How to Analyze Heat Exchanger Lifetime for Long-Term Planning

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Lifetime Analysis Background and Objectives

Heat exchangers represent critical components in numerous industrial processes, serving as the backbone of thermal management systems across sectors including power generation, chemical processing, HVAC, and oil refining. The evolution of heat exchanger technology spans over a century, with significant advancements in materials science, design methodologies, and manufacturing techniques driving continuous improvements in efficiency and durability.

The trajectory of heat exchanger development has been characterized by a progressive shift from simple shell-and-tube designs to more complex and specialized configurations such as plate, spiral, and printed circuit heat exchangers. This evolution has been primarily driven by increasing demands for energy efficiency, space optimization, and operational reliability in increasingly demanding industrial environments.

Current technological trends in heat exchanger development focus on enhancing thermal performance while simultaneously extending operational lifetimes. These include the integration of advanced materials with superior corrosion resistance, the implementation of computational fluid dynamics for optimized flow distribution, and the development of novel surface enhancement techniques to maximize heat transfer coefficients.

The primary objective of heat exchanger lifetime analysis is to establish reliable methodologies for predicting the functional lifespan of these critical components under various operational conditions. This encompasses the development of accelerated testing protocols, the creation of comprehensive degradation models, and the implementation of condition monitoring systems capable of providing real-time insights into equipment health.

Long-term planning for heat exchanger deployment necessitates accurate lifetime predictions to optimize maintenance schedules, minimize unexpected failures, and inform capital expenditure decisions. The economic implications of premature heat exchanger failure can be substantial, encompassing not only replacement costs but also production losses associated with unplanned downtime.

Regulatory frameworks increasingly emphasize the importance of equipment reliability and safety, particularly in high-risk industries such as nuclear power generation and petrochemical processing. Consequently, robust lifetime analysis methodologies have become essential components of regulatory compliance strategies, further underscoring the importance of this technical domain.

The convergence of digital technologies with traditional heat exchanger design and operation presents significant opportunities for lifetime extension through predictive maintenance and intelligent operational management. The integration of IoT sensors, machine learning algorithms, and digital twin technologies represents the frontier of heat exchanger lifetime optimization, enabling unprecedented levels of operational insight and control.

The trajectory of heat exchanger development has been characterized by a progressive shift from simple shell-and-tube designs to more complex and specialized configurations such as plate, spiral, and printed circuit heat exchangers. This evolution has been primarily driven by increasing demands for energy efficiency, space optimization, and operational reliability in increasingly demanding industrial environments.

Current technological trends in heat exchanger development focus on enhancing thermal performance while simultaneously extending operational lifetimes. These include the integration of advanced materials with superior corrosion resistance, the implementation of computational fluid dynamics for optimized flow distribution, and the development of novel surface enhancement techniques to maximize heat transfer coefficients.

The primary objective of heat exchanger lifetime analysis is to establish reliable methodologies for predicting the functional lifespan of these critical components under various operational conditions. This encompasses the development of accelerated testing protocols, the creation of comprehensive degradation models, and the implementation of condition monitoring systems capable of providing real-time insights into equipment health.

Long-term planning for heat exchanger deployment necessitates accurate lifetime predictions to optimize maintenance schedules, minimize unexpected failures, and inform capital expenditure decisions. The economic implications of premature heat exchanger failure can be substantial, encompassing not only replacement costs but also production losses associated with unplanned downtime.

Regulatory frameworks increasingly emphasize the importance of equipment reliability and safety, particularly in high-risk industries such as nuclear power generation and petrochemical processing. Consequently, robust lifetime analysis methodologies have become essential components of regulatory compliance strategies, further underscoring the importance of this technical domain.

The convergence of digital technologies with traditional heat exchanger design and operation presents significant opportunities for lifetime extension through predictive maintenance and intelligent operational management. The integration of IoT sensors, machine learning algorithms, and digital twin technologies represents the frontier of heat exchanger lifetime optimization, enabling unprecedented levels of operational insight and control.

Market Demand for Reliable Heat Exchanger Longevity Prediction

The global market for heat exchanger lifetime prediction solutions is experiencing significant growth, driven by industries' increasing focus on asset reliability and operational efficiency. According to recent market analyses, the predictive maintenance market for industrial equipment, including heat exchangers, is projected to reach $23.5 billion by 2025, growing at a CAGR of 25-30% from 2020. Within this broader market, solutions specifically targeting heat exchanger longevity prediction represent a rapidly expanding segment.

Primary demand drivers include the rising costs associated with unplanned downtime, which can exceed $50,000 per hour in process industries such as oil and gas, chemical processing, and power generation. These sectors collectively account for approximately 65% of the current market demand for heat exchanger lifetime prediction solutions. The financial implications of premature heat exchanger failure extend beyond replacement costs to include production losses, safety risks, and potential regulatory penalties.

Energy efficiency regulations and sustainability initiatives are further accelerating market demand. In regions with stringent environmental regulations like the European Union, North America, and increasingly in Asia-Pacific countries, organizations face mounting pressure to optimize equipment performance and extend operational lifespans. This regulatory landscape has created a 40% increase in demand for advanced predictive tools over the past five years.

The market shows distinct segmentation based on industry requirements. Process industries demand high-precision prediction models with accuracy rates above 90%, while utilities and manufacturing sectors prioritize cost-effective solutions that can be integrated with existing asset management systems. This segmentation has led to the development of tiered solution offerings in the marketplace.

Recent surveys indicate that 78% of maintenance professionals consider reliable lifetime prediction capabilities as "very important" or "critical" for their heat exchanger management strategies. However, only 35% report satisfaction with current prediction methodologies, highlighting a significant market gap. This dissatisfaction primarily stems from the limitations of traditional approaches that fail to account for variable operating conditions and cumulative damage mechanisms.

The market is also witnessing a shift toward subscription-based predictive maintenance services, with annual growth rates exceeding 30%. This trend reflects industrial customers' preference for operational expenditure models over capital investments, particularly for specialized technical solutions requiring regular updates and expert support.

Primary demand drivers include the rising costs associated with unplanned downtime, which can exceed $50,000 per hour in process industries such as oil and gas, chemical processing, and power generation. These sectors collectively account for approximately 65% of the current market demand for heat exchanger lifetime prediction solutions. The financial implications of premature heat exchanger failure extend beyond replacement costs to include production losses, safety risks, and potential regulatory penalties.

Energy efficiency regulations and sustainability initiatives are further accelerating market demand. In regions with stringent environmental regulations like the European Union, North America, and increasingly in Asia-Pacific countries, organizations face mounting pressure to optimize equipment performance and extend operational lifespans. This regulatory landscape has created a 40% increase in demand for advanced predictive tools over the past five years.

The market shows distinct segmentation based on industry requirements. Process industries demand high-precision prediction models with accuracy rates above 90%, while utilities and manufacturing sectors prioritize cost-effective solutions that can be integrated with existing asset management systems. This segmentation has led to the development of tiered solution offerings in the marketplace.

Recent surveys indicate that 78% of maintenance professionals consider reliable lifetime prediction capabilities as "very important" or "critical" for their heat exchanger management strategies. However, only 35% report satisfaction with current prediction methodologies, highlighting a significant market gap. This dissatisfaction primarily stems from the limitations of traditional approaches that fail to account for variable operating conditions and cumulative damage mechanisms.

The market is also witnessing a shift toward subscription-based predictive maintenance services, with annual growth rates exceeding 30%. This trend reflects industrial customers' preference for operational expenditure models over capital investments, particularly for specialized technical solutions requiring regular updates and expert support.

Current Challenges in Heat Exchanger Lifetime Assessment

Heat exchanger lifetime assessment faces significant challenges in today's industrial landscape, primarily due to the complex interplay of multiple degradation mechanisms. Corrosion, fouling, erosion, and thermal fatigue simultaneously affect these critical components, making accurate prediction models exceptionally difficult to develop. Traditional assessment methods often focus on individual degradation factors rather than their combined effects, leading to incomplete lifetime projections.

Material-specific challenges further complicate assessment efforts. Different heat exchanger materials (stainless steel, titanium, copper alloys, etc.) exhibit unique degradation patterns under varying operational conditions. The lack of comprehensive material performance data across diverse industrial environments creates substantial uncertainty in lifetime predictions, particularly for newer alloys with limited field history.

Operating condition variability represents another major obstacle. Heat exchangers rarely operate under steady-state conditions throughout their service life. Fluctuations in temperature, pressure, flow rates, and fluid compositions accelerate degradation in ways that are difficult to model mathematically. Current assessment methodologies struggle to account for these dynamic operational profiles, especially in batch processing industries where conditions change frequently.

Data collection limitations severely restrict assessment accuracy. Many facilities lack sufficient instrumentation to monitor key parameters affecting heat exchanger health. Historical maintenance records often contain gaps or inconsistencies, making it challenging to establish reliable baseline performance metrics or degradation trends. Without robust data, even sophisticated predictive models yield questionable results.

Computational modeling constraints present additional barriers. While computational fluid dynamics (CFD) and finite element analysis (FEA) offer powerful simulation capabilities, they remain computationally intensive and require significant expertise to implement effectively. Many organizations lack the specialized knowledge or resources to utilize these advanced tools, defaulting to simplified models with limited predictive value.

Industry standardization gaps further impede progress. Unlike pressure vessels or piping systems, heat exchangers lack universally accepted lifetime assessment protocols. Different industries and regions employ varied approaches, creating inconsistency in how remaining useful life is calculated and reported. This fragmentation hampers knowledge sharing and comparative analysis across sectors.

Economic evaluation challenges also affect lifetime assessment practices. Organizations struggle to quantify the financial implications of different maintenance strategies or replacement timelines. Without clear cost-benefit frameworks that incorporate both direct costs (replacement, downtime) and indirect costs (efficiency losses, environmental impact), decision-makers lack the economic context needed for optimal long-term planning.

Material-specific challenges further complicate assessment efforts. Different heat exchanger materials (stainless steel, titanium, copper alloys, etc.) exhibit unique degradation patterns under varying operational conditions. The lack of comprehensive material performance data across diverse industrial environments creates substantial uncertainty in lifetime predictions, particularly for newer alloys with limited field history.

Operating condition variability represents another major obstacle. Heat exchangers rarely operate under steady-state conditions throughout their service life. Fluctuations in temperature, pressure, flow rates, and fluid compositions accelerate degradation in ways that are difficult to model mathematically. Current assessment methodologies struggle to account for these dynamic operational profiles, especially in batch processing industries where conditions change frequently.

Data collection limitations severely restrict assessment accuracy. Many facilities lack sufficient instrumentation to monitor key parameters affecting heat exchanger health. Historical maintenance records often contain gaps or inconsistencies, making it challenging to establish reliable baseline performance metrics or degradation trends. Without robust data, even sophisticated predictive models yield questionable results.

Computational modeling constraints present additional barriers. While computational fluid dynamics (CFD) and finite element analysis (FEA) offer powerful simulation capabilities, they remain computationally intensive and require significant expertise to implement effectively. Many organizations lack the specialized knowledge or resources to utilize these advanced tools, defaulting to simplified models with limited predictive value.

Industry standardization gaps further impede progress. Unlike pressure vessels or piping systems, heat exchangers lack universally accepted lifetime assessment protocols. Different industries and regions employ varied approaches, creating inconsistency in how remaining useful life is calculated and reported. This fragmentation hampers knowledge sharing and comparative analysis across sectors.

Economic evaluation challenges also affect lifetime assessment practices. Organizations struggle to quantify the financial implications of different maintenance strategies or replacement timelines. Without clear cost-benefit frameworks that incorporate both direct costs (replacement, downtime) and indirect costs (efficiency losses, environmental impact), decision-makers lack the economic context needed for optimal long-term planning.

Established Methodologies for Heat Exchanger Lifetime Prediction

01 Materials and coatings for extending heat exchanger lifetime

Advanced materials and protective coatings can significantly extend the operational lifetime of heat exchangers by enhancing corrosion resistance and reducing wear. These materials include specialized alloys and surface treatments that can withstand harsh operating conditions, high temperatures, and corrosive environments. Implementing these material solutions helps prevent degradation of heat exchanger components, minimizing maintenance requirements and extending service intervals.- Materials and coatings for extending heat exchanger lifetime: Selection of appropriate materials and application of protective coatings can significantly extend the lifetime of heat exchangers. Corrosion-resistant alloys, specialized surface treatments, and anti-fouling coatings help prevent degradation in harsh operating environments. These materials and coatings protect against chemical attack, erosion, and thermal stress, maintaining heat transfer efficiency and structural integrity over extended periods.

- Design optimizations for durability: Innovative design approaches can enhance heat exchanger longevity. Features such as optimized flow patterns, stress-relieving geometries, and modular construction allow for better thermal expansion management and reduced mechanical fatigue. Advanced computational modeling helps identify potential failure points during the design phase, enabling preventive measures that extend operational life in various industrial applications.

- Maintenance techniques and condition monitoring: Regular maintenance procedures and real-time condition monitoring systems are crucial for maximizing heat exchanger lifetime. Techniques include scheduled cleaning to remove fouling, non-destructive testing to detect early signs of failure, and predictive maintenance based on performance data. Monitoring parameters such as pressure drop, temperature differentials, and flow rates helps identify degradation before catastrophic failure occurs.

- Thermal cycling and stress management: Managing thermal cycling and mechanical stress is essential for extending heat exchanger lifetime. Controlled startup and shutdown procedures, temperature gradient management, and stress-relieving designs help minimize fatigue damage. Implementing expansion joints, flexible connections, and proper support structures accommodates thermal expansion and contraction, reducing stress concentrations that could lead to premature failure.

- Environmental adaptation and specialized applications: Heat exchangers designed for specific environmental conditions demonstrate extended operational lifetimes. Customized solutions for extreme temperatures, corrosive media, or high-pressure applications incorporate specialized features that address unique challenges. These adaptations may include enhanced fouling resistance for marine environments, high-temperature capabilities for industrial processes, or cryogenic designs for specialized cooling applications.

02 Design optimizations for improved durability

Innovative design approaches can enhance heat exchanger longevity by addressing common failure points. These include optimized flow distribution to prevent localized erosion, improved tube-to-header connections to reduce thermal stress, and modular designs that facilitate targeted component replacement. Strategic design considerations focus on minimizing thermal cycling damage and mechanical stress concentrations that typically lead to premature failure.Expand Specific Solutions03 Monitoring and predictive maintenance systems

Advanced monitoring technologies and predictive maintenance approaches help extend heat exchanger lifetime by identifying potential issues before catastrophic failure occurs. These systems utilize sensors, data analytics, and machine learning algorithms to track performance parameters and detect early signs of degradation. Implementing condition-based maintenance strategies allows for timely interventions that can significantly extend operational life while optimizing maintenance schedules.Expand Specific Solutions04 Fouling mitigation techniques

Fouling is a major factor limiting heat exchanger lifetime. Various techniques have been developed to address this issue, including self-cleaning mechanisms, specialized surface treatments that reduce deposit adhesion, and optimized flow patterns that minimize sediment accumulation. Chemical treatments and mechanical cleaning systems can be integrated into heat exchanger designs to maintain thermal efficiency and extend operational lifetime by preventing performance degradation due to fouling.Expand Specific Solutions05 Thermal stress management solutions

Managing thermal stresses is crucial for extending heat exchanger lifetime. Innovative approaches include flexible mounting systems that accommodate thermal expansion, controlled startup and shutdown procedures, and designs that distribute thermal loads more evenly. These solutions help prevent fatigue cracking and joint failures caused by repeated thermal cycling, particularly in applications with frequent temperature fluctuations or extreme operating conditions.Expand Specific Solutions

Leading Organizations in Heat Exchanger Reliability Research

The heat exchanger lifetime analysis market is currently in a growth phase, with increasing demand driven by aging industrial infrastructure and sustainability requirements. The market size is expanding as industries prioritize asset management and operational efficiency, particularly in energy, petrochemical, and manufacturing sectors. Technologically, the field shows moderate maturity with established methodologies, but innovation continues in predictive analytics and materials science. Key players include industrial equipment manufacturers like ABB Group and Siemens, energy giants such as Saudi Aramco and Suncor Energy, specialized thermal engineering firms like Xi'an Thermal Power Research Institute, and research institutions including Shanghai Power Equipment Research Institute. These organizations are advancing computational modeling, non-destructive testing, and AI-based predictive maintenance to extend heat exchanger service life.

ABB Group

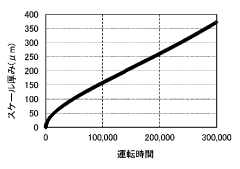

Technical Solution: ABB Group has developed an advanced Heat Exchanger Lifetime Analysis System (HELAS) that combines real-time monitoring with predictive analytics for comprehensive lifetime assessment. The system employs multiple sensor arrays to track critical parameters including temperature gradients, pressure differentials, flow rates, and material degradation indicators. ABB's approach integrates these data points into a proprietary algorithm that accounts for thermal cycling fatigue, corrosion rates, fouling progression, and mechanical stress accumulation. Their solution incorporates digital twin technology to simulate heat exchanger performance under various operating conditions, allowing for scenario planning and optimization. The system features adaptive maintenance scheduling based on actual degradation rates rather than fixed time intervals, significantly improving operational efficiency. ABB's predictive models have demonstrated accuracy rates of over 85% in forecasting remaining useful life across various industrial applications, enabling more precise capital expenditure planning for replacement or refurbishment.

Strengths: Comprehensive integration with industrial control systems, extensive historical performance database spanning multiple industries, and proven accuracy in lifetime predictions. Weaknesses: Higher implementation costs compared to traditional monitoring systems, requires significant historical data for optimal performance, and may need customization for specialized heat exchanger designs.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive Heat Exchanger Reliability and Integrity Management System (HERIMS) specifically designed for oil and gas processing facilities operating in extreme environments. Their approach combines traditional reliability-centered maintenance principles with advanced materials science and computational fluid dynamics to create highly accurate lifetime prediction models. Aramco's system incorporates specialized corrosion monitoring techniques that account for the unique chemical compositions found in hydrocarbon processing, including high-sulfur crude streams and various process catalysts. Their methodology employs a multi-tiered risk assessment framework that evaluates both the probability and consequence of failure for critical heat exchangers, allowing for prioritized resource allocation. The company has implemented a fleet-wide monitoring network that enables comparative analysis across similar equipment operating under different conditions, creating a powerful database for predictive analytics. Aramco's approach includes regular metallurgical sampling and analysis to track actual material degradation rates against predicted values, continuously refining their lifetime models based on real-world performance data.

Strengths: Exceptional expertise in high-temperature, high-pressure, and corrosive environments typical of oil and gas processing; extensive historical performance database; and proven track record in extending equipment life in harsh operating conditions. Weaknesses: Models optimized primarily for petrochemical applications may require significant adaptation for other industries; system complexity requires specialized expertise to implement and maintain; high implementation costs for smaller operations.

Critical Technologies for Heat Exchanger Failure Analysis

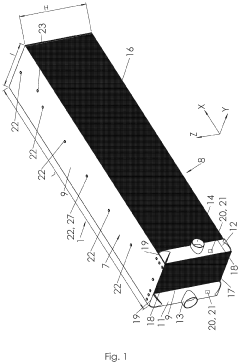

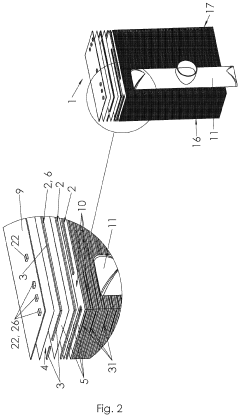

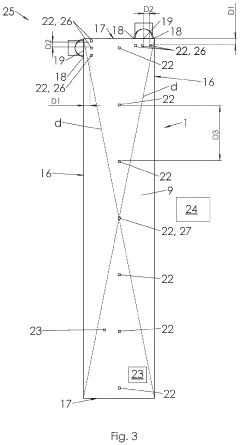

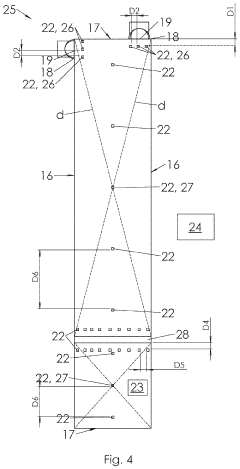

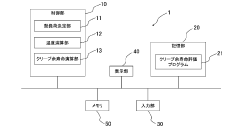

Instrumented heat exchanger and method for estimating a lifespan of said heat exchanger

PatentPendingUS20240027148A1

Innovation

- A heat exchanger equipped with temperature, pressure, and strain gauges, along with a communication device, continuously measures and processes data to recalculate the maintenance and replacement schedule in real-time, allowing for adaptive management of the heat exchanger's service life based on actual usage.

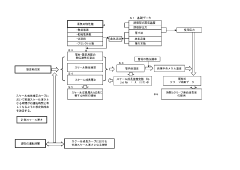

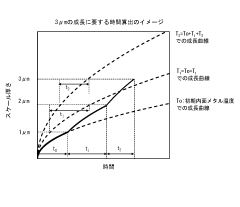

Remaining lifetime evaluation method for heat transfer tube, and remaining lifetime evaluation device for heat transfer tube

PatentActiveJP2023005279A

Innovation

- A method and apparatus that calculate the relationship between steam oxide scale thickness and growth time, using heat flux to determine the central tube wall temperature and stress, thereby accurately estimating the remaining creep life by considering temperature gradients and actual operating conditions.

Economic Impact of Heat Exchanger Lifecycle Management

The economic implications of heat exchanger lifecycle management extend far beyond the immediate costs of equipment purchase and installation. Comprehensive lifecycle economic analysis reveals that initial capital expenditure typically represents only 20-30% of the total lifetime cost of ownership, with maintenance, energy consumption, and downtime expenses constituting the majority of long-term costs.

Effective lifecycle management strategies can yield substantial financial benefits through reduced energy consumption. Studies indicate that properly maintained heat exchangers operate at 15-25% higher efficiency compared to neglected units, translating to significant energy savings over operational lifespans of 15-30 years. For large industrial facilities, these savings can amount to millions of dollars annually.

Predictive maintenance approaches, when compared to reactive maintenance models, demonstrate compelling economic advantages. Organizations implementing condition-based maintenance programs for heat exchangers report maintenance cost reductions of 25-35% while simultaneously extending equipment lifespan by 20-40%. The return on investment for implementing advanced monitoring systems typically materializes within 12-24 months.

Downtime costs represent another critical economic consideration. Unplanned heat exchanger failures in process industries can result in production losses ranging from $5,000 to $100,000 per hour depending on the application. Structured lifecycle management reduces these incidents by 60-80%, substantially improving overall plant economics and production reliability.

Environmental compliance and sustainability factors increasingly influence the economic equation. Modern lifecycle management approaches incorporate environmental cost accounting, recognizing that efficient operation reduces carbon footprints and associated regulatory costs. Companies implementing comprehensive heat exchanger lifecycle programs report 10-15% reductions in environmental compliance expenses.

The economic impact extends to capital planning as well. Organizations with mature lifecycle management programs demonstrate more predictable capital expenditure patterns, with replacement cycles becoming more consistent and plannable. This predictability enables more strategic allocation of capital resources and improved financial forecasting accuracy, typically improving capital efficiency by 15-20%.

Risk management benefits provide additional economic value. Comprehensive lifecycle programs reduce insurance premiums through demonstrated risk reduction, while also mitigating potential liability costs associated with catastrophic failures. These risk-related savings, though difficult to quantify precisely, represent significant value in high-consequence operating environments.

Effective lifecycle management strategies can yield substantial financial benefits through reduced energy consumption. Studies indicate that properly maintained heat exchangers operate at 15-25% higher efficiency compared to neglected units, translating to significant energy savings over operational lifespans of 15-30 years. For large industrial facilities, these savings can amount to millions of dollars annually.

Predictive maintenance approaches, when compared to reactive maintenance models, demonstrate compelling economic advantages. Organizations implementing condition-based maintenance programs for heat exchangers report maintenance cost reductions of 25-35% while simultaneously extending equipment lifespan by 20-40%. The return on investment for implementing advanced monitoring systems typically materializes within 12-24 months.

Downtime costs represent another critical economic consideration. Unplanned heat exchanger failures in process industries can result in production losses ranging from $5,000 to $100,000 per hour depending on the application. Structured lifecycle management reduces these incidents by 60-80%, substantially improving overall plant economics and production reliability.

Environmental compliance and sustainability factors increasingly influence the economic equation. Modern lifecycle management approaches incorporate environmental cost accounting, recognizing that efficient operation reduces carbon footprints and associated regulatory costs. Companies implementing comprehensive heat exchanger lifecycle programs report 10-15% reductions in environmental compliance expenses.

The economic impact extends to capital planning as well. Organizations with mature lifecycle management programs demonstrate more predictable capital expenditure patterns, with replacement cycles becoming more consistent and plannable. This predictability enables more strategic allocation of capital resources and improved financial forecasting accuracy, typically improving capital efficiency by 15-20%.

Risk management benefits provide additional economic value. Comprehensive lifecycle programs reduce insurance premiums through demonstrated risk reduction, while also mitigating potential liability costs associated with catastrophic failures. These risk-related savings, though difficult to quantify precisely, represent significant value in high-consequence operating environments.

Sustainability Considerations in Heat Exchanger Replacement Planning

Sustainability considerations are becoming increasingly critical in heat exchanger replacement planning as organizations face growing environmental regulations and corporate social responsibility expectations. The lifecycle environmental impact of heat exchangers extends beyond operational efficiency to include raw material extraction, manufacturing processes, transportation, and end-of-life disposal. A comprehensive sustainability assessment must consider these factors when planning replacement strategies.

Energy consumption represents the most significant environmental impact during a heat exchanger's operational life. Modern heat exchangers with advanced designs and materials can reduce energy consumption by 15-30% compared to older models, substantially decreasing carbon emissions over their lifetime. This improvement must be factored into replacement decisions beyond simple economic calculations.

Material selection plays a crucial role in sustainability planning. Traditional heat exchangers often utilize copper, aluminum, and stainless steel, which have varying environmental footprints in terms of mining impacts and recyclability. Newer sustainable alternatives include bio-based composites and recycled metal alloys that reduce virgin material requirements. Organizations should evaluate the embodied carbon in different material options when planning replacements.

Water consumption associated with heat exchanger operation presents another sustainability concern, particularly in water-stressed regions. Advanced designs can reduce water requirements by up to 40% through closed-loop systems and improved efficiency. Replacement planning should incorporate water footprint analysis, especially for facilities in areas facing increasing water scarcity.

End-of-life considerations significantly impact the overall sustainability profile of heat exchangers. Approximately 85% of heat exchanger materials can be recycled when properly processed, reducing landfill waste and raw material demand. Developing partnerships with specialized recycling facilities before replacement ensures proper handling of decommissioned units and maximizes material recovery.

Regulatory compliance represents both a challenge and opportunity in sustainable replacement planning. Environmental regulations are becoming increasingly stringent worldwide, with many jurisdictions implementing carbon pricing mechanisms and extended producer responsibility laws. Forward-thinking organizations can gain competitive advantage by anticipating regulatory changes and implementing sustainable replacement strategies proactively.

Life cycle assessment (LCA) methodologies provide valuable frameworks for quantifying the environmental impacts of heat exchanger replacement decisions. These assessments consider impacts across all lifecycle stages and help organizations make data-driven sustainability decisions. Integrating LCA into replacement planning enables organizations to balance economic, technical, and environmental considerations effectively.

Energy consumption represents the most significant environmental impact during a heat exchanger's operational life. Modern heat exchangers with advanced designs and materials can reduce energy consumption by 15-30% compared to older models, substantially decreasing carbon emissions over their lifetime. This improvement must be factored into replacement decisions beyond simple economic calculations.

Material selection plays a crucial role in sustainability planning. Traditional heat exchangers often utilize copper, aluminum, and stainless steel, which have varying environmental footprints in terms of mining impacts and recyclability. Newer sustainable alternatives include bio-based composites and recycled metal alloys that reduce virgin material requirements. Organizations should evaluate the embodied carbon in different material options when planning replacements.

Water consumption associated with heat exchanger operation presents another sustainability concern, particularly in water-stressed regions. Advanced designs can reduce water requirements by up to 40% through closed-loop systems and improved efficiency. Replacement planning should incorporate water footprint analysis, especially for facilities in areas facing increasing water scarcity.

End-of-life considerations significantly impact the overall sustainability profile of heat exchangers. Approximately 85% of heat exchanger materials can be recycled when properly processed, reducing landfill waste and raw material demand. Developing partnerships with specialized recycling facilities before replacement ensures proper handling of decommissioned units and maximizes material recovery.

Regulatory compliance represents both a challenge and opportunity in sustainable replacement planning. Environmental regulations are becoming increasingly stringent worldwide, with many jurisdictions implementing carbon pricing mechanisms and extended producer responsibility laws. Forward-thinking organizations can gain competitive advantage by anticipating regulatory changes and implementing sustainable replacement strategies proactively.

Life cycle assessment (LCA) methodologies provide valuable frameworks for quantifying the environmental impacts of heat exchanger replacement decisions. These assessments consider impacts across all lifecycle stages and help organizations make data-driven sustainability decisions. Integrating LCA into replacement planning enables organizations to balance economic, technical, and environmental considerations effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!