How to Choose the Right PLA Type for Your Project?

JUN 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Types and Applications

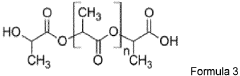

Polylactic acid (PLA) is a versatile bioplastic with various types tailored for specific applications. The selection of the appropriate PLA type is crucial for project success, as each variant offers unique properties and characteristics.

Standard PLA is the most common type, suitable for general-purpose 3D printing and packaging applications. It offers good printability, moderate strength, and biodegradability. However, its limitations in heat resistance and impact strength may restrict its use in certain scenarios.

High-temperature PLA variants address the heat sensitivity issue of standard PLA. These formulations incorporate additives or modified molecular structures to enhance thermal stability, making them suitable for applications requiring higher heat resistance, such as automotive parts or outdoor products.

Impact-modified PLA types are engineered to improve toughness and impact resistance. These variants often incorporate elastomeric additives or copolymers, resulting in enhanced flexibility and durability. They are particularly useful in applications requiring higher impact strength, such as consumer electronics casings or sporting goods.

Crystalline PLA grades exhibit improved mechanical properties and heat resistance compared to amorphous PLA. These types undergo controlled crystallization during processing, resulting in higher strength, stiffness, and temperature resistance. They are well-suited for applications in automotive, electronics, and durable goods industries.

Fiber-reinforced PLA composites incorporate natural or synthetic fibers to enhance mechanical properties. These materials offer improved strength, stiffness, and dimensional stability, making them suitable for structural applications in automotive, construction, and aerospace sectors.

Food-grade PLA types are specifically formulated to meet regulatory requirements for food contact applications. These variants undergo rigorous testing to ensure compliance with food safety standards and are commonly used in food packaging, disposable cutlery, and beverage containers.

Medical-grade PLA is designed for biomedical applications, such as implants, drug delivery systems, and tissue engineering scaffolds. These types undergo stringent purification processes and are formulated to meet biocompatibility and biodegradability requirements for medical use.

When choosing the right PLA type for a project, several factors must be considered. These include the intended application, required mechanical properties, thermal performance, regulatory compliance, and processing conditions. Additionally, the availability of specific PLA grades from suppliers and their compatibility with existing manufacturing processes should be evaluated.

Standard PLA is the most common type, suitable for general-purpose 3D printing and packaging applications. It offers good printability, moderate strength, and biodegradability. However, its limitations in heat resistance and impact strength may restrict its use in certain scenarios.

High-temperature PLA variants address the heat sensitivity issue of standard PLA. These formulations incorporate additives or modified molecular structures to enhance thermal stability, making them suitable for applications requiring higher heat resistance, such as automotive parts or outdoor products.

Impact-modified PLA types are engineered to improve toughness and impact resistance. These variants often incorporate elastomeric additives or copolymers, resulting in enhanced flexibility and durability. They are particularly useful in applications requiring higher impact strength, such as consumer electronics casings or sporting goods.

Crystalline PLA grades exhibit improved mechanical properties and heat resistance compared to amorphous PLA. These types undergo controlled crystallization during processing, resulting in higher strength, stiffness, and temperature resistance. They are well-suited for applications in automotive, electronics, and durable goods industries.

Fiber-reinforced PLA composites incorporate natural or synthetic fibers to enhance mechanical properties. These materials offer improved strength, stiffness, and dimensional stability, making them suitable for structural applications in automotive, construction, and aerospace sectors.

Food-grade PLA types are specifically formulated to meet regulatory requirements for food contact applications. These variants undergo rigorous testing to ensure compliance with food safety standards and are commonly used in food packaging, disposable cutlery, and beverage containers.

Medical-grade PLA is designed for biomedical applications, such as implants, drug delivery systems, and tissue engineering scaffolds. These types undergo stringent purification processes and are formulated to meet biocompatibility and biodegradability requirements for medical use.

When choosing the right PLA type for a project, several factors must be considered. These include the intended application, required mechanical properties, thermal performance, regulatory compliance, and processing conditions. Additionally, the availability of specific PLA grades from suppliers and their compatibility with existing manufacturing processes should be evaluated.

Market Analysis for PLA

The global market for Polylactic Acid (PLA) has been experiencing significant growth in recent years, driven by increasing environmental concerns and the shift towards sustainable materials. PLA, a biodegradable and renewable thermoplastic derived from plant-based sources, has gained traction across various industries due to its eco-friendly properties and versatile applications.

The PLA market is segmented based on end-use industries, including packaging, textiles, agriculture, electronics, and medical devices. Among these, packaging remains the dominant sector, accounting for the largest market share. The food packaging industry, in particular, has been a major contributor to PLA demand, as consumers and regulators push for more sustainable packaging solutions.

Geographically, North America and Europe have been leading the PLA market, owing to stringent environmental regulations and growing consumer awareness. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing disposable income, and government initiatives promoting sustainable materials.

The market dynamics of PLA are influenced by several factors. On the supply side, advancements in production technologies have led to improved PLA grades with enhanced properties, expanding its potential applications. Additionally, the increasing availability of raw materials, such as corn starch and sugarcane, has helped stabilize PLA production costs.

On the demand side, the growing emphasis on reducing carbon footprint and plastic waste has been a key driver for PLA adoption. Many companies are incorporating PLA into their product lines as part of their sustainability initiatives. However, the relatively higher cost of PLA compared to conventional plastics remains a challenge, particularly in price-sensitive markets.

Looking ahead, the PLA market is poised for continued growth. Emerging applications in 3D printing, automotive interiors, and disposable medical devices are expected to create new opportunities. Moreover, ongoing research and development efforts are focused on improving PLA's heat resistance and mechanical properties, which could further expand its market potential.

Despite the positive outlook, the PLA market faces some challenges. Competition from other bioplastics and the need for proper end-of-life management infrastructure for biodegradable plastics are factors that could impact market growth. Additionally, fluctuations in raw material prices and the debate over using food crops for industrial purposes may influence the market dynamics in the future.

The PLA market is segmented based on end-use industries, including packaging, textiles, agriculture, electronics, and medical devices. Among these, packaging remains the dominant sector, accounting for the largest market share. The food packaging industry, in particular, has been a major contributor to PLA demand, as consumers and regulators push for more sustainable packaging solutions.

Geographically, North America and Europe have been leading the PLA market, owing to stringent environmental regulations and growing consumer awareness. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing disposable income, and government initiatives promoting sustainable materials.

The market dynamics of PLA are influenced by several factors. On the supply side, advancements in production technologies have led to improved PLA grades with enhanced properties, expanding its potential applications. Additionally, the increasing availability of raw materials, such as corn starch and sugarcane, has helped stabilize PLA production costs.

On the demand side, the growing emphasis on reducing carbon footprint and plastic waste has been a key driver for PLA adoption. Many companies are incorporating PLA into their product lines as part of their sustainability initiatives. However, the relatively higher cost of PLA compared to conventional plastics remains a challenge, particularly in price-sensitive markets.

Looking ahead, the PLA market is poised for continued growth. Emerging applications in 3D printing, automotive interiors, and disposable medical devices are expected to create new opportunities. Moreover, ongoing research and development efforts are focused on improving PLA's heat resistance and mechanical properties, which could further expand its market potential.

Despite the positive outlook, the PLA market faces some challenges. Competition from other bioplastics and the need for proper end-of-life management infrastructure for biodegradable plastics are factors that could impact market growth. Additionally, fluctuations in raw material prices and the debate over using food crops for industrial purposes may influence the market dynamics in the future.

Current PLA Technology

Polylactic acid (PLA) has emerged as a versatile and eco-friendly material in various industries, with different types tailored to specific applications. The current PLA technology offers a range of options, each with unique properties and characteristics.

Extrusion-grade PLA is widely used in the packaging industry due to its excellent processability and barrier properties. This type of PLA is suitable for producing films, sheets, and thermoformed containers. It offers good clarity, high stiffness, and moderate heat resistance, making it ideal for food packaging and disposable items.

Injection molding-grade PLA is designed for manufacturing complex shapes and parts with high dimensional accuracy. This type of PLA exhibits good flow properties and rapid crystallization, resulting in shorter cycle times and improved productivity. It is commonly used in consumer goods, automotive components, and medical devices.

3D printing-grade PLA has gained significant popularity in the additive manufacturing industry. This type of PLA offers excellent printability, low warping, and good layer adhesion. It comes in various colors and finishes, allowing for the creation of detailed and aesthetically pleasing prototypes and functional parts.

Fiber-grade PLA is specifically formulated for textile applications. It can be spun into fibers and used in the production of biodegradable fabrics, nonwovens, and composites. This type of PLA offers good tensile strength, moisture-wicking properties, and compatibility with conventional textile processing equipment.

High-heat PLA is a specialized grade designed to withstand elevated temperatures. It undergoes a crystallization process, resulting in improved heat resistance and mechanical properties. This type of PLA is suitable for applications requiring higher temperature stability, such as automotive parts and durable consumer goods.

Foam-grade PLA is engineered for the production of lightweight, insulating materials. It can be processed using various foaming techniques, including extrusion foaming and bead foaming. This type of PLA offers excellent thermal insulation properties and is used in packaging, construction, and automotive applications.

Blend-grade PLA is designed to be mixed with other polymers or additives to enhance specific properties. These blends can improve impact resistance, flexibility, or barrier properties, expanding the range of applications for PLA-based materials.

When choosing the right PLA type for a project, it is essential to consider factors such as processing requirements, mechanical properties, thermal stability, and end-use conditions. The current PLA technology offers a diverse range of options, enabling manufacturers to select the most suitable grade for their specific application needs.

Extrusion-grade PLA is widely used in the packaging industry due to its excellent processability and barrier properties. This type of PLA is suitable for producing films, sheets, and thermoformed containers. It offers good clarity, high stiffness, and moderate heat resistance, making it ideal for food packaging and disposable items.

Injection molding-grade PLA is designed for manufacturing complex shapes and parts with high dimensional accuracy. This type of PLA exhibits good flow properties and rapid crystallization, resulting in shorter cycle times and improved productivity. It is commonly used in consumer goods, automotive components, and medical devices.

3D printing-grade PLA has gained significant popularity in the additive manufacturing industry. This type of PLA offers excellent printability, low warping, and good layer adhesion. It comes in various colors and finishes, allowing for the creation of detailed and aesthetically pleasing prototypes and functional parts.

Fiber-grade PLA is specifically formulated for textile applications. It can be spun into fibers and used in the production of biodegradable fabrics, nonwovens, and composites. This type of PLA offers good tensile strength, moisture-wicking properties, and compatibility with conventional textile processing equipment.

High-heat PLA is a specialized grade designed to withstand elevated temperatures. It undergoes a crystallization process, resulting in improved heat resistance and mechanical properties. This type of PLA is suitable for applications requiring higher temperature stability, such as automotive parts and durable consumer goods.

Foam-grade PLA is engineered for the production of lightweight, insulating materials. It can be processed using various foaming techniques, including extrusion foaming and bead foaming. This type of PLA offers excellent thermal insulation properties and is used in packaging, construction, and automotive applications.

Blend-grade PLA is designed to be mixed with other polymers or additives to enhance specific properties. These blends can improve impact resistance, flexibility, or barrier properties, expanding the range of applications for PLA-based materials.

When choosing the right PLA type for a project, it is essential to consider factors such as processing requirements, mechanical properties, thermal stability, and end-use conditions. The current PLA technology offers a diverse range of options, enabling manufacturers to select the most suitable grade for their specific application needs.

PLA Selection Criteria

01 PLA-based composite materials

Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.- PLA Composition and Blends: Polylactic acid (PLA) compositions and blends are developed to enhance material properties. These may include mixing PLA with other polymers or additives to improve characteristics such as strength, flexibility, or biodegradability. The formulations aim to expand PLA's applications in various industries.

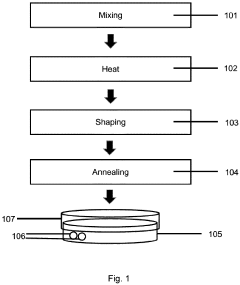

- PLA Processing Techniques: Various processing techniques are employed to manufacture PLA products. These may include extrusion, injection molding, or 3D printing. The focus is on optimizing processing parameters to achieve desired product characteristics and improve production efficiency.

- PLA Surface Modifications: Surface modification techniques are applied to PLA to enhance its properties or compatibility with other materials. This may involve chemical treatments, plasma treatments, or coating applications to improve characteristics such as adhesion, hydrophobicity, or biocompatibility.

- PLA-based Composites: PLA is used as a matrix material in composite formulations. These composites may incorporate natural fibers, nanoparticles, or other reinforcing materials to enhance mechanical properties, thermal stability, or functionality of the resulting materials.

- PLA Degradation and Recycling: Research focuses on understanding and controlling PLA degradation processes, as well as developing effective recycling methods. This includes studies on biodegradation mechanisms, composting conditions, and chemical recycling techniques to address end-of-life considerations for PLA products.

02 PLA processing techniques

Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.Expand Specific Solutions03 PLA modification for improved properties

Chemical or physical modification of PLA to enhance its properties such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to overcome limitations of pure PLA.Expand Specific Solutions04 Biodegradable PLA applications

Development of biodegradable products using PLA, focusing on environmentally friendly alternatives to traditional plastics. Applications include packaging materials, disposable items, and agricultural films that can decompose naturally without harming the environment.Expand Specific Solutions05 PLA in medical and pharmaceutical applications

Utilization of PLA in medical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and bioabsorbable implants. Research focuses on biocompatibility, controlled release mechanisms, and tailoring PLA properties for specific medical needs.Expand Specific Solutions

Key PLA Manufacturers

The PLA (Polylactic Acid) market is in a growth phase, driven by increasing demand for sustainable materials. The global PLA market size is projected to expand significantly, with a compound annual growth rate exceeding 15% in the coming years. Technologically, PLA is relatively mature, but ongoing research focuses on enhancing its properties and applications. Companies like NatureWorks, Total Corbion, and Futerro are leading producers, while research institutions such as The University of Manchester and Sichuan University are advancing PLA science. Innovative firms like Evolved by Nature and Arctic Biomaterials are developing specialized PLA formulations. Established players like DuPont de Nemours and 3M are also active in the PLA space, indicating the technology's growing importance across various industries.

Toray Plastics (America), Inc.

Technical Solution: Toray has developed Ecodear® PLA, a portfolio of PLA films and sheets designed for various applications. Their technology focuses on enhancing the barrier properties and heat resistance of PLA films. Toray employs a proprietary stretching process during film production, which improves the material's strength and gas barrier properties. They also use specialized coating technologies to further enhance the performance of their PLA films, making them suitable for food packaging and other demanding applications.

Strengths: Enhanced barrier properties, improved heat resistance, specialized for film and sheet applications. Weaknesses: Focused primarily on film products, may have limitations in other PLA forms.

UPM-Kymmene Oyj

Technical Solution: UPM has developed UPM BioVerno, a range of renewable materials including PLA-based products. Their technology focuses on producing PLA from sustainable sources, particularly wood-based feedstocks. UPM employs a biorefinery concept to extract and convert wood components into lactic acid, which is then polymerized into PLA. This approach allows for the production of PLA with a lower carbon footprint compared to traditional corn-based PLA. UPM's PLA products are designed to offer improved sustainability while maintaining performance characteristics suitable for packaging and consumer goods applications.

Strengths: Sustainable wood-based feedstock, lower carbon footprint, integration with existing forestry operations. Weaknesses: Potentially limited production capacity compared to established PLA manufacturers, may face challenges in scaling up the technology.

Innovative PLA Formulations

Injection molding sole material, sole containing same and preparation method and application thereof

PatentInactiveUS20230058137A1

Innovation

- A chain extension modified PLA injection molding sole material is developed, incorporating epoxidized soybean oil, SBS, SEBS, heavy calcium, naphthenic oil, and wear-resistant agents, enhancing thermal stability, toughness, and biodegradability, and utilizing a dynamic crosslinking process with TMPTA and zinc oxide to improve molecular weight and properties.

Polylactide cell culture containers and use in cell culture without surface modification

PatentPendingEP3875572A1

Innovation

- Development of cell culture containers made from a blend of poly-L-lactide and poly-D-lactide polymers that are biodegradable, compostable, and transparent, with enhanced thermal stability, allowing for cell adhesion without surface treatments, and suitable for both 2D and 3D growth surfaces.

Environmental Impact of PLA

Polylactic acid (PLA) has gained significant attention as an eco-friendly alternative to traditional petroleum-based plastics. When considering the environmental impact of PLA, it is essential to examine its entire lifecycle, from production to disposal.

PLA production generally requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. The raw materials for PLA, such as corn or sugarcane, are renewable resources that can be replenished relatively quickly. This aspect contributes to PLA's lower carbon footprint and reduced dependence on fossil fuels.

During its use phase, PLA exhibits biodegradability under specific conditions, which sets it apart from many traditional plastics. In industrial composting facilities, PLA can break down into water, carbon dioxide, and biomass within a few months. However, it is crucial to note that PLA does not biodegrade readily in natural environments or landfills, where conditions are not optimal for its decomposition.

The end-of-life management of PLA presents both opportunities and challenges. While PLA can be composted in industrial facilities, the lack of widespread infrastructure for proper disposal and composting can limit its environmental benefits. Improper disposal of PLA in regular waste streams may lead to contamination of recycling processes for other plastics.

When comparing PLA to other bioplastics and traditional plastics, its environmental impact is generally favorable. PLA production typically results in lower greenhouse gas emissions and reduced energy consumption compared to petroleum-based plastics. However, the environmental benefits of PLA can vary depending on factors such as production methods, transportation, and end-of-life management.

It is important to consider the potential land-use implications of large-scale PLA production. The cultivation of crops for PLA feedstock may compete with food production or lead to land-use changes, which could have indirect environmental impacts.

In conclusion, while PLA offers several environmental advantages over traditional plastics, its overall impact depends on various factors throughout its lifecycle. Proper management, from production to disposal, is crucial to maximize the environmental benefits of PLA. As technology and infrastructure continue to evolve, the environmental profile of PLA is likely to improve further, making it an increasingly attractive option for sustainable material solutions.

PLA production generally requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. The raw materials for PLA, such as corn or sugarcane, are renewable resources that can be replenished relatively quickly. This aspect contributes to PLA's lower carbon footprint and reduced dependence on fossil fuels.

During its use phase, PLA exhibits biodegradability under specific conditions, which sets it apart from many traditional plastics. In industrial composting facilities, PLA can break down into water, carbon dioxide, and biomass within a few months. However, it is crucial to note that PLA does not biodegrade readily in natural environments or landfills, where conditions are not optimal for its decomposition.

The end-of-life management of PLA presents both opportunities and challenges. While PLA can be composted in industrial facilities, the lack of widespread infrastructure for proper disposal and composting can limit its environmental benefits. Improper disposal of PLA in regular waste streams may lead to contamination of recycling processes for other plastics.

When comparing PLA to other bioplastics and traditional plastics, its environmental impact is generally favorable. PLA production typically results in lower greenhouse gas emissions and reduced energy consumption compared to petroleum-based plastics. However, the environmental benefits of PLA can vary depending on factors such as production methods, transportation, and end-of-life management.

It is important to consider the potential land-use implications of large-scale PLA production. The cultivation of crops for PLA feedstock may compete with food production or lead to land-use changes, which could have indirect environmental impacts.

In conclusion, while PLA offers several environmental advantages over traditional plastics, its overall impact depends on various factors throughout its lifecycle. Proper management, from production to disposal, is crucial to maximize the environmental benefits of PLA. As technology and infrastructure continue to evolve, the environmental profile of PLA is likely to improve further, making it an increasingly attractive option for sustainable material solutions.

PLA Testing and Standards

When selecting the appropriate PLA type for a project, it is crucial to understand and adhere to relevant testing standards and quality control measures. These standards ensure consistency, reliability, and performance of PLA materials across different applications.

The American Society for Testing and Materials (ASTM) has developed several standards specifically for PLA testing. ASTM D6400 is a key standard that outlines specifications for compostable plastics, including PLA. This standard evaluates the material's biodegradability, disintegration, and eco-toxicity in controlled composting environments.

For mechanical properties, ASTM D638 is commonly used to determine the tensile strength and elongation of PLA samples. ASTM D790 provides guidelines for flexural testing, which is essential for assessing the material's bending strength and stiffness. These tests help in comparing different PLA grades and selecting the most suitable option for specific applications.

Thermal properties of PLA are often evaluated using ASTM D3418, which outlines the procedure for determining the glass transition temperature and melting point through differential scanning calorimetry (DSC). This information is critical for understanding the material's behavior during processing and end-use conditions.

The International Organization for Standardization (ISO) also provides relevant standards for PLA testing. ISO 527 series covers the determination of tensile properties for plastics, including PLA. ISO 75 is used for measuring the heat deflection temperature, which is crucial for applications involving elevated temperatures.

For food contact applications, compliance with FDA regulations is essential. The FDA has established guidelines for the use of PLA in food packaging, outlined in 21 CFR 177.1630. These regulations specify migration limits and testing procedures to ensure the safety of PLA materials in contact with food.

When choosing PLA for 3D printing applications, it is important to consider standards related to filament quality and consistency. ASTM F2971 provides guidelines for evaluating the properties of materials used in additive manufacturing processes, including PLA filaments.

By adhering to these testing standards and quality control measures, manufacturers and end-users can ensure that the selected PLA type meets the required specifications for their specific project. This approach helps in maintaining product quality, consistency, and regulatory compliance across various applications of PLA materials.

The American Society for Testing and Materials (ASTM) has developed several standards specifically for PLA testing. ASTM D6400 is a key standard that outlines specifications for compostable plastics, including PLA. This standard evaluates the material's biodegradability, disintegration, and eco-toxicity in controlled composting environments.

For mechanical properties, ASTM D638 is commonly used to determine the tensile strength and elongation of PLA samples. ASTM D790 provides guidelines for flexural testing, which is essential for assessing the material's bending strength and stiffness. These tests help in comparing different PLA grades and selecting the most suitable option for specific applications.

Thermal properties of PLA are often evaluated using ASTM D3418, which outlines the procedure for determining the glass transition temperature and melting point through differential scanning calorimetry (DSC). This information is critical for understanding the material's behavior during processing and end-use conditions.

The International Organization for Standardization (ISO) also provides relevant standards for PLA testing. ISO 527 series covers the determination of tensile properties for plastics, including PLA. ISO 75 is used for measuring the heat deflection temperature, which is crucial for applications involving elevated temperatures.

For food contact applications, compliance with FDA regulations is essential. The FDA has established guidelines for the use of PLA in food packaging, outlined in 21 CFR 177.1630. These regulations specify migration limits and testing procedures to ensure the safety of PLA materials in contact with food.

When choosing PLA for 3D printing applications, it is important to consider standards related to filament quality and consistency. ASTM F2971 provides guidelines for evaluating the properties of materials used in additive manufacturing processes, including PLA filaments.

By adhering to these testing standards and quality control measures, manufacturers and end-users can ensure that the selected PLA type meets the required specifications for their specific project. This approach helps in maintaining product quality, consistency, and regulatory compliance across various applications of PLA materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!