How to Adopt Modular Designs in Heat Exchanger Manufacturing

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Modular Design Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple tube-based designs to complex, highly efficient systems. The industry has witnessed a gradual shift from traditional monolithic structures to more adaptable configurations, driven by increasing demands for energy efficiency, space optimization, and cost reduction. Recent technological advancements have accelerated this evolution, with modular design principles emerging as a promising approach to address contemporary challenges in heat exchanger manufacturing.

Modular design in heat exchangers refers to the development of standardized, interchangeable components that can be assembled in various configurations to meet specific thermal requirements. This approach represents a paradigm shift from custom-built, application-specific units toward flexible systems that can be rapidly deployed and modified. The concept gained significant traction in the 2010s as manufacturing technologies matured and global competition intensified, compelling manufacturers to seek innovative methods to enhance product offerings while controlling costs.

The primary objective of adopting modular designs in heat exchanger manufacturing is to achieve greater manufacturing efficiency while maintaining or improving thermal performance. By standardizing components and assembly processes, manufacturers can realize economies of scale, reduce lead times, and minimize inventory requirements. Additionally, modularization enables more agile response to market demands, allowing companies to quickly adapt their product offerings to changing customer requirements without extensive redesign efforts.

Another critical goal is to enhance product customization capabilities without corresponding increases in engineering and production costs. Modular systems allow for the creation of application-specific solutions through the recombination of standard modules, effectively balancing the benefits of mass production with the flexibility of custom design. This approach is particularly valuable in industries with diverse thermal management requirements, such as chemical processing, HVAC, and power generation.

Sustainability objectives also drive the adoption of modular heat exchanger designs. Standardized components facilitate easier maintenance, repair, and eventual recycling, aligning with growing environmental regulations and corporate sustainability initiatives. Furthermore, the ability to upgrade specific modules rather than replacing entire units extends product lifecycles and reduces material waste, contributing to circular economy principles.

The technological trajectory suggests continued refinement of modular design principles in heat exchangers, with increasing integration of digital technologies for optimization and customization. Future developments are likely to focus on enhancing module interfaces, improving thermal efficiency of standardized components, and developing advanced manufacturing techniques that further reduce production costs while maintaining high quality standards.

Modular design in heat exchangers refers to the development of standardized, interchangeable components that can be assembled in various configurations to meet specific thermal requirements. This approach represents a paradigm shift from custom-built, application-specific units toward flexible systems that can be rapidly deployed and modified. The concept gained significant traction in the 2010s as manufacturing technologies matured and global competition intensified, compelling manufacturers to seek innovative methods to enhance product offerings while controlling costs.

The primary objective of adopting modular designs in heat exchanger manufacturing is to achieve greater manufacturing efficiency while maintaining or improving thermal performance. By standardizing components and assembly processes, manufacturers can realize economies of scale, reduce lead times, and minimize inventory requirements. Additionally, modularization enables more agile response to market demands, allowing companies to quickly adapt their product offerings to changing customer requirements without extensive redesign efforts.

Another critical goal is to enhance product customization capabilities without corresponding increases in engineering and production costs. Modular systems allow for the creation of application-specific solutions through the recombination of standard modules, effectively balancing the benefits of mass production with the flexibility of custom design. This approach is particularly valuable in industries with diverse thermal management requirements, such as chemical processing, HVAC, and power generation.

Sustainability objectives also drive the adoption of modular heat exchanger designs. Standardized components facilitate easier maintenance, repair, and eventual recycling, aligning with growing environmental regulations and corporate sustainability initiatives. Furthermore, the ability to upgrade specific modules rather than replacing entire units extends product lifecycles and reduces material waste, contributing to circular economy principles.

The technological trajectory suggests continued refinement of modular design principles in heat exchangers, with increasing integration of digital technologies for optimization and customization. Future developments are likely to focus on enhancing module interfaces, improving thermal efficiency of standardized components, and developing advanced manufacturing techniques that further reduce production costs while maintaining high quality standards.

Market Demand Analysis for Modular Heat Exchangers

The global market for modular heat exchangers has been experiencing significant growth, driven by increasing demand for energy-efficient solutions across various industries. Current market analysis indicates that the modular heat exchanger segment is expanding at a compound annual growth rate of approximately 6.5% and is projected to reach $9.2 billion by 2027. This growth trajectory is primarily fueled by stringent environmental regulations, rising energy costs, and the industrial sector's push toward sustainable manufacturing practices.

The oil and gas industry remains the largest consumer of modular heat exchangers, accounting for roughly 28% of the total market share. This sector's demand is particularly focused on compact, high-efficiency units that can withstand harsh operating conditions while offering flexibility in deployment. Following closely is the chemical processing industry, which represents about 24% of market demand, where modular designs are valued for their ability to handle corrosive fluids and operate under varying temperature and pressure conditions.

HVAC applications constitute another significant market segment, growing at the fastest rate among all sectors due to increasing construction activities in developing economies and the global emphasis on building energy efficiency. The food and beverage industry has also emerged as a promising market, with demand rising for sanitary, easy-to-clean modular heat exchangers that comply with strict hygiene standards.

Geographically, Asia-Pacific leads the market with approximately 35% share, driven by rapid industrialization in China and India. North America and Europe follow with 28% and 25% market shares respectively, where the focus is increasingly on replacement and upgrade of existing systems with more efficient modular designs.

Customer requirements are evolving toward more customizable, plug-and-play solutions that offer reduced installation time and lower maintenance costs. Market research indicates that end-users are willing to pay a premium of up to 15% for modular systems that demonstrate superior energy efficiency and operational flexibility compared to traditional designs.

The market is also witnessing a growing demand for smart modular heat exchangers equipped with IoT capabilities for real-time monitoring and predictive maintenance. This trend is expected to accelerate, with smart features becoming standard offerings rather than premium add-ons within the next five years.

Supply chain considerations are increasingly influencing purchasing decisions, with customers showing preference for manufacturers who can ensure shorter lead times and offer local technical support. This has prompted many global players to adopt regionalized manufacturing strategies to better serve key markets and reduce logistics costs.

The oil and gas industry remains the largest consumer of modular heat exchangers, accounting for roughly 28% of the total market share. This sector's demand is particularly focused on compact, high-efficiency units that can withstand harsh operating conditions while offering flexibility in deployment. Following closely is the chemical processing industry, which represents about 24% of market demand, where modular designs are valued for their ability to handle corrosive fluids and operate under varying temperature and pressure conditions.

HVAC applications constitute another significant market segment, growing at the fastest rate among all sectors due to increasing construction activities in developing economies and the global emphasis on building energy efficiency. The food and beverage industry has also emerged as a promising market, with demand rising for sanitary, easy-to-clean modular heat exchangers that comply with strict hygiene standards.

Geographically, Asia-Pacific leads the market with approximately 35% share, driven by rapid industrialization in China and India. North America and Europe follow with 28% and 25% market shares respectively, where the focus is increasingly on replacement and upgrade of existing systems with more efficient modular designs.

Customer requirements are evolving toward more customizable, plug-and-play solutions that offer reduced installation time and lower maintenance costs. Market research indicates that end-users are willing to pay a premium of up to 15% for modular systems that demonstrate superior energy efficiency and operational flexibility compared to traditional designs.

The market is also witnessing a growing demand for smart modular heat exchangers equipped with IoT capabilities for real-time monitoring and predictive maintenance. This trend is expected to accelerate, with smart features becoming standard offerings rather than premium add-ons within the next five years.

Supply chain considerations are increasingly influencing purchasing decisions, with customers showing preference for manufacturers who can ensure shorter lead times and offer local technical support. This has prompted many global players to adopt regionalized manufacturing strategies to better serve key markets and reduce logistics costs.

Current Modular Technologies and Implementation Challenges

The heat exchanger industry has witnessed significant evolution in modular design approaches over the past decade. Currently, several modular technologies dominate the market, each with distinct advantages and implementation challenges. The plate-and-frame modular system represents one of the most widely adopted solutions, featuring standardized plate components that can be assembled in various configurations to meet specific thermal requirements. This technology offers excellent scalability but faces challenges in high-pressure and extreme temperature applications.

Shell-and-tube modular systems have evolved to incorporate standardized tube bundles and shell components that can be interchanged based on performance requirements. Manufacturers have developed cataloged modules with predetermined thermal characteristics, allowing for rapid selection and assembly. However, these systems often struggle with customization limitations when unique process conditions fall outside standard module parameters.

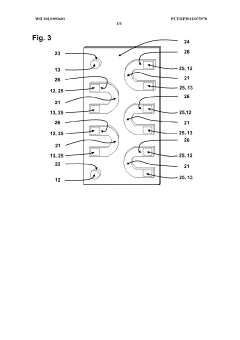

Microchannel modular heat exchangers represent a newer technology gaining traction, particularly in compact applications. These systems utilize small, standardized modules that can be arranged in parallel or series configurations. While offering superior heat transfer efficiency, they present significant manufacturing challenges related to precision fabrication and quality control of the microchannels.

Implementation of modular designs faces several technical barriers across the industry. Material compatibility issues arise when modules designed for one application are repurposed for another with different fluid properties or operating conditions. This often necessitates comprehensive material selection protocols and extensive testing procedures, increasing development costs and timelines.

Manufacturing standardization presents another significant challenge. The transition from custom-built heat exchangers to modular designs requires substantial retooling and process redesign. Many manufacturers struggle with establishing efficient production lines that maintain consistent quality across standardized modules while remaining flexible enough to accommodate design variations.

Connection and interface standardization remains problematic, with different manufacturers often employing proprietary connection systems. This creates compatibility issues when integrating modules from multiple suppliers, limiting the true interchangeability promised by modular design philosophy. Industry efforts to establish universal connection standards have progressed slowly due to competing commercial interests.

Performance prediction and validation represent technical challenges that impact widespread adoption. Current computational models often fail to accurately predict the thermal performance of complex modular arrangements, necessitating extensive physical testing. This increases development costs and extends time-to-market for new modular configurations, particularly for novel applications or extreme operating conditions.

Shell-and-tube modular systems have evolved to incorporate standardized tube bundles and shell components that can be interchanged based on performance requirements. Manufacturers have developed cataloged modules with predetermined thermal characteristics, allowing for rapid selection and assembly. However, these systems often struggle with customization limitations when unique process conditions fall outside standard module parameters.

Microchannel modular heat exchangers represent a newer technology gaining traction, particularly in compact applications. These systems utilize small, standardized modules that can be arranged in parallel or series configurations. While offering superior heat transfer efficiency, they present significant manufacturing challenges related to precision fabrication and quality control of the microchannels.

Implementation of modular designs faces several technical barriers across the industry. Material compatibility issues arise when modules designed for one application are repurposed for another with different fluid properties or operating conditions. This often necessitates comprehensive material selection protocols and extensive testing procedures, increasing development costs and timelines.

Manufacturing standardization presents another significant challenge. The transition from custom-built heat exchangers to modular designs requires substantial retooling and process redesign. Many manufacturers struggle with establishing efficient production lines that maintain consistent quality across standardized modules while remaining flexible enough to accommodate design variations.

Connection and interface standardization remains problematic, with different manufacturers often employing proprietary connection systems. This creates compatibility issues when integrating modules from multiple suppliers, limiting the true interchangeability promised by modular design philosophy. Industry efforts to establish universal connection standards have progressed slowly due to competing commercial interests.

Performance prediction and validation represent technical challenges that impact widespread adoption. Current computational models often fail to accurately predict the thermal performance of complex modular arrangements, necessitating extensive physical testing. This increases development costs and extends time-to-market for new modular configurations, particularly for novel applications or extreme operating conditions.

Current Modular Design Solutions and Methodologies

01 Modular plate heat exchanger designs

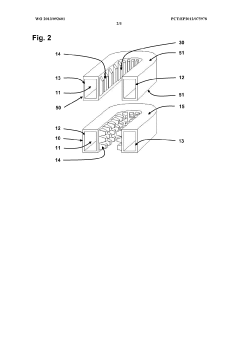

Modular plate heat exchangers feature stackable or interconnectable plate units that can be assembled in various configurations to meet specific thermal requirements. These designs allow for easy scaling, maintenance, and customization of heat transfer capacity. The modular approach enables efficient heat exchange while optimizing space utilization and facilitating future expansion or modification of the system.- Modular plate heat exchanger designs: Modular plate heat exchangers feature stackable or interconnectable plate units that can be assembled in various configurations to meet specific thermal requirements. These designs allow for easy scaling, maintenance, and customization of heat transfer capacity. The modular approach enables efficient heat exchange while optimizing space utilization and facilitating future expansion or modification of the system.

- Sectional or segmented heat exchanger modules: Heat exchangers designed with distinct sections or segments that can be individually manufactured, transported, and assembled at the installation site. This approach allows for easier handling of large heat exchange systems, simplified manufacturing, and the ability to replace specific sections when needed. Sectional designs also enable customization of different zones within the heat exchanger for varying thermal conditions or fluid types.

- Modular shell and tube heat exchanger configurations: Shell and tube heat exchangers with modular components that allow for flexible assembly and configuration. These designs feature standardized tube bundles, shells, or header sections that can be combined in different arrangements. The modular approach facilitates maintenance by allowing removal of specific sections, enables capacity adjustment through addition or removal of modules, and simplifies manufacturing through standardization of components.

- Compact and portable modular heat exchanger units: Small-scale, self-contained heat exchanger modules designed for portability and easy installation in space-constrained applications. These compact units can be deployed individually or connected in series/parallel configurations to meet varying capacity requirements. Features include standardized connections, integrated mounting systems, and optimized internal geometries to maximize heat transfer efficiency while minimizing the physical footprint.

- Modular heat exchanger systems with integrated controls: Heat exchanger modules that incorporate control systems, sensors, and automation components as part of their modular design. These integrated systems allow for intelligent operation, monitoring, and adjustment of thermal performance. The modular approach extends beyond the physical heat transfer components to include the control architecture, enabling plug-and-play installation, simplified commissioning, and distributed control capabilities across multiple connected modules.

02 Modular shell and tube heat exchanger configurations

Shell and tube heat exchangers with modular designs feature interchangeable tube bundles, sectional shells, or standardized components that can be assembled in different arrangements. These modular configurations allow for customization of heat transfer surface area, flow patterns, and thermal performance. The modular approach simplifies manufacturing, transportation, installation, and maintenance while providing flexibility to adapt to various industrial applications.Expand Specific Solutions03 Compact modular heat exchangers for space-constrained applications

Compact modular heat exchangers are designed for applications with limited installation space, featuring high thermal efficiency in reduced volumes. These designs incorporate innovative geometries, optimized flow paths, and high-density heat transfer surfaces. The modular nature allows for installation in tight spaces while maintaining accessibility for maintenance and the ability to expand capacity through the addition of modules as needed.Expand Specific Solutions04 Modular heat exchanger systems with integrated control mechanisms

Modular heat exchanger systems incorporating integrated control mechanisms feature standardized modules with built-in sensors, valves, and control interfaces. These systems enable precise temperature regulation, flow distribution, and performance monitoring across multiple heat exchange modules. The integration of control elements within the modular design allows for automated operation, remote monitoring, and optimization of thermal performance based on varying load conditions.Expand Specific Solutions05 Scalable modular heat exchanger networks for industrial applications

Scalable modular heat exchanger networks consist of standardized heat exchange units that can be interconnected to form larger systems for industrial processes. These networks allow for phased implementation, redundancy, and adaptation to changing process requirements. The modular approach enables optimization of energy recovery, simplified maintenance through module replacement, and the ability to reconfigure the system as operational needs evolve.Expand Specific Solutions

Key Industry Players in Modular Heat Exchanger Manufacturing

The modular heat exchanger manufacturing sector is currently in a growth phase, with increasing market demand driven by energy efficiency requirements across industries. The global market size is expanding steadily, particularly in automotive, energy, and industrial applications. Technologically, the field shows varying maturity levels, with established players like Robert Bosch GmbH, Valeo Thermal Systems, and Midea Group leading commercial implementation of modular designs. Research institutions such as Xi'an Jiaotong University and Sichuan University are advancing theoretical frameworks, while specialized manufacturers like T.RAD Co. and Wuxi Mashan Yonghong Heat Exchanger are developing innovative modular solutions. The competitive landscape features both diversified industrial conglomerates (Lockheed Martin, RTX Corp.) and specialized heat exchanger manufacturers, with increasing collaboration between academic and industrial sectors driving technological advancement.

Robert Bosch GmbH

Technical Solution: Robert Bosch has pioneered modular heat exchanger designs through their Advanced Thermal Management System (ATMS). Their approach involves standardized core modules that can be configured in various arrangements to meet different thermal requirements. The company utilizes a platform-based design methodology where base heat exchanger components are designed with standardized interfaces, allowing for rapid customization across automotive, industrial, and HVAC applications. Their manufacturing process incorporates automated assembly lines specifically designed for modular components, with robotic systems handling the precise alignment and joining of heat exchanger modules. Bosch has implemented digital twin technology to simulate and optimize modular heat exchanger performance before physical production, reducing development cycles by approximately 30%. Their modular designs feature quick-connect interfaces that enable easier maintenance and component replacement in the field.

Strengths: Extensive manufacturing infrastructure allows for economies of scale; strong integration capabilities with other vehicle systems; advanced simulation capabilities for thermal optimization. Weaknesses: Higher initial tooling costs for modular platforms; potential weight penalties compared to fully customized solutions; requires significant upfront engineering investment.

Behr GmbH & Co. KG

Technical Solution: Behr has developed a comprehensive modular heat exchanger platform called ModulTherm that revolutionizes traditional manufacturing approaches. Their system employs a building block concept where standardized core, header, and connection modules can be combined to create customized heat exchangers without custom tooling for each design. The manufacturing process utilizes specialized brazing techniques that maintain consistent quality across module interfaces. Behr's modular approach incorporates advanced aluminum microchannels with optimized flow patterns that can be arranged in various configurations to meet specific cooling requirements. Their production lines feature flexible automation systems capable of handling different module combinations without significant retooling. The company has implemented a parametric design system that allows engineers to rapidly configure new heat exchanger variants by selecting and arranging pre-validated modules, reducing development time by up to 40% compared to traditional design approaches.

Strengths: Specialized expertise in automotive thermal management; highly optimized aluminum microchannel technology; flexible manufacturing processes adaptable to various production volumes. Weaknesses: Limited application outside automotive sector; higher material costs for premium aluminum components; requires sophisticated inventory management for module components.

Core Patents and Technical Literature on Modular Heat Exchangers

Modular heat exchanger

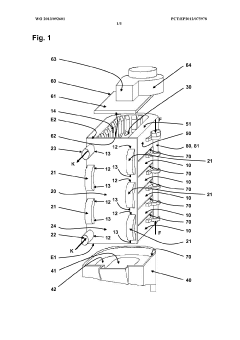

PatentInactiveEP2795219A2

Innovation

- A modular heat exchanger design featuring connectable modules and a connecting plate with hydraulic channels, allowing for the creation of heat exchangers of different sizes using cheaper tools and reducing complexity, enabling easy handling and adaptation to specific needs.

Modular heat exchanger

PatentWO2013092601A2

Innovation

- A modular heat exchanger design featuring connecting plates and interchangeable heat exchanger modules that can be easily assembled into different sizes using cheaper tools, with fluid channels and connecting channels that reduce complexity and allow for efficient heat transfer, enabling the use of identical parts for various sizes and reducing production costs.

Standardization and Compatibility Considerations

Standardization is a critical factor in the successful implementation of modular designs for heat exchanger manufacturing. The establishment of industry-wide standards enables manufacturers to develop interchangeable components that can be easily integrated across different heat exchanger systems. These standards typically encompass dimensional specifications, material requirements, connection interfaces, and performance parameters. Organizations such as ASME, TEMA, and ISO have developed comprehensive guidelines that facilitate the adoption of modular approaches while ensuring safety and reliability in heat transfer applications.

Compatibility between modules represents another essential consideration in modular heat exchanger design. Manufacturers must ensure that individual modules can seamlessly interface with one another, both mechanically and thermodynamically. This requires careful attention to connection types, sealing mechanisms, and flow path configurations. The development of standardized connection interfaces—such as flanged, welded, or quick-connect systems—significantly enhances the versatility of modular heat exchanger components while reducing assembly complexity and maintenance requirements.

Material compatibility across modules presents unique challenges that must be addressed during the design phase. Different heat transfer applications may require varying materials based on temperature ranges, pressure conditions, and chemical compatibility with process fluids. Standardizing material selection within modular families while maintaining performance capabilities requires sophisticated material science knowledge and extensive testing. Leading manufacturers have developed material compatibility matrices that guide designers in selecting appropriate module combinations for specific applications.

Thermal performance standardization represents another dimension of compatibility considerations. Modules must be designed with predictable heat transfer characteristics that can be accurately modeled when combined in various configurations. This necessitates standardized testing methodologies and performance rating systems that enable engineers to confidently predict the behavior of assembled modular systems. Computational fluid dynamics (CFD) modeling has become an invaluable tool in validating the thermal performance of modular heat exchanger designs before physical prototyping.

Lifecycle compatibility considerations extend beyond initial installation to include maintenance, repair, and upgrade scenarios. Truly effective modular designs incorporate standardized access points for inspection and cleaning, as well as provisions for the replacement of individual modules without disrupting the entire system. Forward-thinking manufacturers are increasingly adopting design approaches that anticipate future technological advancements, ensuring that next-generation modules will remain compatible with existing installations through carefully planned interface standards and upgrade paths.

Compatibility between modules represents another essential consideration in modular heat exchanger design. Manufacturers must ensure that individual modules can seamlessly interface with one another, both mechanically and thermodynamically. This requires careful attention to connection types, sealing mechanisms, and flow path configurations. The development of standardized connection interfaces—such as flanged, welded, or quick-connect systems—significantly enhances the versatility of modular heat exchanger components while reducing assembly complexity and maintenance requirements.

Material compatibility across modules presents unique challenges that must be addressed during the design phase. Different heat transfer applications may require varying materials based on temperature ranges, pressure conditions, and chemical compatibility with process fluids. Standardizing material selection within modular families while maintaining performance capabilities requires sophisticated material science knowledge and extensive testing. Leading manufacturers have developed material compatibility matrices that guide designers in selecting appropriate module combinations for specific applications.

Thermal performance standardization represents another dimension of compatibility considerations. Modules must be designed with predictable heat transfer characteristics that can be accurately modeled when combined in various configurations. This necessitates standardized testing methodologies and performance rating systems that enable engineers to confidently predict the behavior of assembled modular systems. Computational fluid dynamics (CFD) modeling has become an invaluable tool in validating the thermal performance of modular heat exchanger designs before physical prototyping.

Lifecycle compatibility considerations extend beyond initial installation to include maintenance, repair, and upgrade scenarios. Truly effective modular designs incorporate standardized access points for inspection and cleaning, as well as provisions for the replacement of individual modules without disrupting the entire system. Forward-thinking manufacturers are increasingly adopting design approaches that anticipate future technological advancements, ensuring that next-generation modules will remain compatible with existing installations through carefully planned interface standards and upgrade paths.

Sustainability Impact of Modular Heat Exchanger Manufacturing

The adoption of modular designs in heat exchanger manufacturing represents a significant shift toward more sustainable industrial practices. Modular heat exchangers offer substantial environmental benefits through their entire lifecycle, starting with reduced material consumption during manufacturing. By standardizing components and optimizing designs for assembly, manufacturers can achieve material efficiency improvements of 15-25% compared to traditional monolithic designs, directly reducing the extraction of raw materials and associated environmental impacts.

Energy consumption during production processes also decreases significantly with modular approaches. Research indicates that modular manufacturing can reduce energy requirements by up to 30% through more efficient production lines, shorter heating cycles, and optimized welding processes. This translates to lower carbon emissions from manufacturing operations, contributing to corporate and national climate goals.

The sustainability advantages extend throughout the product lifecycle. Modular heat exchangers facilitate easier maintenance and part replacement, extending operational lifespans by an estimated 40-60% compared to conventional units. When components fail, only the affected modules need replacement rather than entire systems, dramatically reducing waste generation and resource consumption over time.

End-of-life management represents perhaps the most significant sustainability improvement. Modular designs enable straightforward disassembly, allowing for approximately 85-95% of materials to be recovered for recycling or remanufacturing. This circular economy approach contrasts sharply with traditional heat exchangers, where complex integrated designs often result in less than 60% material recovery rates.

Water conservation benefits also emerge from modular manufacturing approaches. Production processes for modular components typically require 20-35% less water than conventional manufacturing methods, addressing growing concerns about industrial water usage in water-stressed regions.

From a chemical perspective, modular designs often incorporate newer, more environmentally friendly materials and coatings that reduce the use of harmful substances. This transition supports compliance with increasingly stringent environmental regulations like REACH and RoHS, while also improving workplace safety conditions.

The carbon footprint reduction potential is substantial when considering the entire lifecycle. Life Cycle Assessment (LCA) studies indicate that modular heat exchangers can achieve 25-40% lower carbon emissions across manufacturing, operation, and end-of-life phases compared to conventional alternatives, particularly when designed with sustainability principles from the outset.

Energy consumption during production processes also decreases significantly with modular approaches. Research indicates that modular manufacturing can reduce energy requirements by up to 30% through more efficient production lines, shorter heating cycles, and optimized welding processes. This translates to lower carbon emissions from manufacturing operations, contributing to corporate and national climate goals.

The sustainability advantages extend throughout the product lifecycle. Modular heat exchangers facilitate easier maintenance and part replacement, extending operational lifespans by an estimated 40-60% compared to conventional units. When components fail, only the affected modules need replacement rather than entire systems, dramatically reducing waste generation and resource consumption over time.

End-of-life management represents perhaps the most significant sustainability improvement. Modular designs enable straightforward disassembly, allowing for approximately 85-95% of materials to be recovered for recycling or remanufacturing. This circular economy approach contrasts sharply with traditional heat exchangers, where complex integrated designs often result in less than 60% material recovery rates.

Water conservation benefits also emerge from modular manufacturing approaches. Production processes for modular components typically require 20-35% less water than conventional manufacturing methods, addressing growing concerns about industrial water usage in water-stressed regions.

From a chemical perspective, modular designs often incorporate newer, more environmentally friendly materials and coatings that reduce the use of harmful substances. This transition supports compliance with increasingly stringent environmental regulations like REACH and RoHS, while also improving workplace safety conditions.

The carbon footprint reduction potential is substantial when considering the entire lifecycle. Life Cycle Assessment (LCA) studies indicate that modular heat exchangers can achieve 25-40% lower carbon emissions across manufacturing, operation, and end-of-life phases compared to conventional alternatives, particularly when designed with sustainability principles from the outset.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!