, and industry stakeholders in the evolving energy landscape.

Technical Challenges

The development of sodium acetate as an innovative solution for renewable energy storage faces several significant technical challenges that need to be addressed for widespread adoption. One of the primary obstacles is the optimization of the thermal properties of sodium acetate trihydrate (SAT), the key compound in this technology. While SAT has a high latent heat of fusion, which makes it attractive for thermal energy storage, it often suffers from phase segregation and supercooling issues during repeated melting and solidification cycles.

The phase segregation problem occurs when the anhydrous salt separates from the water component, leading to a reduction in the overall heat storage capacity and efficiency of the system. This separation can result in the formation of a layer of anhydrous salt at the bottom of the storage container, which reduces the effective heat transfer and storage capabilities. Addressing this issue requires the development of advanced nucleating agents or mechanical stirring mechanisms that can maintain the homogeneity of the SAT mixture throughout multiple thermal cycles.

Supercooling is another critical challenge in SAT-based energy storage systems. The material often fails to crystallize at its theoretical phase change temperature, remaining in a liquid state well below the melting point. This phenomenon can lead to unpredictable energy release and difficulties in controlling the thermal discharge process. Researchers are exploring various nucleation techniques and additives to induce controlled crystallization and mitigate the supercooling effect.

The corrosive nature of sodium acetate solutions presents another hurdle in the development of long-lasting and reliable storage systems. The material can degrade containment vessels and heat exchangers over time, potentially leading to system failures and reduced lifespan. This necessitates the use of corrosion-resistant materials or protective coatings, which can significantly increase the overall cost of the storage system.

Heat transfer efficiency is also a key area of concern. While sodium acetate has favorable thermal properties, optimizing the heat exchange between the storage medium and the working fluid (typically water or air) remains challenging. Enhancing heat transfer rates without compromising the structural integrity of the storage system is crucial for improving the overall efficiency and response time of the energy storage process.

Lastly, the scalability of sodium acetate-based energy storage systems poses a significant technical challenge. While the technology shows promise at small scales, designing and implementing large-scale systems that can effectively store and release megawatt-hours of thermal energy requires innovative engineering solutions. This includes addressing issues related to thermal insulation, uniform heat distribution, and the integration of these systems with existing renewable energy infrastructure.

The phase segregation problem occurs when the anhydrous salt separates from the water component, leading to a reduction in the overall heat storage capacity and efficiency of the system. This separation can result in the formation of a layer of anhydrous salt at the bottom of the storage container, which reduces the effective heat transfer and storage capabilities. Addressing this issue requires the development of advanced nucleating agents or mechanical stirring mechanisms that can maintain the homogeneity of the SAT mixture throughout multiple thermal cycles.

Supercooling is another critical challenge in SAT-based energy storage systems. The material often fails to crystallize at its theoretical phase change temperature, remaining in a liquid state well below the melting point. This phenomenon can lead to unpredictable energy release and difficulties in controlling the thermal discharge process. Researchers are exploring various nucleation techniques and additives to induce controlled crystallization and mitigate the supercooling effect.

The corrosive nature of sodium acetate solutions presents another hurdle in the development of long-lasting and reliable storage systems. The material can degrade containment vessels and heat exchangers over time, potentially leading to system failures and reduced lifespan. This necessitates the use of corrosion-resistant materials or protective coatings, which can significantly increase the overall cost of the storage system.

Heat transfer efficiency is also a key area of concern. While sodium acetate has favorable thermal properties, optimizing the heat exchange between the storage medium and the working fluid (typically water or air) remains challenging. Enhancing heat transfer rates without compromising the structural integrity of the storage system is crucial for improving the overall efficiency and response time of the energy storage process.

Lastly, the scalability of sodium acetate-based energy storage systems poses a significant technical challenge. While the technology shows promise at small scales, designing and implementing large-scale systems that can effectively store and release megawatt-hours of thermal energy requires innovative engineering solutions. This includes addressing issues related to thermal insulation, uniform heat distribution, and the integration of these systems with existing renewable energy infrastructure.

Current Sodium Acetate Solutions

01 Sodium acetate-based phase change materials for thermal energy storage

Sodium acetate trihydrate is used as a phase change material for thermal energy storage due to its high latent heat of fusion and suitable melting temperature. These materials can store and release large amounts of energy during phase transitions, making them effective for various energy storage applications.- Phase change materials for thermal energy storage: Sodium acetate trihydrate is used as a phase change material for thermal energy storage due to its high latent heat of fusion and suitable melting temperature. It can absorb, store, and release large amounts of energy during phase transitions, making it effective for various energy storage applications.

- Composite materials for improved energy storage: Composite materials incorporating sodium acetate are developed to enhance energy storage capacity and thermal conductivity. These composites often include additives or supporting materials to address issues like supercooling and phase segregation, improving the overall performance of the energy storage system.

- Encapsulation techniques for sodium acetate-based energy storage: Various encapsulation methods are employed to contain sodium acetate-based phase change materials, preventing leakage and improving heat transfer. These techniques include microencapsulation, macro-encapsulation, and the use of shape-stabilized composites, enhancing the practicality and efficiency of energy storage systems.

- Integration of sodium acetate energy storage in heating systems: Sodium acetate-based energy storage is integrated into heating systems for buildings and industrial processes. These systems utilize the material's thermal properties to store excess heat during off-peak hours and release it when needed, improving energy efficiency and reducing costs.

- Novel applications and system designs for sodium acetate energy storage: Innovative applications and system designs are developed to expand the use of sodium acetate in energy storage. These include portable heat storage devices, solar thermal energy systems, and waste heat recovery solutions, demonstrating the versatility of sodium acetate-based energy storage technologies.

02 Composite materials incorporating sodium acetate for enhanced energy storage

Composite materials combining sodium acetate with other substances, such as graphene or carbon nanotubes, are developed to improve thermal conductivity and energy storage capacity. These composites can enhance the overall performance of thermal energy storage systems.Expand Specific Solutions03 Encapsulation techniques for sodium acetate-based energy storage

Various encapsulation methods are employed to contain sodium acetate-based phase change materials, preventing leakage and improving thermal stability. These techniques can include microencapsulation or incorporation into porous materials, enhancing the practicality of sodium acetate for energy storage applications.Expand Specific Solutions04 Integration of sodium acetate energy storage in building materials

Sodium acetate-based energy storage materials are incorporated into building materials such as concrete, wallboards, or insulation to improve thermal management in buildings. This integration can help regulate indoor temperatures and reduce energy consumption for heating and cooling.Expand Specific Solutions05 Sodium acetate energy storage systems for industrial applications

Large-scale sodium acetate energy storage systems are developed for industrial applications, including waste heat recovery and temperature regulation in manufacturing processes. These systems can help improve energy efficiency and reduce overall energy consumption in industrial settings.Expand Specific Solutions

Key Industry Players

The sodium acetate-based renewable energy storage market is in its early growth stage, with increasing interest from both industry and academia. The market size is expanding as the technology demonstrates potential for efficient thermal energy storage. Companies like Sunamp Ltd. and Neothermal Energy Storage, Inc. are at the forefront of commercializing this technology, while research institutions such as the University of Technology Sydney and National University of Singapore are advancing the scientific understanding. The technology's maturity is progressing, with firms like Faradion Ltd. and SK Innovation Co., Ltd. developing sodium-ion batteries, indicating a broader trend towards sodium-based energy storage solutions. However, the field is still evolving, with ongoing research and development efforts aimed at improving efficiency and scalability.

Zhejiang Sodium Innovation Energy Co., Ltd.

Technical Solution: Zhejiang Sodium Innovation Energy Co., Ltd. has developed a sodium-ion battery technology that utilizes sodium acetate as a key component in their energy storage solutions. Their approach involves using a sodium acetate-based electrolyte, which enhances the battery's performance and stability. The company has achieved energy densities of up to 160 Wh/kg [1], making their batteries competitive with some lithium-ion technologies. They have also implemented a unique electrode design that incorporates sodium acetate crystals, allowing for improved charge-discharge cycles and longer battery life [2]. The company's batteries have demonstrated over 2000 charge cycles while maintaining 80% capacity retention [3], showcasing the durability of their sodium acetate-based technology.

Strengths: Cost-effective materials, abundant sodium resources, and improved safety compared to lithium-ion batteries. Weaknesses: Lower energy density compared to advanced lithium-ion batteries, and potential challenges in scaling up production.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a sodium-sulfur (NaS) battery system that incorporates sodium acetate as a thermal energy storage material. Their innovative approach combines the high energy density of NaS batteries with the thermal stability of sodium acetate trihydrate. The system operates at temperatures around 300°C, where molten sodium serves as the anode and molten sulfur as the cathode [4]. During discharge, the sodium acetate trihydrate absorbs excess heat, maintaining optimal battery temperature. This integration allows for efficient energy storage and release, with reported round-trip efficiencies of up to 85% [5]. NGK's system can provide both electrical and thermal energy, making it suitable for grid-scale applications and industrial processes requiring heat.

Strengths: High energy density, long discharge duration (up to 6 hours), and ability to provide both electrical and thermal energy. Weaknesses: High operating temperatures require sophisticated thermal management systems, and initial costs can be significant.

Core Innovations

Energy store for a power plant on the basis of a phase change material (PCM)

PatentWO2016050540A1

Innovation

- The use of acetates of metals and non-metals, such as sodium and potassium acetates, which are non-toxic, biodegradable, and cost-effective, with controlled formulations to achieve high energy storage capacity and minimal volume changes during phase transitions, operating within the desired temperature range.

Sodium ion based aqueous electrolyte electrochemical secondary energy storage device

PatentInactiveUS20090253025A1

Innovation

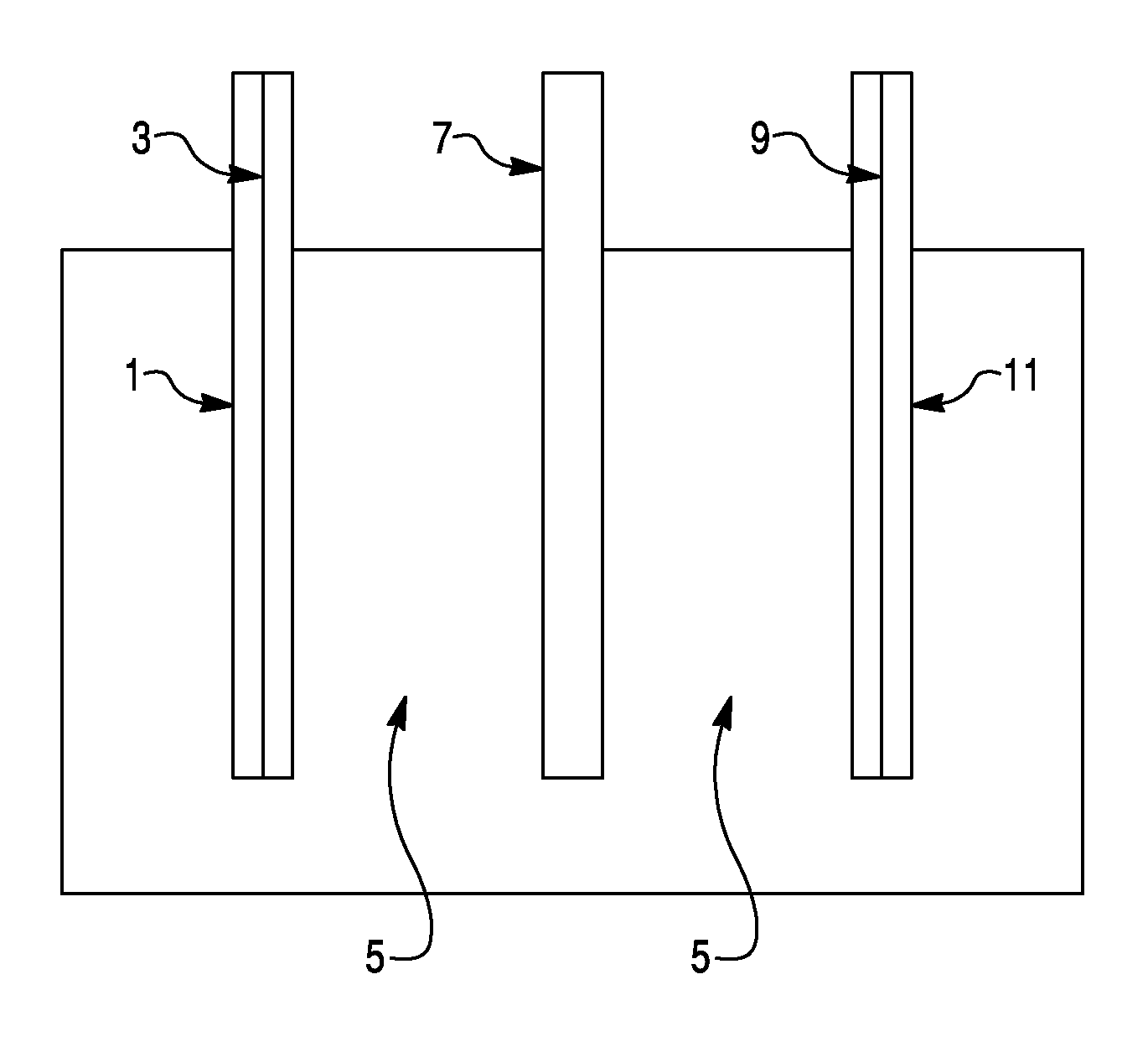

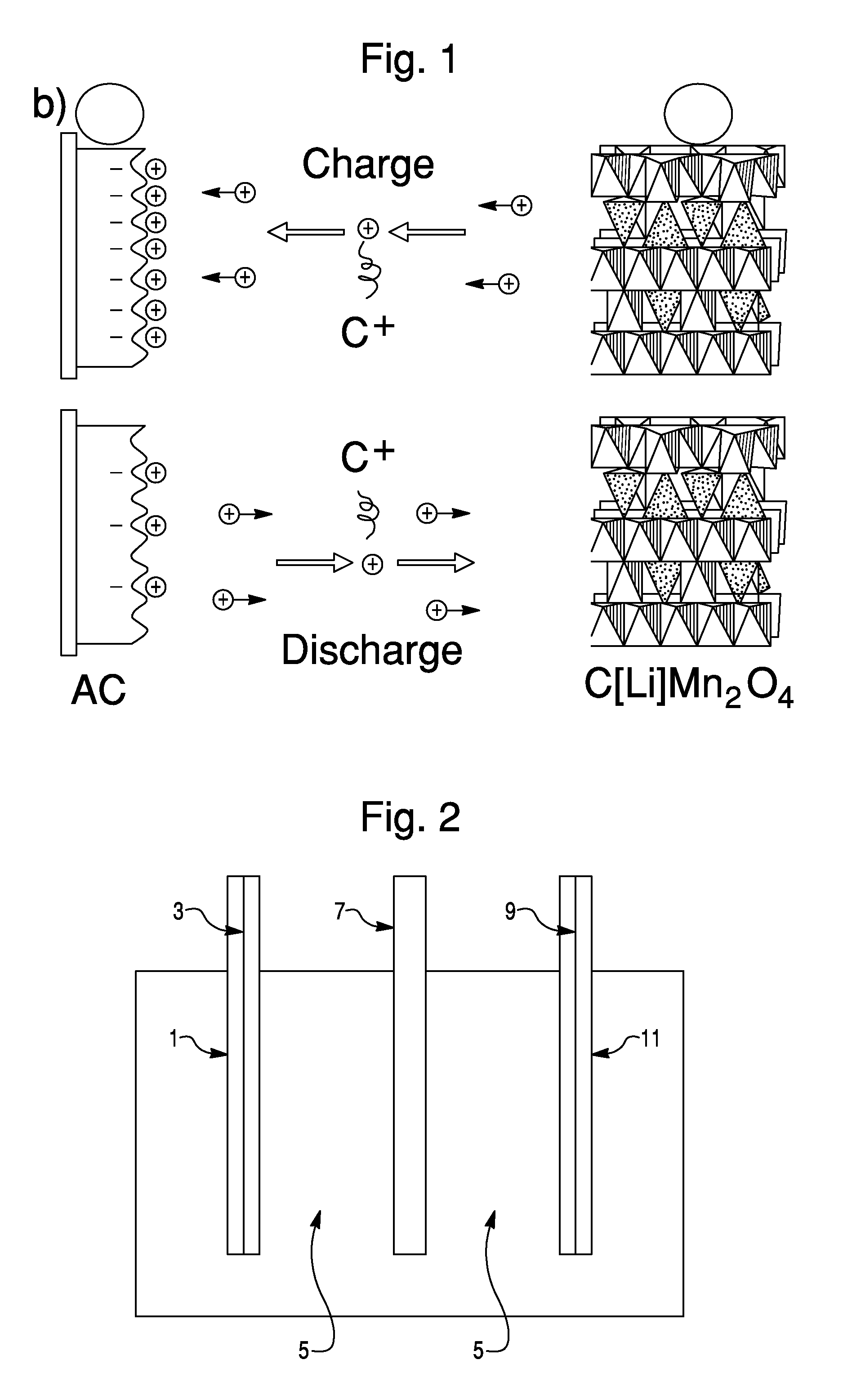

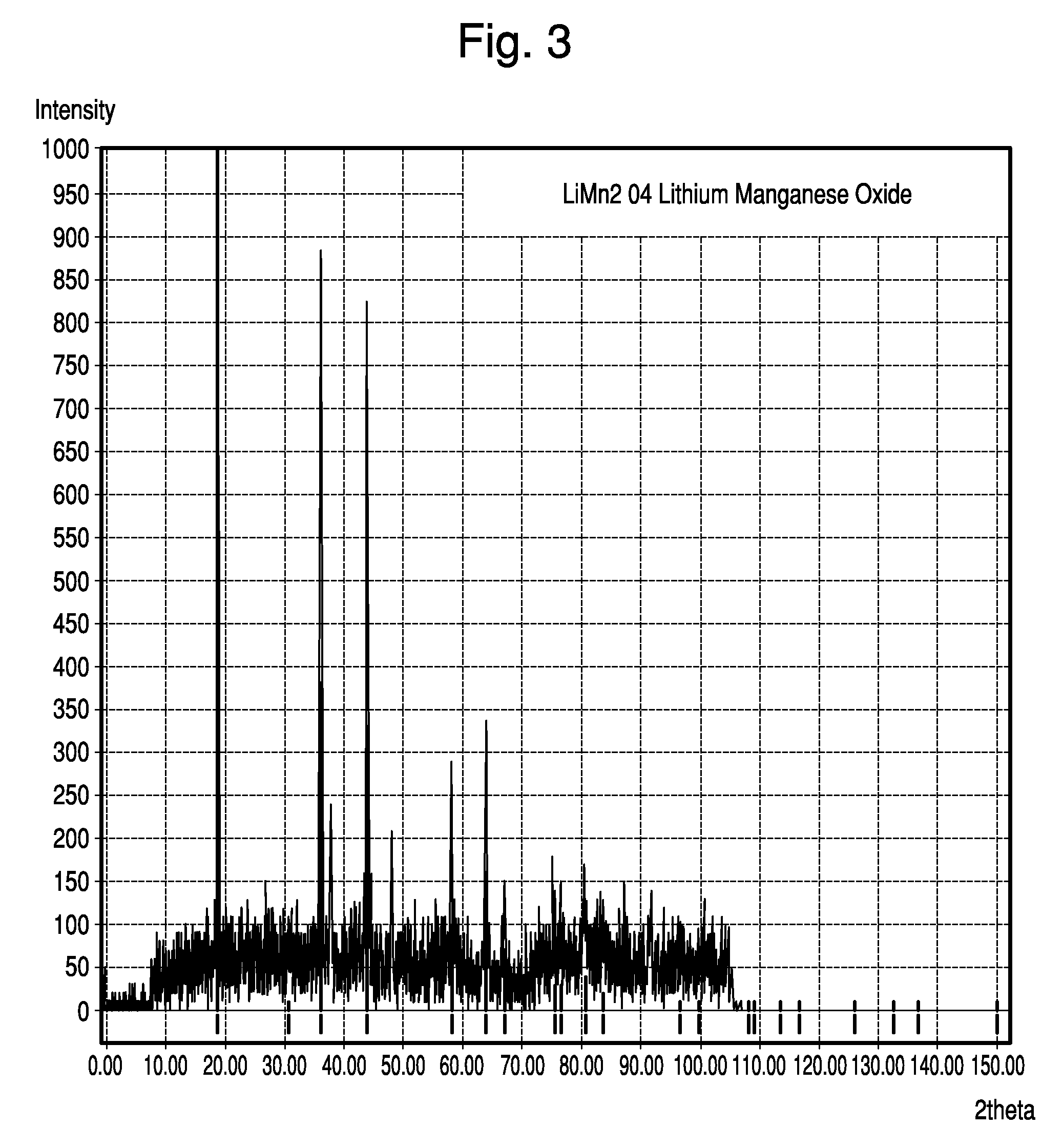

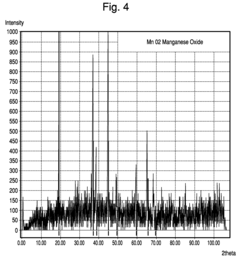

- Development of a hybrid aqueous energy storage device using a sodium cation containing aqueous electrolyte, an anode electrode, a cathode electrode capable of reversible sodium ion intercalation, and a separator, allowing for the deintercalation of alkali metal ions during charging and intercalation during discharge cycles.

Environmental Impact

The environmental impact of sodium acetate as an innovative renewable energy storage solution is a critical aspect to consider in its development and implementation. This compound offers several environmental advantages over traditional energy storage methods, particularly in terms of sustainability and reduced carbon footprint.

Sodium acetate, being a non-toxic and biodegradable substance, presents a significantly lower environmental risk compared to conventional battery technologies that often rely on heavy metals or hazardous materials. Its production process is relatively clean, utilizing readily available and renewable resources such as acetic acid and sodium hydroxide. This contributes to a reduced overall environmental impact throughout its lifecycle.

One of the key environmental benefits of sodium acetate in energy storage is its potential to enhance the efficiency of renewable energy systems. By providing a reliable and efficient means of storing excess energy generated from intermittent sources like solar and wind, it can help maximize the utilization of clean energy and reduce reliance on fossil fuels. This, in turn, leads to a substantial reduction in greenhouse gas emissions and air pollution associated with conventional power generation.

The thermal energy storage capabilities of sodium acetate also offer environmental advantages in building applications. When used in phase change materials for passive heating and cooling systems, it can significantly reduce the energy consumption of buildings, leading to lower carbon emissions and decreased strain on power grids. This application is particularly valuable in urban environments where energy demand is high and the need for sustainable solutions is critical.

Furthermore, the recyclability of sodium acetate contributes to its environmental appeal. Unlike many battery technologies that pose challenges in terms of disposal and recycling, sodium acetate can be easily reclaimed and reprocessed at the end of its life cycle. This characteristic aligns well with circular economy principles, minimizing waste and reducing the need for continuous raw material extraction.

However, it is important to note that the large-scale production and deployment of sodium acetate for energy storage may have some environmental considerations. These include the energy and resources required for manufacturing, transportation, and installation of storage systems. Additionally, the long-term effects of widespread use on local ecosystems and water resources should be carefully monitored and studied to ensure sustainable implementation.

In conclusion, while sodium acetate shows promising environmental benefits as an innovative energy storage solution, a comprehensive life cycle assessment and ongoing environmental monitoring will be crucial to fully understand and optimize its ecological footprint. As research and development in this field progress, it is expected that further improvements in production methods and system designs will continue to enhance the environmental performance of sodium acetate-based energy storage technologies.

Sodium acetate, being a non-toxic and biodegradable substance, presents a significantly lower environmental risk compared to conventional battery technologies that often rely on heavy metals or hazardous materials. Its production process is relatively clean, utilizing readily available and renewable resources such as acetic acid and sodium hydroxide. This contributes to a reduced overall environmental impact throughout its lifecycle.

One of the key environmental benefits of sodium acetate in energy storage is its potential to enhance the efficiency of renewable energy systems. By providing a reliable and efficient means of storing excess energy generated from intermittent sources like solar and wind, it can help maximize the utilization of clean energy and reduce reliance on fossil fuels. This, in turn, leads to a substantial reduction in greenhouse gas emissions and air pollution associated with conventional power generation.

The thermal energy storage capabilities of sodium acetate also offer environmental advantages in building applications. When used in phase change materials for passive heating and cooling systems, it can significantly reduce the energy consumption of buildings, leading to lower carbon emissions and decreased strain on power grids. This application is particularly valuable in urban environments where energy demand is high and the need for sustainable solutions is critical.

Furthermore, the recyclability of sodium acetate contributes to its environmental appeal. Unlike many battery technologies that pose challenges in terms of disposal and recycling, sodium acetate can be easily reclaimed and reprocessed at the end of its life cycle. This characteristic aligns well with circular economy principles, minimizing waste and reducing the need for continuous raw material extraction.

However, it is important to note that the large-scale production and deployment of sodium acetate for energy storage may have some environmental considerations. These include the energy and resources required for manufacturing, transportation, and installation of storage systems. Additionally, the long-term effects of widespread use on local ecosystems and water resources should be carefully monitored and studied to ensure sustainable implementation.

In conclusion, while sodium acetate shows promising environmental benefits as an innovative energy storage solution, a comprehensive life cycle assessment and ongoing environmental monitoring will be crucial to fully understand and optimize its ecological footprint. As research and development in this field progress, it is expected that further improvements in production methods and system designs will continue to enhance the environmental performance of sodium acetate-based energy storage technologies.

Regulatory Framework

The regulatory framework surrounding sodium acetate as an innovative solution for renewable energy storage is still evolving, reflecting the nascent nature of this technology. Currently, there are no specific regulations directly addressing sodium acetate-based energy storage systems. However, existing regulations for energy storage technologies and renewable energy integration provide a foundation for future regulatory developments.

In many jurisdictions, energy storage systems are subject to grid connection requirements, safety standards, and performance criteria. These regulations typically focus on ensuring grid stability, preventing safety hazards, and maintaining power quality. As sodium acetate storage systems become more prevalent, regulators may need to develop specific guidelines addressing their unique characteristics, such as thermal management and material handling.

Environmental regulations also play a crucial role in shaping the adoption of sodium acetate storage. The technology's potential for reducing carbon emissions aligns with many countries' climate goals and renewable energy targets. Policymakers may introduce incentives or mandates to encourage the deployment of sodium acetate storage systems as part of broader clean energy initiatives.

Safety regulations are particularly important for sodium acetate storage, given its use of thermal energy. Existing fire safety codes and hazardous material handling regulations may need to be adapted to address the specific risks associated with large-scale sodium acetate installations. This could include requirements for containment systems, emergency response procedures, and regular safety inspections.

Standardization efforts are likely to emerge as the technology matures. Industry associations and standards organizations may develop guidelines for the design, installation, and operation of sodium acetate storage systems. These standards would help ensure interoperability, reliability, and safety across different manufacturers and applications.

Regulatory bodies may also need to address the lifecycle management of sodium acetate storage systems. This could include guidelines for the sourcing of raw materials, recycling of spent materials, and proper disposal methods. Such regulations would aim to minimize environmental impacts and promote sustainable practices throughout the technology's lifecycle.

As sodium acetate storage technology advances, regulators will need to balance innovation with safety and reliability concerns. Adaptive regulatory approaches, such as regulatory sandboxes or pilot programs, may be employed to allow for real-world testing and refinement of regulations. This would enable policymakers to gather data on the technology's performance and impacts before finalizing comprehensive regulatory frameworks.

In many jurisdictions, energy storage systems are subject to grid connection requirements, safety standards, and performance criteria. These regulations typically focus on ensuring grid stability, preventing safety hazards, and maintaining power quality. As sodium acetate storage systems become more prevalent, regulators may need to develop specific guidelines addressing their unique characteristics, such as thermal management and material handling.

Environmental regulations also play a crucial role in shaping the adoption of sodium acetate storage. The technology's potential for reducing carbon emissions aligns with many countries' climate goals and renewable energy targets. Policymakers may introduce incentives or mandates to encourage the deployment of sodium acetate storage systems as part of broader clean energy initiatives.

Safety regulations are particularly important for sodium acetate storage, given its use of thermal energy. Existing fire safety codes and hazardous material handling regulations may need to be adapted to address the specific risks associated with large-scale sodium acetate installations. This could include requirements for containment systems, emergency response procedures, and regular safety inspections.

Standardization efforts are likely to emerge as the technology matures. Industry associations and standards organizations may develop guidelines for the design, installation, and operation of sodium acetate storage systems. These standards would help ensure interoperability, reliability, and safety across different manufacturers and applications.

Regulatory bodies may also need to address the lifecycle management of sodium acetate storage systems. This could include guidelines for the sourcing of raw materials, recycling of spent materials, and proper disposal methods. Such regulations would aim to minimize environmental impacts and promote sustainable practices throughout the technology's lifecycle.

As sodium acetate storage technology advances, regulators will need to balance innovation with safety and reliability concerns. Adaptive regulatory approaches, such as regulatory sandboxes or pilot programs, may be employed to allow for real-world testing and refinement of regulations. This would enable policymakers to gather data on the technology's performance and impacts before finalizing comprehensive regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!