How To Assess Environmental Impact Of Lithium Hydroxide Disposal

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Disposal Background and Objectives

Lithium hydroxide has emerged as a critical component in the global transition towards sustainable energy systems, particularly in the production of high-performance lithium-ion batteries for electric vehicles and renewable energy storage. The historical development of lithium hydroxide usage traces back to industrial applications in ceramics, lubricants, and glass manufacturing, but has seen exponential growth in the past decade due to the electrification revolution in transportation and energy sectors.

The environmental implications of lithium hydroxide disposal represent a significant concern as global production scales dramatically to meet clean energy demands. Lithium hydroxide is highly alkaline (pH >14) and water-soluble, presenting potential risks to aquatic ecosystems, soil chemistry, and groundwater quality when improperly managed. Current disposal practices vary widely across regions, with inconsistent regulatory frameworks governing end-of-life management.

Technical evolution in this domain has progressed from basic neutralization techniques to more sophisticated recovery and recycling methodologies. The industry is witnessing a paradigm shift from linear "extract-use-dispose" models toward circular economy approaches that prioritize material recovery and reuse. This transition is driven by both environmental imperatives and economic incentives, as lithium remains a strategically valuable resource.

The primary objective of environmental impact assessment for lithium hydroxide disposal is to develop standardized, scientifically rigorous methodologies that quantify ecological risks across multiple environmental compartments. These assessments must account for both acute and chronic exposure scenarios, considering transformation products and bioaccumulation potential in diverse ecosystems.

Secondary objectives include establishing threshold values for environmentally acceptable disposal concentrations, identifying cost-effective treatment technologies for contaminated sites, and developing predictive models for long-term environmental fate. Additionally, there is growing recognition of the need to integrate social and economic dimensions into comprehensive impact assessments, particularly in lithium-producing regions where mining and processing activities intersect with community interests.

The technical goals for advancing assessment methodologies include developing rapid analytical techniques for monitoring lithium hydroxide in complex environmental matrices, standardizing leaching tests that simulate various disposal scenarios, and creating life-cycle assessment tools specifically calibrated for lithium compounds. These developments must keep pace with the rapidly evolving battery chemistry landscape, which continues to introduce new lithium formulations with potentially distinct environmental profiles.

The environmental implications of lithium hydroxide disposal represent a significant concern as global production scales dramatically to meet clean energy demands. Lithium hydroxide is highly alkaline (pH >14) and water-soluble, presenting potential risks to aquatic ecosystems, soil chemistry, and groundwater quality when improperly managed. Current disposal practices vary widely across regions, with inconsistent regulatory frameworks governing end-of-life management.

Technical evolution in this domain has progressed from basic neutralization techniques to more sophisticated recovery and recycling methodologies. The industry is witnessing a paradigm shift from linear "extract-use-dispose" models toward circular economy approaches that prioritize material recovery and reuse. This transition is driven by both environmental imperatives and economic incentives, as lithium remains a strategically valuable resource.

The primary objective of environmental impact assessment for lithium hydroxide disposal is to develop standardized, scientifically rigorous methodologies that quantify ecological risks across multiple environmental compartments. These assessments must account for both acute and chronic exposure scenarios, considering transformation products and bioaccumulation potential in diverse ecosystems.

Secondary objectives include establishing threshold values for environmentally acceptable disposal concentrations, identifying cost-effective treatment technologies for contaminated sites, and developing predictive models for long-term environmental fate. Additionally, there is growing recognition of the need to integrate social and economic dimensions into comprehensive impact assessments, particularly in lithium-producing regions where mining and processing activities intersect with community interests.

The technical goals for advancing assessment methodologies include developing rapid analytical techniques for monitoring lithium hydroxide in complex environmental matrices, standardizing leaching tests that simulate various disposal scenarios, and creating life-cycle assessment tools specifically calibrated for lithium compounds. These developments must keep pace with the rapidly evolving battery chemistry landscape, which continues to introduce new lithium formulations with potentially distinct environmental profiles.

Environmental Impact Assessment Market Demand

The environmental impact assessment market for lithium hydroxide disposal is experiencing significant growth driven by increasing lithium production for batteries and energy storage systems. As electric vehicle adoption accelerates globally, the demand for lithium compounds has surged, creating parallel growth in assessment services to monitor and mitigate environmental impacts of disposal processes.

Market research indicates that the global environmental assessment services market related to battery materials is expanding at approximately 6.8% annually, with the lithium-specific segment growing even faster. This growth is particularly pronounced in regions with substantial lithium processing activities, including Australia, Chile, China, and increasingly North America and Europe as they develop domestic battery supply chains.

Regulatory frameworks are becoming a primary market driver, with countries implementing stricter environmental protection measures for critical mineral processing. The European Union's Battery Directive revision, China's tightened industrial waste regulations, and the U.S. EPA's increased scrutiny of extraction industries have all contributed to heightened demand for comprehensive environmental impact assessments specifically addressing lithium compounds.

Corporate sustainability commitments represent another significant market force. Major battery manufacturers and automotive companies are increasingly requiring environmental impact data throughout their supply chains. This trend has created demand for specialized assessment services that can evaluate the full lifecycle environmental footprint of lithium hydroxide, from production through disposal or recycling.

The market shows distinct segmentation between preventive assessment services (evaluating disposal methods before implementation) and remediation assessment services (measuring existing contamination and recommending mitigation strategies). Preventive services currently command premium pricing due to their ability to reduce long-term environmental liabilities.

Technological advancements in assessment methodologies constitute a notable market trend. Remote sensing, real-time monitoring systems, and advanced analytical techniques for detecting lithium compounds in soil and water systems are gaining traction. These innovations are enabling more accurate quantification of environmental impacts while reducing assessment costs.

Emerging economies with developing lithium industries represent the fastest-growing market segment, particularly in South America and parts of Africa. These regions are seeking assessment expertise to establish environmentally sustainable practices from the outset of industry development, creating opportunities for assessment service providers with international experience.

Market research indicates that the global environmental assessment services market related to battery materials is expanding at approximately 6.8% annually, with the lithium-specific segment growing even faster. This growth is particularly pronounced in regions with substantial lithium processing activities, including Australia, Chile, China, and increasingly North America and Europe as they develop domestic battery supply chains.

Regulatory frameworks are becoming a primary market driver, with countries implementing stricter environmental protection measures for critical mineral processing. The European Union's Battery Directive revision, China's tightened industrial waste regulations, and the U.S. EPA's increased scrutiny of extraction industries have all contributed to heightened demand for comprehensive environmental impact assessments specifically addressing lithium compounds.

Corporate sustainability commitments represent another significant market force. Major battery manufacturers and automotive companies are increasingly requiring environmental impact data throughout their supply chains. This trend has created demand for specialized assessment services that can evaluate the full lifecycle environmental footprint of lithium hydroxide, from production through disposal or recycling.

The market shows distinct segmentation between preventive assessment services (evaluating disposal methods before implementation) and remediation assessment services (measuring existing contamination and recommending mitigation strategies). Preventive services currently command premium pricing due to their ability to reduce long-term environmental liabilities.

Technological advancements in assessment methodologies constitute a notable market trend. Remote sensing, real-time monitoring systems, and advanced analytical techniques for detecting lithium compounds in soil and water systems are gaining traction. These innovations are enabling more accurate quantification of environmental impacts while reducing assessment costs.

Emerging economies with developing lithium industries represent the fastest-growing market segment, particularly in South America and parts of Africa. These regions are seeking assessment expertise to establish environmentally sustainable practices from the outset of industry development, creating opportunities for assessment service providers with international experience.

Current Disposal Challenges and Technical Limitations

The disposal of lithium hydroxide presents significant environmental challenges due to its high alkalinity (pH >14) and potential toxicity to aquatic organisms. Current disposal methods often fail to adequately address these concerns, leading to environmental contamination and regulatory compliance issues. Traditional landfill disposal remains common despite being increasingly problematic as lithium hydroxide can leach into groundwater, altering pH levels and potentially mobilizing heavy metals in surrounding soil.

Wastewater treatment facilities face technical limitations when processing lithium hydroxide-containing effluents. Conventional precipitation methods struggle to effectively remove lithium ions, which can pass through treatment systems and enter natural water bodies. The high solubility of lithium compounds further complicates removal efforts, requiring specialized treatment technologies that many facilities lack.

Neutralization processes, while theoretically straightforward, present practical challenges including precise pH control requirements and the generation of secondary waste streams. The exothermic nature of neutralization reactions demands careful handling protocols and specialized equipment that smaller waste management operations often cannot support. Additionally, the resulting lithium salts still require proper disposal or recovery pathways.

Recovery and recycling technologies for lithium hydroxide remain underdeveloped compared to other industrial chemicals. Current recovery methods are energy-intensive and often economically unfeasible at smaller scales. The technical complexity of separating lithium from mixed waste streams presents a significant barrier to widespread implementation of circular economy approaches for this material.

Monitoring and detection systems for lithium contamination in environmental matrices show limitations in sensitivity and specificity. Standard analytical methods may not detect lithium at environmentally relevant concentrations, creating challenges for compliance verification and environmental impact assessment. Real-time monitoring solutions remain largely unavailable, hampering rapid response to potential release events.

Regulatory frameworks governing lithium hydroxide disposal vary significantly across jurisdictions, creating compliance challenges for multinational operations. Many existing regulations were not specifically designed with lithium compounds in mind, resulting in regulatory gaps and inconsistent enforcement. The classification of lithium wastes differs between regions, further complicating standardized disposal approaches.

The growing battery industry has dramatically increased lithium hydroxide production volumes, outpacing the development of appropriate disposal infrastructure. This scale mismatch creates bottlenecks in the waste management pipeline, with disposal facilities increasingly unable to handle the volume and concentration of lithium-containing wastes generated by manufacturing operations.

Wastewater treatment facilities face technical limitations when processing lithium hydroxide-containing effluents. Conventional precipitation methods struggle to effectively remove lithium ions, which can pass through treatment systems and enter natural water bodies. The high solubility of lithium compounds further complicates removal efforts, requiring specialized treatment technologies that many facilities lack.

Neutralization processes, while theoretically straightforward, present practical challenges including precise pH control requirements and the generation of secondary waste streams. The exothermic nature of neutralization reactions demands careful handling protocols and specialized equipment that smaller waste management operations often cannot support. Additionally, the resulting lithium salts still require proper disposal or recovery pathways.

Recovery and recycling technologies for lithium hydroxide remain underdeveloped compared to other industrial chemicals. Current recovery methods are energy-intensive and often economically unfeasible at smaller scales. The technical complexity of separating lithium from mixed waste streams presents a significant barrier to widespread implementation of circular economy approaches for this material.

Monitoring and detection systems for lithium contamination in environmental matrices show limitations in sensitivity and specificity. Standard analytical methods may not detect lithium at environmentally relevant concentrations, creating challenges for compliance verification and environmental impact assessment. Real-time monitoring solutions remain largely unavailable, hampering rapid response to potential release events.

Regulatory frameworks governing lithium hydroxide disposal vary significantly across jurisdictions, creating compliance challenges for multinational operations. Many existing regulations were not specifically designed with lithium compounds in mind, resulting in regulatory gaps and inconsistent enforcement. The classification of lithium wastes differs between regions, further complicating standardized disposal approaches.

The growing battery industry has dramatically increased lithium hydroxide production volumes, outpacing the development of appropriate disposal infrastructure. This scale mismatch creates bottlenecks in the waste management pipeline, with disposal facilities increasingly unable to handle the volume and concentration of lithium-containing wastes generated by manufacturing operations.

Current Environmental Assessment Methodologies

01 Environmental impact assessment of lithium hydroxide disposal

The disposal of lithium hydroxide can have significant environmental impacts that need to be assessed and managed. These impacts include potential contamination of soil and water bodies, effects on aquatic ecosystems, and long-term environmental persistence. Environmental impact assessments are conducted to evaluate these risks and develop appropriate mitigation strategies for safe disposal of lithium hydroxide waste.- Environmental impact assessment of lithium hydroxide disposal: The disposal of lithium hydroxide poses significant environmental concerns due to its high alkalinity and potential to contaminate soil and water systems. Environmental impact assessments are conducted to evaluate the effects of lithium hydroxide disposal on ecosystems, groundwater, and surrounding habitats. These assessments help in developing appropriate disposal strategies that minimize ecological damage and comply with environmental regulations.

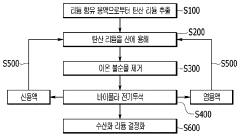

- Recycling and recovery methods for lithium hydroxide waste: Various technologies have been developed to recycle and recover lithium hydroxide from waste streams, reducing the need for disposal and minimizing environmental impact. These methods include chemical precipitation, membrane filtration, and electrochemical processes that enable the extraction of lithium compounds for reuse in battery manufacturing and other applications. Recycling lithium hydroxide not only reduces environmental contamination but also conserves valuable lithium resources.

- Neutralization and treatment processes for lithium hydroxide waste: Before disposal, lithium hydroxide waste often requires neutralization and treatment to reduce its alkalinity and potential environmental harm. Treatment processes may involve acid neutralization, chemical stabilization, or conversion to less harmful compounds. These processes aim to transform lithium hydroxide into more environmentally benign forms that can be safely disposed of in landfills or through other waste management systems.

- Regulatory frameworks and compliance for lithium hydroxide disposal: Disposal of lithium hydroxide is subject to various regulatory frameworks designed to protect the environment. These regulations establish guidelines for proper handling, storage, transportation, and disposal of lithium-containing waste. Compliance with these regulations requires implementing specific waste management practices, documentation, and reporting procedures to ensure that lithium hydroxide disposal meets environmental safety standards.

- Innovative containment and monitoring systems for lithium waste: Advanced containment systems and monitoring technologies have been developed to manage lithium hydroxide disposal sites and prevent environmental contamination. These systems include specialized liners for landfills, leachate collection systems, groundwater monitoring wells, and sensor networks that detect potential leaks or contamination. Continuous monitoring allows for early detection of environmental impacts and implementation of remediation measures when necessary.

02 Recycling and recovery methods for lithium hydroxide waste

Various technologies have been developed for recycling and recovering lithium hydroxide from waste streams to minimize environmental impact. These methods include chemical precipitation, membrane filtration, electrochemical processes, and thermal treatment. Recycling lithium hydroxide not only reduces environmental pollution but also conserves valuable lithium resources, making it an economically and environmentally sustainable approach to waste management.Expand Specific Solutions03 Neutralization and treatment processes for lithium hydroxide waste

Before disposal, lithium hydroxide waste often requires neutralization and treatment to reduce its alkalinity and potential environmental hazards. Treatment processes may include acid neutralization, chemical stabilization, and conversion to less reactive compounds. These processes aim to transform lithium hydroxide into forms that are less harmful to the environment and safer for disposal in landfills or through other waste management systems.Expand Specific Solutions04 Monitoring and management systems for lithium waste disposal

Advanced monitoring and management systems are essential for tracking the environmental impact of lithium hydroxide disposal. These systems include sensors for detecting leakage, data analytics for environmental impact prediction, and comprehensive waste management protocols. Continuous monitoring helps in early detection of potential environmental issues and enables timely intervention to prevent or mitigate adverse effects on ecosystems and human health.Expand Specific Solutions05 Sustainable disposal practices and regulatory compliance

Sustainable disposal practices for lithium hydroxide involve adherence to regulatory standards and implementation of best environmental practices. This includes proper containment, controlled disposal in designated facilities, and compliance with local and international environmental regulations. Companies are increasingly adopting sustainable disposal methods that go beyond minimum regulatory requirements to minimize their environmental footprint and demonstrate corporate responsibility.Expand Specific Solutions

Key Industry Players and Waste Management Organizations

The lithium hydroxide disposal environmental impact assessment landscape is currently in an emerging phase, with the market growing rapidly due to increasing lithium battery production worldwide. The technology maturity varies significantly among key players, with established mining and metallurgical companies like POSCO Holdings, Sumitomo Metal Mining, and SK Innovation leading in industrial-scale solutions. Specialized technology firms such as Watercycle Technologies and Cemvita Factory are developing innovative extraction and recycling approaches. Battery manufacturers including CATL and LG Energy Solution are increasingly investing in closed-loop systems. Research institutions like Central South University and RIST are advancing fundamental assessment methodologies, creating a competitive environment where collaboration between industry and academia is driving standardization of environmental impact metrics.

Sumitomo Metal Mining Co., Ltd.

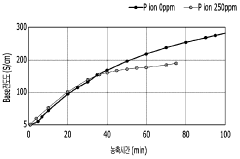

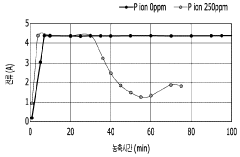

Technical Solution: Sumitomo Metal Mining has developed an advanced environmental impact assessment protocol for lithium hydroxide disposal called Li-EIAT (Lithium Environmental Impact Assessment Tool). This comprehensive system integrates geochemical modeling with ecological risk assessment to evaluate both immediate and long-term environmental consequences. Their methodology begins with detailed characterization of waste properties, including mineralogy, particle size distribution, and leaching behavior under various environmental conditions. Sumitomo's approach incorporates hydrogeological modeling to predict contaminant transport in groundwater systems, with particular attention to lithium mobility in different soil types[7]. The company has implemented an innovative phytoremediation strategy using specially selected halophytic plants that can accumulate lithium, providing both assessment data and potential remediation options. Their assessment framework includes a novel biomonitoring component using sentinel organisms to detect early warning signs of ecosystem stress before significant damage occurs[8]. Sumitomo has also developed a geopolymer encapsulation technique that can immobilize lithium hydroxide waste, reducing leachability by up to 98% compared to conventional landfill disposal.

Strengths: Science-based assessment methodology that combines predictive modeling with biological monitoring to provide early detection of environmental impacts. Their phytoremediation approach offers potential for site restoration following disposal activities. Weaknesses: The comprehensive assessment protocol requires significant time and resources to implement fully. The geopolymer encapsulation technique, while effective, substantially increases the volume of material requiring ultimate disposal, creating potential land use conflicts.

SK Innovation Co., Ltd.

Technical Solution: SK Innovation has pioneered a multi-parameter environmental impact assessment framework for lithium hydroxide disposal called LiEcoMetrics. This system employs a weighted scoring methodology that evaluates impacts across five environmental domains: water quality, soil chemistry, air emissions, biodiversity, and resource depletion. Their approach incorporates both laboratory testing and field monitoring to establish baseline conditions and track changes following disposal activities. SK Innovation's methodology includes specialized leaching tests designed specifically for lithium compounds that simulate various environmental conditions (acidic rain, groundwater interaction, etc.) to predict mobility and bioavailability[5]. The company has developed a proprietary pre-treatment process that converts highly alkaline lithium hydroxide waste into more stable lithium silicate compounds, reducing pH-related impacts by approximately 70%[6]. Their assessment framework includes a temporal dimension, with modeling capabilities to predict environmental impacts over periods ranging from 1 to 100 years post-disposal, allowing for more informed long-term management decisions.

Strengths: Holistic assessment approach that quantifies impacts across multiple environmental compartments with different temporal scales. Their conversion technology significantly reduces the alkalinity hazard of disposed materials. Weaknesses: The weighted scoring system involves subjective judgments about the relative importance of different environmental impacts. The silicate conversion process is energy-intensive and may not be economically feasible for smaller operations or in regions with high energy costs.

Critical Research on Lithium Hydroxide Ecotoxicology

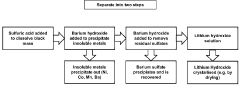

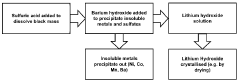

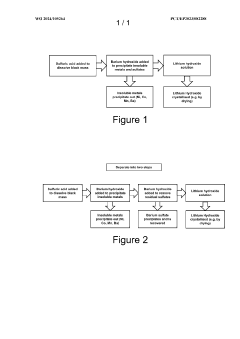

Method for preparing lithium hydroxide by using lithium carbonate

PatentWO2024135907A1

Innovation

- A method involving the dissolution of lithium carbonate in acid, followed by removal of ionic impurities using an ion exchange resin and subsequent conversion through bipolar electrodialysis to produce lithium hydroxide, minimizing by-product generation and maintaining high productivity.

method

PatentWO2024105264A1

Innovation

- A multi-step precipitation method involving acid treatment followed by sequential addition of bases to precipitate out insoluble metals and conjugate acid compounds, allowing for the isolation of lithium hydroxide with reduced contaminants and lower reagent costs, and potential recycling of by-products.

Regulatory Compliance and Global Standards

The regulatory landscape governing lithium hydroxide disposal is complex and varies significantly across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates lithium hydroxide under the Resource Conservation and Recovery Act (RCRA) as a hazardous waste due to its corrosive properties. Companies must adhere to strict disposal protocols, including proper containment, labeling, and transportation to authorized treatment facilities. The EPA's Toxicity Characteristic Leaching Procedure (TCLP) is commonly used to determine if waste materials containing lithium hydroxide exceed regulatory thresholds.

In the European Union, the management of lithium hydroxide falls under the Waste Framework Directive (2008/98/EC) and the Classification, Labelling and Packaging (CLP) Regulation. The European Chemicals Agency (ECHA) has established specific guidelines for handling and disposing of lithium compounds, with particular emphasis on preventing contamination of water bodies due to lithium's high water solubility.

China, as the world's largest producer of lithium compounds, has implemented the Solid Waste Pollution Prevention and Control Law, which was significantly revised in 2020 to strengthen environmental protection measures. These regulations impose stricter requirements on waste generators and disposal facilities, including comprehensive environmental impact assessments before disposal activities can commence.

International standards such as ISO 14001 (Environmental Management Systems) provide frameworks for organizations to systematically assess and minimize environmental impacts of their operations, including waste disposal. The Global Reporting Initiative (GRI) standards, particularly GRI 306: Waste, offer guidance on disclosure of waste-related impacts, which many lithium-processing companies voluntarily adopt to demonstrate environmental responsibility.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal regulates international shipments of hazardous waste, including lithium hydroxide waste. Signatory countries must implement measures to ensure environmentally sound management of hazardous wastes and restrict their movement across borders without proper authorization.

Emerging regulatory trends include the development of circular economy frameworks that emphasize recovery and recycling of lithium compounds rather than disposal. The European Battery Directive, currently under revision, aims to establish more stringent requirements for battery manufacturers regarding the recyclability of lithium-ion batteries and the recovery of valuable materials, including lithium compounds.

Compliance with these diverse regulatory frameworks requires companies to implement comprehensive environmental management systems, conduct regular audits, maintain detailed documentation of disposal practices, and stay informed about evolving regulations across different jurisdictions where they operate.

In the European Union, the management of lithium hydroxide falls under the Waste Framework Directive (2008/98/EC) and the Classification, Labelling and Packaging (CLP) Regulation. The European Chemicals Agency (ECHA) has established specific guidelines for handling and disposing of lithium compounds, with particular emphasis on preventing contamination of water bodies due to lithium's high water solubility.

China, as the world's largest producer of lithium compounds, has implemented the Solid Waste Pollution Prevention and Control Law, which was significantly revised in 2020 to strengthen environmental protection measures. These regulations impose stricter requirements on waste generators and disposal facilities, including comprehensive environmental impact assessments before disposal activities can commence.

International standards such as ISO 14001 (Environmental Management Systems) provide frameworks for organizations to systematically assess and minimize environmental impacts of their operations, including waste disposal. The Global Reporting Initiative (GRI) standards, particularly GRI 306: Waste, offer guidance on disclosure of waste-related impacts, which many lithium-processing companies voluntarily adopt to demonstrate environmental responsibility.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal regulates international shipments of hazardous waste, including lithium hydroxide waste. Signatory countries must implement measures to ensure environmentally sound management of hazardous wastes and restrict their movement across borders without proper authorization.

Emerging regulatory trends include the development of circular economy frameworks that emphasize recovery and recycling of lithium compounds rather than disposal. The European Battery Directive, currently under revision, aims to establish more stringent requirements for battery manufacturers regarding the recyclability of lithium-ion batteries and the recovery of valuable materials, including lithium compounds.

Compliance with these diverse regulatory frameworks requires companies to implement comprehensive environmental management systems, conduct regular audits, maintain detailed documentation of disposal practices, and stay informed about evolving regulations across different jurisdictions where they operate.

Life Cycle Assessment Frameworks

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of lithium hydroxide disposal throughout its entire lifecycle. The ISO 14040 and 14044 standards establish the foundational methodology for conducting LCAs, offering a structured approach that includes goal and scope definition, inventory analysis, impact assessment, and interpretation phases. These standards ensure consistency and comparability across different assessments in the lithium industry.

For lithium hydroxide specifically, several specialized LCA frameworks have been developed to address the unique challenges of battery materials. The GaBi and SimaPro software platforms incorporate dedicated modules for battery materials assessment, enabling detailed modeling of disposal scenarios with consideration for leaching behavior, soil contamination, and groundwater impacts.

The Global Battery Alliance's framework emphasizes circularity metrics alongside traditional environmental indicators, providing a more holistic view of lithium hydroxide's end-of-life management. This approach quantifies resource efficiency and recovery potential, which are particularly relevant for lithium compounds given their economic value and limited global reserves.

Recent methodological advances have introduced spatially explicit LCA frameworks that account for the geographical variability in disposal impacts. This is crucial for lithium hydroxide assessment as environmental sensitivity to alkaline compounds varies significantly across different ecosystems and geological settings. These frameworks incorporate GIS data to model site-specific factors such as precipitation patterns, soil composition, and proximity to water bodies.

The Battery Environmental Assessment Tool (BEAT) represents another specialized framework that focuses on the unique characteristics of battery materials throughout their lifecycle. It incorporates specific parameters for lithium compounds, including pH neutralization potential, mobility in various soil types, and aquatic toxicity thresholds.

Emerging frameworks are also beginning to integrate social and economic dimensions alongside environmental metrics, reflecting the growing recognition of sustainability's triple bottom line. These approaches consider factors such as community impacts from disposal sites, long-term monitoring costs, and the economic implications of different disposal strategies versus recovery and reuse options.

For comprehensive assessment, hybrid LCA approaches that combine process-based and economic input-output methodologies offer particular advantages when evaluating complex supply chains and disposal networks typical in the lithium industry. These frameworks help capture indirect impacts that might otherwise be overlooked in traditional process-based assessments.

For lithium hydroxide specifically, several specialized LCA frameworks have been developed to address the unique challenges of battery materials. The GaBi and SimaPro software platforms incorporate dedicated modules for battery materials assessment, enabling detailed modeling of disposal scenarios with consideration for leaching behavior, soil contamination, and groundwater impacts.

The Global Battery Alliance's framework emphasizes circularity metrics alongside traditional environmental indicators, providing a more holistic view of lithium hydroxide's end-of-life management. This approach quantifies resource efficiency and recovery potential, which are particularly relevant for lithium compounds given their economic value and limited global reserves.

Recent methodological advances have introduced spatially explicit LCA frameworks that account for the geographical variability in disposal impacts. This is crucial for lithium hydroxide assessment as environmental sensitivity to alkaline compounds varies significantly across different ecosystems and geological settings. These frameworks incorporate GIS data to model site-specific factors such as precipitation patterns, soil composition, and proximity to water bodies.

The Battery Environmental Assessment Tool (BEAT) represents another specialized framework that focuses on the unique characteristics of battery materials throughout their lifecycle. It incorporates specific parameters for lithium compounds, including pH neutralization potential, mobility in various soil types, and aquatic toxicity thresholds.

Emerging frameworks are also beginning to integrate social and economic dimensions alongside environmental metrics, reflecting the growing recognition of sustainability's triple bottom line. These approaches consider factors such as community impacts from disposal sites, long-term monitoring costs, and the economic implications of different disposal strategies versus recovery and reuse options.

For comprehensive assessment, hybrid LCA approaches that combine process-based and economic input-output methodologies offer particular advantages when evaluating complex supply chains and disposal networks typical in the lithium industry. These frameworks help capture indirect impacts that might otherwise be overlooked in traditional process-based assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!