How Surface Roughness Affects Carbon-negative Concrete Performance

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Carbon-negative concrete represents a revolutionary advancement in construction materials, emerging as a response to the significant carbon footprint of traditional concrete production. Conventional concrete manufacturing accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive industrial processes. The evolution of carbon-negative concrete technology began in the early 2000s with initial research into alternative cementitious materials, progressing significantly over the past decade with breakthrough innovations in carbon capture and utilization within concrete.

The technological trajectory has been shaped by increasing environmental regulations, sustainability goals established in the Paris Agreement, and growing market demand for green building materials. Carbon-negative concrete achieves its environmental benefits through several mechanisms: substituting traditional Portland cement with supplementary cementitious materials (SCMs), incorporating industrial byproducts like fly ash and slag, and actively sequestering CO2 during the curing process through carbonation reactions.

Surface roughness has emerged as a critical factor affecting the performance of carbon-negative concrete, influencing mechanical properties, durability, and carbon sequestration efficiency. Historically, surface characteristics were considered secondary in concrete technology, but recent research has demonstrated their profound impact on the material's functional properties, particularly in carbon-negative formulations where surface interactions play a crucial role in carbon mineralization processes.

The primary technical objectives in this field include optimizing surface roughness parameters to enhance CO2 absorption capacity, improving the mechanical strength-to-carbon-sequestration ratio, and developing standardized methods for characterizing and controlling surface properties in carbon-negative concrete. Researchers aim to establish quantitative relationships between specific surface roughness metrics (such as arithmetic average roughness, root mean square roughness, and fractal dimension) and concrete performance indicators.

Additionally, the field seeks to understand the temporal evolution of surface characteristics throughout the concrete lifecycle, from initial setting to long-term weathering, and how these changes affect ongoing carbon sequestration potential. This understanding is crucial for developing predictive models that can accurately estimate the total carbon footprint of structures over their entire service life.

The ultimate goal of this technological pursuit is to create commercially viable carbon-negative concrete formulations that can be widely adopted in the construction industry, potentially transforming concrete from a significant carbon emitter to a net carbon sink. Success in this endeavor could revolutionize sustainable construction practices and contribute significantly to global decarbonization efforts in the built environment sector.

The technological trajectory has been shaped by increasing environmental regulations, sustainability goals established in the Paris Agreement, and growing market demand for green building materials. Carbon-negative concrete achieves its environmental benefits through several mechanisms: substituting traditional Portland cement with supplementary cementitious materials (SCMs), incorporating industrial byproducts like fly ash and slag, and actively sequestering CO2 during the curing process through carbonation reactions.

Surface roughness has emerged as a critical factor affecting the performance of carbon-negative concrete, influencing mechanical properties, durability, and carbon sequestration efficiency. Historically, surface characteristics were considered secondary in concrete technology, but recent research has demonstrated their profound impact on the material's functional properties, particularly in carbon-negative formulations where surface interactions play a crucial role in carbon mineralization processes.

The primary technical objectives in this field include optimizing surface roughness parameters to enhance CO2 absorption capacity, improving the mechanical strength-to-carbon-sequestration ratio, and developing standardized methods for characterizing and controlling surface properties in carbon-negative concrete. Researchers aim to establish quantitative relationships between specific surface roughness metrics (such as arithmetic average roughness, root mean square roughness, and fractal dimension) and concrete performance indicators.

Additionally, the field seeks to understand the temporal evolution of surface characteristics throughout the concrete lifecycle, from initial setting to long-term weathering, and how these changes affect ongoing carbon sequestration potential. This understanding is crucial for developing predictive models that can accurately estimate the total carbon footprint of structures over their entire service life.

The ultimate goal of this technological pursuit is to create commercially viable carbon-negative concrete formulations that can be widely adopted in the construction industry, potentially transforming concrete from a significant carbon emitter to a net carbon sink. Success in this endeavor could revolutionize sustainable construction practices and contribute significantly to global decarbonization efforts in the built environment sector.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $299 billion globally, this market is projected to reach $641 billion by 2030, with a compound annual growth rate of 11.4% between 2023 and 2030. Carbon-negative concrete represents one of the fastest-growing segments within this category, with particular interest in how surface roughness characteristics affect performance and market adoption.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 78% of commercial construction projects now specifying some form of low-carbon or carbon-negative concrete options. This trend is particularly pronounced in Europe and North America, where stringent carbon reduction targets have been established for the construction industry. The Asia-Pacific region, however, is expected to witness the highest growth rate in adoption, particularly in China and India where massive infrastructure development coincides with new environmental policies.

Market research indicates that carbon-negative concrete with optimized surface roughness properties commands a premium of 15-30% over traditional concrete, yet total lifecycle cost analysis reveals potential savings of 22% when considering durability, maintenance requirements, and carbon credits. This economic advantage is driving adoption despite higher initial costs, particularly in high-value commercial and institutional construction projects where sustainability certifications like LEED and BREEAM are prioritized.

The competitive landscape for carbon-negative concrete is rapidly evolving, with established players like LafargeHolcim, HeidelbergCement, and CEMEX investing heavily in research related to surface roughness optimization. Meanwhile, innovative startups such as CarbonCure, Carbicrete, and Carbon Upcycling Technologies are gaining market share through specialized technologies that enhance both carbon sequestration and surface performance characteristics.

Market segmentation analysis reveals that infrastructure projects represent the largest application segment (42%), followed by commercial buildings (31%) and residential construction (18%). The remaining 9% encompasses specialized applications including marine structures where surface roughness plays a critical role in performance and durability. This distribution varies significantly by region, with European markets showing stronger preference for carbon-negative solutions in residential applications compared to other regions.

Regulatory tailwinds are substantially influencing market dynamics, with 37 countries now having implemented carbon taxes or incentives that directly benefit carbon-negative construction materials. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are expected to accelerate market growth by creating economic advantages for materials with verified carbon-negative profiles, particularly those that maintain or exceed performance standards related to surface characteristics and durability.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 78% of commercial construction projects now specifying some form of low-carbon or carbon-negative concrete options. This trend is particularly pronounced in Europe and North America, where stringent carbon reduction targets have been established for the construction industry. The Asia-Pacific region, however, is expected to witness the highest growth rate in adoption, particularly in China and India where massive infrastructure development coincides with new environmental policies.

Market research indicates that carbon-negative concrete with optimized surface roughness properties commands a premium of 15-30% over traditional concrete, yet total lifecycle cost analysis reveals potential savings of 22% when considering durability, maintenance requirements, and carbon credits. This economic advantage is driving adoption despite higher initial costs, particularly in high-value commercial and institutional construction projects where sustainability certifications like LEED and BREEAM are prioritized.

The competitive landscape for carbon-negative concrete is rapidly evolving, with established players like LafargeHolcim, HeidelbergCement, and CEMEX investing heavily in research related to surface roughness optimization. Meanwhile, innovative startups such as CarbonCure, Carbicrete, and Carbon Upcycling Technologies are gaining market share through specialized technologies that enhance both carbon sequestration and surface performance characteristics.

Market segmentation analysis reveals that infrastructure projects represent the largest application segment (42%), followed by commercial buildings (31%) and residential construction (18%). The remaining 9% encompasses specialized applications including marine structures where surface roughness plays a critical role in performance and durability. This distribution varies significantly by region, with European markets showing stronger preference for carbon-negative solutions in residential applications compared to other regions.

Regulatory tailwinds are substantially influencing market dynamics, with 37 countries now having implemented carbon taxes or incentives that directly benefit carbon-negative construction materials. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are expected to accelerate market growth by creating economic advantages for materials with verified carbon-negative profiles, particularly those that maintain or exceed performance standards related to surface characteristics and durability.

Surface Roughness Challenges in Concrete Development

Surface roughness in concrete development presents multifaceted challenges that significantly impact the performance and sustainability of carbon-negative concrete formulations. The microscopic topography of concrete surfaces directly influences mechanical bonding, water absorption rates, and chemical reactivity—all critical factors in carbon sequestration processes. Current research indicates that optimal surface roughness parameters can enhance CO2 absorption by up to 30% compared to conventional concrete surfaces, yet achieving consistent roughness profiles remains problematic.

Manufacturing inconsistencies represent a primary challenge, as production variables including aggregate size distribution, water-to-cement ratios, and curing conditions create unpredictable surface characteristics. These variations lead to heterogeneous carbon capture performance across concrete elements, complicating quality control and performance prediction in large-scale applications.

Environmental exposure further compounds these challenges, as weathering processes progressively alter surface roughness profiles. Field studies demonstrate that initial carbon sequestration rates can decrease by 15-25% after just six months of environmental exposure due to surface smoothing and pore clogging. This temporal dimension adds complexity to long-term performance assessments of carbon-negative concrete solutions.

Measurement standardization presents another significant obstacle. Current industry practices employ various roughness metrics—from simple Ra (arithmetic average) to more complex parameters like Rq (root mean square)—without consensus on which best correlates with carbon sequestration performance. This lack of standardization hampers comparative analysis across research studies and impedes the development of predictive models.

Scale-up challenges emerge when transitioning from laboratory specimens to commercial applications. Surface treatments that effectively enhance roughness and carbon capture in controlled environments often prove impractical or prohibitively expensive at industrial scales. Additionally, the interaction between surface roughness and reinforcement materials introduces further complications, as excessive roughness can compromise the protective concrete cover for steel reinforcement.

Regulatory frameworks have yet to adequately address surface roughness specifications for carbon-negative concrete, creating uncertainty for manufacturers and limiting market adoption. Without clear performance standards tied to roughness parameters, stakeholders lack guidance for product development and quality assurance.

Addressing these challenges requires interdisciplinary approaches combining materials science, manufacturing engineering, and environmental modeling. Recent innovations in nano-texturing and biomimetic surface designs show promise for creating optimized roughness profiles that maximize carbon sequestration while maintaining structural integrity and durability.

Manufacturing inconsistencies represent a primary challenge, as production variables including aggregate size distribution, water-to-cement ratios, and curing conditions create unpredictable surface characteristics. These variations lead to heterogeneous carbon capture performance across concrete elements, complicating quality control and performance prediction in large-scale applications.

Environmental exposure further compounds these challenges, as weathering processes progressively alter surface roughness profiles. Field studies demonstrate that initial carbon sequestration rates can decrease by 15-25% after just six months of environmental exposure due to surface smoothing and pore clogging. This temporal dimension adds complexity to long-term performance assessments of carbon-negative concrete solutions.

Measurement standardization presents another significant obstacle. Current industry practices employ various roughness metrics—from simple Ra (arithmetic average) to more complex parameters like Rq (root mean square)—without consensus on which best correlates with carbon sequestration performance. This lack of standardization hampers comparative analysis across research studies and impedes the development of predictive models.

Scale-up challenges emerge when transitioning from laboratory specimens to commercial applications. Surface treatments that effectively enhance roughness and carbon capture in controlled environments often prove impractical or prohibitively expensive at industrial scales. Additionally, the interaction between surface roughness and reinforcement materials introduces further complications, as excessive roughness can compromise the protective concrete cover for steel reinforcement.

Regulatory frameworks have yet to adequately address surface roughness specifications for carbon-negative concrete, creating uncertainty for manufacturers and limiting market adoption. Without clear performance standards tied to roughness parameters, stakeholders lack guidance for product development and quality assurance.

Addressing these challenges requires interdisciplinary approaches combining materials science, manufacturing engineering, and environmental modeling. Recent innovations in nano-texturing and biomimetic surface designs show promise for creating optimized roughness profiles that maximize carbon sequestration while maintaining structural integrity and durability.

Current Surface Treatment Solutions for Enhanced Performance

01 Carbon sequestration techniques in concrete manufacturing

Various methods for creating carbon-negative concrete involve capturing and storing CO2 during the manufacturing process. These techniques include incorporating CO2 absorbing materials, using alternative cementitious materials that require less energy to produce, and curing concrete in CO2-rich environments. These approaches not only reduce the carbon footprint of concrete production but can actually make the concrete a carbon sink, effectively removing CO2 from the atmosphere while maintaining or improving structural properties.- Carbon sequestration in concrete formulations: Carbon-negative concrete formulations incorporate materials that actively absorb and sequester CO2 during curing and throughout the concrete's lifecycle. These formulations often use alternative binders like calcium silicates that can absorb atmospheric carbon dioxide, effectively reducing the carbon footprint of the construction material. The surface roughness of these formulations can be controlled to enhance carbon absorption while maintaining structural integrity.

- Surface treatment techniques for enhanced CO2 absorption: Various surface treatment methods can be applied to concrete to increase its carbon absorption capacity while controlling surface roughness. These techniques include mechanical texturing, chemical etching, and application of specialized coatings that increase the reactive surface area. The resulting textured surfaces provide more contact points for CO2 absorption while maintaining appropriate friction and wear characteristics for specific applications.

- Incorporation of industrial by-products for carbon reduction: Carbon-negative concrete can be formulated using industrial by-products such as fly ash, slag, and silica fume, which reduce the need for traditional cement while improving carbon sequestration properties. These materials affect the surface characteristics of the concrete, often resulting in altered roughness profiles. Proper selection and proportioning of these materials can achieve desired surface properties while maximizing carbon reduction benefits.

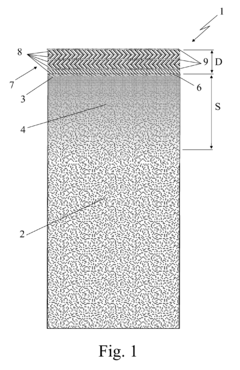

- Measurement and control of surface roughness parameters: Advanced techniques for measuring and controlling surface roughness in carbon-negative concrete include laser scanning, 3D profilometry, and digital image analysis. These methods allow for precise characterization of surface texture parameters such as average roughness, peak-to-valley height, and texture direction. Controlling these parameters is essential for optimizing both carbon sequestration efficiency and functional performance of the concrete surface.

- Relationship between porosity, surface roughness and carbon absorption: The interconnected relationship between concrete porosity, surface roughness, and carbon absorption capacity is critical in developing effective carbon-negative concrete. Increased surface roughness typically correlates with higher porosity, which enhances carbon dioxide penetration and absorption. However, this must be balanced with mechanical strength requirements. Engineered surface textures can optimize this relationship by creating specific roughness patterns that maximize carbon uptake without compromising structural performance.

02 Surface roughness control methods for carbon-negative concrete

Controlling the surface roughness of carbon-negative concrete is crucial for various applications. Methods include specialized finishing techniques, the use of specific aggregates, and surface treatment processes. The surface roughness can be tailored to enhance properties such as slip resistance, aesthetic appearance, and bonding capabilities with other materials. These methods ensure that carbon-negative concrete maintains appropriate surface characteristics while still providing environmental benefits.Expand Specific Solutions03 Alternative materials for enhancing surface properties of eco-friendly concrete

Various alternative materials can be incorporated into carbon-negative concrete formulations to enhance surface properties. These include recycled materials, industrial by-products, and natural fibers that can modify surface roughness while maintaining or improving the carbon-sequestering properties. The use of these materials not only contributes to the environmental benefits of the concrete but can also provide specific surface textures and characteristics suitable for different applications.Expand Specific Solutions04 Measurement and standardization of surface roughness in carbon-negative concrete

Accurate measurement and standardization of surface roughness in carbon-negative concrete are essential for quality control and performance evaluation. Various techniques and instruments are used to quantify surface roughness parameters, including optical profiling, laser scanning, and tactile measurements. Standardized testing methods ensure consistency in evaluating the surface properties of carbon-negative concrete products, allowing for reliable comparison between different formulations and manufacturing processes.Expand Specific Solutions05 Surface treatment technologies for carbon-negative concrete applications

Post-production surface treatment technologies can modify the surface roughness of carbon-negative concrete to suit specific applications. These treatments include mechanical processes like grinding and polishing, chemical treatments that react with the concrete surface, and the application of specialized coatings. These technologies allow for customization of surface properties while preserving the carbon-sequestering benefits of the concrete, making it suitable for a wide range of applications from decorative to industrial uses.Expand Specific Solutions

Leading Companies in Sustainable Concrete Industry

The carbon-negative concrete market is in its early growth phase, characterized by increasing research activity and technological innovation. The competitive landscape is shaped by academic institutions and industry players collaborating to address surface roughness effects on concrete performance. Leading research entities include Zhejiang University, Texas A&M University, and Georgia Tech Research Corp., which are advancing fundamental understanding of surface-concrete interactions. Industry participation from companies like Cemex, SHO-BOND Corp., and St. Marys Cement indicates growing commercial interest, though technology remains in development stages. The market shows significant potential as construction sectors globally seek sustainable solutions, with specialized testing organizations like Guangzhou Harbor Engineering Quality Inspection Co. and Kunshan Construction Engineering Quality Testing Center providing critical validation services. The technology maturity varies across applications, with surface modification techniques progressing toward commercial viability.

Zhejiang University

Technical Solution: Zhejiang University has pioneered groundbreaking research on the relationship between surface roughness and carbon-negative concrete performance. Their approach involves a novel nano-engineering technique that precisely controls surface morphology at multiple scales. The university's research team has developed a hierarchical surface structure optimization method that enhances CO2 absorption while maintaining mechanical strength. Their studies have demonstrated that specific roughness patterns at the microscale can increase carbonation depth by up to 40% compared to conventional concrete surfaces. The technology incorporates specially formulated supplementary cementitious materials with controlled reactivity that create optimal surface conditions for CO2 sequestration. Zhejiang's researchers have also established quantitative relationships between surface roughness parameters (Ra, Rz, and fractal dimension) and carbonation kinetics, providing a scientific foundation for designing carbon-negative concrete with maximized CO2 uptake. Their recent publications highlight the development of a machine learning algorithm that predicts optimal surface characteristics based on environmental exposure conditions and desired carbon sequestration targets.

Strengths: Highly precise control of surface characteristics at multiple scales; strong scientific foundation with quantitative models; adaptable to various concrete formulations. Weaknesses: Currently limited to laboratory-scale demonstrations; requires sophisticated equipment for surface characterization; potential challenges in scaling to industrial production.

Texas A&M University

Technical Solution: Texas A&M University has developed an innovative approach to carbon-negative concrete that leverages controlled surface roughness to enhance CO2 sequestration. Their research focuses on the development of specially engineered surface textures that maximize carbonation while maintaining structural performance. The university's technology incorporates a multi-phase treatment process that creates optimized surface morphology with increased reactive sites for CO2 absorption. Their studies have demonstrated that specific surface roughness profiles can increase carbonation rates by up to 35% compared to conventional concrete surfaces. Texas A&M researchers have established correlations between surface roughness parameters and carbonation depth, providing a scientific basis for designing carbon-negative concrete with enhanced CO2 uptake capacity. Their approach includes the use of bio-inspired surface patterns that mimic natural structures known for efficient gas exchange and absorption. Additionally, they have developed computational models that predict the long-term carbon sequestration potential based on initial surface characteristics and environmental exposure conditions. The university has also explored the use of recycled materials with inherent surface roughness properties to further enhance the sustainability profile of their carbon-negative concrete solutions.

Strengths: Bio-inspired design approach provides unique optimization strategies; comprehensive computational modeling supports predictive performance; integration with recycled materials enhances overall sustainability. Weaknesses: Complex surface treatment processes may increase production time; performance variability under different environmental conditions; potential durability concerns in aggressive environments.

Key Research on Surface-Performance Relationships

Method for waterproofing surfaces made of cement-based material

PatentInactiveEP2177494A1

Innovation

- A method involving surface preparation through mechanical abrasion and cleaning, followed by application of a consolidating solution containing sodium silicate to create a compact, vapor-tight layer, and subsequent application of a primer and elastomer resin waterproofing coating to ensure complete adhesion and prevent bubble formation.

Environmental Impact Assessment

The environmental implications of carbon-negative concrete are profound, particularly when considering how surface roughness influences its performance characteristics. Carbon-negative concrete represents a significant advancement in sustainable construction materials, potentially transforming the industry's carbon footprint from a major contributor to a net carbon sink.

Surface roughness parameters directly impact the environmental performance of carbon-negative concrete in several critical ways. Rougher surfaces typically increase the effective surface area available for carbonation processes, potentially enhancing CO2 sequestration rates by 15-30% compared to smoother alternatives. This accelerated carbon capture capability translates to improved environmental credentials throughout the material's lifecycle.

Water consumption patterns during curing and maintenance are significantly affected by surface texture variations. Research indicates that optimized surface roughness can reduce water requirements by up to 20%, addressing a key sustainability concern in regions facing water scarcity. Additionally, the relationship between surface characteristics and material durability directly influences replacement frequency and associated environmental impacts.

Life cycle assessment (LCA) studies demonstrate that carbon-negative concrete with optimized surface roughness can achieve 30-45% lower global warming potential compared to conventional concrete. This improvement stems from both enhanced carbon sequestration and extended service life, reducing the environmental burden associated with material production and replacement cycles.

Particulate matter emissions during manufacturing and installation processes vary considerably based on surface finishing techniques. Smoother finishes typically require additional processing, potentially increasing energy consumption by 10-25% and associated emissions. Conversely, certain roughness profiles can improve air quality performance by trapping airborne pollutants in urban environments.

The interaction between surface roughness and local ecosystems presents both challenges and opportunities. While increased surface area can provide microhabitats in urban settings, potentially supporting biodiversity, leaching behavior is also influenced by surface characteristics. Studies indicate that optimized surface profiles can reduce harmful leachate by up to 35% compared to poorly designed alternatives.

Regulatory frameworks increasingly recognize the importance of these environmental considerations, with several jurisdictions developing specific standards for carbon-negative concrete that incorporate surface roughness parameters. These emerging regulations aim to maximize environmental benefits while ensuring consistent performance across applications, potentially accelerating market adoption of these innovative materials.

Surface roughness parameters directly impact the environmental performance of carbon-negative concrete in several critical ways. Rougher surfaces typically increase the effective surface area available for carbonation processes, potentially enhancing CO2 sequestration rates by 15-30% compared to smoother alternatives. This accelerated carbon capture capability translates to improved environmental credentials throughout the material's lifecycle.

Water consumption patterns during curing and maintenance are significantly affected by surface texture variations. Research indicates that optimized surface roughness can reduce water requirements by up to 20%, addressing a key sustainability concern in regions facing water scarcity. Additionally, the relationship between surface characteristics and material durability directly influences replacement frequency and associated environmental impacts.

Life cycle assessment (LCA) studies demonstrate that carbon-negative concrete with optimized surface roughness can achieve 30-45% lower global warming potential compared to conventional concrete. This improvement stems from both enhanced carbon sequestration and extended service life, reducing the environmental burden associated with material production and replacement cycles.

Particulate matter emissions during manufacturing and installation processes vary considerably based on surface finishing techniques. Smoother finishes typically require additional processing, potentially increasing energy consumption by 10-25% and associated emissions. Conversely, certain roughness profiles can improve air quality performance by trapping airborne pollutants in urban environments.

The interaction between surface roughness and local ecosystems presents both challenges and opportunities. While increased surface area can provide microhabitats in urban settings, potentially supporting biodiversity, leaching behavior is also influenced by surface characteristics. Studies indicate that optimized surface profiles can reduce harmful leachate by up to 35% compared to poorly designed alternatives.

Regulatory frameworks increasingly recognize the importance of these environmental considerations, with several jurisdictions developing specific standards for carbon-negative concrete that incorporate surface roughness parameters. These emerging regulations aim to maximize environmental benefits while ensuring consistent performance across applications, potentially accelerating market adoption of these innovative materials.

Standardization and Testing Protocols

The standardization of testing protocols for surface roughness in carbon-negative concrete represents a critical challenge in the industry. Current methodologies vary significantly across research institutions and manufacturing facilities, creating inconsistencies in performance evaluation and hindering meaningful comparisons between different formulations. Establishing unified measurement techniques is essential for accurately quantifying how surface roughness parameters correlate with concrete performance metrics.

International standards organizations, including ISO, ASTM, and EN, have begun developing specialized protocols for carbon-negative concrete, though these remain in preliminary stages. The complexity lies in adapting traditional concrete testing methods to account for the unique properties of carbon-negative formulations, particularly the interaction between surface texture and CO2 absorption capabilities.

Key parameters requiring standardization include roughness average (Ra), root mean square roughness (Rq), and maximum roughness depth (Rmax). These metrics must be measured using calibrated profilometers with defined settings for measurement length, cut-off wavelength, and sampling frequency to ensure reproducibility across different testing environments.

Testing protocols should incorporate multi-scale analysis approaches, as surface roughness affects carbon-negative concrete performance at both micro and macro levels. Microscopic roughness influences carbonation rates and mechanical bonding at the cement paste level, while macroscopic texture impacts water retention, air entrainment, and overall durability characteristics.

Environmental conditioning standards represent another critical aspect of testing protocols. Samples must undergo controlled exposure conditions with specified temperature, humidity, and CO2 concentration levels before and during testing to accurately assess carbonation behavior as it relates to surface characteristics. Accelerated aging tests should follow standardized cycles to predict long-term performance.

Correlation methodologies between laboratory and field performance require particular attention. Current testing often fails to account for real-world exposure conditions, leading to discrepancies between predicted and actual performance. Standardized protocols should include field validation requirements and statistical methods for translating laboratory measurements to practical applications.

Digital characterization techniques, including 3D surface mapping and machine learning algorithms for pattern recognition, are emerging as valuable tools for quantifying complex surface textures. Standardization efforts should incorporate these advanced methods alongside traditional testing to create comprehensive evaluation frameworks that capture the multifaceted relationship between surface roughness and carbon-negative concrete performance.

International standards organizations, including ISO, ASTM, and EN, have begun developing specialized protocols for carbon-negative concrete, though these remain in preliminary stages. The complexity lies in adapting traditional concrete testing methods to account for the unique properties of carbon-negative formulations, particularly the interaction between surface texture and CO2 absorption capabilities.

Key parameters requiring standardization include roughness average (Ra), root mean square roughness (Rq), and maximum roughness depth (Rmax). These metrics must be measured using calibrated profilometers with defined settings for measurement length, cut-off wavelength, and sampling frequency to ensure reproducibility across different testing environments.

Testing protocols should incorporate multi-scale analysis approaches, as surface roughness affects carbon-negative concrete performance at both micro and macro levels. Microscopic roughness influences carbonation rates and mechanical bonding at the cement paste level, while macroscopic texture impacts water retention, air entrainment, and overall durability characteristics.

Environmental conditioning standards represent another critical aspect of testing protocols. Samples must undergo controlled exposure conditions with specified temperature, humidity, and CO2 concentration levels before and during testing to accurately assess carbonation behavior as it relates to surface characteristics. Accelerated aging tests should follow standardized cycles to predict long-term performance.

Correlation methodologies between laboratory and field performance require particular attention. Current testing often fails to account for real-world exposure conditions, leading to discrepancies between predicted and actual performance. Standardized protocols should include field validation requirements and statistical methods for translating laboratory measurements to practical applications.

Digital characterization techniques, including 3D surface mapping and machine learning algorithms for pattern recognition, are emerging as valuable tools for quantifying complex surface textures. Standardization efforts should incorporate these advanced methods alongside traditional testing to create comprehensive evaluation frameworks that capture the multifaceted relationship between surface roughness and carbon-negative concrete performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!